Microwave radiation polymerization method for polyamide

A technology of microwave radiation and polymerization method, which is applied in the field of microwave radiation polymerization of polyamide, can solve the problems such as the lack of reaction time and uniformity, the limitation of large-volume kettle-type equipment, and the limited penetration depth of microwaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

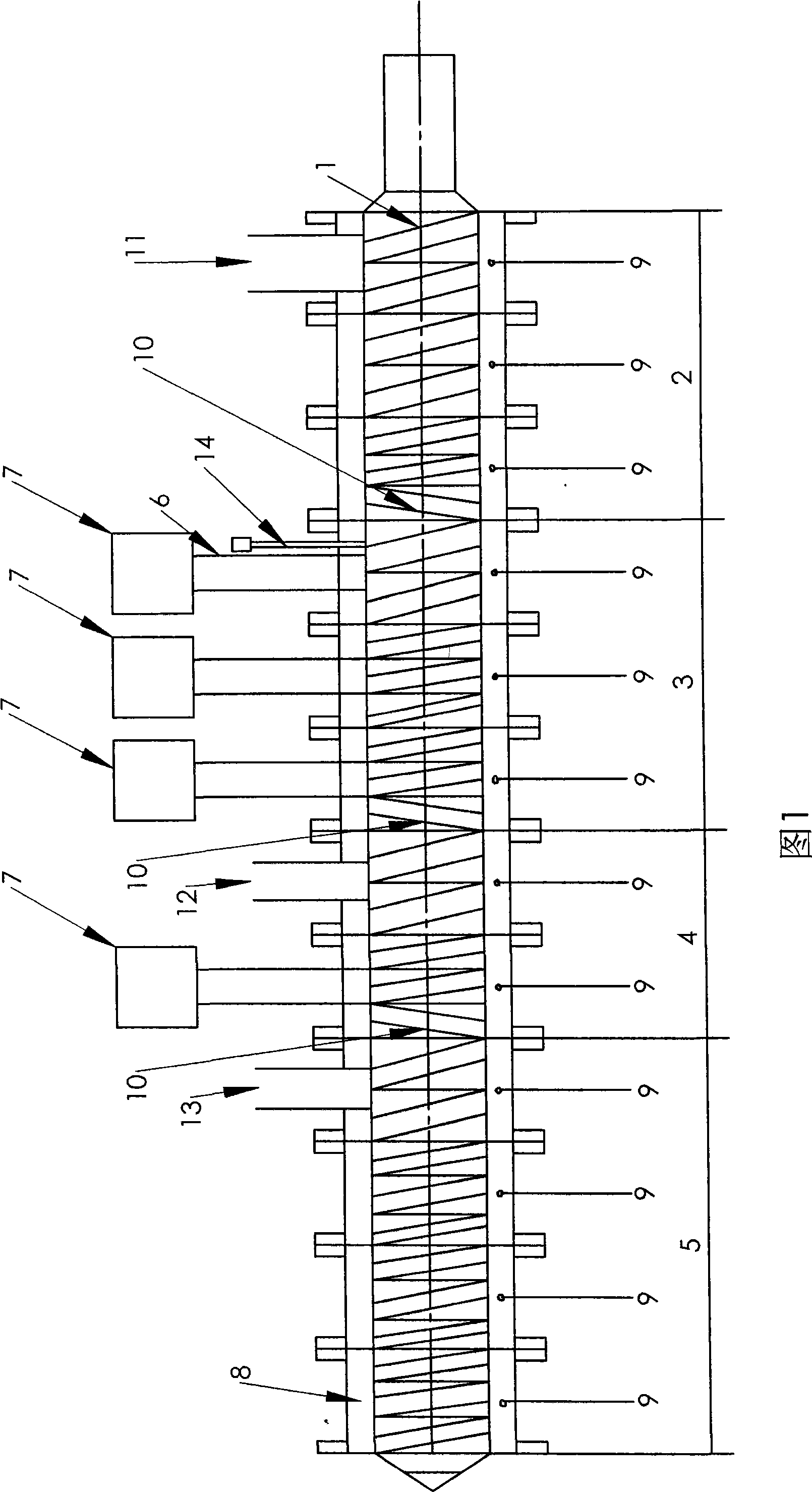

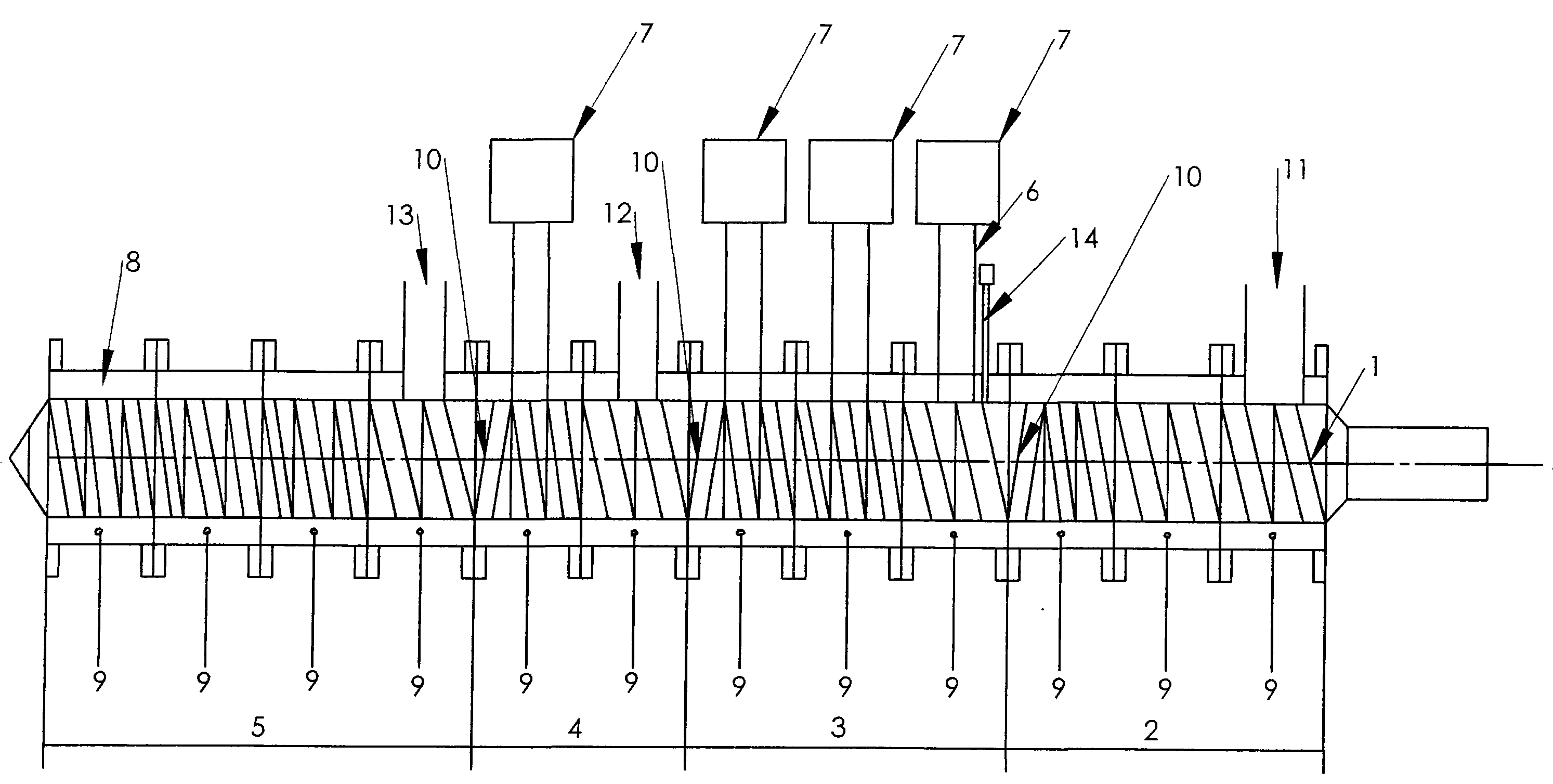

[0054] According to the ratio of AH salt and adipic acid molar ratio 78 / 1, measure the AH salt of 38438.4g and the adipic acid of 436.4g, 80g1098, 80g168, 200g calcium stearate (adipic acid, 1098, 168, stearic acid Calcium is pre-mixed uniformly and added as an auxiliary agent) and evenly added to the first feeding port of the twin-screw extruder, and N 2 Protection, the screw speed is 350rpm, adjust the feeding speed so that the feeding amount is enough to fill the screw groove (neither make it overflow, nor make it hungry), so as to ensure that the AH salt can be enough to form a pressure seal in the reverse thread sealing section ; Sections 1, 2, and 3, control the temperature at 150°C to 250°C, inject water with a metering pump between 9 and 10D, and ensure that the AH salt concentration is between 70% and 90%. Control at 250-300°C, preferably 275-285°C, evacuate with a water ring vacuum pump to make the vacuum at the vacuum port ≥0.04MPa, extrude after microwave radiation...

Embodiment 2

[0057] Measure the AH salt of 69280g and 436.4g adipic acid, 140g1098, 140g168, 350g calcium stearate (adipate, 1098, 168, calcium stearate in advance according to the ratio of AH salt and adipic acid molar ratio 100 / 1) Mix evenly and add as a kind of auxiliary agent) and evenly add in the first feeding port of the twin-screw extruder, extrude and pelletize with the method of Example 1.

[0058] After testing, the relative viscosity of PA66 product is 3.25. The color of the product is good, and the extrusion is uniform and stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com