Vibrating mirror-based spiral scanning laser projection method and system

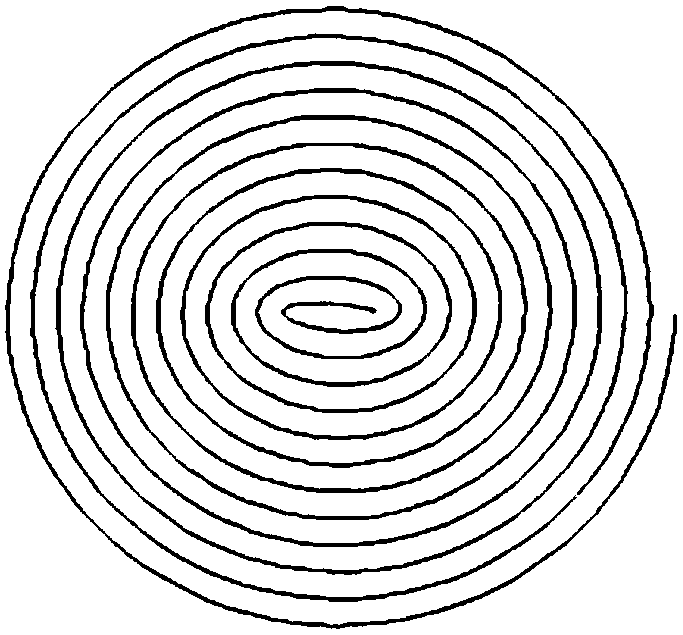

A scanning laser and helical line technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of low vibration resistance, low projection resolution, complex algorithm, etc., to achieve small driving force, simple projection algorithm, and uniform projection screen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

