Device and method for manufacturing tapered optical fiber

A technology for producing a tapered optical fiber and a device, which is applied to the coupling of optical waveguides and other directions, can solve the problems of complex device and long processing time, and achieve the effects of flexible design, improved work efficiency, and shortened processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

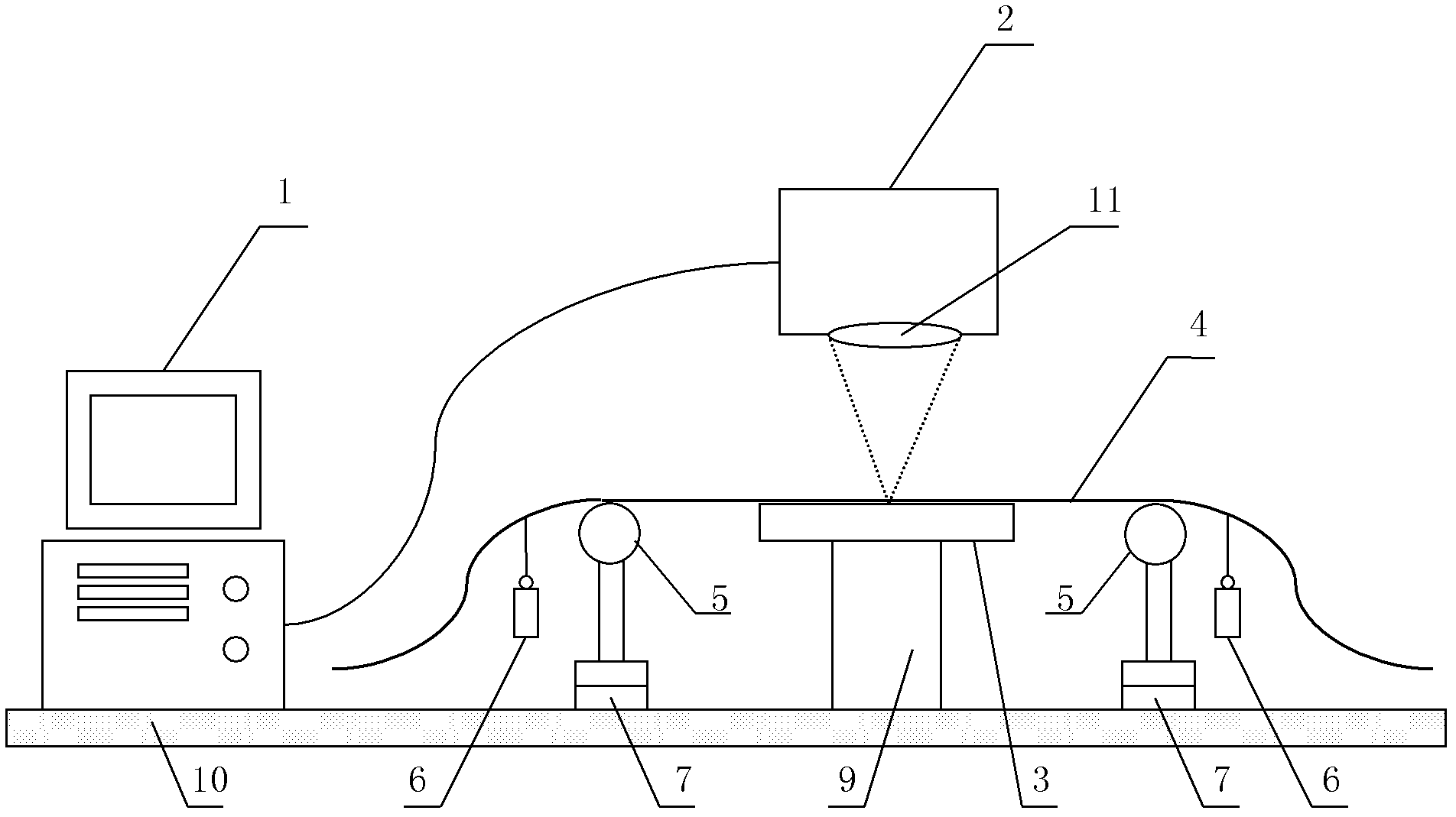

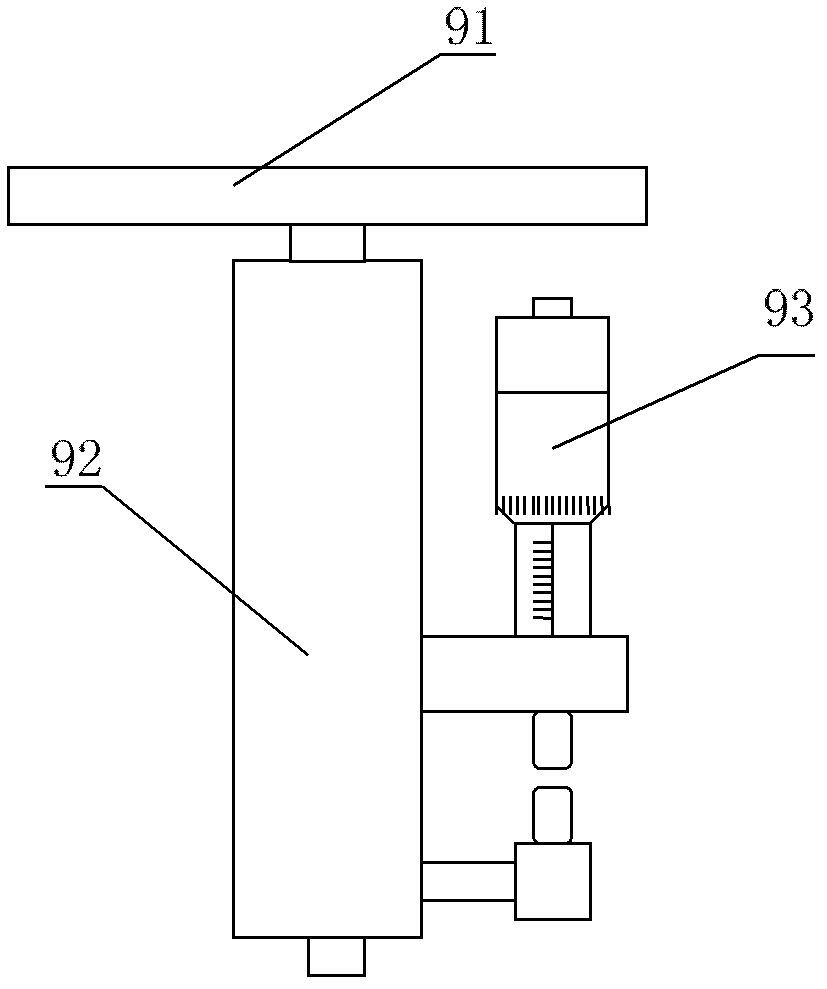

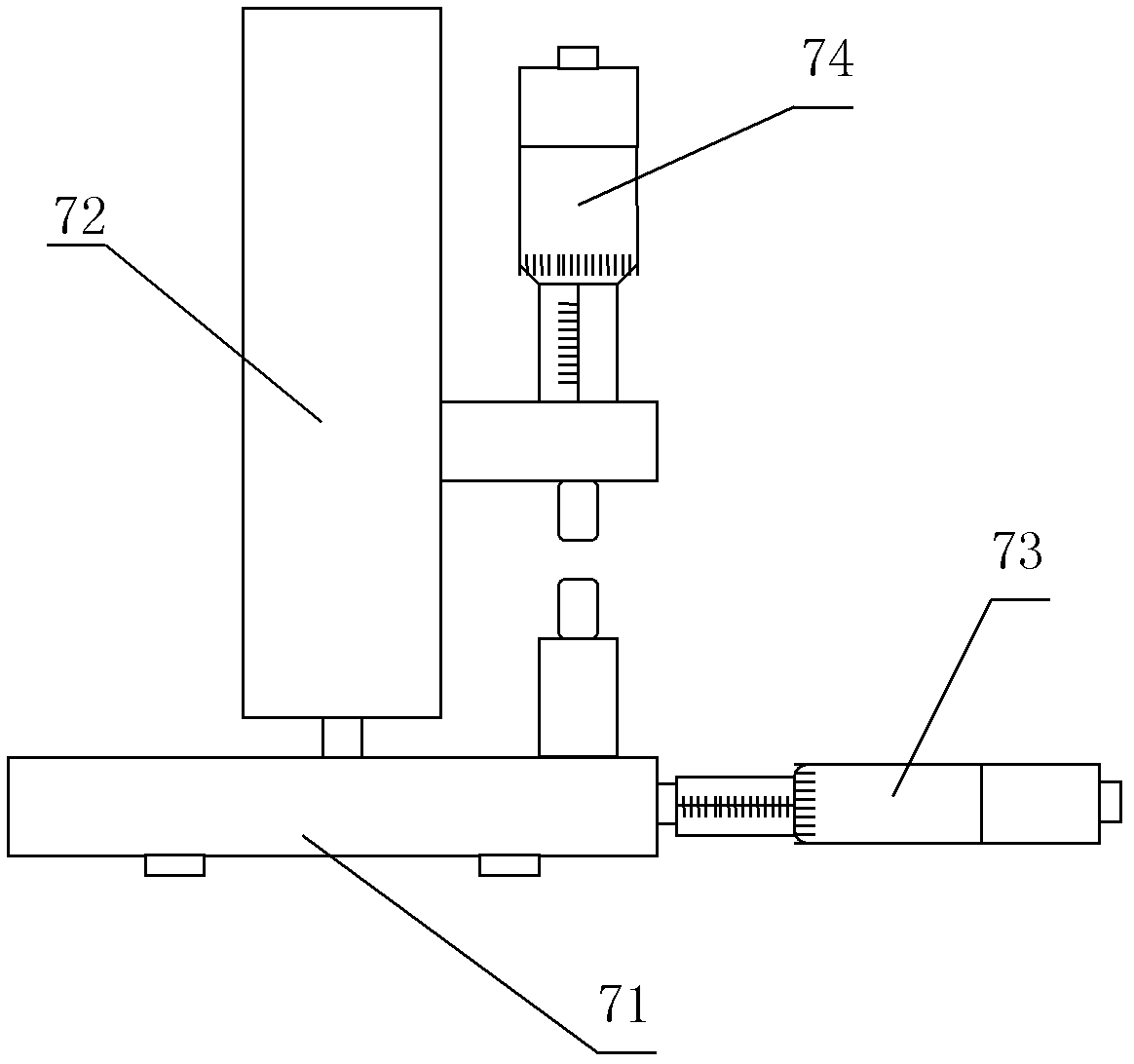

[0044] A kind of manufacturing device of tapered optical fiber, such as figure 1 As shown, it includes a computer terminal 1, a carbon dioxide laser 2, a scanning vibrating mirror 11, a metal-coated film mirror 3 with high reflectivity, a placement platform 9 for placing the metal-coated film mirror 3, two places distributed The two-dimensional precision adjustment frame 7 placed on both sides of the platform 9, two optical fiber fixtures 5 distributed on both sides of the placed platform 9 and used to fix the two ends of the processed optical fiber 4 respectively, and a pair of equal quality for hanging on the Both ends of the optical fiber 4 are