Composite elastic sheet and manufacturing method and manufacturing equipment thereof

A technology of elastic sheet material and production method, which is applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve the problem of affecting production efficiency and product stability, unable to achieve higher density distribution, affecting use Comfort and other issues, to achieve good elastic function, moderate distribution density, and improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

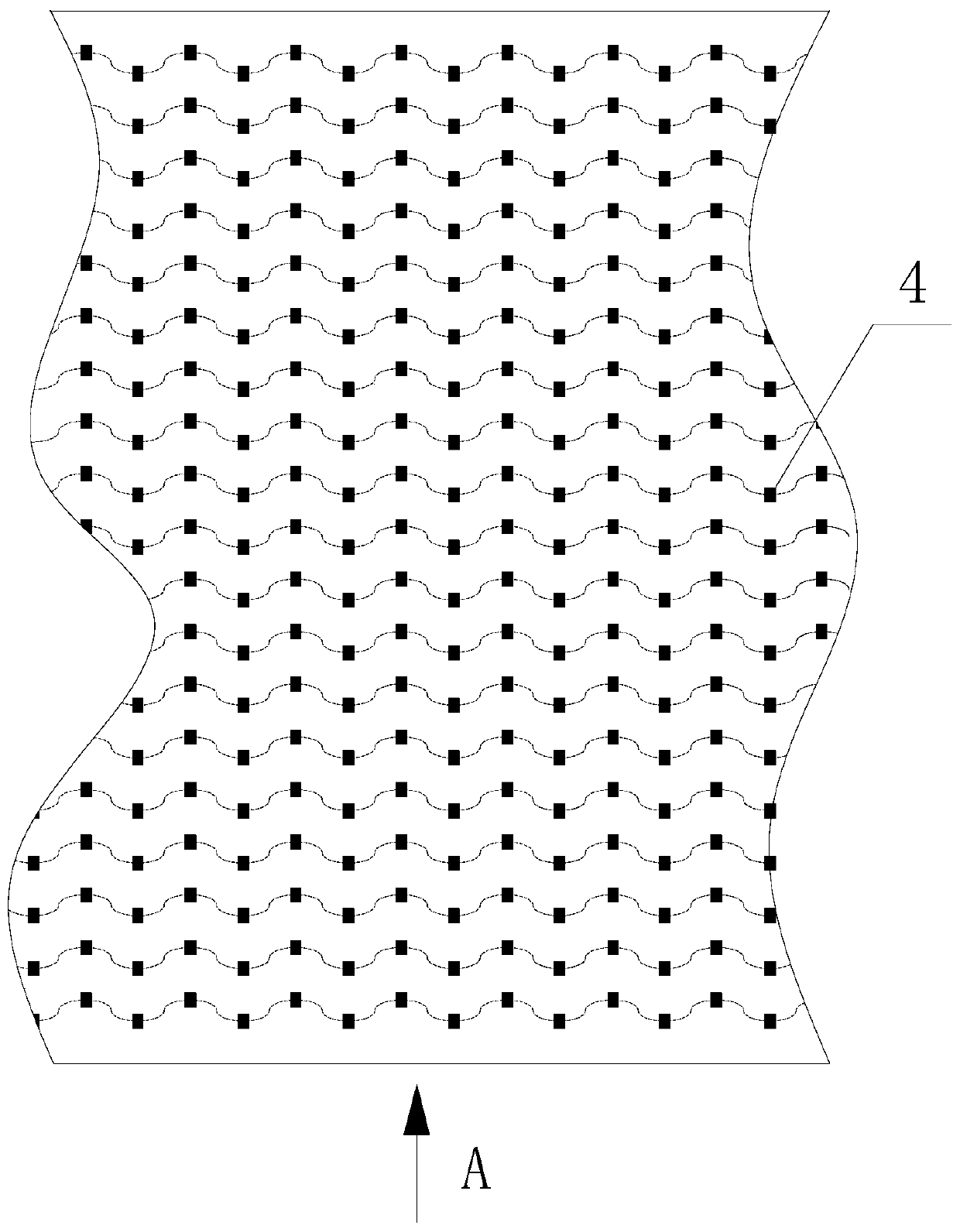

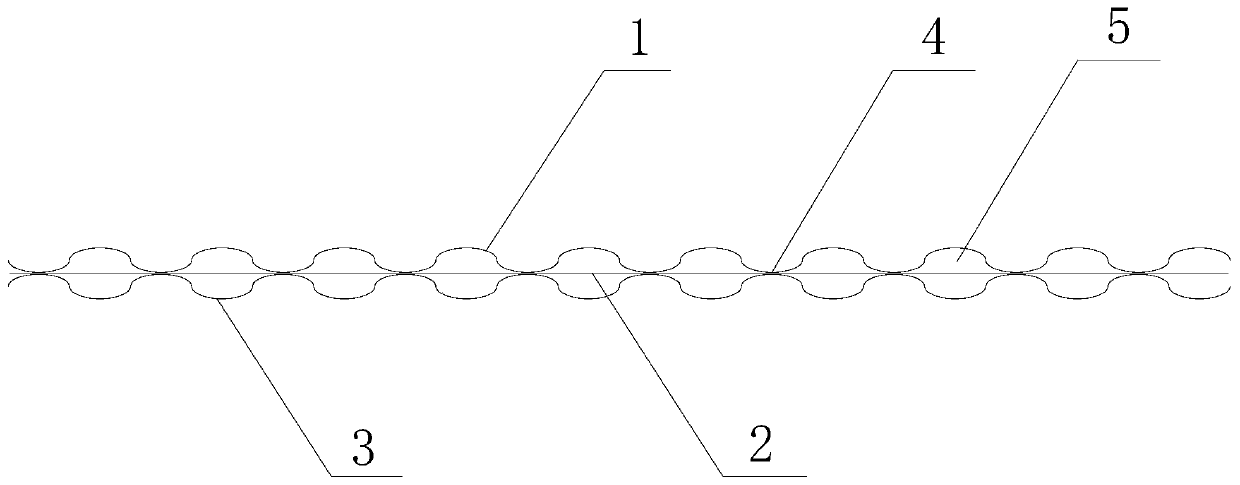

[0037] A kind of composite elastic sheet material of present embodiment, as figure 1 or figure 2 As shown, it includes the first surface layer 1, the middle elastic layer 2 and the second surface layer 3 which are sequentially compounded. The middle elastic layer is a layered structure formed by distributing a plurality of continuous elastic fiber filaments side by side. The middle elastic layer is connected with the first surface layer, the second The composite method between the two surface layers is discontinuous composite. A composite region 4 is formed at each composite part of the middle elastic layer, the first surface layer and the second surface layer. When the middle elastic layer is in a contracted state, a composite area 4 is formed between two adjacent composite regions, and between the first surface layer and the second surface layer. Bubble-like structures 5 (such as figure 1 shown).

[0038] Wherein, the elastic fiber filaments are PP fiber filaments or PET...

Embodiment 2

[0042] This embodiment is the manufacturing method and manufacturing equipment of the composite elastic sheet described in Embodiment 1.

