Rubber with excellent flame retardant and wave absorbing performance and preparation method thereof

A wave-absorbing performance and rubber technology, applied in the field of rubber products, can solve the problems and solutions that it is difficult to mix inorganic metal materials and polymer materials uniformly, the uniform mixing is not considered, and the performance consistency cannot meet the requirements. It is beneficial to large-scale production, not easy to settle and separate, and does not have the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

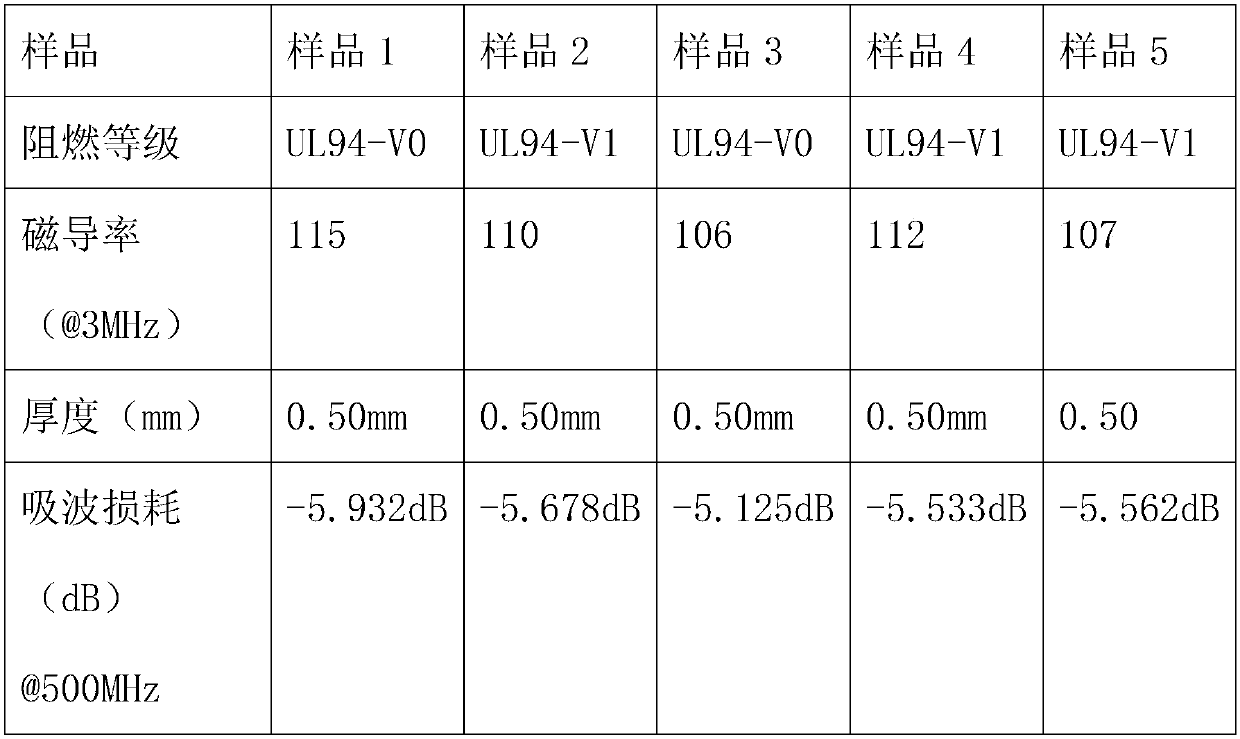

Examples

Embodiment 1

[0030] A kind of rubber with excellent flame-retardant and wave-absorbing properties, including the following components by weight: 100 parts of rubber matrix, 10 parts of electromagnetic wave absorber: 10 parts of flake Sendust alloy, particle size D50: 50.8 μm; 5 parts of base silicone oil, 5 parts of talcum powder, flame retardant: 10 parts of tributyl phosphate, 5 parts of carbon fiber material, the particle size of the carbon fiber material is 0.5 μm; mold release agent: 0.1 part of calcium stearate, silane coupling Joint agent KH550: 1 part, vulcanizing agent: 1 part of tert-butyl hydroperoxide.

[0031] The preparation method of the above-mentioned rubber with excellent flame-retardant and wave-absorbing properties comprises the following steps:

[0032] 1) Mix and transfer the electromagnetic wave absorber and maleic anhydride to the ball mill for high-speed ball milling for 2 hours, filter and dry for later use; the ball milling speed is 200r / min, and the ball-to-mate...

Embodiment 2

[0038] A rubber with excellent flame-retardant and wave-absorbing properties, including the following components in terms of weight components: 100 parts of rubber matrix, 50 parts of electromagnetic wave absorber: flaky Sendust alloy, particle size D50: 62.1 μm; 20 parts of base silicone oil, 20 parts of talcum powder, flame retardant: 50 parts of tris(2,3-dibromopropyl) phosphate, 20 parts of carbon fiber material, the particle size of the carbon fiber material is 200 μm; mold release agent: hard 5 parts of zinc fatty acid, 10 parts of silane coupling agent A-172, 5 parts of vulcanizing agent: benzoyl peroxide.

[0039] The preparation method of the above-mentioned rubber with excellent flame-retardant and wave-absorbing properties comprises the following steps:

[0040] 1) Mix and transfer the electromagnetic wave absorber and maleic anhydride to a ball mill for high-speed ball milling for 3 hours, filter and dry for later use; the milling speed is 600r / min, and the ball-to...

Embodiment 3

[0046] A rubber with excellent flame-retardant and wave-absorbing properties, including the following components by weight: 100 parts of rubber matrix, 30 parts of electromagnetic wave absorber: 30 parts of flaky Sendust alloy, particle size D50: 55 μm; dimethyl 16 parts of silicone oil, 10 parts of talcum powder, flame retardant: 15 parts of melamine cyanuric acid, 10 parts of carbon fiber material, the particle size of the carbon fiber material is 50 μm; release agent: 1 part of zinc stearate, silane coupling agent SI -69: 5 parts, vulcanizing agent: 3 parts of dicumyl peroxide.

[0047] The preparation method of the above-mentioned rubber with excellent flame-retardant and wave-absorbing properties comprises the following steps:

[0048] 1) Mix and transfer the electromagnetic wave absorber and maleic anhydride to the ball mill for high-speed ball milling for 2.5 hours, filter and dry for later use; the ball milling speed is 400r / min, and the ball-to-material ratio is elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com