PU adhesive for single-component microfiber leather and preparation method of PU adhesive

A microfiber leather, one-component technology, applied in the directions of adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of poor adhesion, no resin adhesion, etc. Excellent, good adhesion, good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

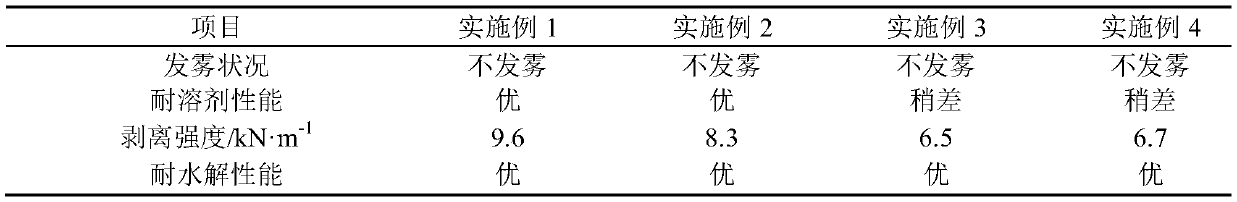

Embodiment 1

[0028] Example 1: 400 g of polyhexamethylene adipate diol (molecular weight: 2000) was weighed and added into a three-necked flask, and the reaction temperature was raised to 110° C. to melt it, and at the same time, water removal treatment was carried out. Then add 0.02g antioxidant and 0.003g phosphoric acid and stir well therein, then add 50g of molten isocyanate MDI (R value is set to 1). Stir at high speed to make it viscosifying reaction, the reaction temperature is about 110 ℃, add the organic solvent N,N-dimethylformamide to dilute during the viscosifying process. Another organic solvent, isopropanol, was added after the reaction was finished and the mixture was stirred for 1 h. The solid content of the prepared PU adhesive is controlled to be 40%, and the viscosity is 80,000 to 120,000 (cps / °C). Wherein, the mass ratio of the used solvent N,N-dimethylformamide to isopropanol is 4:1.

Embodiment 2

[0029] Example 2: 400 g of polybutylene adipate diol (molecular weight: 2000) was weighed and added into a three-neck flask, the reaction temperature was raised to 110° C. to melt, and water removal treatment was carried out at the same time. Then add 0.02g of antioxidant and 0.003g of phosphoric acid and stir well therein, then add 42g of molten isocyanate NDI (R value is set to 1). Stir at high speed to make it viscosifying reaction, the reaction temperature is about 110 ℃, add the organic solvent N,N-dimethylformamide to dilute during the viscosifying process. Add another organic solvent, acetone, to continue stirring for 1 h after the reaction is complete. The prepared PU adhesive has a solid content of 40% and a viscosity of 80,000-120,000 (cps / °C). Wherein, the mass ratio of the used solvent N,N-dimethylformamide to acetone is 4:1.

Embodiment 3

[0030]Example 3: Weigh 400 g of polyhexamethylene sebacate diol (molecular weight: 2000) and add it into a three-necked flask. The reaction temperature is raised to 110° C. to melt it, and at the same time, water removal treatment is carried out. Then add 0.02g of antioxidant and 0.003g of phosphoric acid and stir well therein, then add 48.9g of molten isocyanate TMXDI (R value is set to 1). Stir at high speed to make it viscosifying reaction, the reaction temperature is about 110 ℃, add the organic solvent N,N-dimethylformamide to dilute during the viscosifying process. After the reaction, another organic solvent butanone was added to continue stirring for 1 h. The prepared PU adhesive has a solid content of 40% and a viscosity of 80,000-120,000 (cps / °C). Wherein, the mass ratio of the used solvent N,N-dimethylformamide to butanone is 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com