Method and equipment for preparing remolded soil specimen

A technique for specimens and soils, applied in the preparation of test samples, etc., which can solve the problems of long time consumption, discontinuity of layered position, low permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

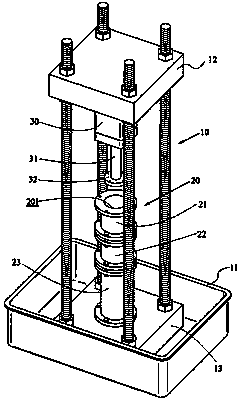

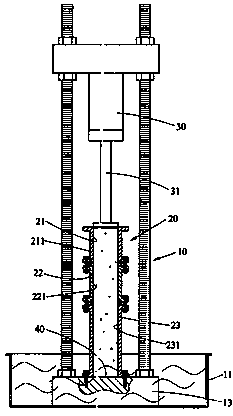

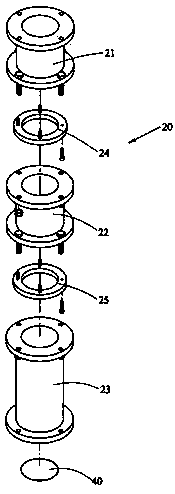

[0019] In conjunction with the accompanying drawings, the present invention will be described in further detail.

[0020]As shown in the figure, the method for making a heavy-duty soil test body of the present invention is characterized in that: the method includes: a. putting the reaction force frame 10 into a water storage bucket 11 filled with water, so that the test body production system is maintained at The state in water; b. Lock the first test body mold 21, the second test body mold 22, and the long test body mold 23 in order, but the first ring must be locked first in the interval between the first two or the latter two Water-permeable gasket 24, the second annular water-permeable gasket 25, and then carefully move the test body mold group 20 to the reaction force frame 10; c. lock the piston air cylinder 30 on the upper adjustment plate 12 on the reaction force frame 10 , adjust the vertical and horizontal after locking; d. place the first permeable stone 40 at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com