Electromagnetic sensor for aluminum alloy electromagnetic field auxiliary semi-continuous casting

An electromagnetic inductor and electromagnetic field technology, which is applied in the field of aluminum alloy semi-continuous casting, can solve the problems of large number of coil turns, poor stability, difficult coil cooling, etc., and achieve the effects of improving surface quality, ensuring penetration depth, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

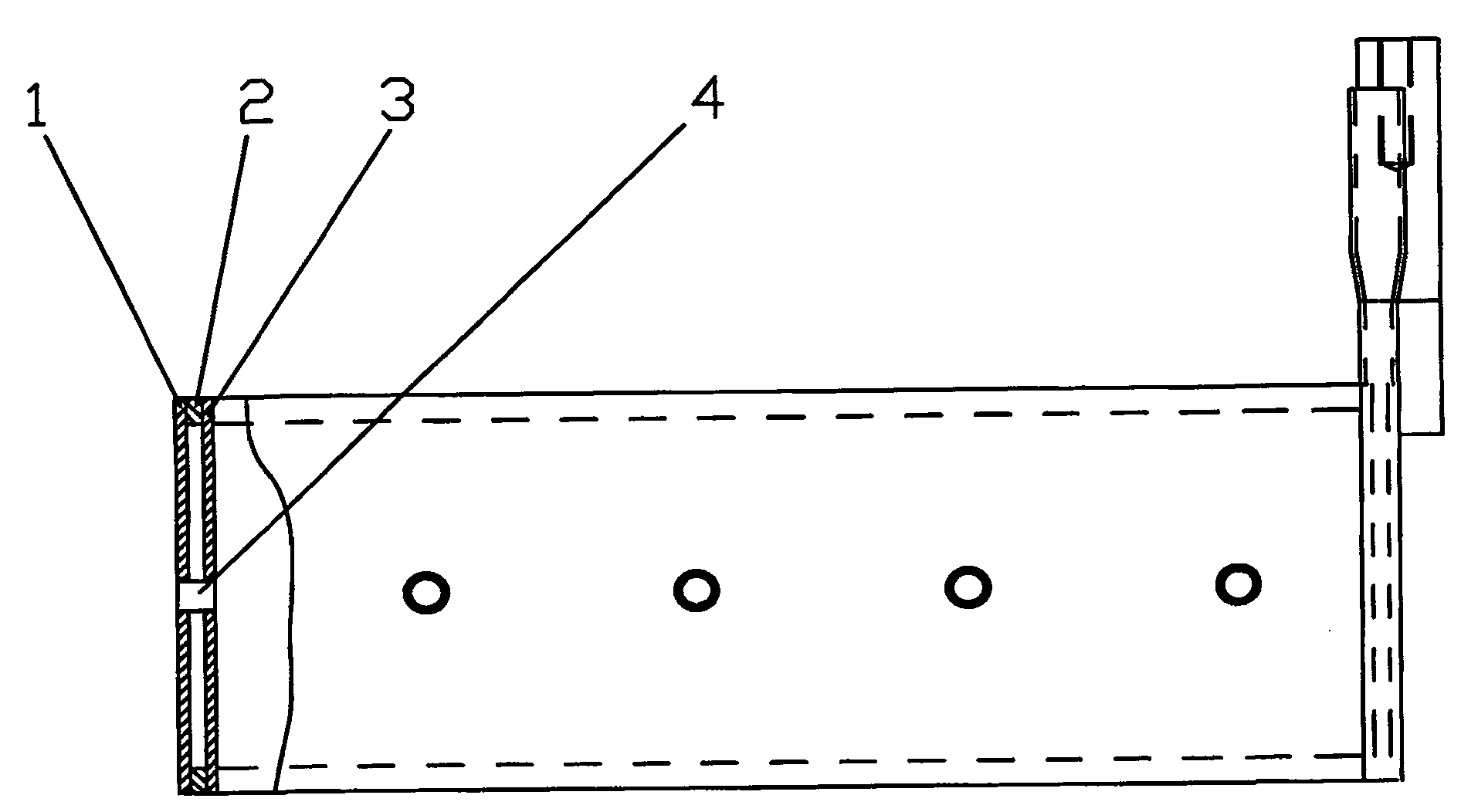

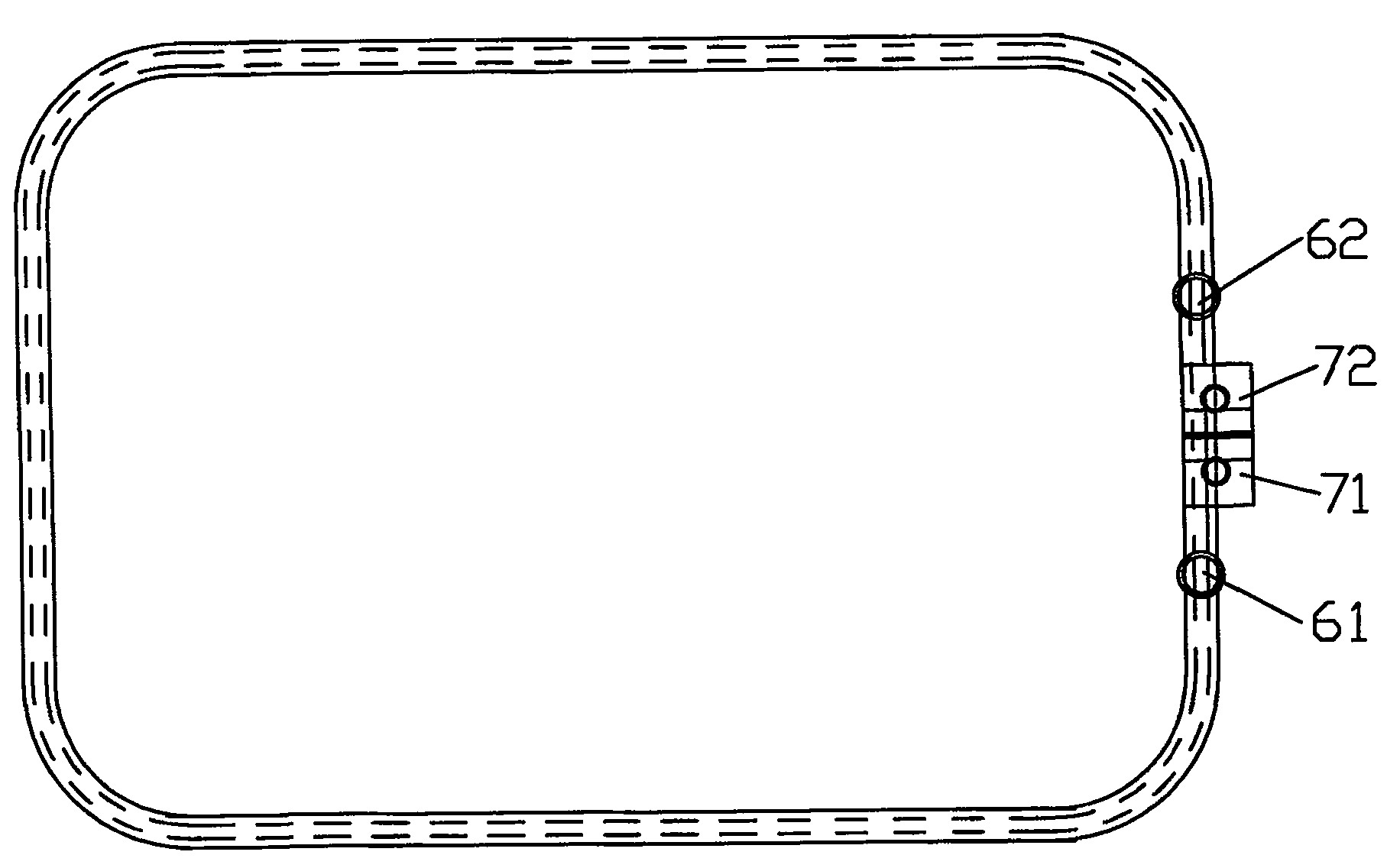

