Method and apparatus for constructing inner wall moulding board

A construction method and formwork technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of spending 24 hours, or even more time, hanging all the time, or It needs to be hoisted away from other places, the construction speed is limited, etc., to achieve the effect of simple structure, shortened construction period, and avoidance of hoisting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

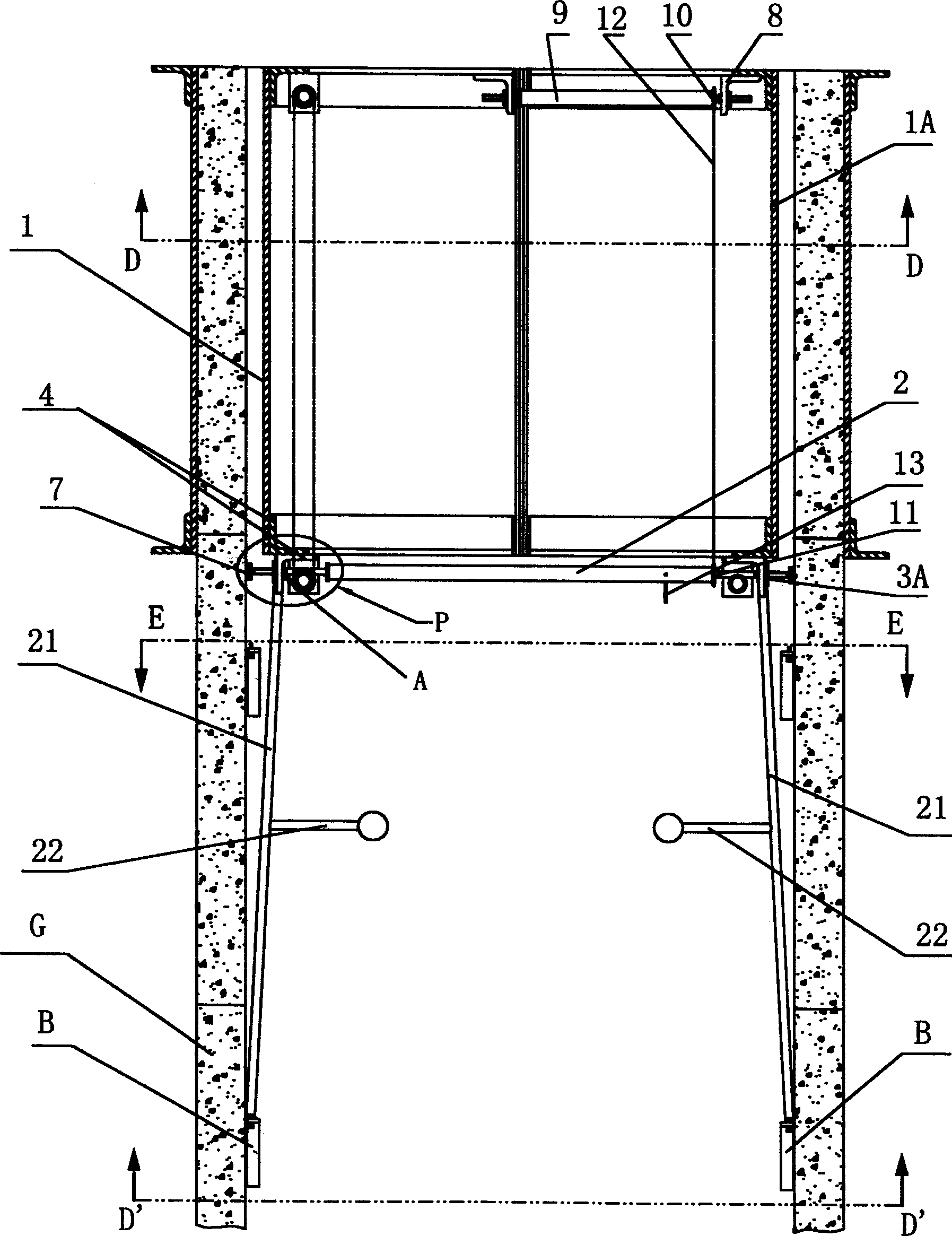

[0050] The structural representation of the present invention is as shown in the accompanying drawings, and the construction method of the interior wall formwork of the present invention includes demoulding, lifting, supporting and spreading of the formwork (1), and the promotion of the formwork (1) is realized by a hoisting machine, wherein:

