Hot melt adhesive membrane for cross-linking polyolefin wall cloth and preparation method of hot melt adhesive membrane

A technology of hot-melt adhesive film and polyolefin, which is applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., and can solve adhesive leakage, adhesive performance, drop, adhesive melting flow, etc. problems, to achieve the effect of fast bonding, avoiding melting flow, controlling weight and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

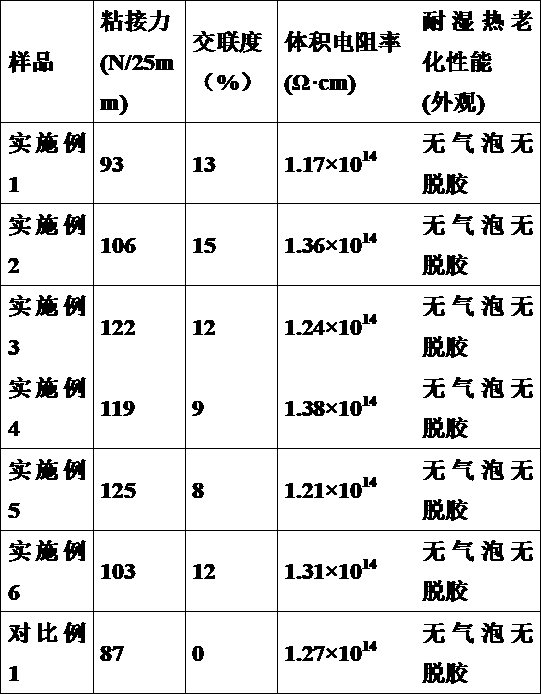

Examples

Embodiment 1

[0036] A hot melt adhesive film for cross-linked polyolefin wallcovering, which consists of the following components by weight: 20 parts of maleic anhydride grafted polyolefin copolymer (grafting rate: 0.31 wt%), 70 parts of ethylene- Octene copolymer (melt index is 18g / 10min (190°C / 2.16kg), melting peak temperature is 76°C), 10 parts of ethylene-acrylic acid copolymer (AA content is 15wt%, melting peak temperature is 90°C), 0.8 Part 1,1-di-tert-butylperoxycyclohexane, 1 part tetraallyloxyethane, 0.3 part maleic anhydride (purity 99.5%, melting point 53°C), 0.5 part thiodiethylenebis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]; wherein the formula of maleic anhydride grafted polyolefin copolymer is: 100 parts of ethylene-octene copolymer (melt index is 18g / 10min (190℃ / 2.16kg), melting peak temperature is 76℃), 0.1 part of 2,5 dimethyl-2,5-di(tert-butylperoxy) hexane, 1 part of maleic anhydride ( The purity is 99.5%, and the melting point is 53°C).

[0037] A preparati...

Embodiment 2

[0042]A hot melt adhesive film for cross-linked polyolefin wallcovering, which consists of the following components by weight: 25 parts of maleic anhydride grafted polyolefin copolymer (grafting rate: 1.12 wt%), 60 parts of ethylene- Octene copolymer (melt index is 18g / 10min (190°C / 2.16kg), melting peak temperature is 76°C), 15 parts of ethylene-acrylic acid copolymer (AA content is 15wt%, melting peak temperature is 90°C), 1 Parts of tert-butylperoxy-3,5,5-trimethylhexyl ester, 0.8 parts of vinyltrimethoxyethoxysilane, 0.5 parts of maleic anhydride (purity: 99.5%, melting point: 53°C), 0.8 parts Dioctadecyl pentaerythritol bisphosphite; the formula of maleic anhydride grafted polyolefin copolymer is: 100 parts of ethylene-octene copolymer (melt index: 18g / 10min (190℃ / 2.16kg), melting peak temperature is 76°C), 1 part of 2,5 dimethyl-2,5-bis(tert-butylperoxy)hexane, 5 parts of maleic anhydride (purity 99.5%, melting point 53°C).

[0043] A preparation method of a hot-melt adh...

Embodiment 3

[0048] A hot-melt adhesive film for cross-linked polyolefin wallcovering, which consists of the following components by weight: 40 parts of maleic anhydride grafted polyolefin copolymer (grafting rate: 0.61 wt%), 50 parts of ethylene- Octene copolymer (melt index is 18g / 10min (190°C / 2.16kg), melting peak temperature is 76°C), 10 parts of ethylene-acrylic acid copolymer (AA content is 15wt%, melting peak temperature is 90°C), 0.6 Parts of 1,1-di-tert-butylperoxycyclohexane, 1.2 parts of diallyl maleate, 0.7 parts of maleic anhydride (99.5% purity, melting point 53°C), 0.2 parts of 3,5-di-tert- Butyl-4-hydroxybenzyl diethylphosphonate; wherein the formula of maleic anhydride grafted polyolefin copolymer is: 100 parts of ethylene-octene copolymer (melt index is 18g / 10min (190℃ / 2.16kg ), the melting peak temperature is 76°C), 0.5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 3 parts of maleic anhydride (purity is 99.5%, melting point is 53°C ).

[0049] A preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com