Solid phase substrate, processing method thereof, and method for determining processing conditions

A basic and specific technology, applied in the direction of biomass post-processing, biomass pre-treatment, biochemical equipment and methods, etc., can solve the problems of unconfirmed or failed, inaccurate and misleading accelerated experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 125

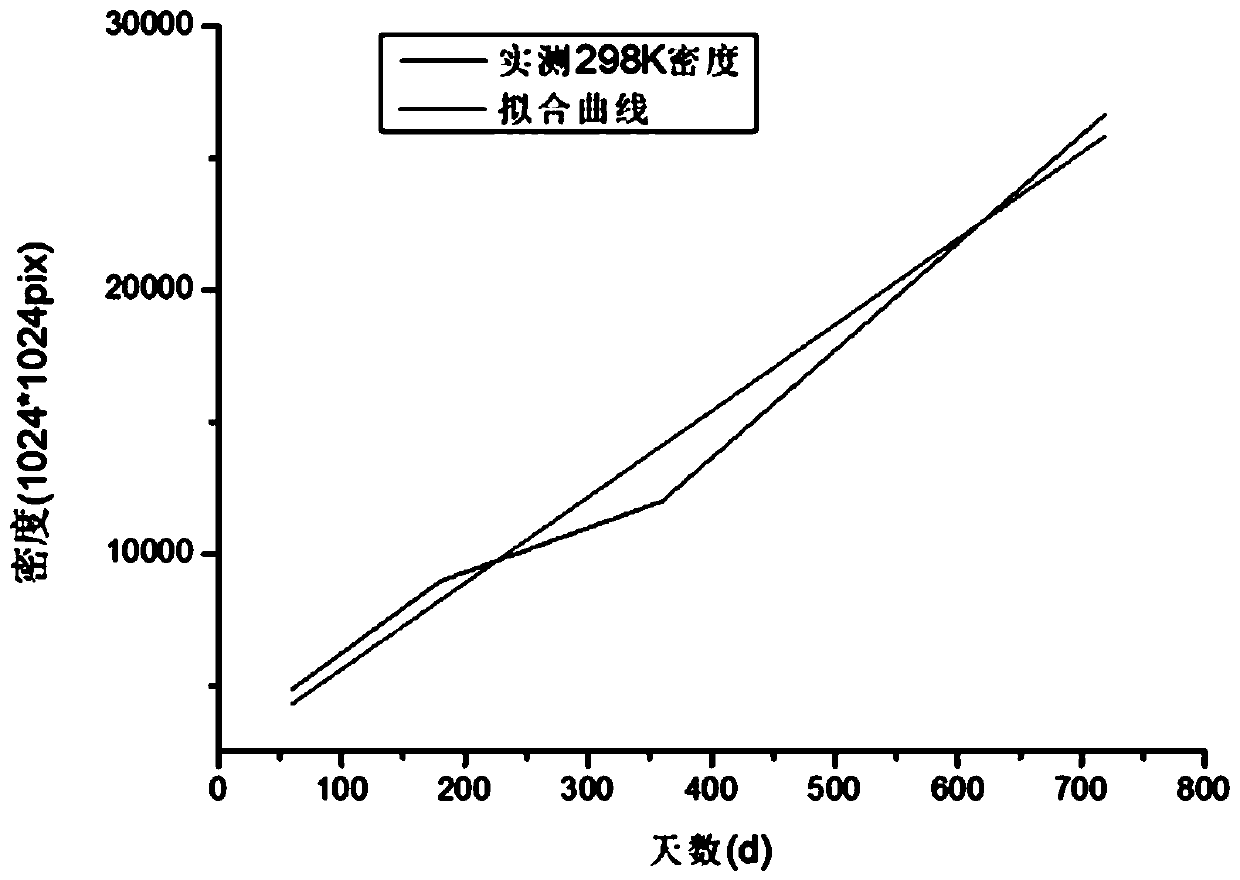

[0260] Experimental example Store the chip at 125°C

[0261] Take a number of chips (more than 12, such as 15) from the same batch and perform the following processing:

