Press arrangement and method for pressing pressed parts

A technology of extrusion device and extrusion parts, which is applied in the direction of presses, ceramic molding machines, material molding presses, etc., and can solve problems such as inability to demould

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

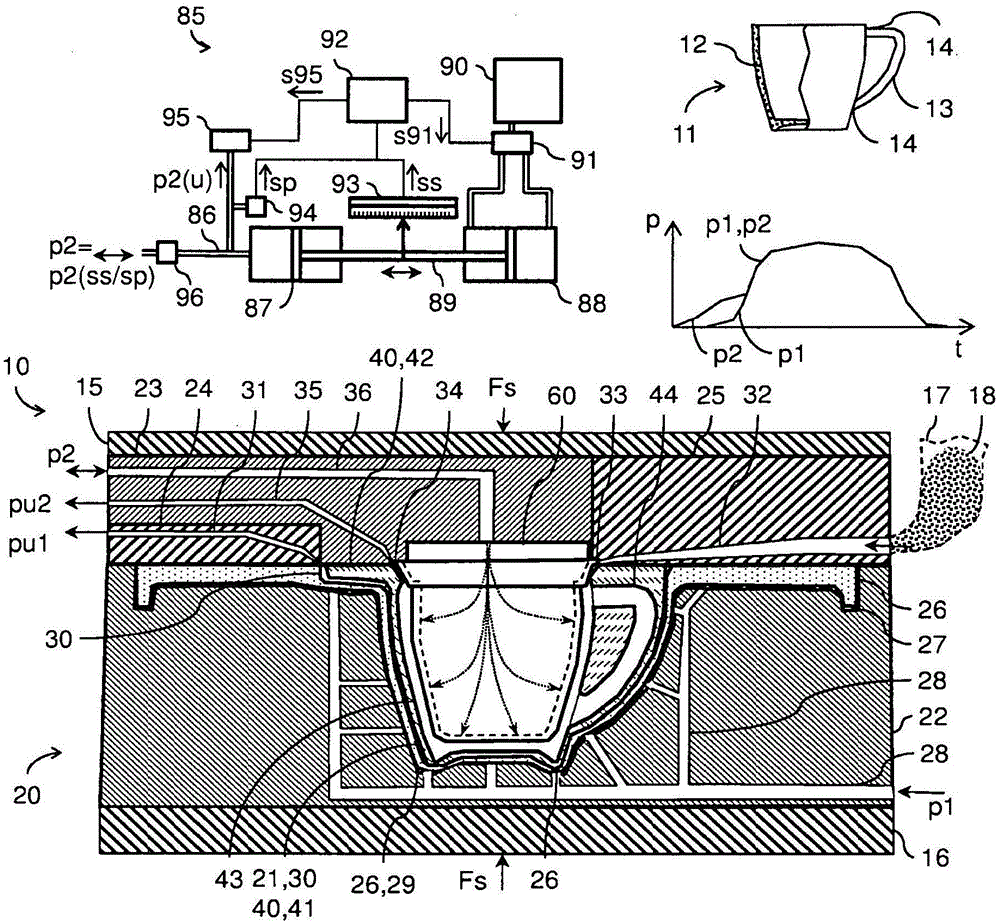

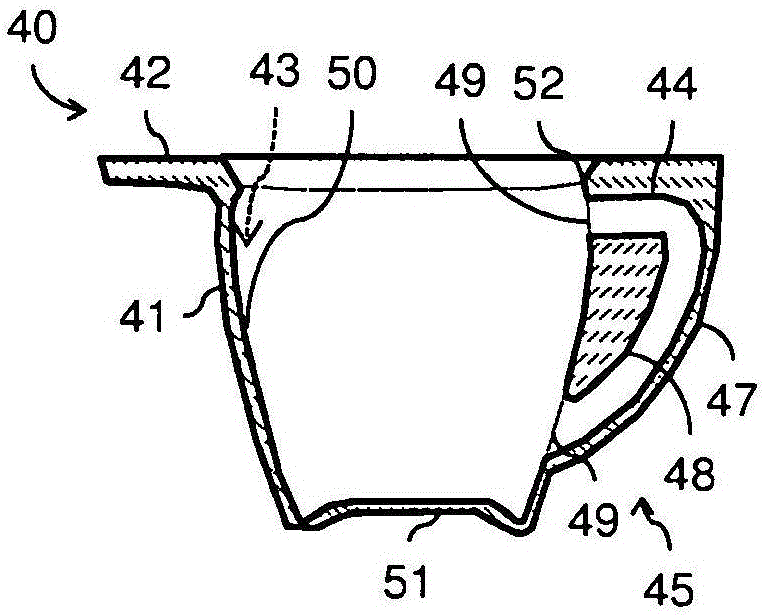

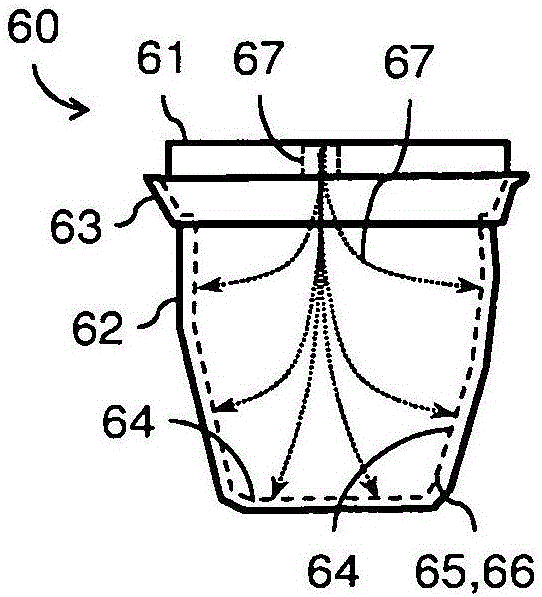

[0066] as from figure 1 As can be seen in FIG. 2 , the container pressing device 10 shown by way of example is used as a pressing device for isostatic pressing of extruded parts, in particular cup-shaped containers 11 or hollow bodies. The container 11 shown by way of example comprises an essentially hollow body or cup section 12 and a lateral projection, in particular a handle 13 , located thereon. The exemplary handle 13 is connected to the cup section 12 via an upper and a lower collar projection or handle projection 14 . The container extrusion device 10 is designed such that a container 11 with cup section 12 and handle 13 can be extruded from powdered and / or granular extrusion material in a single extrusion process.

[0067] The container extrusion device 10 has, in particular, an upper die receptacle 15 and, in particular, a lower die receptacle 16 , between which the actual extrusion die 20 can be clamped. Powdered and / or granular, in particular ceramic, extrusion ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com