Concrete anti-scour guide wall structure and construction method

A construction method and concrete technology, which is applied in the direction of basic structure engineering, excavation, breakwater, etc., can solve the problems of large amount of anti-seepage engineering, long construction period, and complicated procedures, so as to ensure the anti-scour effect, reduce the construction period, reduce the The effect of soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

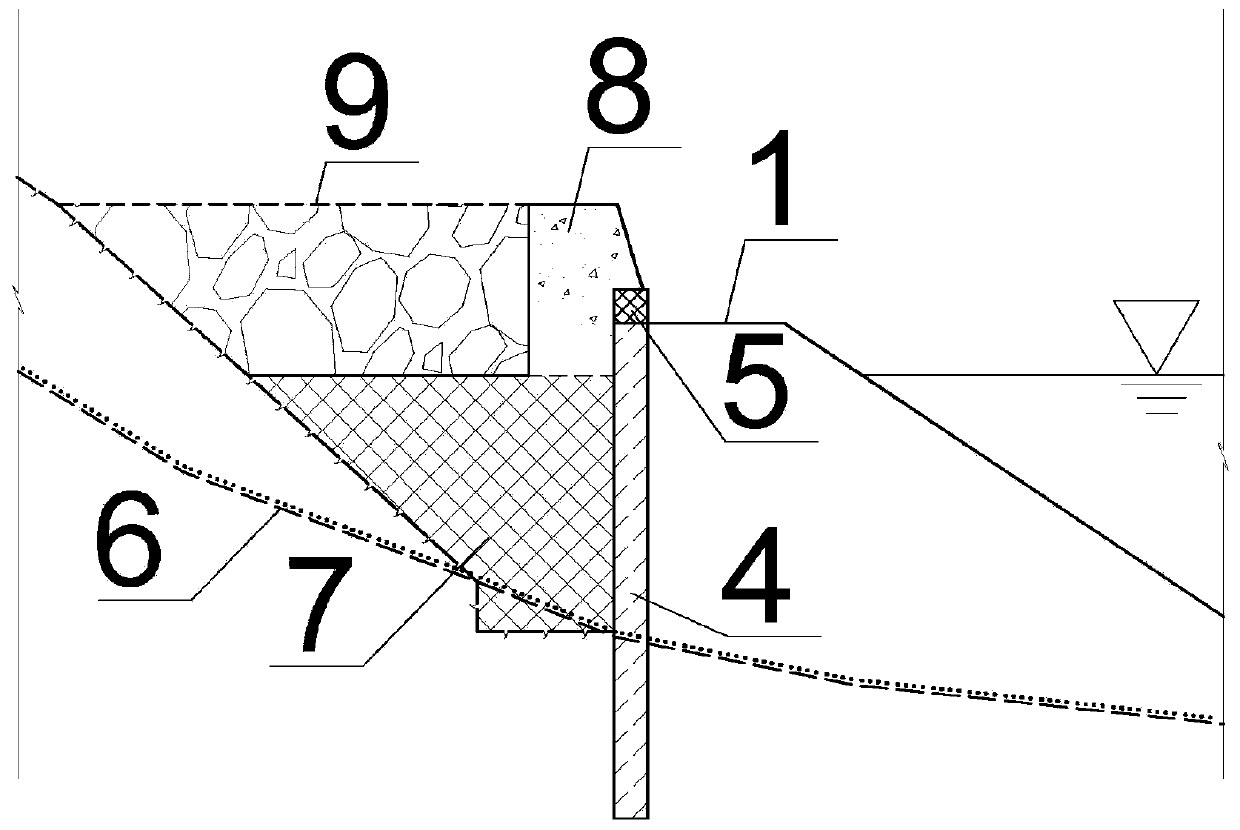

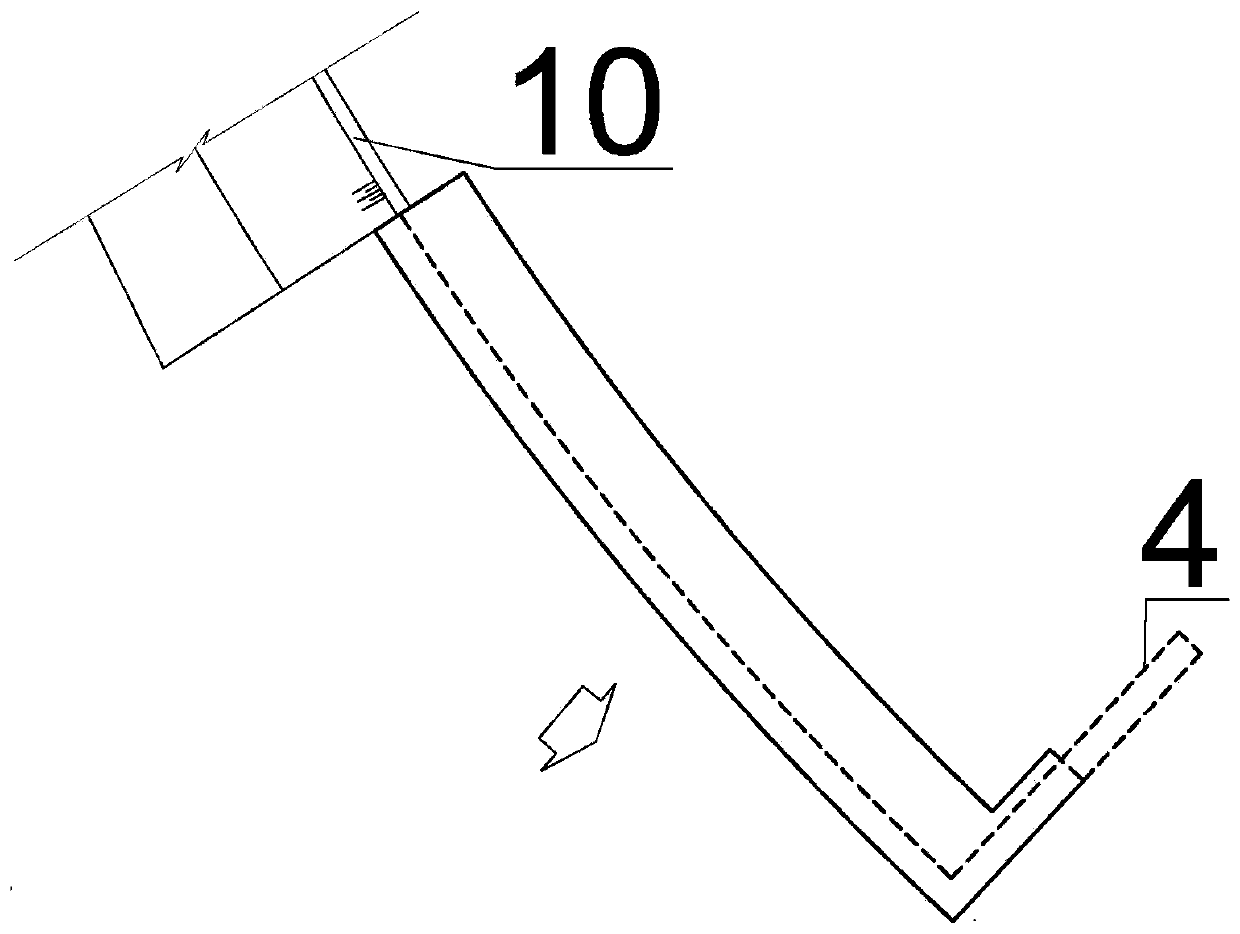

[0029] Such as Figure 1 to Figure 4 As shown, a concrete anti-scouring guide wall structure includes a construction platform 1, and the side of the construction platform 1 far away from the river is poured with an occlusal pile continuous wall 4, and a backfill pit is excavated behind the occlusal pile continuous wall 4, and the backfill pit is filled with There is a plain concrete layer 7, and the upper side of the plain concrete layer 7 close to the occlusal pile diaphragm wall 4 is poured with an upper guide wall structure concrete layer 8, and the part of the guide wall structure concrete 8 above the plain concrete layer 7 to the slope surface is paved with an access road 9 . The side of the construction platform 1 away from the river channel is