Pallet and plasma processing equipment for induction heating

An induction heating and tray technology, applied in induction heating, induction heating device, metal material coating process, etc., can solve the problems of increasing the temperature difference between the edge area and the center area, reducing the temperature, and increasing the amount of heat and heat, so as to improve the uniformity of the process. The effect of reducing the temperature difference and uniform distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order for those skilled in the art to better understand the technical solution of the present invention, the tray for induction heating and the plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0032] For the convenience of description, in the following embodiments, the tray used for induction heating is placed horizontally as the reference plane, and the upper surface and the lower surface of the tray body refer to the upward surface and the downward surface of the tray body respectively.

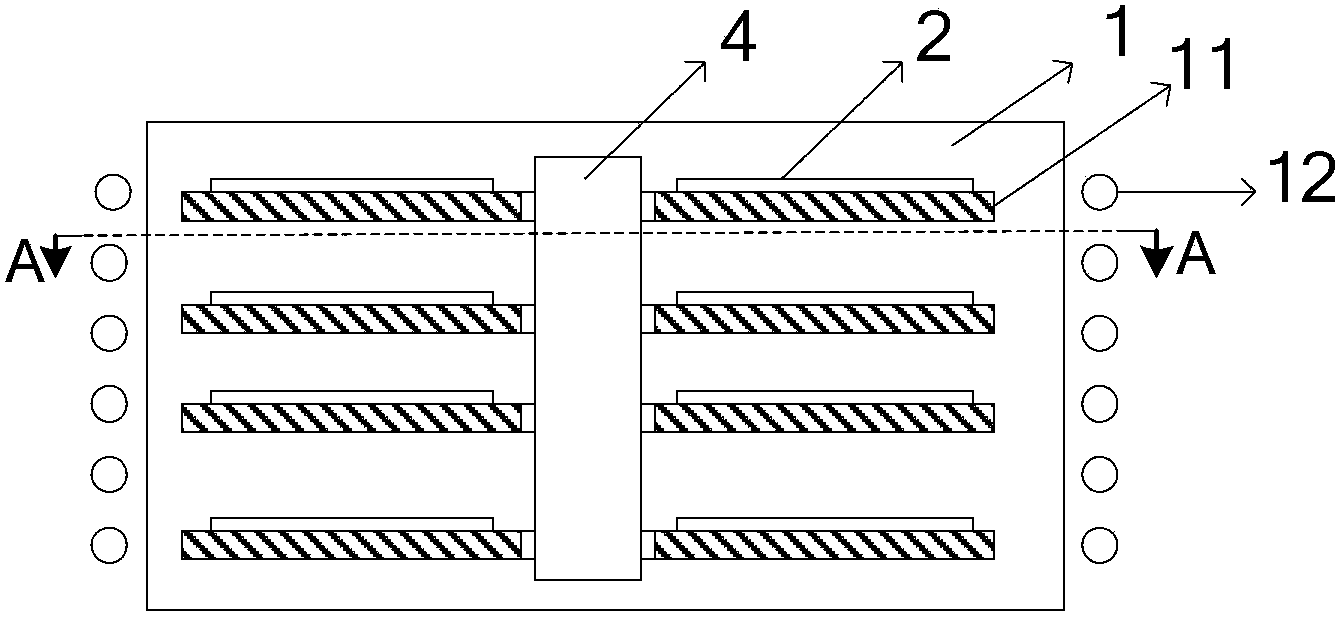

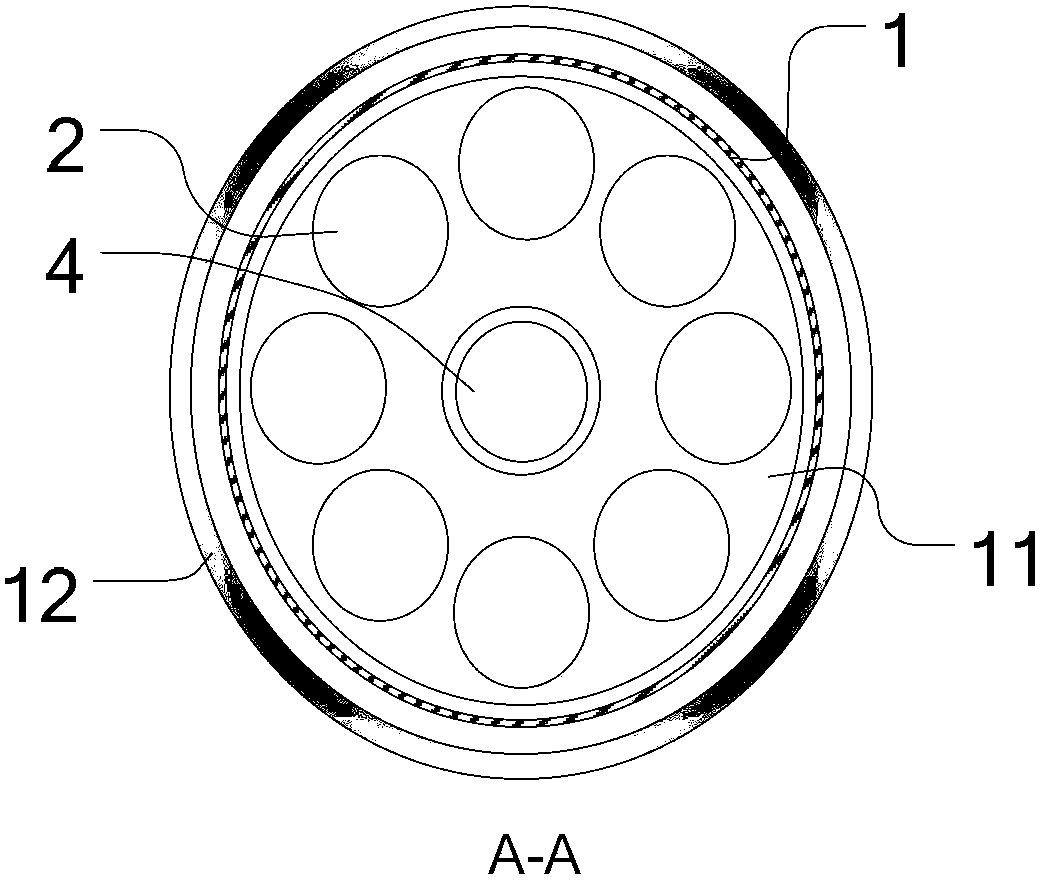

[0033] Figure 3a A cross-sectional view of the tray for induction heating provided by the first embodiment of the present invention.

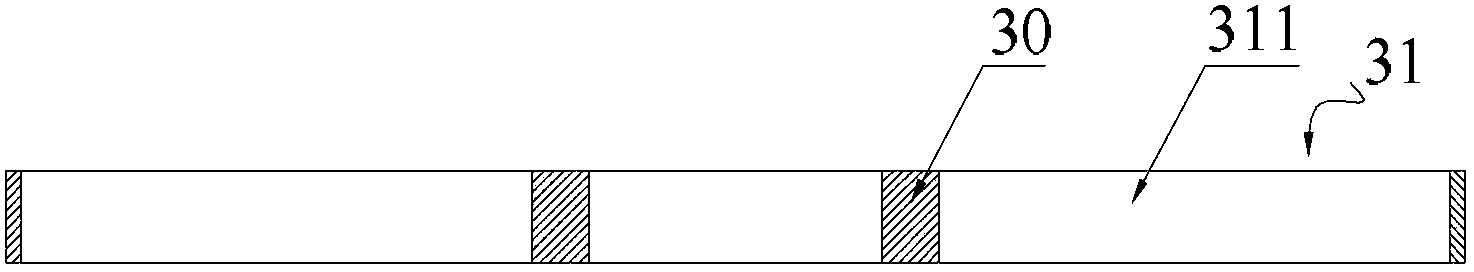

[0034] Figure 3b for Figure 3a Top view of the tray shown. Please also refer to Figure 3a with Figure 3b , the tray used for induction heating includes a tray body 30 made of magnetically conductive material, which is made of high temperature res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com