Silicon heterojunction solar cell with electroplating electrode and manufacturing method thereof

A solar cell and silicon heterojunction technology, applied in the field of solar cells, can solve the problems of high cost, poor control of grid line groove pattern width and flatness, complicated manufacturing process, etc., so as to improve efficiency, equipment and materials. Easy-to-obtain, simple-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A silicon heterojunction solar cell with electroplated electrodes and its manufacturing method provided by the present invention will be described in more detail below with reference to the accompanying drawings and examples.

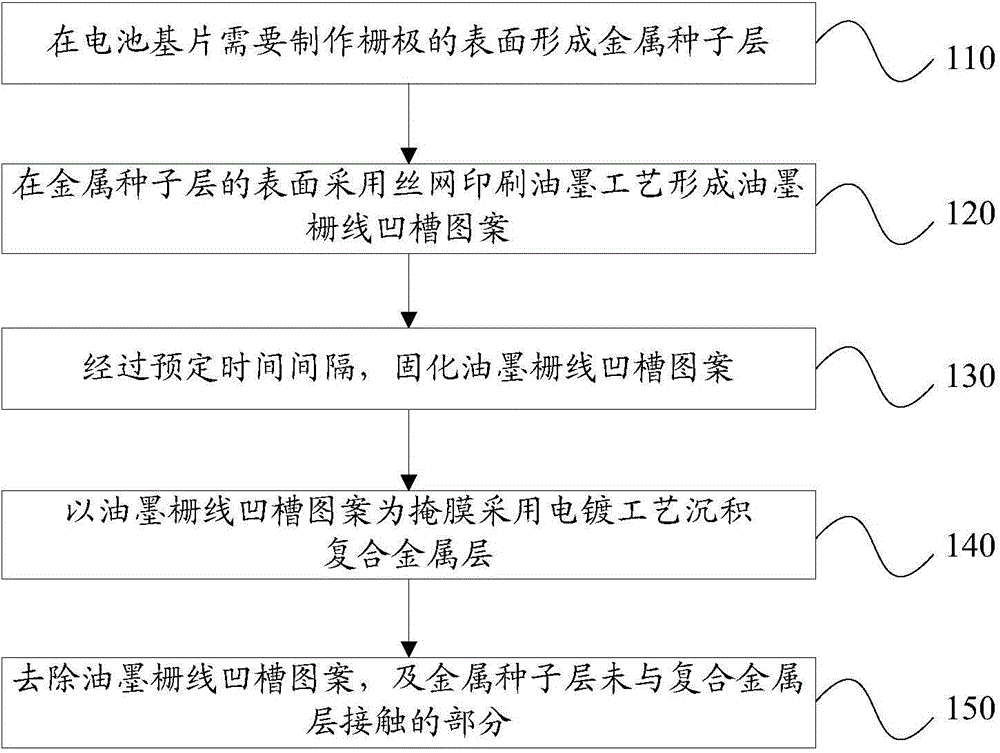

[0044] An embodiment of the present invention provides a method for fabricating a silicon heterojunction solar cell with electroplated electrodes, such as figure 1 As shown, at least the following steps are included:

[0045] Step 110: forming a metal seed layer on the surface of the battery substrate where the grid is to be fabricated.

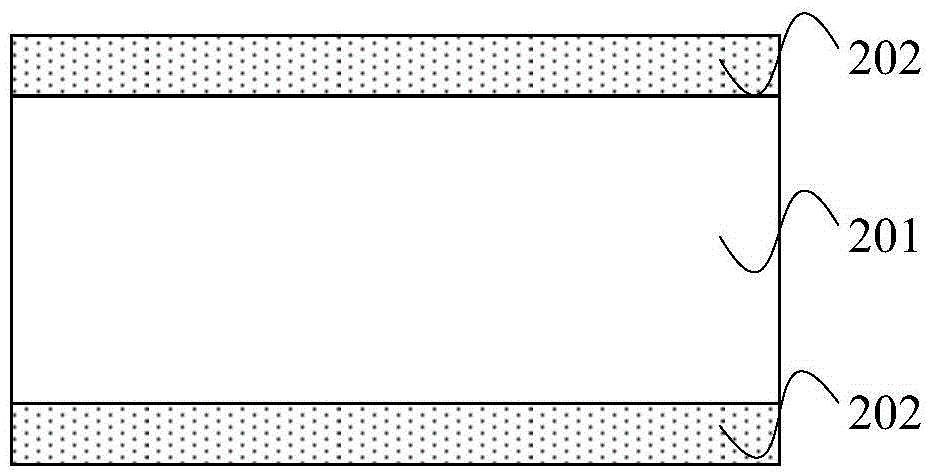

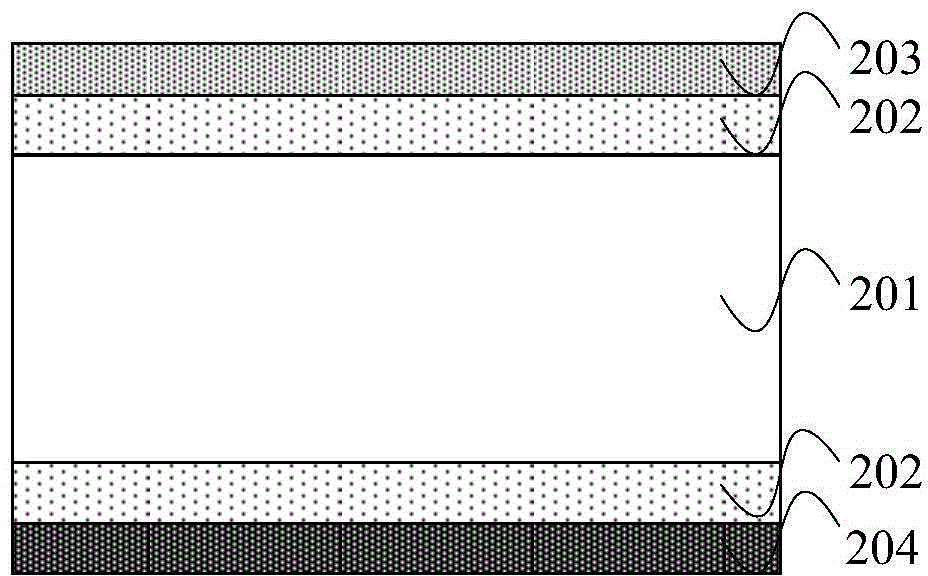

[0046] Wherein, the cell substrate is a substrate for making a silicon heterojunction solar cell with an electroplating electrode, and can be made into a silicon heterojunction solar cell with an electroplating electrode that receives light on one side, that is, the grid needs to be fabricated on one side, or A silicon heterojunction solar cell with electroplated electrodes that receives light from both sides i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com