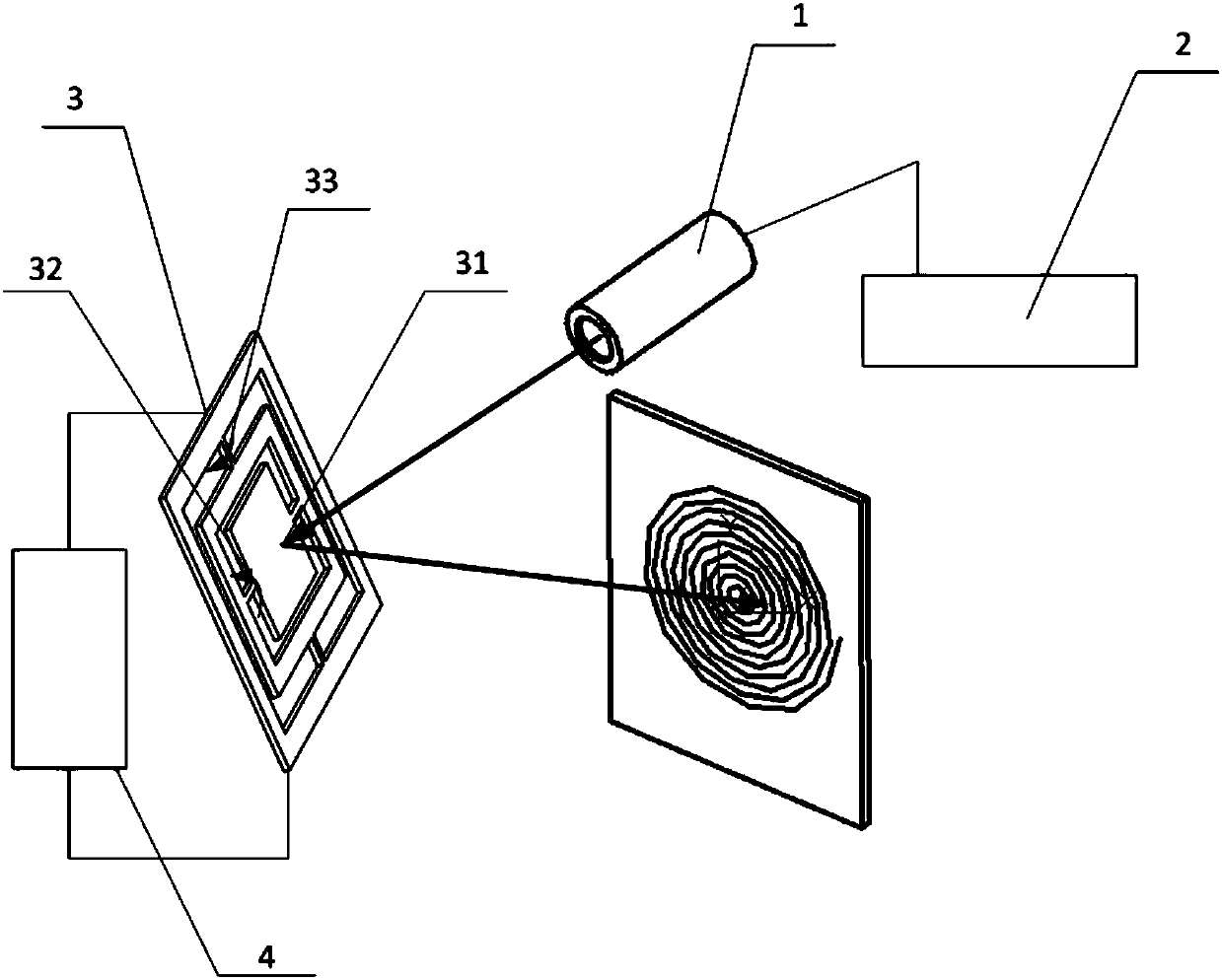

[0063] from figure 1 It can be seen that the projection system of this embodiment mainly includes: a laser light source 1 , a laser light source control module 2 , a vibrating mirror 3 and a vibrating mirror control module 4 . The laser light source 1 can be incident on the reflective surface 31 of the galvanometer, and the laser beam reflected from the reflective surface 31 of the galvanometer is scanned to obtain a projected image.

[0064] Among them, the laser light source 1 provides a light source for the projection system. The laser light source can be a monochromatic laser or a multi-band fusion laser; the laser light source control module 2 can realize the adjustment of the laser light source, and complete the adjustment of the laser light source brightness from zero to maximum in real time. value adjustment.

[0065] Among them, the dual-axis vibrating mirror 3 has modes of twisting around two orthogonal axes (x-axis 32 and y-axis 33 ) at the same frequency. When the...

Embodiment 2

[0089] from Figure 10 It can be seen that the laser projection system in this embodiment includes: a laser light source 1 , a laser light source control module 2 , a first single-axis vibrating mirror 5 , a second single-axis vibrating mirror 6 and a vibrating mirror control module 4 . Wherein the laser light source 1 can be incident on the first uniaxial galvanometer reflective surface of the first uniaxial galvanometer 5, then reflected to the second uniaxial galvanometer reflective surface, and emitted from the second uniaxial galvanometer 6 reflective surface A laser line projects a projected image.

[0090] Among them, the laser light source 1 provides a light source for the projection system. The laser light source can be a monochromatic laser or a multi-band fusion laser. The laser light source control module 2 can realize the adjustment of the laser light source and complete the brightness of the laser light source from zero to the maximum in real time. adjustment. ...

Embodiment 3

[0110] from figure 1 It can be seen that the projection system of this embodiment mainly includes: a laser light source 1 , a laser light source control module 2 , a vibrating mirror 3 and a vibrating mirror control module 4 . The laser light source 1 can be incident on the reflective surface 31 of the galvanometer, and the laser beam reflected from the reflective surface 31 of the galvanometer is scanned to obtain a projected image.

[0111] Among them, the laser light source 1 provides a light source for the projection system. The laser light source can be a monochromatic laser or a multi-band fusion laser; the laser light source control module 2 can realize the adjustment of the laser light source, and complete the adjustment of the laser light source brightness from zero to maximum in real time. value adjustment.

[0112] Among them, the dual-axis vibrating mirror 3 has modes of twisting around two orthogonal axes (x-axis 32 and y-axis 33 ) at the same frequency. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com