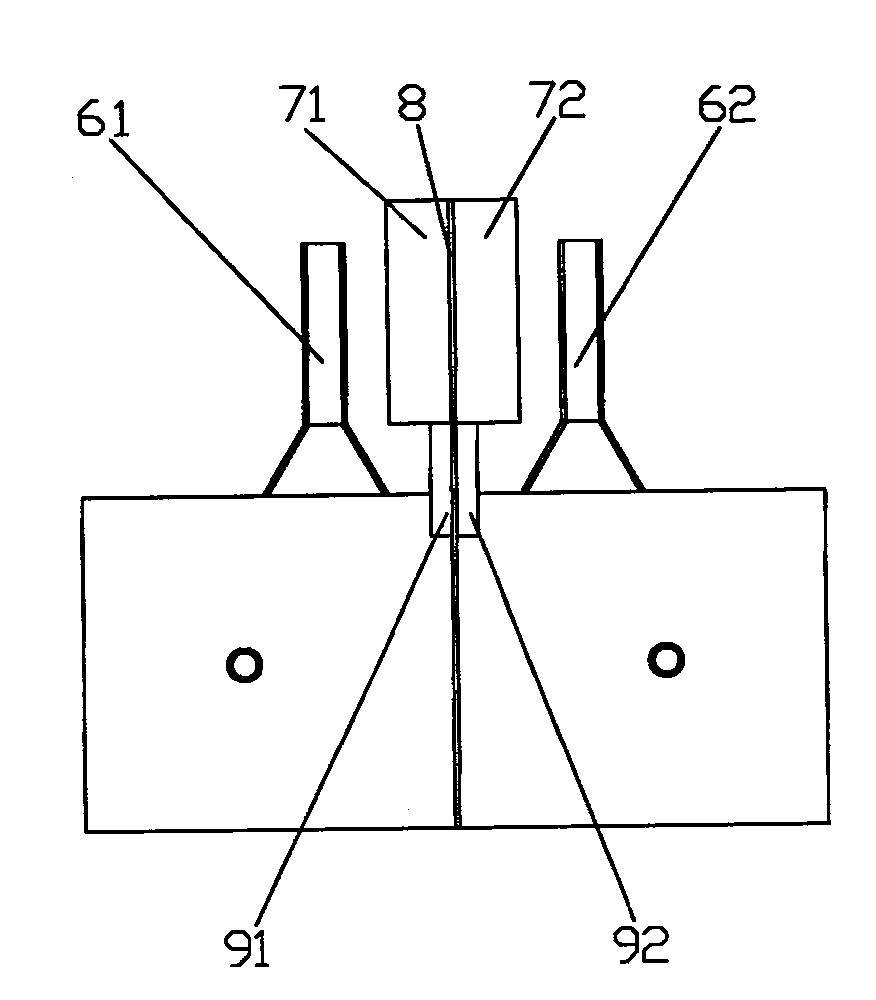

[0019] Such as Figure 1~3 As shown, the electromagnetic inductor for aluminum alloy electromagnetic field assisted semi-continuous casting has a copper plate cavity structure. Copper plate 1 and copper plate 3 are erected, and the upper and lower ends are sealed and welded with copper strips 2 to form a single-turn copper plate coil with a hollow structure. The two copper plates are connected to each other with rivets 4 in the middle of the copper plate 3, which strengthens the strength of the double-layer copper plate on the side wall of the coil; the two ends of the coil are welded with a hollow copper block 91 and a copper block 92, and the copper block 91 is connected to one another. A connecting block 72 is connected to the connecting block 71 and the copper block 92. The connecting block 71 and the connecting block 72 are respectively connected to the positive and negative poles of the transformer. An insulating sheet 8 is arranged between the two ends of the coil. The insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com