Large-tow carbon fiber multifilament tensile sample and preparation device and method thereof

A technology for tensile specimen and carbon fiber, which is applied in the field of large tow carbon fiber multifilament tensile specimen and its preparation device, and can solve the problems of difficulty in meeting fiber tension requirements, high tensile strength, and large tension force. , to reduce the difficulty of sample preparation, avoid distortion and ensure the effect of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

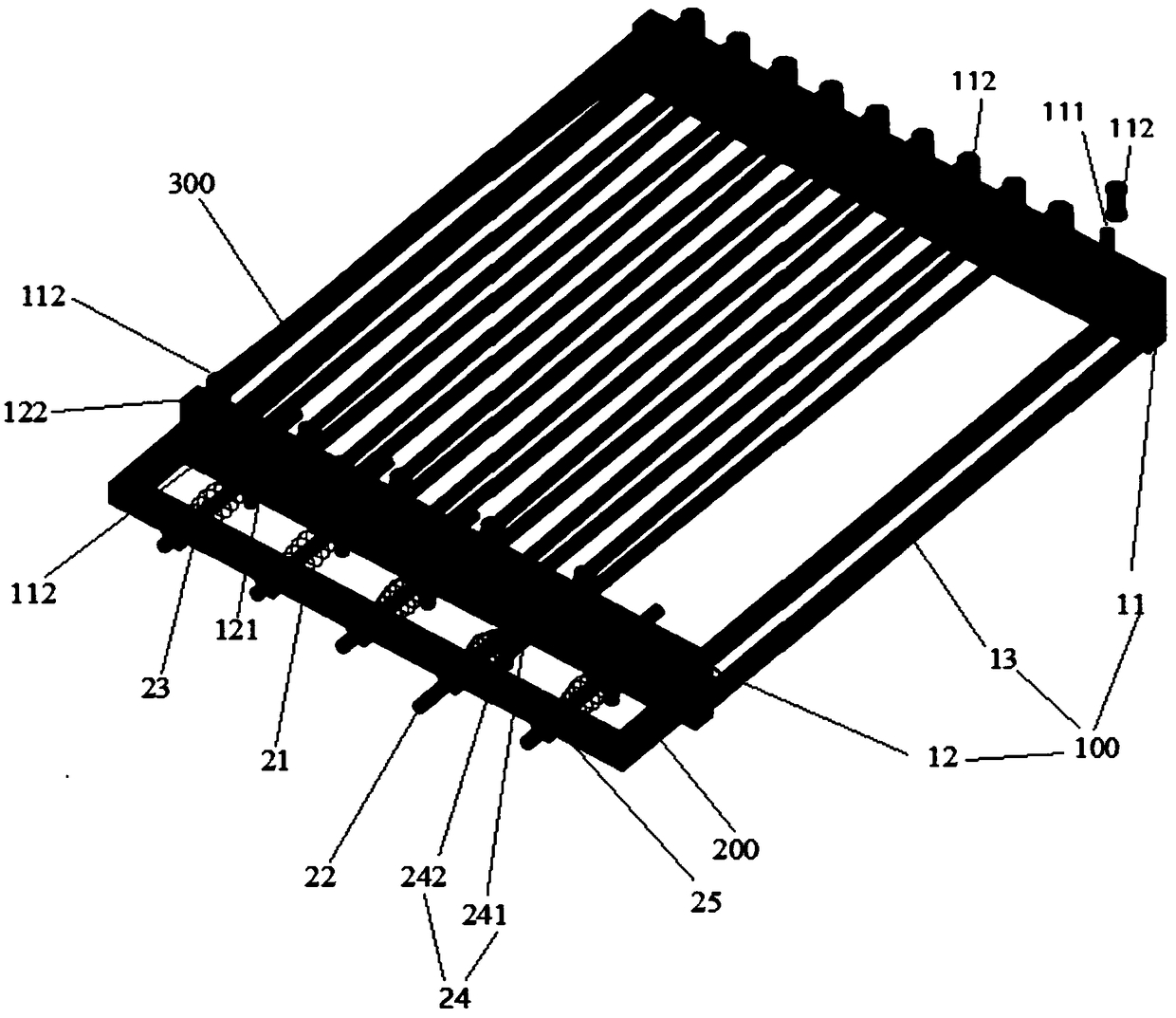

Image

Examples

Embodiment 1

[0047] Prepare the glue solution (the glue solution is configured according to the resin system stipulated in the national standard GB / T3362 or GB / T26749), and pour it into the dipping box. Toray 36K T720S carbon fiber is wound on the winding frame with a tension of 20N, and a winding ring with a width of 4mm at the winding part is used. place, evaporate the acetone, and then heat and cure (according to the curing process corresponding to the resin system specified in the national standard GB / T3362 and GB / T 26749, heat and cure). Both ends of the wire sample were fixed with 0.3 mm thick kraft paper to obtain a sample for testing the tensile properties of 36K carbon fiber multifilament.

Embodiment 2

[0049] Prepare glue solution (make glue solution according to the resin system stipulated in national standard GB / T3362 or GB / T 26749), and pour it into the dipping box. Wrap the Formosa Plastics 48K TC35 carbon fiber on the winding frame with a tension of 35N, and use a winding ring with a width of 7mm at the winding part. Remove acetone, then heat and cure (according to the curing process corresponding to the resin system specified in the national standard GB / T3362 and GB / T 26749, heat and cure), cut out the carbon fiber multifilament spline, and use the adhesive to cure the carbon fiber multifilament spline Both ends were fixed with 0.5 mm thick kraft paper to obtain a sample for testing the tensile properties of 48K carbon fiber multifilament.

Embodiment 3

[0051] Prepare glue solution (make glue solution according to the resin system stipulated in national standard GB / T3362 or GB / T 26749), and pour it into the dipping box. Wrap the Zoltek 50K PX35 carbon fiber on the winding frame with a tension of 40N, and use a winding ring with a width of 8mm at the winding part, put the frame wrapped with the fiber tow into the dipping box, take it out after dipping, and let it dry. Evaporate the acetone, then heat and cure (according to the curing process corresponding to the resin system specified in the national standard GB / T3362 and GB / T 26749, heat and cure), cut the carbon fiber multifilament sample, and use the adhesive to cure the carbon fiber multifilament sample Both ends of the bar were fixed with 0.6 mm thick kraft paper to obtain a sample for testing the tensile properties of 50K carbon fiber multifilament.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com