Preparation method of zinc oxide nanorod

A zinc oxide nanorod, sodium hydroxide technology, applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology and other directions, can solve the problem of long, generally ranging from ten hours to several days, difficult to achieve mass production, Due to the small size of the reactor, the effects of low equipment requirements, short time consumption and cost reduction are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: take by weighing 3 g of sodium hydroxide, add 20 ml of water, add 0.1 g of cetyltrimethylammonium bromide and 1.5 g of carbonamide after sodium hydroxide dissolves, stir for half hour, dubbed solution No. 1; weighed 2.5g of zinc nitrate, dissolved in 30 ml of water, dubbed solution No. 2. Heat No. 1 solution to 70°C, add No. 2 solution to No. 1 solution after 20 minutes, and react for 20 minutes; centrifuge the white suspension, wash it with alcohol and water, and dry it in a drying oven at 50°C for 10 hours to obtain oxidized Zinc nanorod powder.

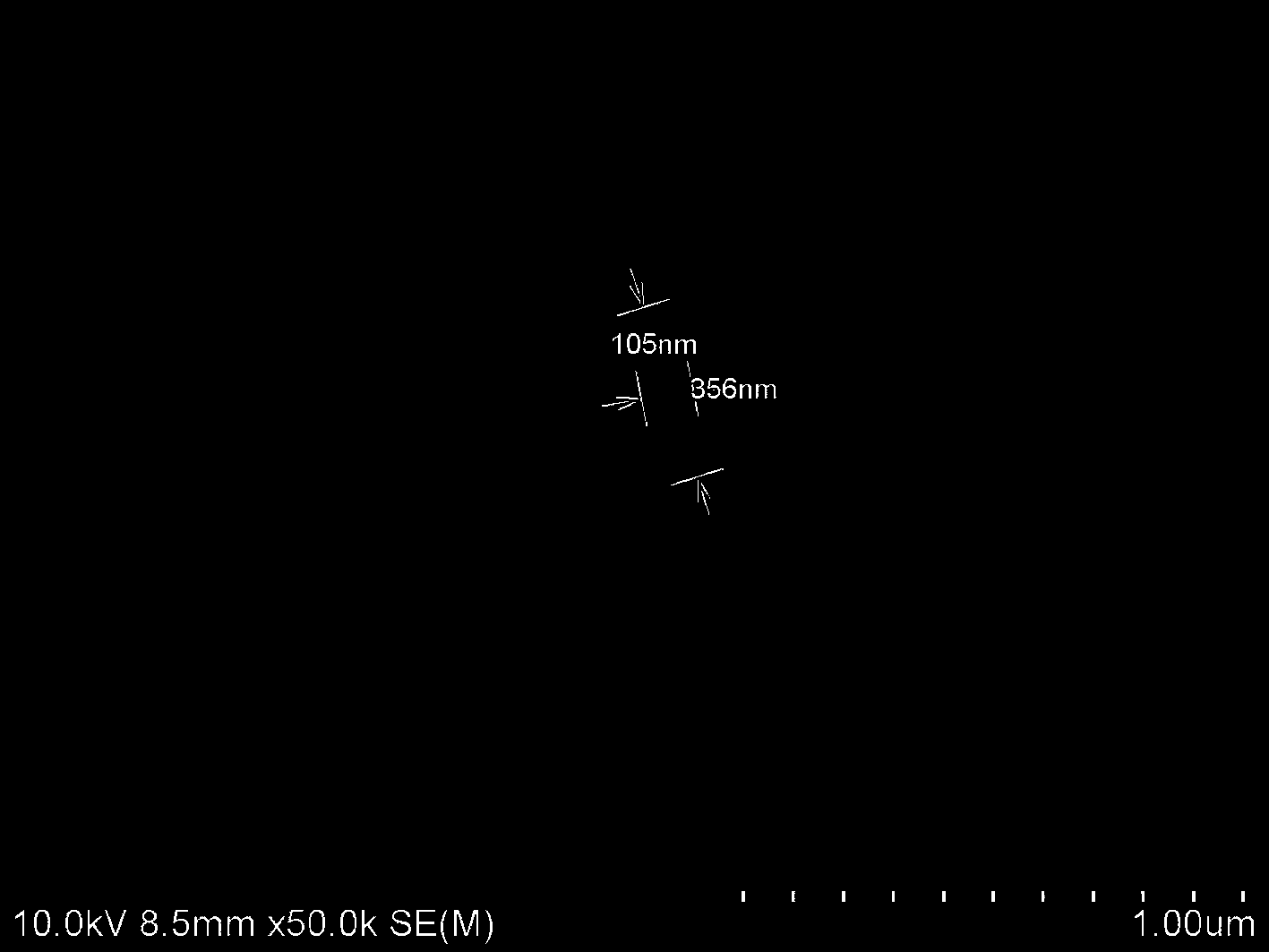

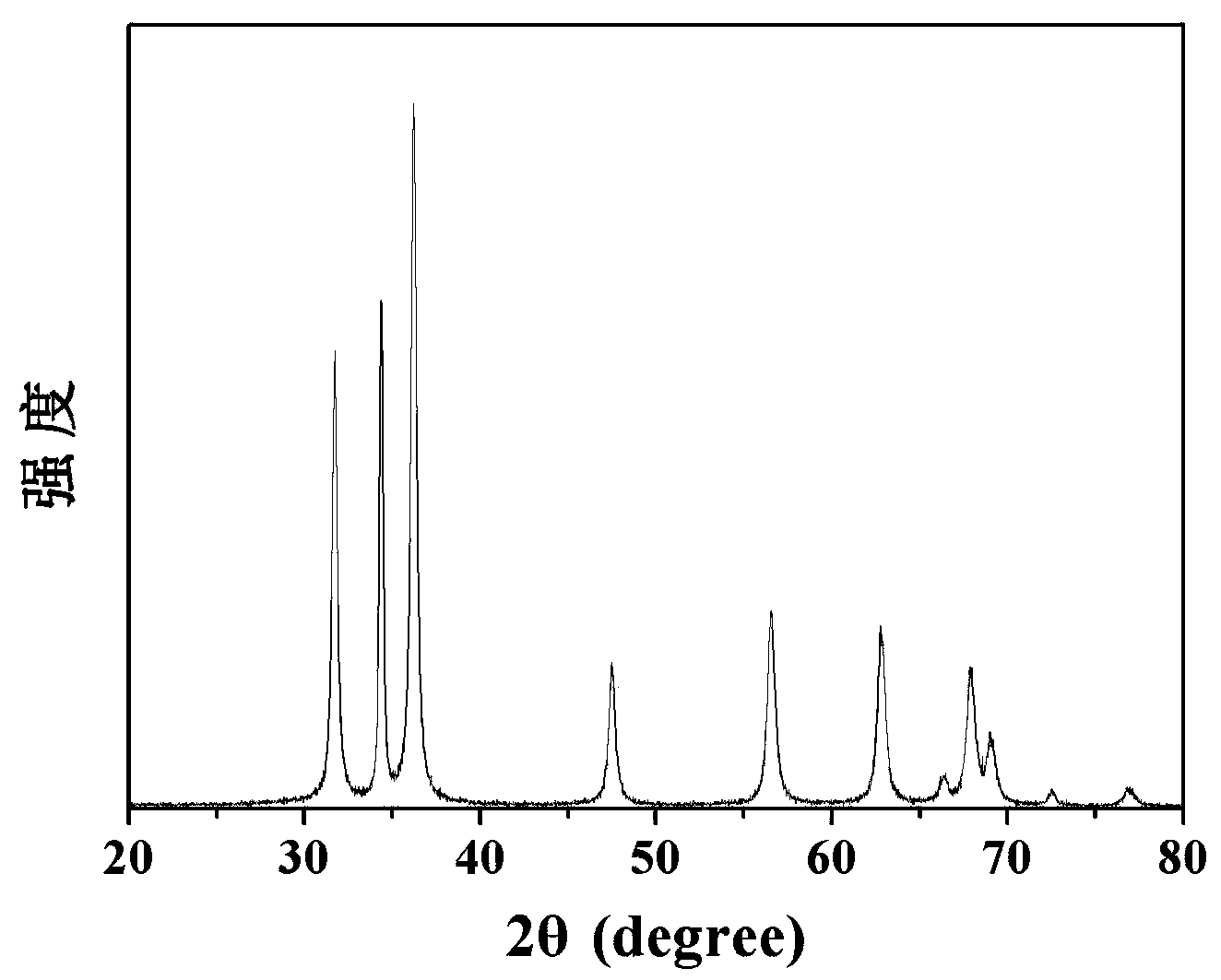

[0022] figure 1 The SEM image of ZnO nanorods is given. It can be seen from the figure that the diameter of the nanorods is about 100 nm and the length is about 350 nm. figure 2 It is the XRD pattern of zinc oxide nanorods. The XRD data results show that the obtained nanorods are standard hexagonal wurtzite ZnO, and the diffraction peaks correspond to the standard card JCPDS card number 36-1451 of ZnO.

Embodiment 2