drilled to the bottom of the bedrock roof line 6 by means of percussion drilling or other methods, and then the continuous wall 4 of occlusal piles is poured into it as a separation wall. The bottom layer of the backfill pit behin...

Embodiment 2

[0036] Such as Figure 1 to Figure 4 As shown, a construction method of a concrete anti-scouring guide wall structure includes the following steps. In the first step, the construction platform 1 is leveled, and the slope on the side of the river is first filled or excavated to be the construction platform 1; Fill or excavate the slope to form a construction platform 1 with an upper plane width of 5-8m, so that subsequent mechanical equipment can work on the construction platform 1.

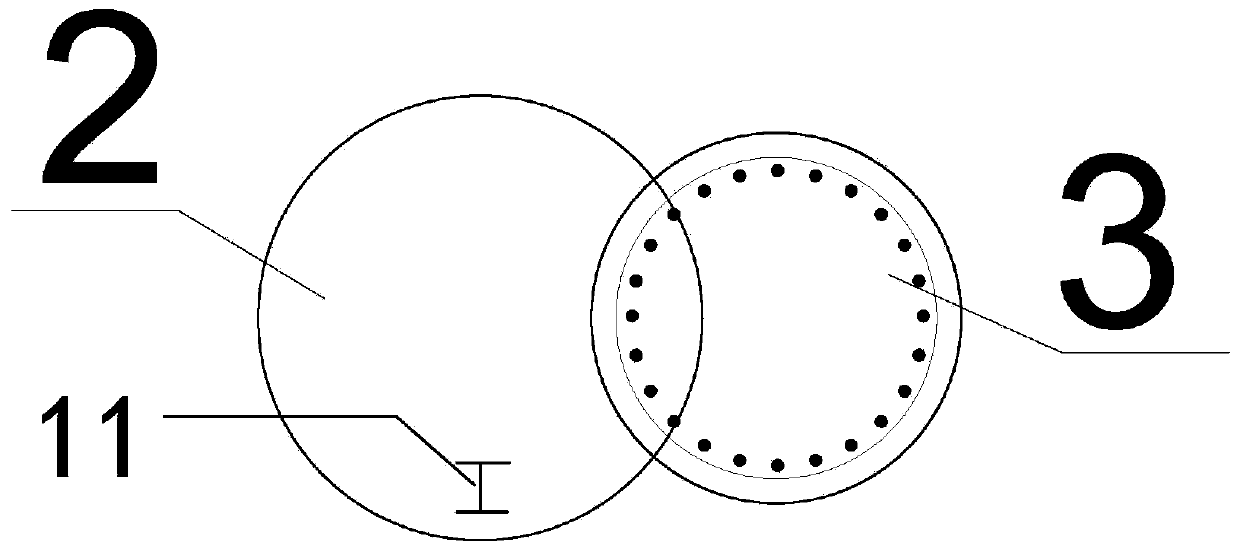

[0037] In the second step, the occlusal pile diaphragm wall 4 is constructed, and the occlusal pile hole is constructed on the side of the construction platform 1 far away from the river, and the first-order concrete plain pile 2 is poured into the occlusal pile hole, and then the second-order reinforced concrete pile 3 is constructed, and the first-order concrete pile is constructed. The plain pile 2 and the second sequence reinforced concrete pile 3 form a closed continuous wall 4 of occlusal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com