Wide-seedling-strip wheat precision planter achieving both minimal tillage and fertilizer and work method thereof

The technology of a seeder and a wide seedling belt is applied in the field of precision seeding machinery for wheat with wide seedling belt, which can solve the problems of low seeding quality and lack of precision seeding machinery for wheat, and achieves high seeding precision, which is beneficial to growth and development and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

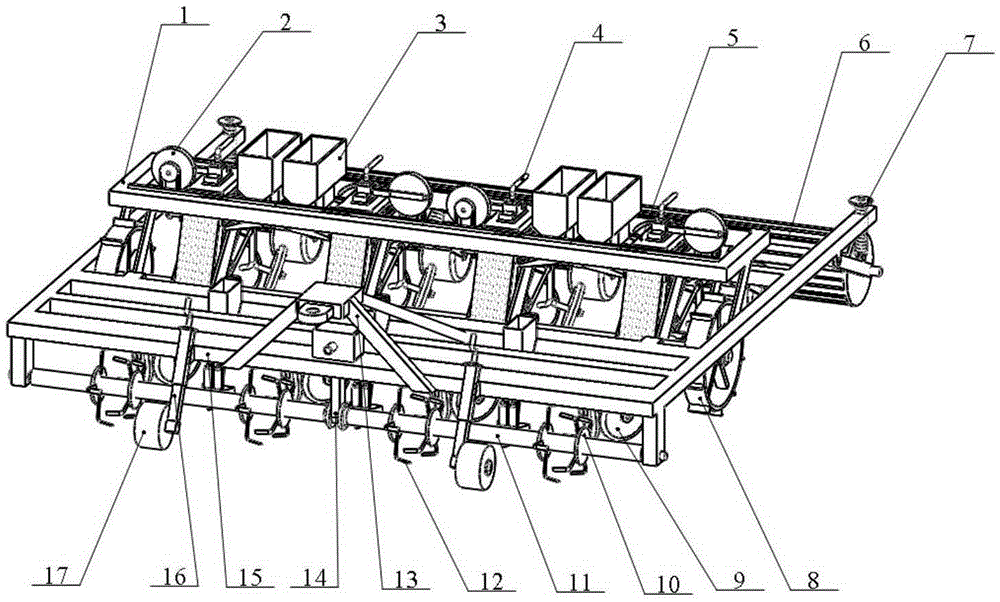

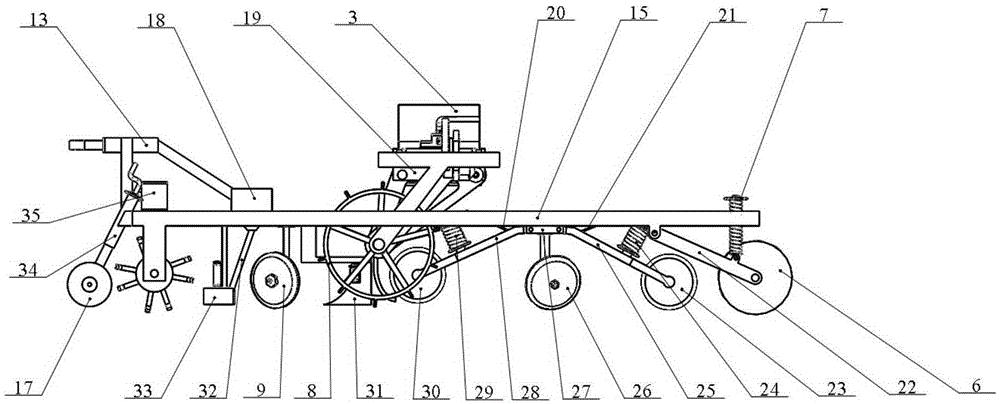

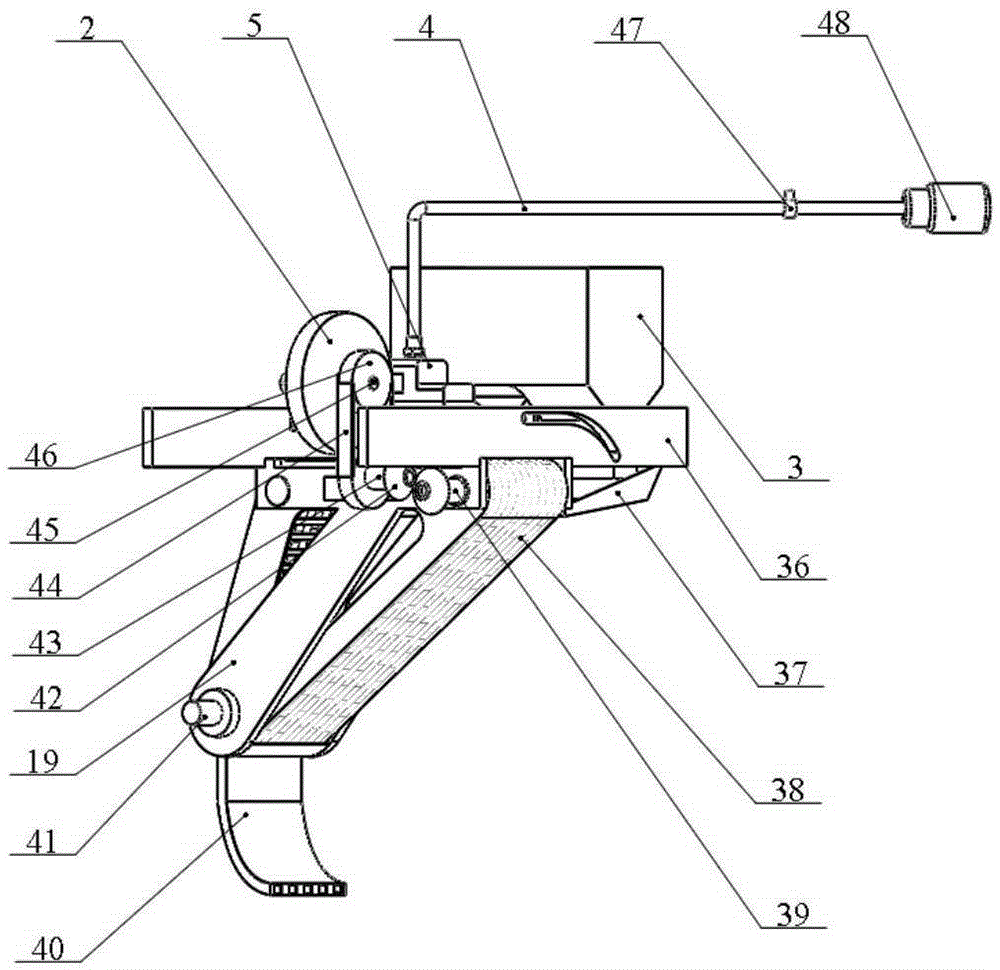

[0038] Below in conjunction with accompanying drawing, the patent of the present invention is further described. In this embodiment, the width of the sowing belt is 10 centimeters, 5 rows of seeds are dropped, and the seeder is equipped with 4 sets of sowing devices as an example. Solid mechanism, flat ground mechanism, kind case 3 and kind dish 37.

[0039] A kind of wide seedling band wheat precision seeder and its working method of less tillage and fertilizer application of the present invention, such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8. A precision seeder for wheat with wide seedlings and a combination of less tillage and fertilizer application, comprising an upper frame 1, a lower frame 15, a traction beam 13, a seeding device, a rotary tillage mechanism, a ditch opener, a fertilization mechanism, a suppression mechanism, Soil-covering mechanism, compacting mechanism, leveling mechanism, ground wheel 8, seed box 3 and seed disc 34.

[0040] The seed metering device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com