[0262] (1) cleaning the glass substrate: cleaning the surface with 5% hydrochloric acid for 3 hours;

[0263] (2) Activated glass substrate: soak in piranha solution (piranha solution) for 30 minutes, wash 5 times with ultrapure water, and wash 1 time with ethanol;

[0264] (3) Surface silane derivatization reaction: prepare 2% GOPTS (3-(2,3-epoxypropoxy)propyltrimethoxysilane) ethanol solution, react at 37°C for 5 hours, then 5 times with pure water, 5 times Wash with ethanol and acetone once, blow dry with nitrogen, and set aside;

[0265] (4) Low-temperature storage treatment: store the prepared chips in a nitrogen cabinet at a temperature of 25°C and a relative humidity of 55%, and store them for different periods of time (0 days, 60 days, 180 days, 360 days, 720 days);

[0266] (5) Immobilization of a...

experiment example 257

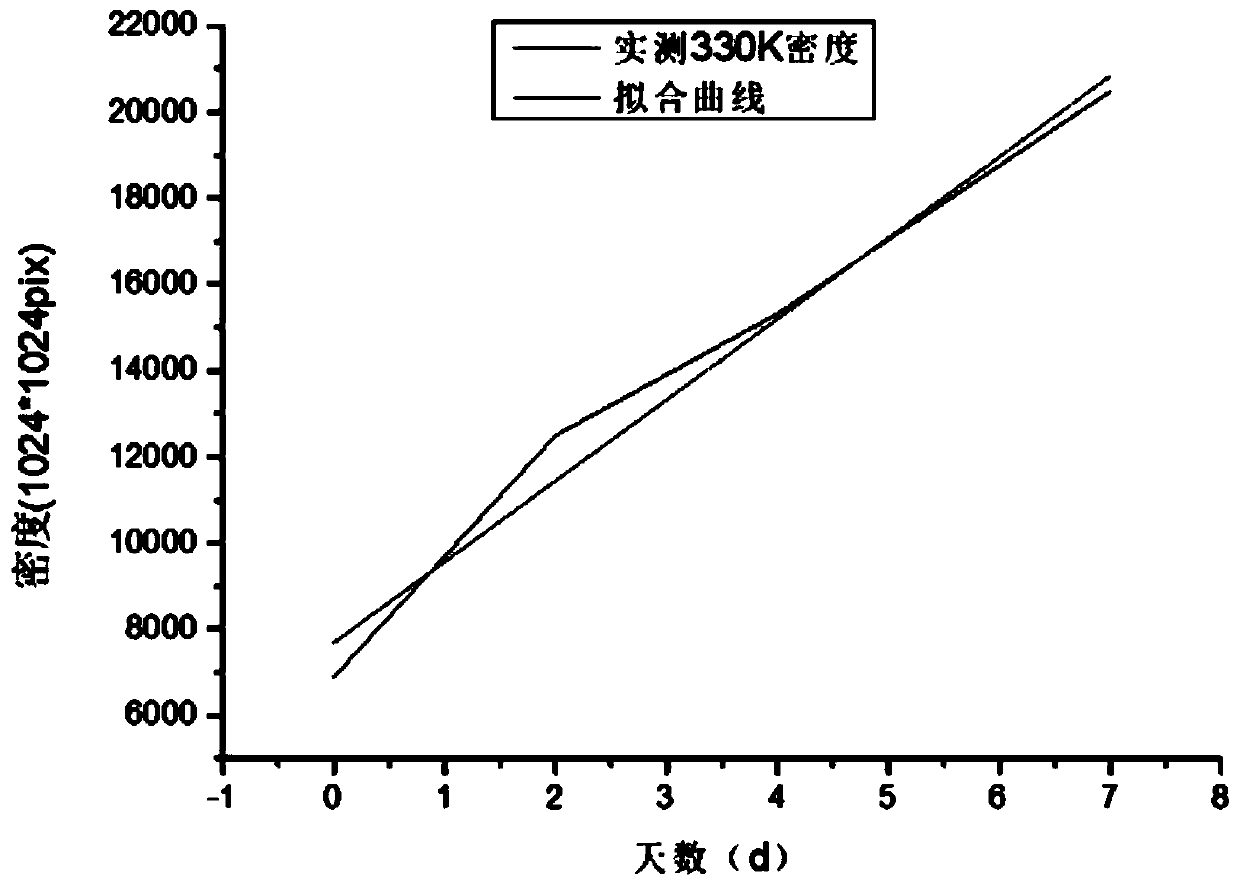

[0269] Experimental example Store the chip at 257°C

[0270] Take a number of chips (more than 12) from the same batch and perform the following processing:

[0271] (1) cleaning the glass substrate: cleaning the surface with 5% hydrochloric acid for 3 hours;

[0272] (2) Activated glass substrate: soak in piranha solution for 30 minutes, wash with ultrapure water for 5 times, and wash with ethanol once;

[0273] (3) Surface silane derivatization reaction: prepare 2% GOPTS ethanol solution, react at 37°C for 5 hours, then wash 5 times with pure water, 5 times with ethanol, 1 time with acetone, blow dry with nitrogen, and set aside;

