Device for manufacturing lithium ion secondary battery pole piece and manufacturing method thereof

A technology for secondary batteries and lithium ions, which is applied to devices and coatings for coating liquid on the surface, and can solve the problems of high production cost of lithium-ion secondary battery pole pieces, waste of substrates, and large waste of leftover tabs and other problems, to achieve the effect of convenient middle blank width, reduce production cost and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

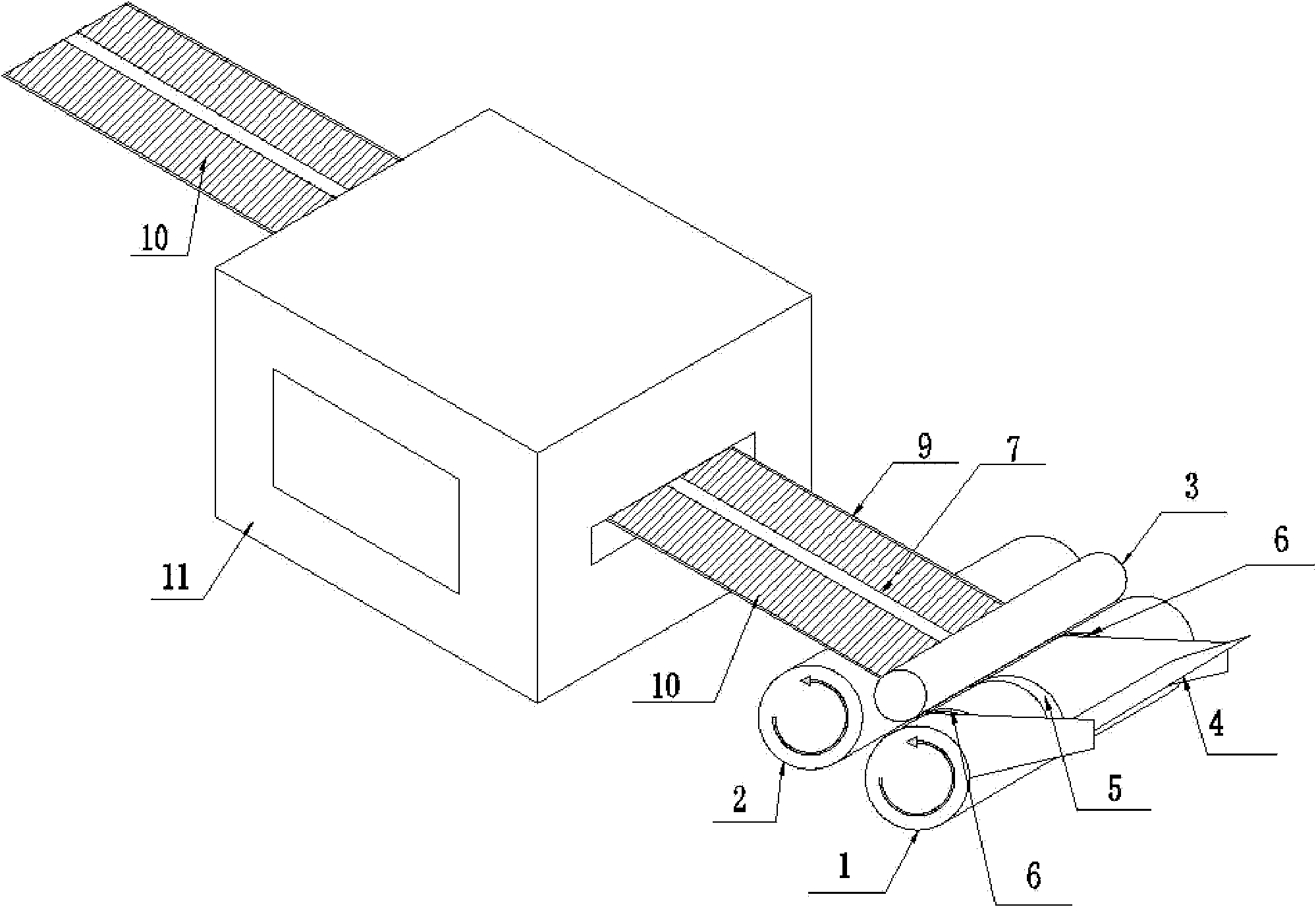

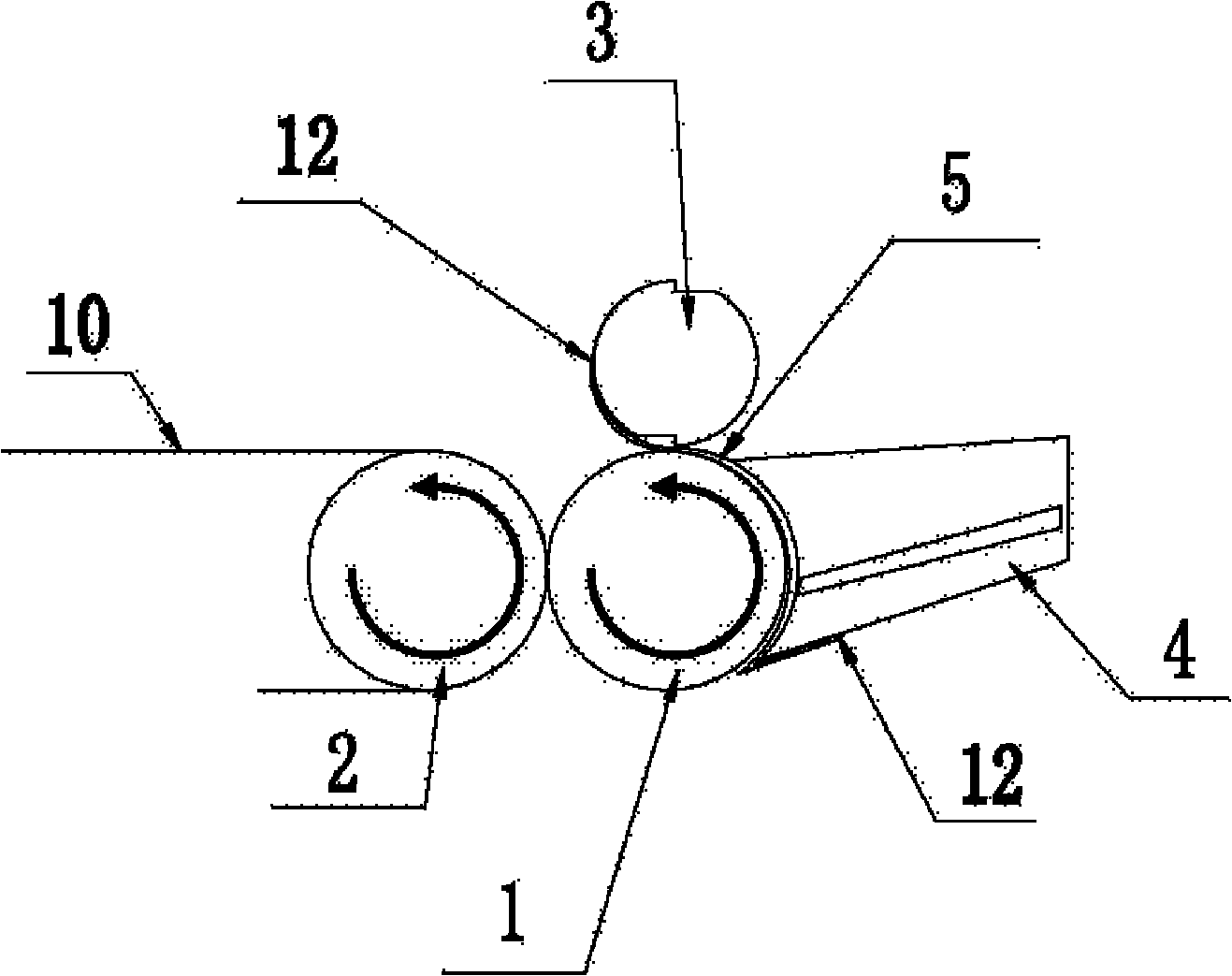

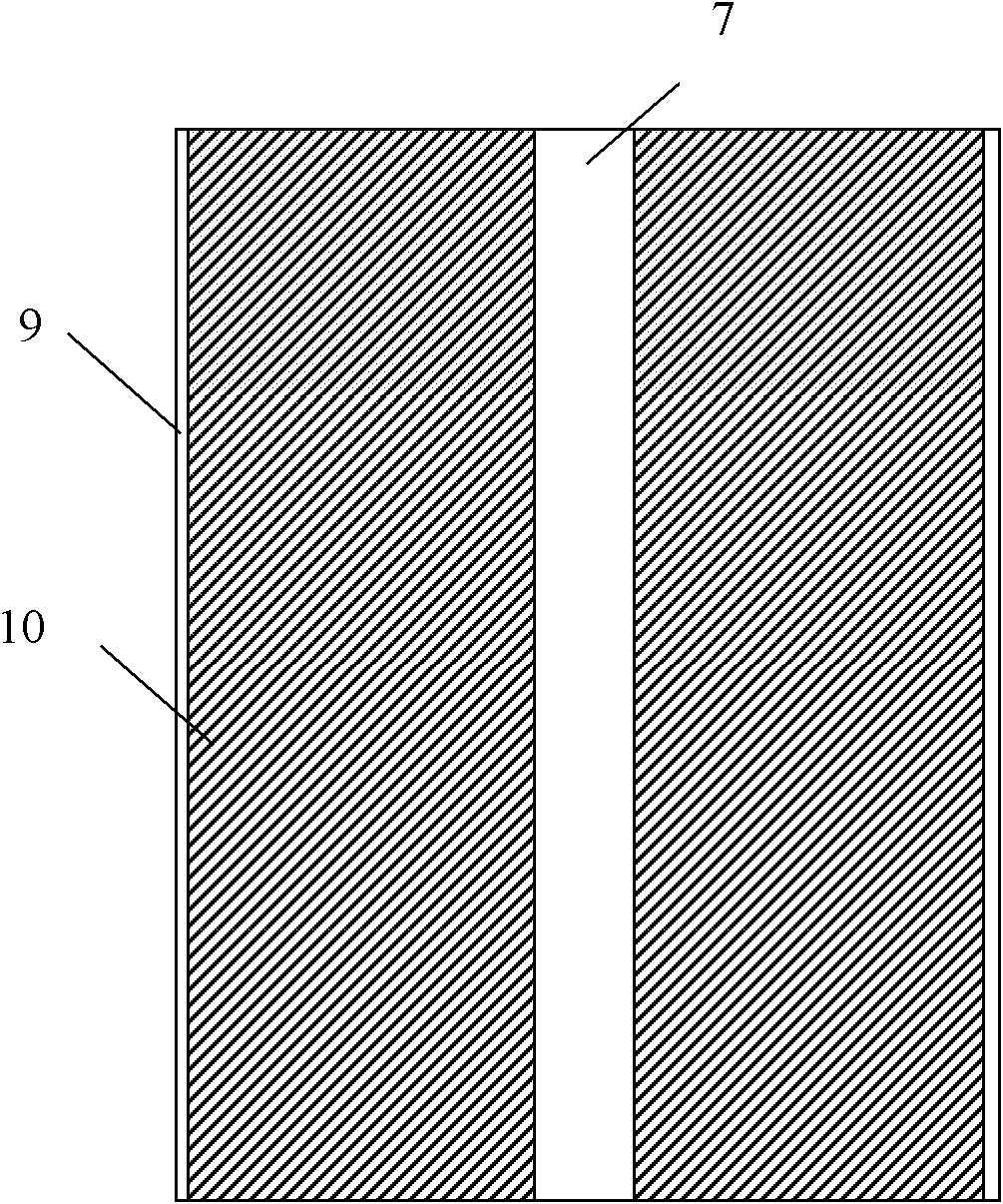

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , figure 2 and image 3 , a device for manufacturing lithium-ion secondary battery pole pieces, comprising a paint roll 1 and a base material transfer roll 2, a scraper 3 is arranged above the paint roll 1, a base material transfer roll 2 is provided on one side of the paint roll 1, and a base material transfer roll 2 is provided on the other A slurry tank 4 is provided on one side, and a trapezoidal retaining foil 5 is provided between the scraper 3 and the paint roller 1. One end of the trapezoidal retainer foil 5 is fixed on the scraper 3, and the other end passes through the gap between the scraper 3 and the paint roller 1. The gap is fixed on the slurry tank 4. There is a bottom baffle at the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com