processed to provide a continuous and constant tension weight 6 and an optical flat plate 10 for placing the above-mentioned various devices. The carbon dioxide laser 2 and the scanning galvanometer 11 are respectively connected to the computer terminal 1 and controlled by the computer terminal 1. , the scanning galvanometer 11 is lo...

Embodiment 2

[0055] This embodiment proposes a method for manufacturing a tapered optical fiber using the manufacturing device described in Embodiment 1. First, the processed optical fiber 4 used to make the tapered optical fiber is decoated and placed on the mirror surface of the metal-coated mirror 3, and then several pairs of weights 6 are suspended symmetrically on the two ends of the processed optical fiber 4, The height and the horizontal position of the optical fiber fixing member 5 are adjusted by the two-dimensional precision adjustment frame 7 so that the optical fiber part that has been stripped of the coating layer in the processed optical fiber 4 is in the focal plane of the focusing lens of the carbon dioxide laser 2, and the processed optical fiber 4 The axial direction is perpendicular to the movement track of the laser spot 8 output by the carbon dioxide laser 2, and the height of the metal-coated mirror 3 is adjusted by placing the platform 9 so that the mirror surface of ...

Embodiment 3

[0072] A method of manufacturing a tapered optical fiber using the manufacturing device described in Embodiment 1. In the manufacturing device described in Embodiment 1, the carbon dioxide laser 2 is a pulsed carbon dioxide laser with an output laser wavelength of 10.6 μm. The method of this embodiment can produce tapered optical fibers with different structural parameters by setting the working parameters of the carbon dioxide laser 2 and selecting weights 6 of different masses. It mainly includes the following steps:

[0073] ① Turn on the carbon dioxide laser 2, and set the working parameters of the carbon dioxide laser 2 in the computer terminal 1. The pulse frequency is set to 5KHz, the output power is set to 7.75W, and the residence time of the laser spot 8 acting on the processed optical fiber 4 is set to 700 μs, and the distance between two laser spots 8 is set to 1 μm.

[0074] ②Prepare a predetermined length of standard single-mode optical fiber (model G.652D) as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com