Lithium battery and preparation method thereof

A lithium battery and lithium ion technology, applied in the field of electrochemical energy storage, can solve the problems of increasing graphite electrode impedance, poor safety, and low cycle efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0118] The preparation method of the lithium battery of the present invention comprises the steps of:

[0119] (a-1) Provide positive electrode, negative electrode, separator, electrolyte and casing;

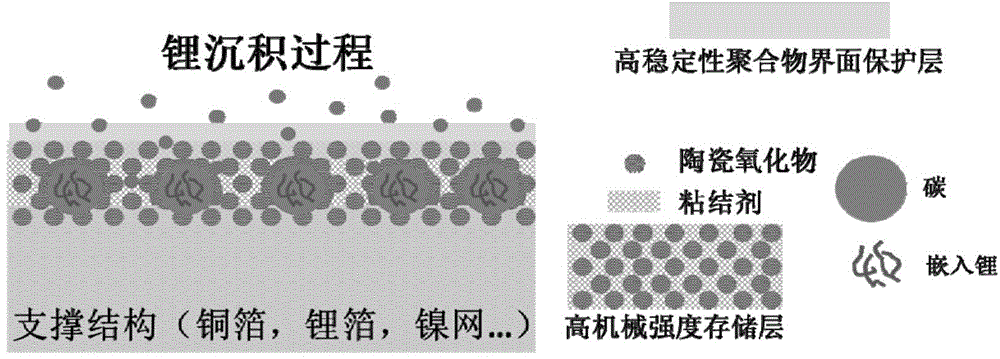

[0120] Wherein, the negative electrode contains or consists of the following negative electrode materials, the negative electrode material includes a support structure and a lithium ion / lithium metal storage layer coated on one side of the support structure, the lithium ion / lithium metal storage layer The layer contains ceramic oxide, carbon material and binder, the electrolyte contains a film-forming additive, and the film-forming additive forms a polymer interface protection layer on the lithium ion / lithium metal storage layer;

[0121] (a-2) Assembling the positive electrode, negative electrode, separator, electrolyte and casing to form the lithium battery.

[0122] In a preferred example, the assembly is performed under the protection of inert gas.

[0123] Wherein, the pr...

