A kind of preparation method of polypropylene foam special material based on sorbitol acetal compound

A technology of sorbitol acetal and compound, which is applied in the field of polypropylene foaming, can solve the problems of reduced processing fluidity, inability to balance polypropylene melt strength and processing fluidity, and processing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

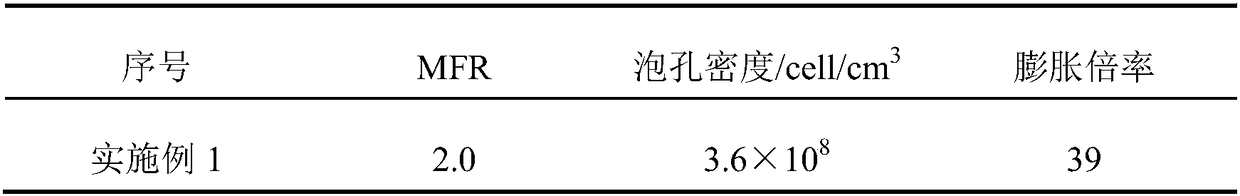

Embodiment 1

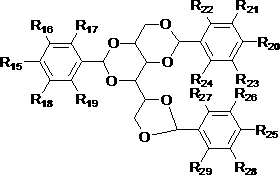

[0016] 100 parts of homopolypropylene (produced by Sinopec Yangzi Petrochemical Company, brand F401) were evenly added from the main feeding port of the extruder; 0.3 parts of benzoyl peroxide and 0.2 parts of 1,3:2,4-bis( p-Methylbenzylidene) sorbitol is evenly added from the weight-loss metering feeding system; 0.3 parts of styrene and 4 parts of petroleum ether are miscible and added from the second heating zone of the extruder through a precision feed pump to extrude and make pellets to obtain special polypropylene foaming materials. Simultaneously open the vacuum pump at the tail of the extruder to remove unreacted styrene.

[0017] Among them, the length-to-diameter ratio of the extruder is 40; the temperatures of the 9 heating zones are: 140°C, 160°C, 180°C, 190°C, 200°C, 200°C, 200°C, 210°C, 210°C; The speed of the main feeding screw is 120r / min, the speed of the main feeding screw is 20r / min, the feeding speed of the loss-in-weight metering feeding system is 2.5Kg / mi...

Embodiment 2

[0021] Add 100 parts of homopolypropylene (produced by Sinopec Yangzi Petrochemical Company, brand F401) from the main feeding port of the extruder; add 0.2 parts of dicumyl peroxide and 0.5 parts of 1,3:2,4-di (3,4-Dimethylbenzaldehyde) sorbitol is evenly added from the weight-loss metering feeding system; 0.2 parts of divinylbenzene, 0.05 parts of styrene and 4 parts of acetone are miscible and heated from the second section of the extruder The zone is added through a precision feed pump, extruded and granulated to obtain foamed polypropylene special materials. Among them, the feeding speed of the loss-in-weight metering feeding system is 3.5Kg / min; the flow rate of the precision feeding pump is 3mL / min.

[0022] Its operating steps and implementation method are all with embodiment 1.

Embodiment 3

[0024] Add 100 parts of homopolypropylene (produced by Sinopec Yangzi Petrochemical Company, brand F401) from the main feeding port of the extruder; 3: 2,4-bis (p-chlorobenzylidene) sorbitol is evenly added from the weight-loss metering feeding system; It is added through a precision feed pump, extruded and granulated to obtain a special material for polypropylene foaming. Among them, the feeding speed of the loss-in-weight metering feeding system is 8Kg / min; the flow rate of the precision feeding pump is 5mL / min.

[0025] Its operating steps and implementation method are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com