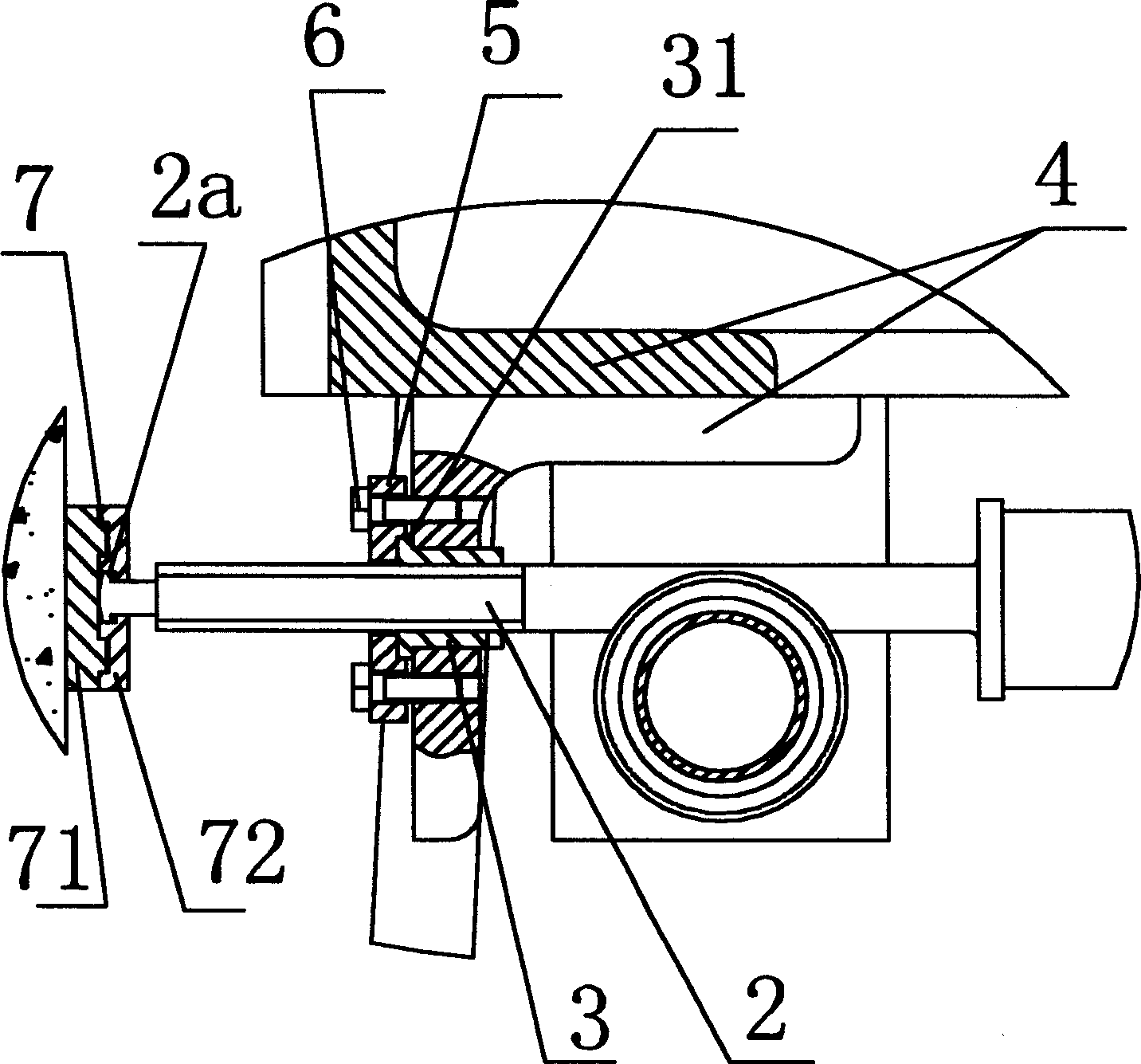

[0051] The demoulding and expansion of the template (1) is driven by the lateral movement mechanism A in which the active part makes a rotary motion and the driven part makes a linear motion. The active part does not move with the template (1), and the driven part of the lateral movement mechanism A and the template (1) is connected, and the follower drives the template (1) to move laterally.

