Preparation method of polyacrylonitrile carbon fiber with evenly distributed copolymerization sequence

A polyacrylonitrile carbon fiber, uniform distribution technology, applied in the direction of spinning solution preparation, fiber chemical characteristics, wet spinning method, etc., can solve the problems of large viscosity changes, poor mixing uniformity, concentrated reaction heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

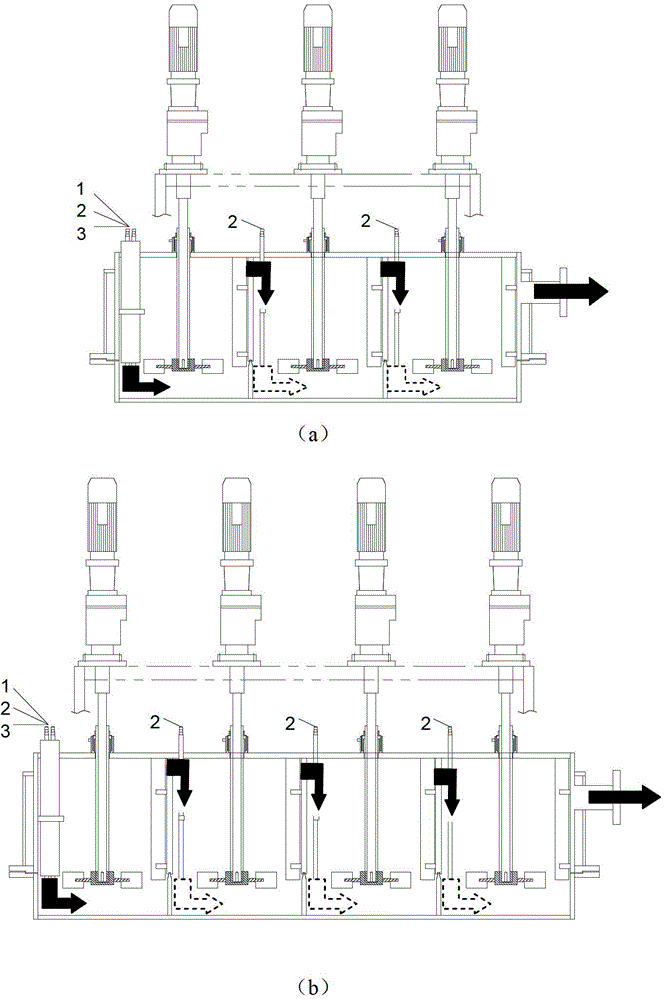

Method used

Image

Examples

Embodiment 1~13

[0061] 1) Acrylonitrile is used as the first comonomer, the second and third comonomers are methyl methacrylate and itaconic acid respectively, and the weight ratio of acrylonitrile and methyl methacrylate is 97:3. The concentration of the total monomer of the material is 22.5wt%, the oxidizing agent is sodium chlorate, and the reducing agent is sodium pyrosulfite. In terms of the total amount of all polymerization monomers charged, the initiator consumption is 0.37% (wherein the mol ratio between the reducing agent and the oxidizing agent is 1.5:1), the reaction temperature is controlled at 53.5°C for copolymerization reaction, the reaction residence time in each series tank is 15-40min, the total reaction time is controlled at 1.0-3.0 hours, the feeding of the third comonomer itaconic acid solution See Table 1 for the ratio and partition ratio, and see Table 1 for the number of series tanks in the polymerization reactor. The polymer overflowed from the last tank passes throu...

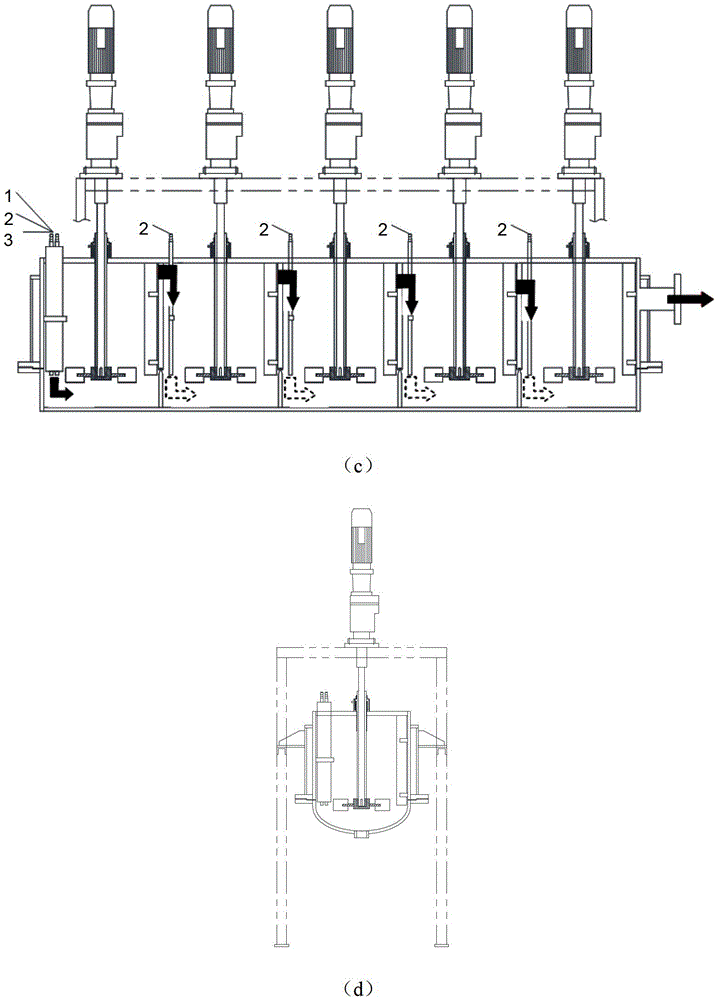

Embodiment 14~26

[0080] 1) Acrylonitrile is used as the first comonomer, the second and third comonomers are ethyl acrylate and itaconic acid respectively, the weight ratio of acrylonitrile and ethyl acrylate is 97:3, and the total monomers fed The concentration of the oxidizing agent is 25wt%, the oxidant is sodium chlorate, and the reducing agent is sodium pyrosulfite. The amount of the initiator is 0.40% (wherein the molar ratio between the reducing agent and the oxidizing agent is 1.5:1) based on the total amount of all polymerized monomers charged. Control the reaction temperature to 54.0°C for the copolymerization reaction, the reaction residence time in each series tank is 15-40min, and the total reaction time is controlled to be 1.0-3.0 hours. For the feeding ratio and partition ratio of the third comonomer itaconic acid solution, see Table 4, the number of tanks in series in the polymerization reactor is shown in Table 4; the polymer overflowed from the last tank passes through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com