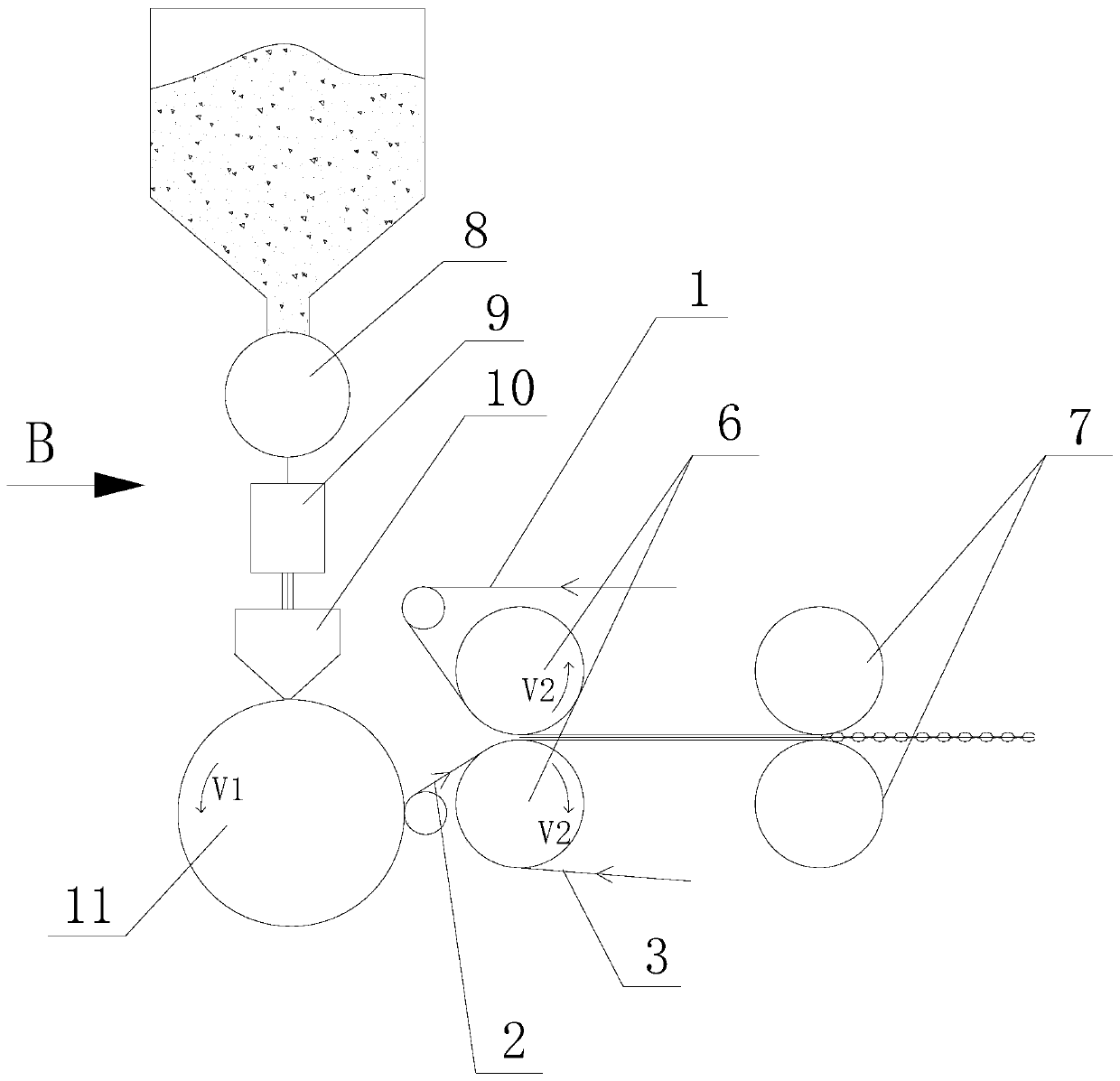

[0043] Such as image 3 As shown, the production equipment includes a first surface layer unwinding mechanism (not shown in the figure), a second surface layer unwinding mechanism (not shown in the figure), an elastic layer forming mechanism, a stretching traction mechanism 6 and a composite mechanism 7, the first The first surface layer unwinding mechanism, the second surface layer unwinding mechanism and the elastic layer forming mechanism are respectively connected with the stretching traction mechanism, and the stretching traction mechanism is connected with the composite mechanism; the elastic layer forming mechanism includes an extruder 8, a metering pump 9, a wire extruder Plate 10 and cooling drum 11, the wire extrusion board is arranged at the die head of the extruder, the wire extrusion board is distributed with a number of extrus...

Embodiment 3

[0054] This embodiment is a kind of composite elastic sheet material. Compared with Embodiment 1, its difference is that the middle elastic layer is a layered structure formed by a plurality of continuous strip-shaped fiber layers distributed side by side. The extruder forms the middle elastic layer, but in this case the extruded middle elastic layer is elastic material distributed in a strip shape, the thickness of which is ≥0.06mm, and the interval between two adjacent strip elastic materials is not required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com