Tank inner ring submerged-arc welding back face protection soldering flux conveying type full-automatic conveying recycling machine

A backside protection, submerged arc welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of wasting manpower, polluting the site environment, reducing welding production efficiency, etc., saving energy, and achieving a high pass rate of radiographic flaw detection. , The effect of improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

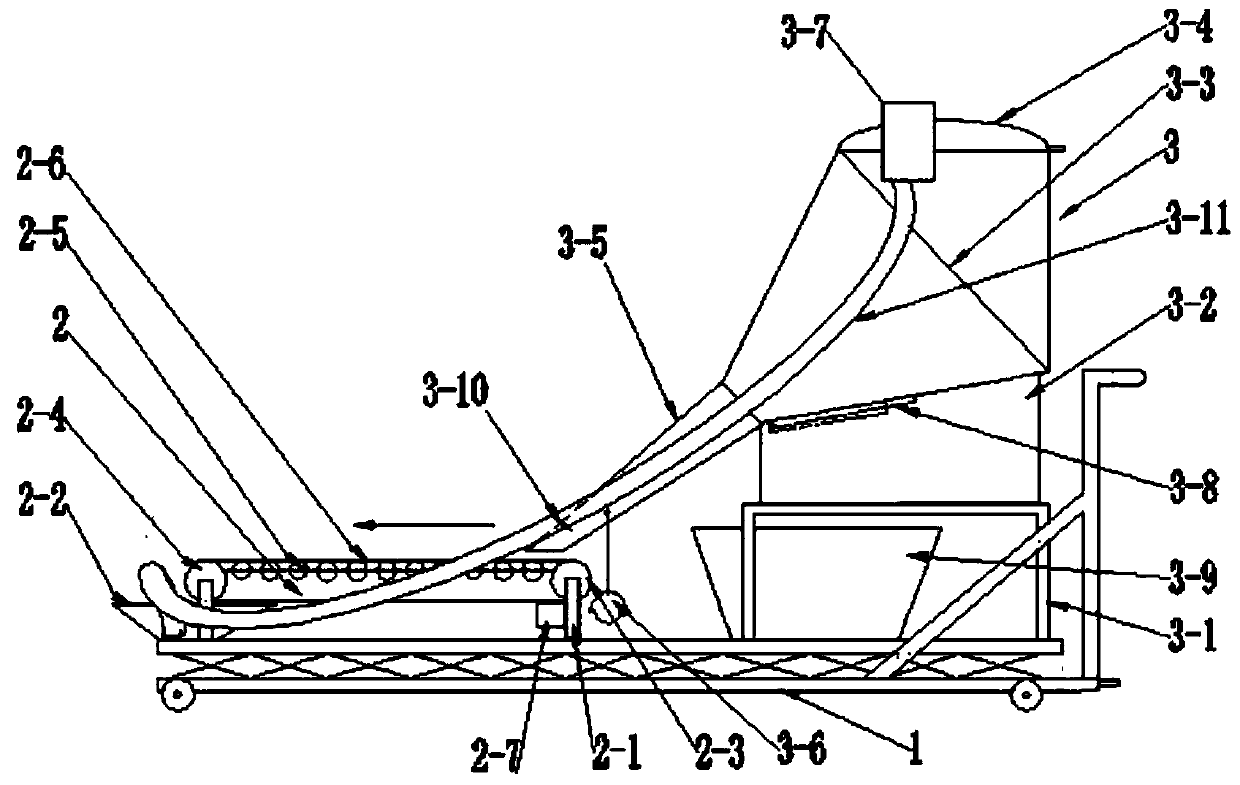

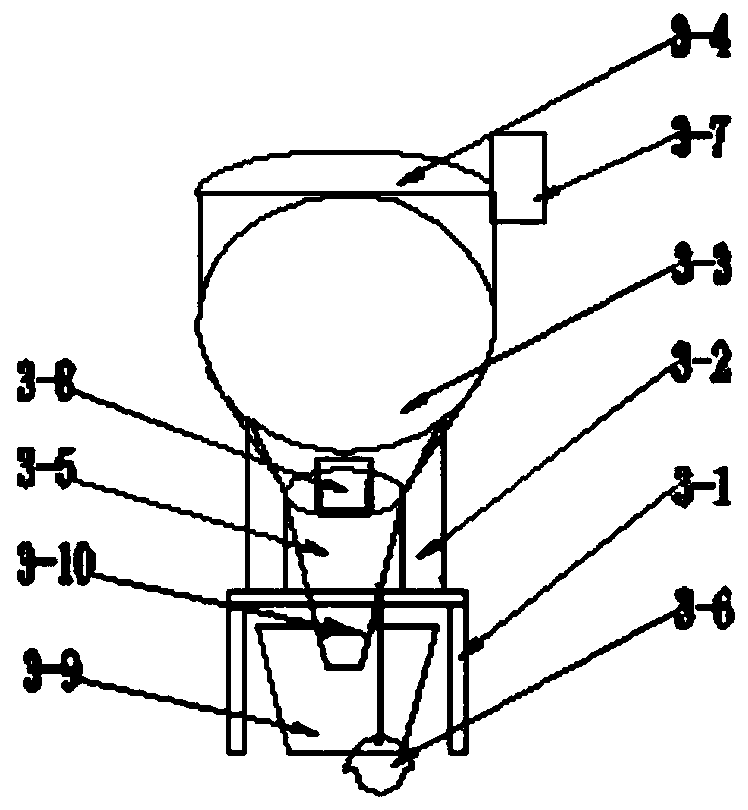

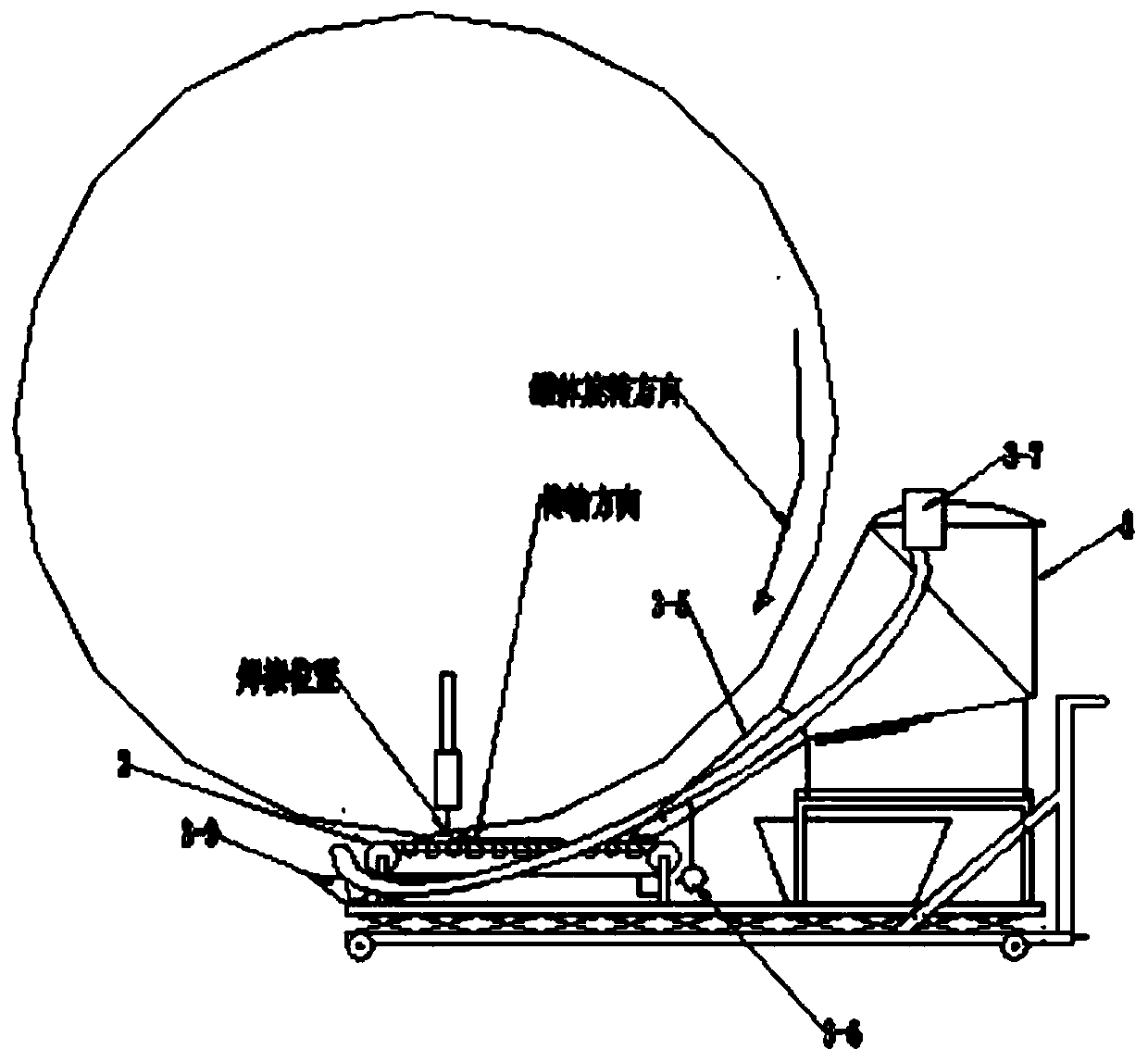

[0025] exist figure 1 In the schematic diagram of the present invention shown, the flux conveyor 2 and the flux storage tank 3 are placed on the lift car 1, and the flux flows out from the flux storage tank, passes through the flux delivery pipe and accumulates on the conveyor belt of the flux conveyor. The flux sent from the flux conveyor and falling in the flux collection tray is drawn back into the flux storage tank through the flux return pipe.

[0026] exist Figure 4 In the schematic diagram of the present invention shown, the lifting car includes guide wheels, fixed universal wheels, base plate, lifting plate, lifting frame, lifting pedals, handles, small jacks, springs and lifting adjustment rods. Fix handles 1-7 at the end of the base plate. A group of guide wheels 1-1 and a group of fixed universal wheels 1-2 are arranged on the bottom of the base plate, and are connected by a lifting frame 1-5 between the base plate and the lifting plate, and the lifting pedal rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com