Continuous Production Technology and Continuous Production Equipment of Emulsion Polymer and Its Application

A technology of production equipment and production process, which is applied in the field of emulsion polymerization, can solve the problems of poor stability and safety, poor product stability, fast reaction speed, etc., and achieve the effect of balanced proportion, high stirring shear strength and strong thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

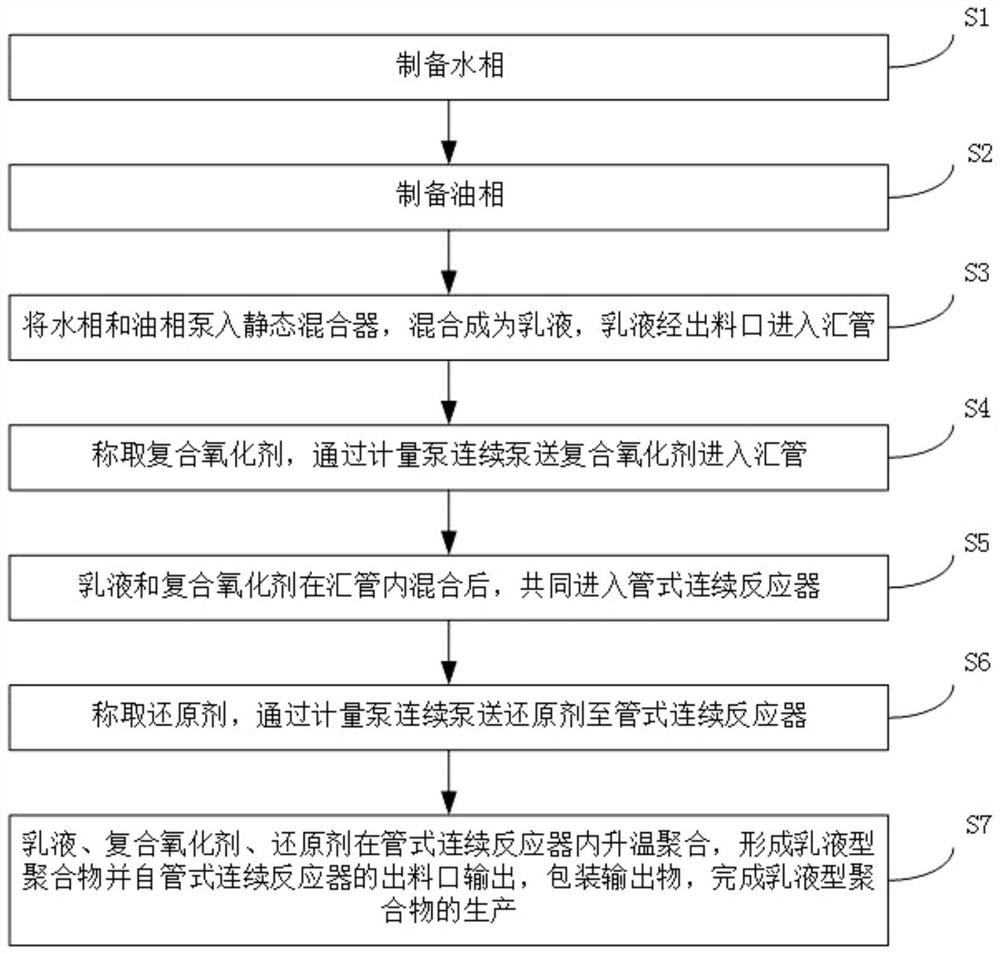

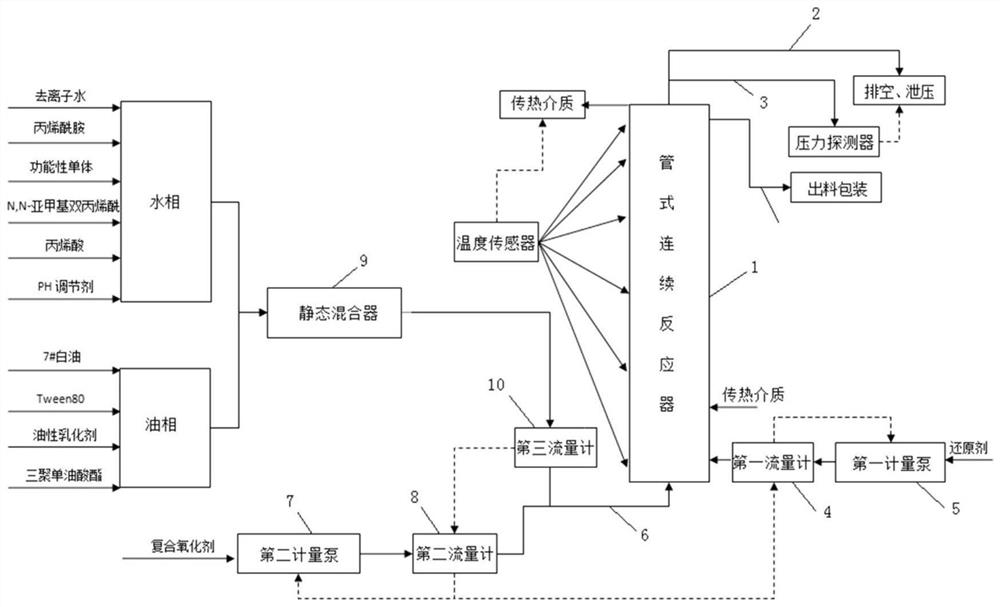

[0063] This embodiment relates to the continuous production process of emulsion polymer, see figure 1 , including the following steps:

[0064] S1. prepare the water phase;

[0065] S2. preparing the oil phase;

[0066] S3. Pump the water phase and the oil phase into the static mixer, mix to form an emulsion, and the emulsion enters the manifold through the discharge port;

[0067] S4. Weigh the compound oxidant, and continuously pump the compound oxidant into the header through the metering pump;

[0068] S5. After the emulsion and the composite oxidant are mixed in the manifold, they enter the tubular continuous reactor together;

[0069] S6. Weigh the reducing agent, and continuously pump the reducing agent to the tubular continuous reactor through the metering pump;

[0070] S7. Emulsion, composite oxidizing agent, and reducing agent are heated and polymerized in the tubular continuous reactor to form an emulsion polymer and output from the discharge port of the tubula...

no. 2 approach

[0075] This embodiment relates to the continuous production process of emulsion polymer, see figure 1 , including the following steps:

[0076] S1. Prepare the aqueous phase, specifically including the preparation of raw materials and preparation methods:

