Driving mechanism used for driving magnetron, and magnetron sputtering processing apparatus

A technology of driving mechanism and processing equipment, applied in sputtering coating, discharge tube, metal material coating process, etc., can solve the problem of lower utilization rate of target material, track range that cannot cover the target material area, and scanning track of magnetron. Uneven density and other problems, to achieve the effect of improving the utilization rate, uniform distribution density, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for those skilled in the art to better understand the technical solution of the present invention, the drive mechanism for driving the magnetron and the magnetron sputtering processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

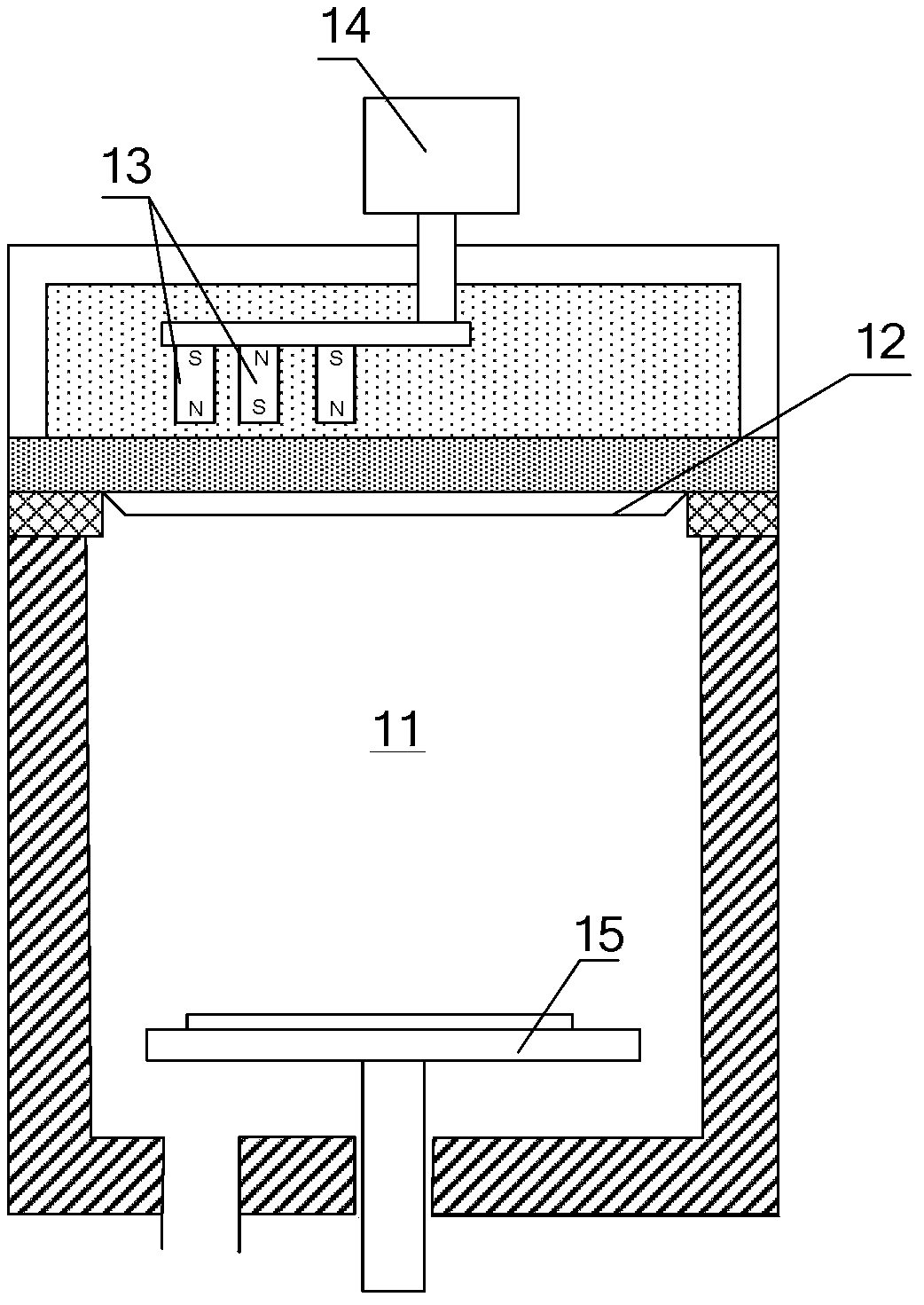

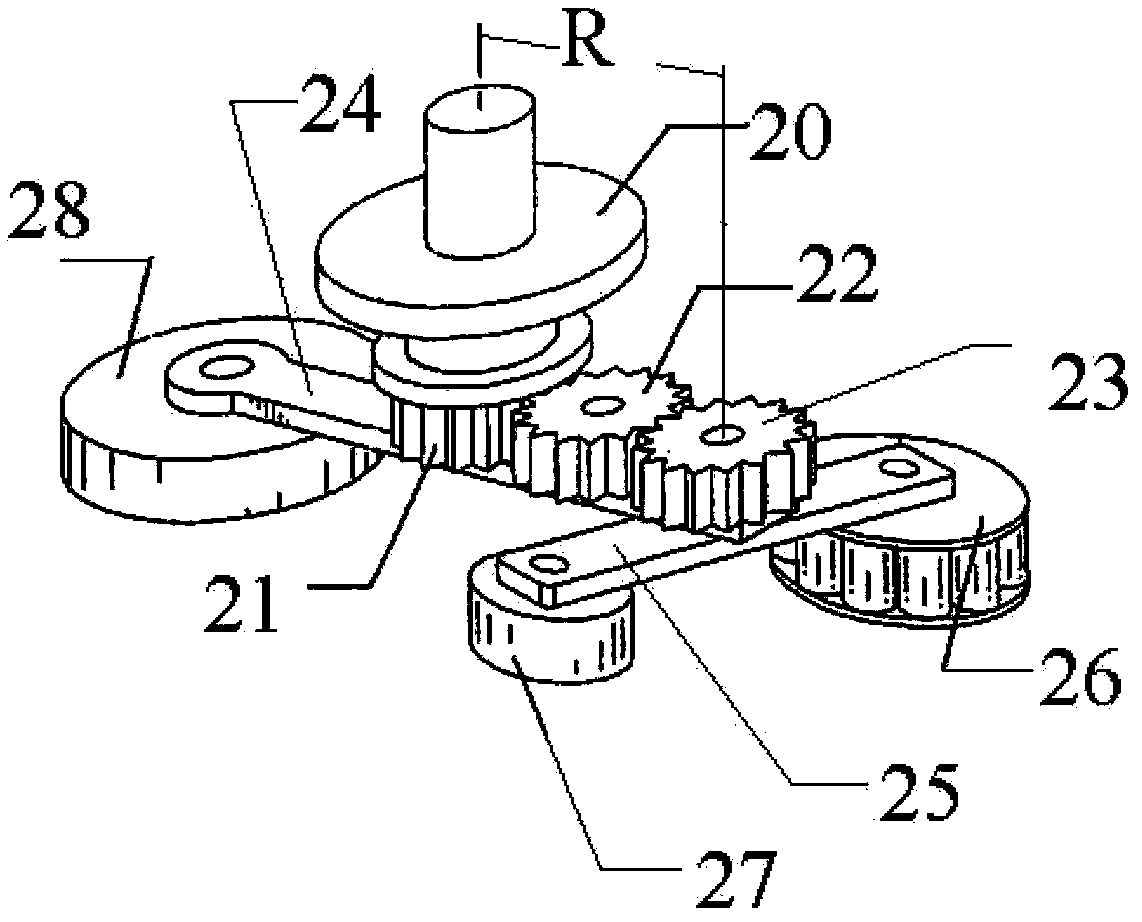

[0031] image 3 It is a structural schematic diagram of a driving mechanism for driving a magnetron provided by the present invention. see image 3, the drive mechanism includes a rotary drive source 37, a transmission shaft 36 and a linear drive source. Wherein, the linear drive source is used to drive the magnetron 34 to perform linear reciprocating motion along the direction perpendicular to the transmission shaft 36 in a hydraulically driven manner; the drive shaft of the rotary drive source 37 is fixedly connected with the linear drive source by means of the transmission shaft 36 for While the magnetron 34 is performing linear reciprocating motion, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com