[0274] (4) Low-temperature storage treatment: store the prepared chips in a nitrogen cabinet at a temperature of 57°C and a relative humidity of 55%, and store them for different periods of time (0 days, 2 days, 4 days, 7 days);

[0275] (5) Immobilization of amino-DNA-CY3 molecules: Take out several chips (for example, 3) on day 0, 2, 4, and 7 ...

Embodiment 3

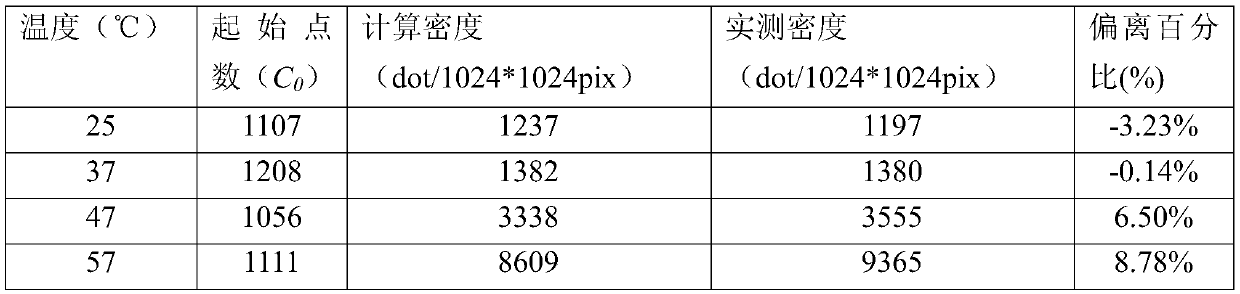

[0282] Preservation at 25°C after silanization in Example 3

[0283] (1) cleaning the glass substrate: cleaning the surface with 5% hydrochloric acid for 3 hours;

[0284] (2) Activated glass substrate: soak in piranha solution for 30 minutes, wash with ultrapure water for 5 times, and wash with ethanol once;

[0285] (3) Surface silane derivatization reaction: prepare 2% GOPTS ethanol solution, react at 37°C for 5 hours, then wash 5 times with pure water, 5 times with ethanol, 1 time with acetone, blow dry with nitrogen, and set aside;

[0286] (4) Fluorescence detection: Detect the number of fluorescent points in different areas on the surface of the chip on a Tirf microscope, and the detection wavelength is 530 nm, and the density constant C of the chip when the storage time is 0 is obtained. 0 ;

[0287] (5) Low-temperature storage treatment: store the prepared chips in a nitrogen cabinet, storage conditions: temperature 25°C, relative humidity 55%, storage time 4 days; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com