Face cutter for machining fibre-reinforced materials such as carbon-fibre-reinforced plastics (cfrp)

一种纤维、塑料的技术,应用在CFK端铣刀领域,能够解决聚酯丝线散开等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

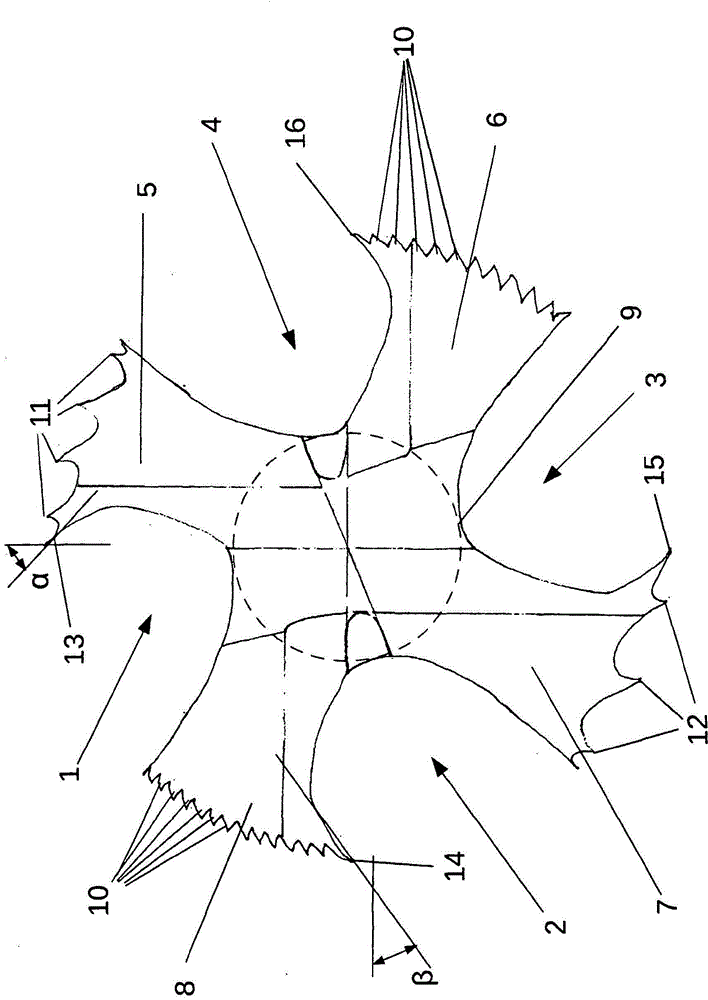

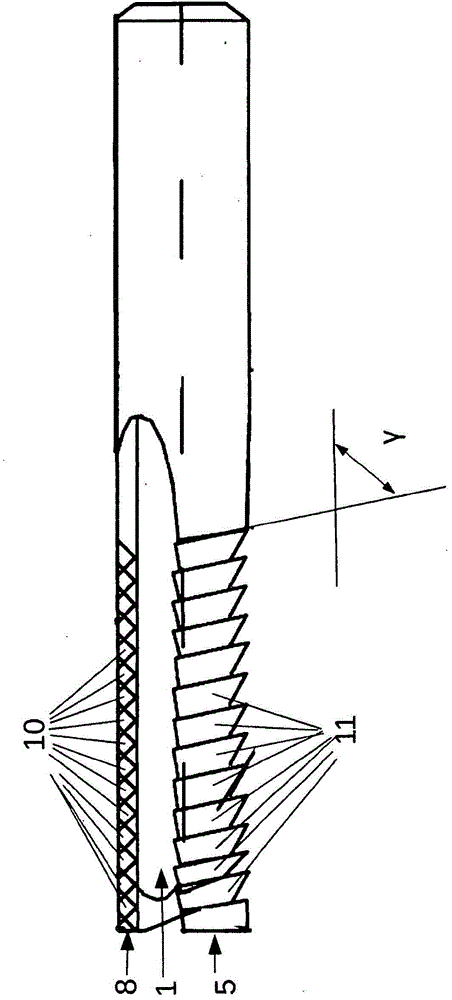

[0029] The end mill shown in the figure has four equidistantly spaced flutes 1 , 2 , 3 , 4 which divide the inserts 5 , 6 , 7 , 8 equidistantly around a cylindrical core section 9 . spaced apart from each other. Cutting edges 13, 14, 15, 16 on acute-angled cutting wedges are respectively provided on the outer edges of the blades 5, 6, 7, 8 towards the peripheral sides of the front flutes 1, 2, 3, 4, in, figure 1 The main rake angle α on the two blades 5, 7 shown in , is the same size, and the main rake angle β on the two blades 6, 8 is the same size, but it is drawn slightly exaggerated in the figure, while in the actual situation down about 8°.

[0030] Pyramidal teeth 10 are machined here on the two opposite inserts 6 , 8 in their peripheral working area extending from the tool tip along the tool axis, in such a way that they follow intersecting lines on the outer circumferential surface toward the insert 6 . , Grinding triangular grooves in the peripheral surface of 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com