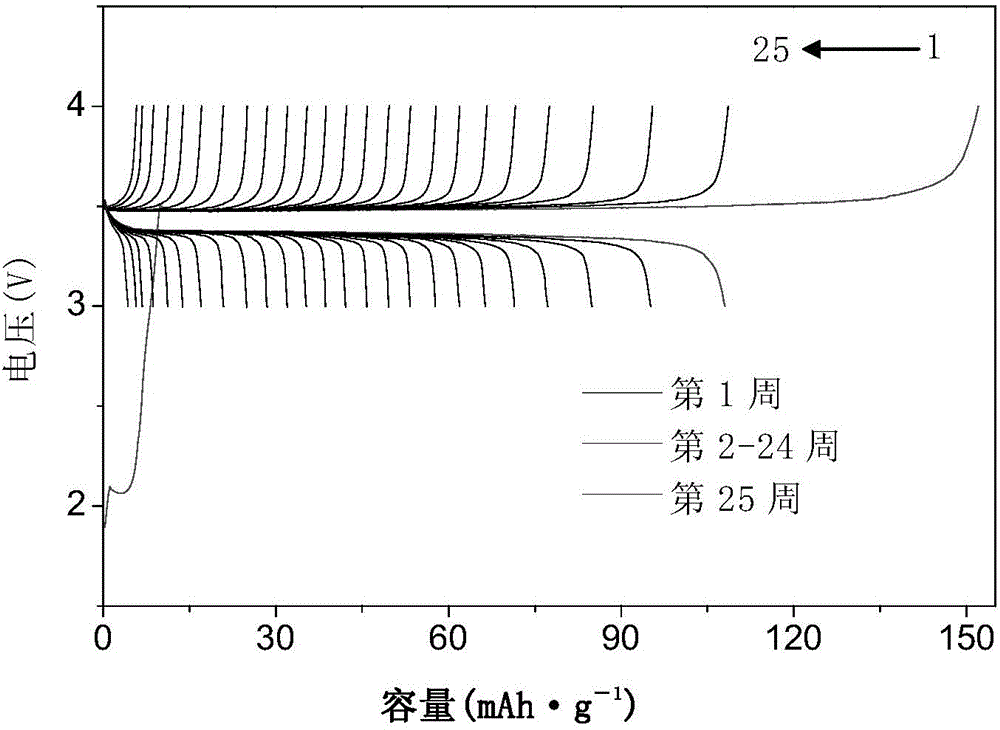

Embodiment 1

[0144] Preparation of Copper Foil Battery 1

[0145] a. Pre-dissolve polyimide with a mass ratio of 10% in N-methylpyrrolidone (NMP) solvent, and mix and stir in a magnetic stirrer for 3 hours to obtain a uniform slurry;

[0146] b. According to the mass ratio of 1:79:20 carbon material super dense high conductivity carbon black (Super-P), Al 2 o 3 powder and polyimide, adding solvent N-methylpyrrolidone (NMP) into the mixture and placed in a magnetic stirrer to mix and stir for 3 hours to obtain a uniform slurry.

[0147] c. Apply the slurry in step b evenly on the surface of copper foil, bake at 120°C for 12 hours in a vacuum environment, and cut into discs with a diameter of 16mm after natural cooling as a lithium ion / lithium metal storage layer. Negative pole piece.

[0148] d. Add hexamethylene diisocyanate (HDI) into the electrolyte at a content of 20 mmol / L, and mix well.

[0149] e. Lithium iron phosphate (LiFePO 4 ), polyvinylidene fluoride (PVdF) and special hig...

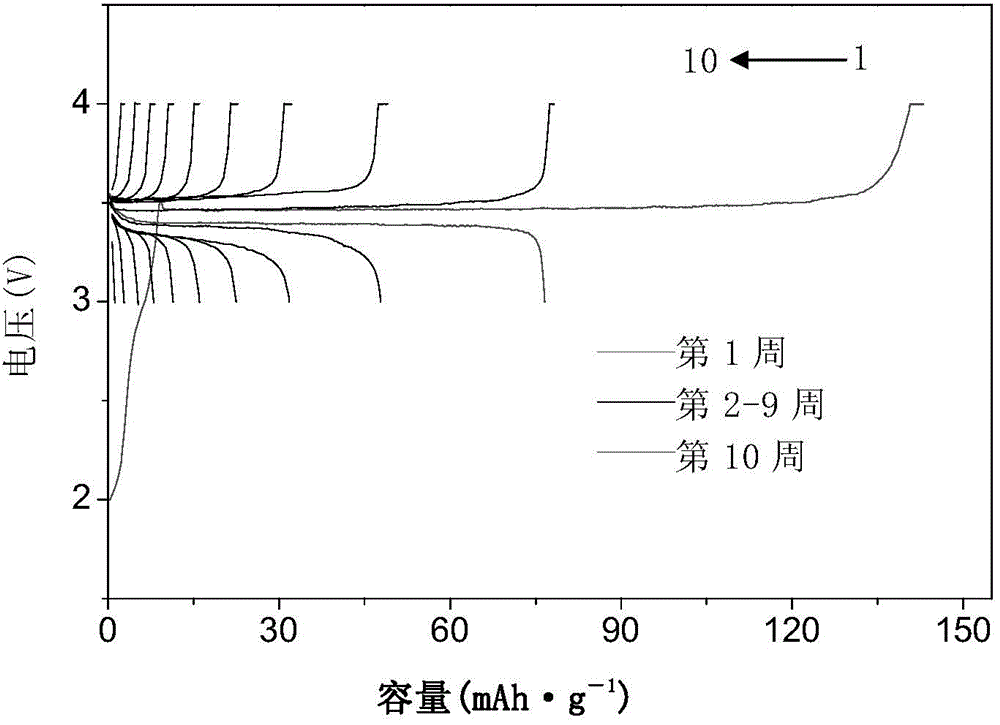

Embodiment 2-12

[0156] Preparation of Copper Foil Batteries 2-12

[0157]Repeat Example 1, the difference is: C: ceramic oxide: binder mass ratio and content of film-forming additives are shown in Table 1.

[0158] C in the embodiment 1-12 of table 1: ceramic oxide: the content of binder mass ratio and film-forming additive

[0159] Example

[0160] 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com