[0077] (1) Prepare the raw materials, including weighing the following components by weight:

[0078] 150-300 parts of deionized water;

[0079] 90-150 parts of acrylamide;

[0080] 10-30 parts of functional monomers;

[0081] 50-80 parts of N,N-methylenebisacrylamide;

[0082] 25-40 parts of acrylic acid;

[0083] 40-64 parts of pH regulator;

[0084] Wherein, the mass ratio of N,N-methylenebisacrylamide and acrylic acid is 2; the mass ratio of acrylic acid and pH regulator is 0.625;

[0085] Among them, the functional monomer is a mixture of one or more of glycidyl methacrylate, ethyl methacrylate, and vinyl tert-carbonate; the pH regulator is NaOH, NaHCO 3 , citric acid in one or more mixed form.

[0086] (2) Pr...

no. 3 approach

[0111] Implement a kind of emulsion type polymer continuous production process as follows:

[0112] (1) Dissolve 150 parts of deionized water, 102 parts of acrylamide, 10 parts of functional monomer, 60 parts of N, N-methylenebisacrylamide, 30 parts of acrylic acid, and 48 parts of pH regulator to form a water phase ,spare.

[0113] (2) Stir 360 parts of 7# white oil, 8080 parts of sorbitan monooleate polyoxyethylene ether Tween, 120 parts of oily emulsifier, and 40 parts of trimerized monooleate according to weight to form an oil phase and set aside .

[0114] (3) According to the mass ratio, pump 400 parts of the prepared water phase and 600 parts of the prepared oil phase into the online mixer in proportion with a metering pump for online emulsification to form a stable emulsion. Among them, the water phase flow rate is 20L / min, the oil phase flow rate is 30L / min, and the total emulsion flow rate is 50L / min.

[0115] (4) At the rear end of the mixer, the compound oxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com