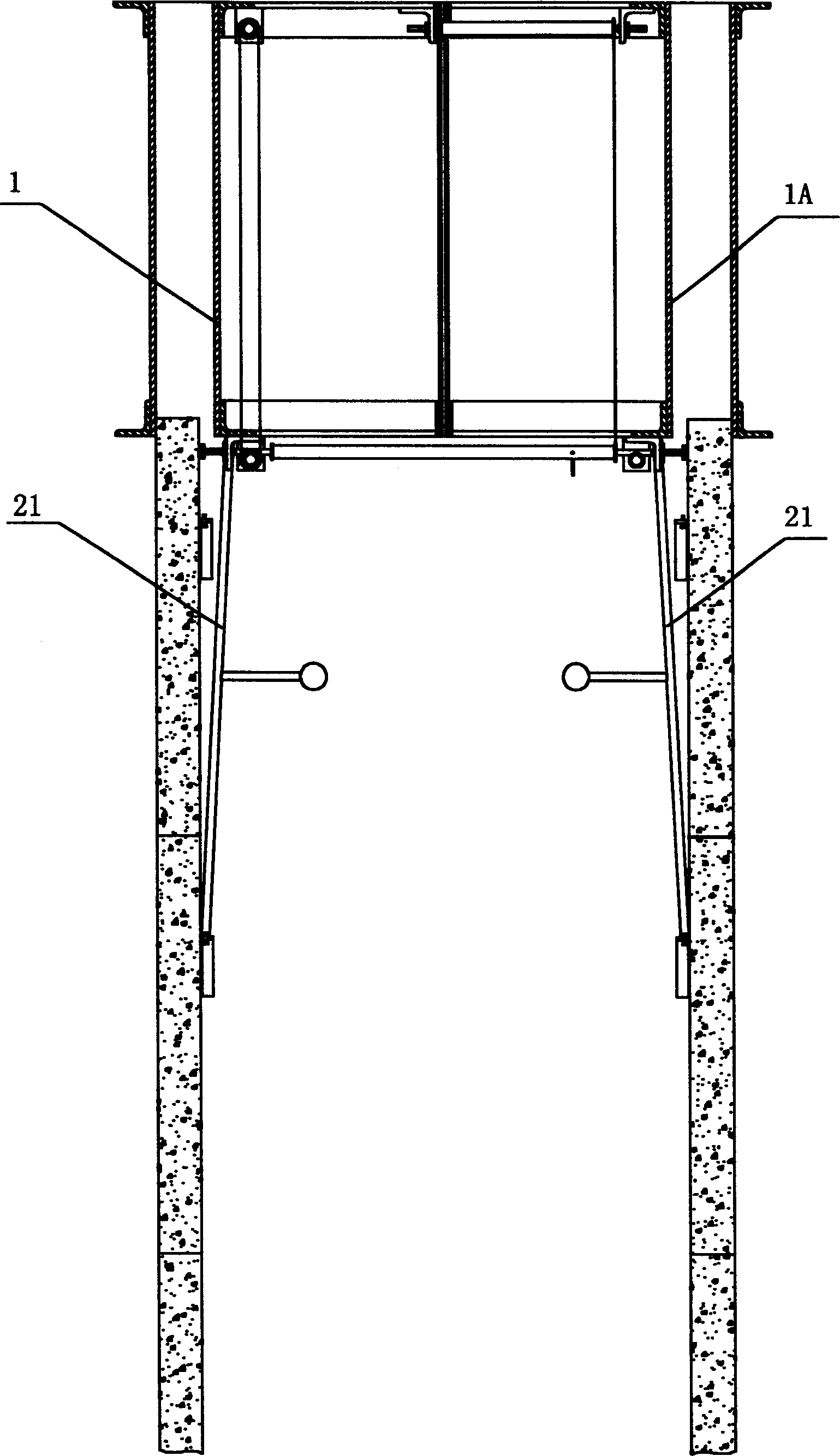

[0052] The support of the template (1) is supported on the locking position B provided on the inner wall by the support member (21) hinged on the lower part of the template.

[0053] The demoulding of the above template (1) is by driving the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com