[0023] Embodiment 2: take by weighing 2 g of sodium hydroxide, add 20 ml of water, add 0.15 g of cetyltrimethylammonium bromide and 1.5 g of carboxamide after the sodium hydroxide dissolves, stir for half hours, to make solution No. 1; weigh 1.5 g of zinc acetate, dissolve it in 20 ml of water, and make solution No. 2. Heat No. 1 solution to 80°C, add No. 2 solution to No. 1 solution after 20 minutes, and react for 20 minutes; centrifuge the white suspension, wash it with alcohol and water, and dry it in a drying oven at 60°C for 9 hours to obtain oxidized Zinc nanorod powder. The pH of the system was changed to increase the concentration of cetyltrimethylammonium bromide at the same time, and the ratio of length and diameter of the prepared zinc oxide nanorods was 4:1.

Embodiment 3

[0024] Embodiment 3: take by weighing the potassium hydroxide of 3.5 g, add the water of 20 ml, after the potassium hydroxide dissolves, add the hexadecyl trimethyl ammonium bromide of 0.1 g and the carboxamide of 1.5 g, stir half hours, to make solution No. 1; weigh 1.5 g of zinc acetate, dissolve it in 20 ml of water, and make solution No. 2. Heat No. 1 solution to 80°C, add No. 2 solution to No. 1 solution after 20 minutes, and react for 20 minutes; centrifuge the white suspension, wash it with alcohol and water, and dry it in a drying oven at 60°C for 9 hours to obtain oxidized Zinc nanorod powder. Potassium hydroxide and sodium hydroxide strong bases have little effect on the final result. The obtained zinc oxide nanorods have a diameter of about 110 nm and a length of about 380 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com