Preparation and sealing method of crack-containing rock sample for multi-field coupling triaxial test

A triaxial test and rock sample technology, which is applied in the preparation of test samples, the sealing of engines, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of damage and damage that cannot comprehensively reflect the hydraulic and mechanical properties of natural rocks Regularity, damage to the seal, and the inability to study the effect of seepage hydraulic pressure on fractures, etc., to ensure the success rate of the triaxial test and the effect of small rock sample damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

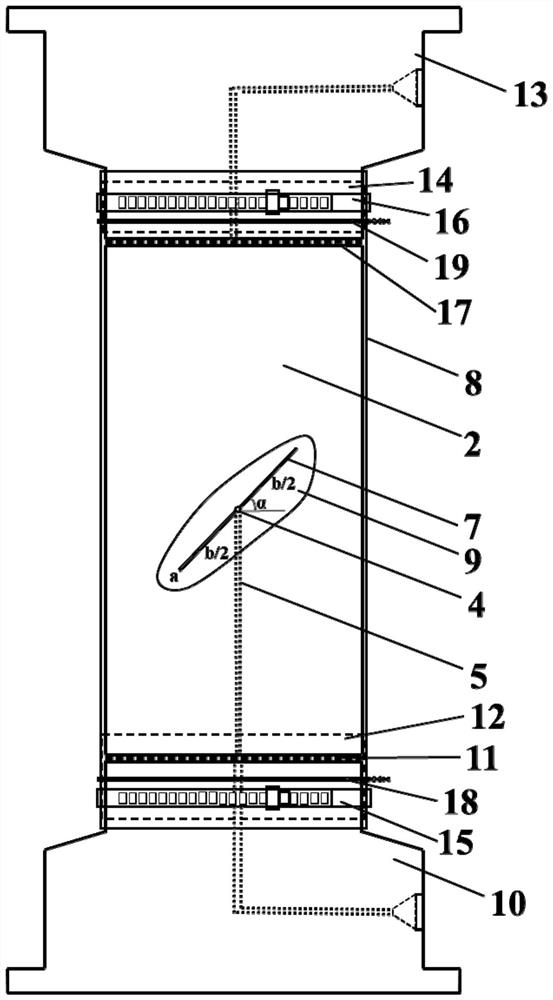

[0026] In order to enable those skilled in the art to better understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A method for preparing and sealing a rock sample containing cracks for a multi-field coupled triaxial test, comprising the following steps:

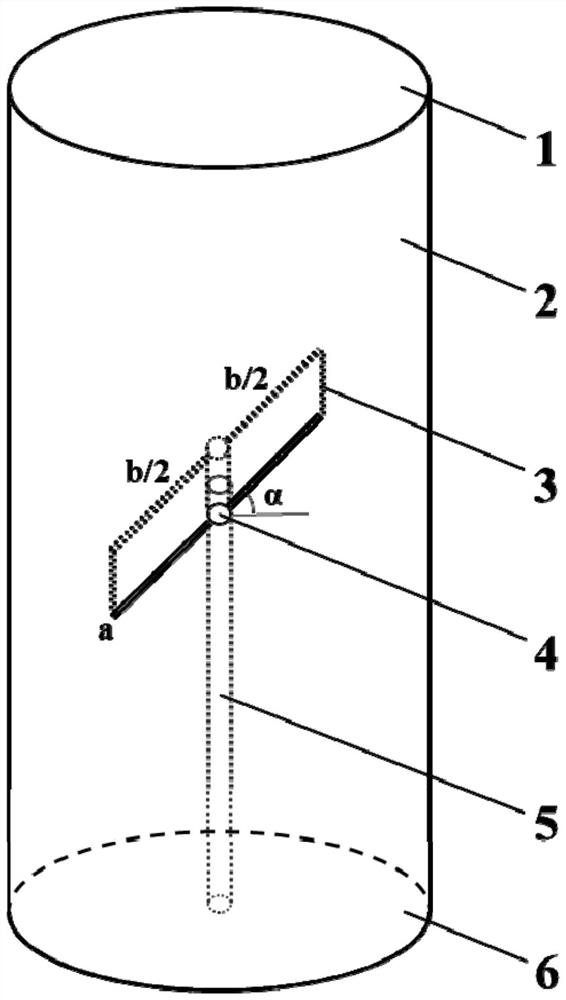

[0028] Step 1, complete rock sample preparation: process the natural rock into a standard cylindrical sample, as attached figure 1 As shown, the non-parallel error between the water inlet end face 6 and the water outlet end face 1 is not more than 0.05mm, and the water inlet end face 6 and the water outlet end face 1 are perpendicular to the axis of the test piece, and the maximum deviation is not more than 0.25°. The standard cylindrical sample is 50mm in diameter and 100mm in height.

[0029] Step 2, rock sample crack processing: process crack 3 on the standard cylindrical rock sample 2 prepared in step 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com