Nickel-based target material and preparation method and application thereof

A target material, nickel-based technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of few preparation methods, and achieve the effect of improving quality, uniform distribution, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

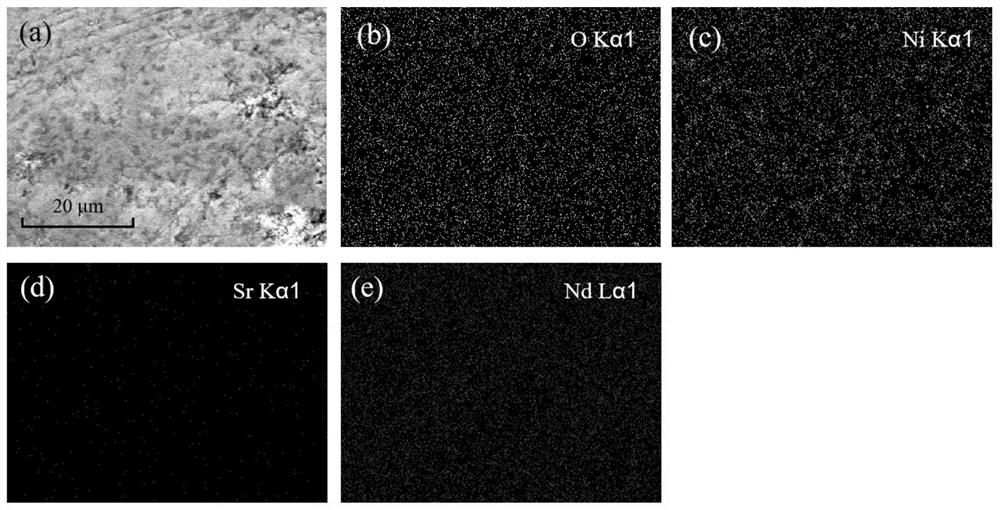

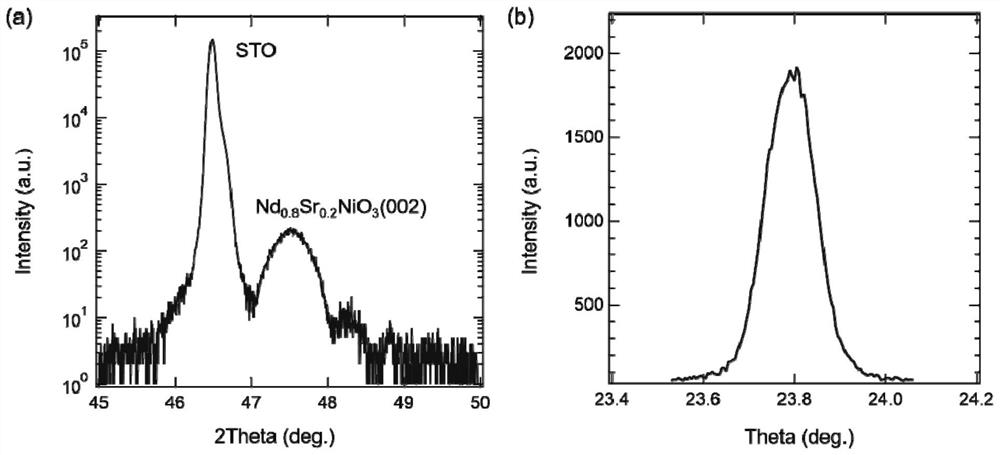

[0028] The present invention provides a kind of Nd 1-x A x NiO 3 (A=Ca or Sr or Ba, 0

[0029] Step S1. Using neodymium oxide, alkaline earth carbonate, and nickel oxide as raw materials, and the alkaline earth carbonate is calcium carbonate, strontium carbonate, or barium carbonate, performing ball milling for the first time to prepare the first intermediate;

[0030] Step S2. Pre-calcining the first intermediate, the pre-calcination temperature is 1150°C-1250°C, and the pre-calcination time is 7h-9h, to prepare the second intermediate;

[0031] Step S3. The second intermediate is ball milled for the second time, and then granulated to prepare the third intermediate;

[0032] Step S4. Making the third intermediate into a green target body and performing debinding treatment to prepare the fourth intermediate;

[0033] Step S5. The fourth intermediate is heated up to the sintering temperature by progra...

Embodiment 1

[0054] (1) Ultrasonic clean all utensils with deionized water or absolute ethanol. Be 0.8:0.2:1 by the ratio of the amount of substance and take neodymium oxide, strontium carbonate, nickel oxide respectively, as raw material, with dehydrated alcohol, zirconia ball (mass ratio: raw material: dehydrated alcohol: zirconia ball=1 :1:2, zirconia ball diameter is 2mm) placed in a nylon tank, ball milled in a planetary ball mill for 6 hours to obtain a mixed slurry, pour the mixed slurry into a container, put it in an oven for drying, and the drying temperature is 120°C , drying time 8h;

[0055] (2) Put the powder obtained after drying into a crucible, place it in a muffle furnace for pre-burning, the pre-burning temperature is 1200°C, and the pre-burning time is 8h;

[0056] (3) the powder after pre-calcination is used as raw material, according to the parameter setting in the step (1), carry out ball milling and drying for the second time, the powder after drying is granulated w...

Embodiment 2

[0062] (1) Ultrasonic clean all utensils with deionized water or absolute ethanol. Be 0.8:0.2:1 by the ratio of the amount of substance and take neodymium oxide, barium carbonate, nickel oxide respectively, as raw material, with dehydrated alcohol, alumina sphere (mass ratio: raw material: dehydrated alcohol: alumina sphere=0.9 :1:2.1, alumina ball diameter is 1.8mm) placed in a nylon tank, ball milled in a planetary ball mill for 6 hours to obtain a mixed slurry, pour the mixed slurry into a container, put it into an oven for drying, and the drying temperature is 120 ℃, drying time 8h;

[0063](2) Put the powder obtained after drying into a crucible, place it in a muffle furnace for pre-calcination, the pre-fire temperature is 1250°C, and the pre-fire time is 7h;

[0064] (3) The powder after pre-burning is used as raw material, and ball milling and drying are carried out for the second time according to the parameter setting in step (1), and the powder after drying is granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com