Membrane filament array production technology based on membrane filament array filament dispenser

A production process and dispensing machine technology, applied in membrane technology, semi-permeable membrane separation, transportation of filamentous materials, etc., can solve problems such as the inability to guarantee product quality, poor equipment versatility, and lack of monitoring methods. , to achieve the effect of improving market competitiveness, high production efficiency, and uniform dispensing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

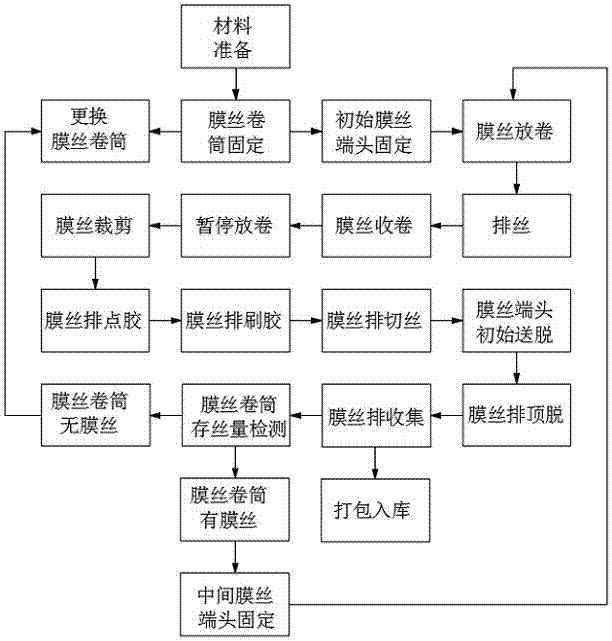

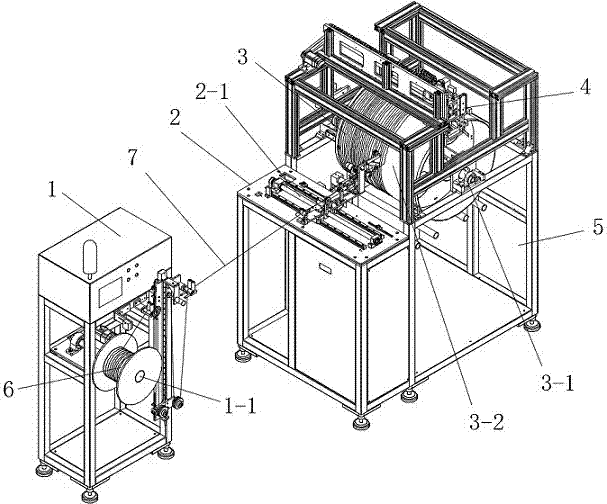

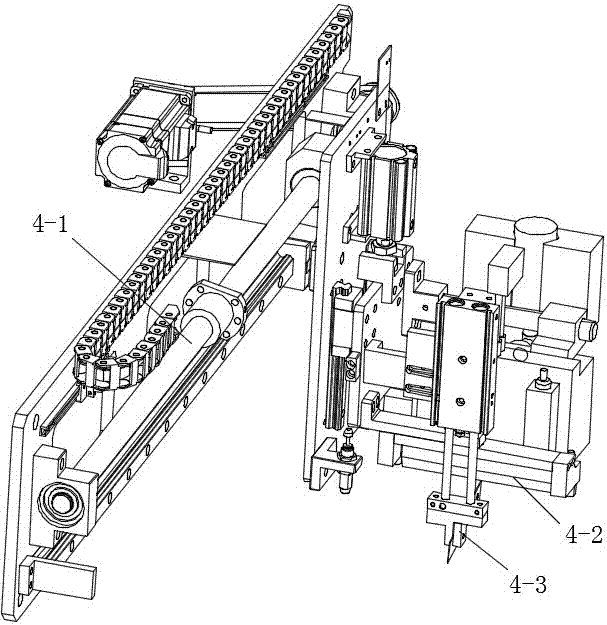

[0065] Embodiment: a kind of membrane wire row production process based on the membrane wire row wire dispensing machine provided by the present invention, wherein, such as figure 2 As shown, the membrane wire dispensing machine includes unwinding station 1, wire dispensing station 2, rewinding station 3, dispensing and shredding station 4 and collecting station 5, such as Figure 1 to Figure 3 As shown, the production process of membrane wire row includes the following steps:

[0066] Step A: Prepare

[0067] A.1 Material preparation: Pre-wind the film to be wound on the film reel for standby;

[0068] A.2 Fixing of the membrane filament reel: install and fix the membrane filament reel 6 wound with the membrane filament 7 on the unwinding shaft 1-1 at the unwinding station 1;

[0069] A.3 The end of the initial membrane filament is fixed

[0070] A.3.1 Wire pulling and wire drawing: Pull the initial end of the membrane yarn from the membrane yarn reel 6 installed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com