Chip carrier with dams

A carrier and chip technology, which is applied in electric solid state devices, semiconductor devices, semiconductor/solid state device components and other directions, and can solve problems such as easy overflow and contamination of solder ball connection pads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

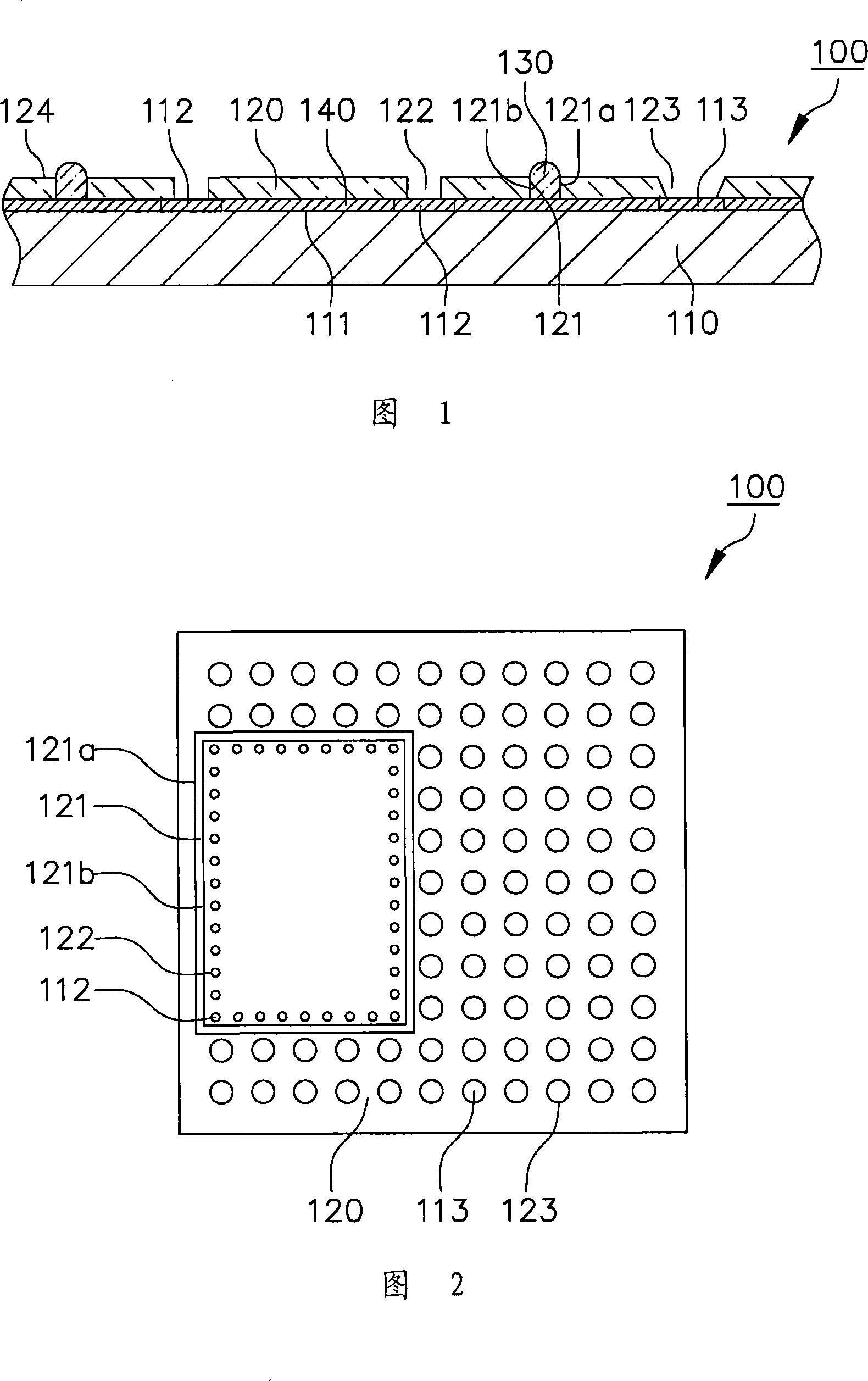

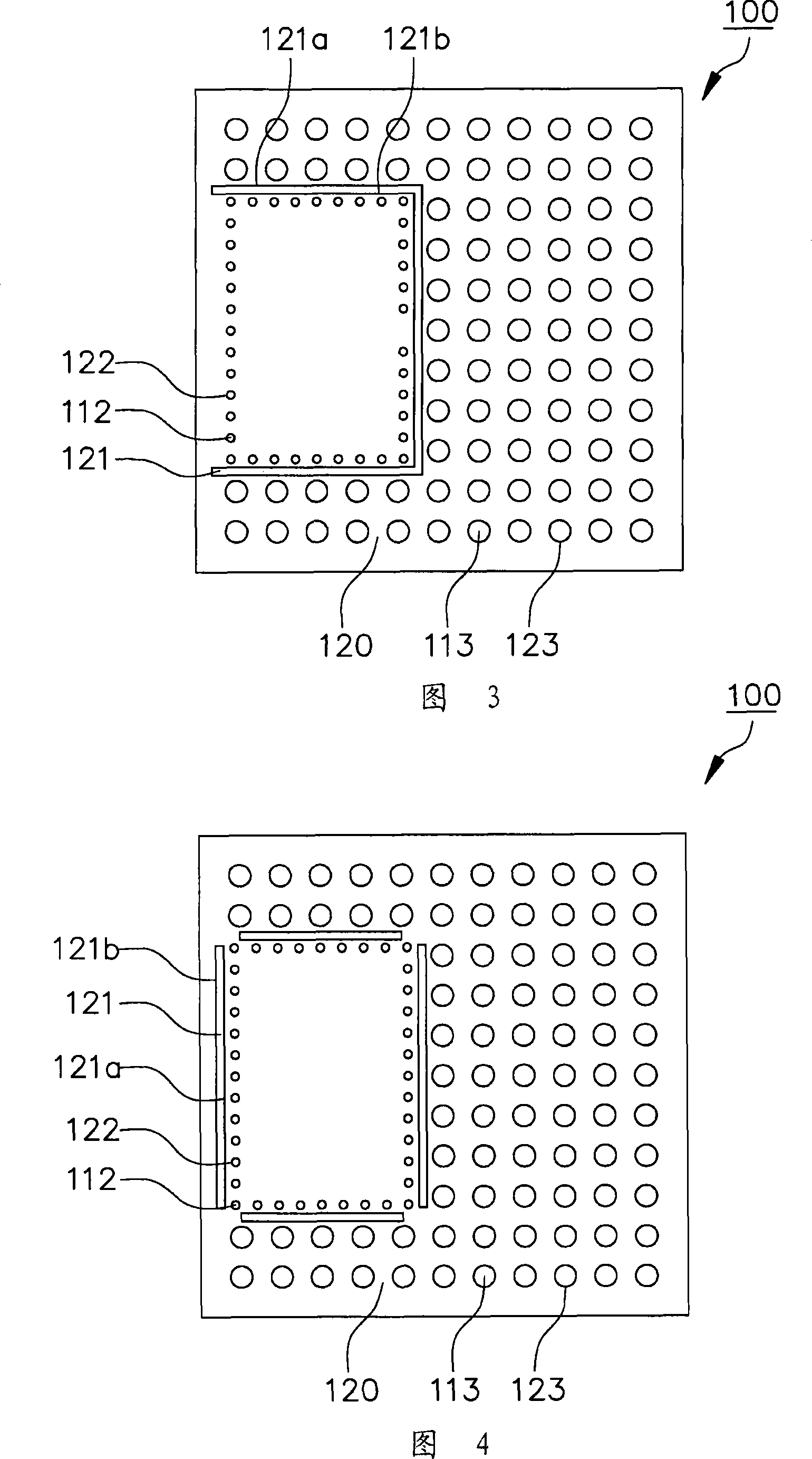

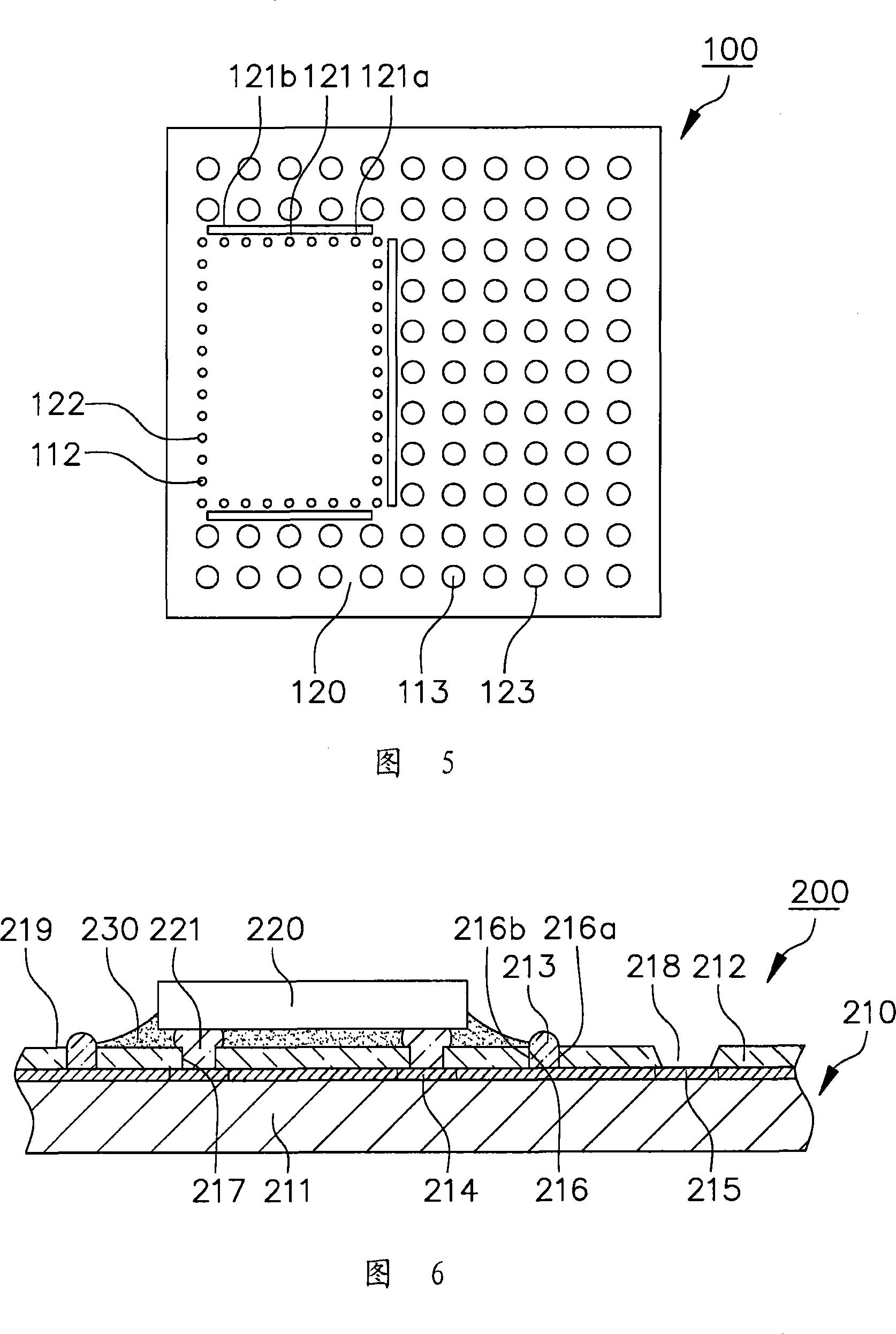

[0027] Please refer to FIG. 1 , according to a specific embodiment of the present invention, a chip carrier 100 with a dam is disclosed, which mainly includes a substrate 110, a protective layer 120 and a dam 130. The substrate 110 can be selected from a chip , chip or circuit board, the substrate 110 has a substrate surface 111, a plurality of first connection pads 112 and a plurality of second connection pads 113, the first connection pads 112 and the second connection pads 113 are formed on the substrate Surface 111, in addition, the chip carrier 100 further includes a circuit layer 140, the circuit layer 140, the first connection pad 112 and the second connection pad 113 can be formed by a metal layer after a patterning step, in this embodiment , the base material 110 is a printed circuit board, the protective layer 120 is a solder mask, such as green paint, the first connection pad 112 is a bump connection pad, and the second connection pad 113 is a solder ball connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com