Fiber grating sensor based on composite grating linear array and sensing method

A composite grating and fiber grating technology, which is applied in the phase influence characteristic measurement and other directions, can solve the problem that multiple optical structures cannot be connected in series and multi-point refractive index monitoring, and achieve the effect of avoiding physical structure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

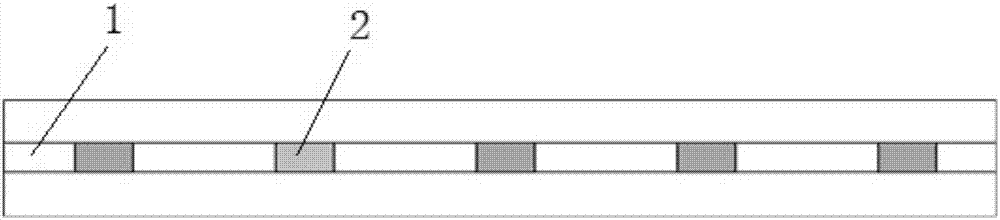

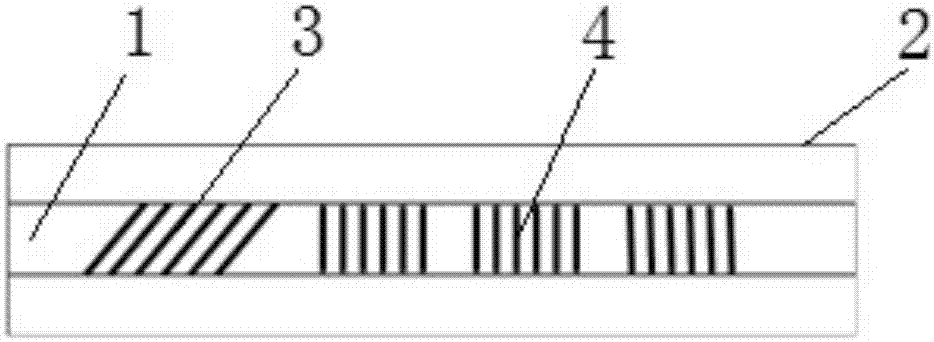

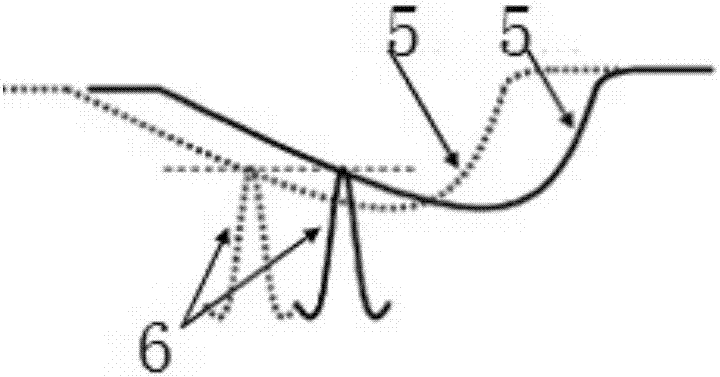

[0033] The invention provides a fiber grating sensor based on a composite grating line array, such as figure 1 with figure 2 As shown, including an optical fiber, the present embodiment is a single-mode optical fiber 1, which also includes a composite grating array 2, and the composite grating array 2 includes a tilted grating 3 and a Bragg reflection grating group connected in series on the optical fiber in sequence; wherein, the tilted grating 3 It is one group, forming an included angle of 3º-15º with the fiber section; the Bragg reflection grating group is two or more groups of Bragg reflection gratings 4 written along the fiber section, and the Bragg reflection wavelengths of each group of Bragg reflection gratings 4 are different; the inclined grating package The reflection peak wavelength of layer mode and Bragg reflection grating 4 is affect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com