Novel hydrodynamic turbine pump free of shaft seal structure

A hydraulic turbine pump, no shaft seal technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of shaft seal leakage, large space occupation, etc., achieve a compact structure, avoid shaft seal leakage problems, and improve installation. Effects of performance and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

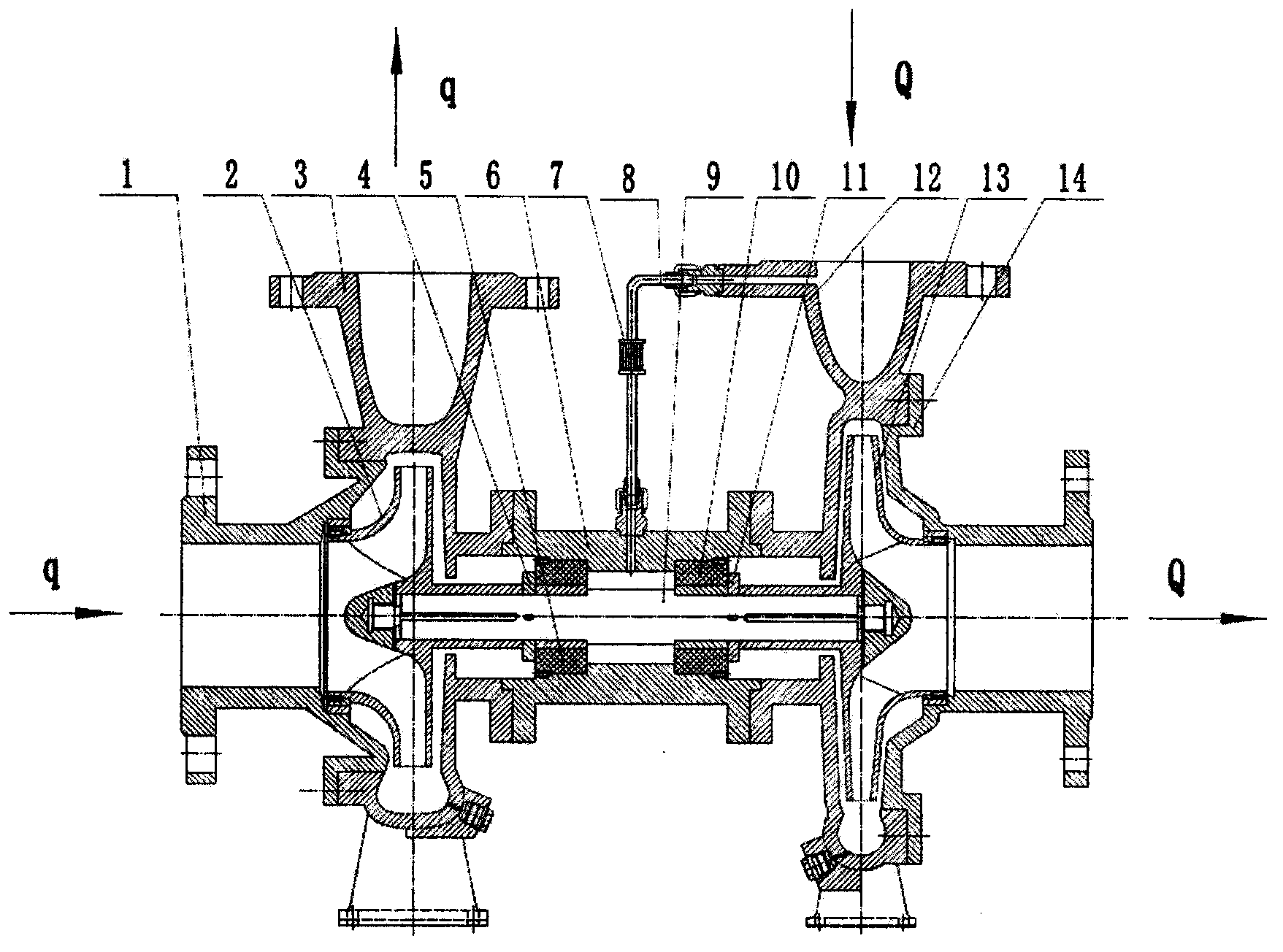

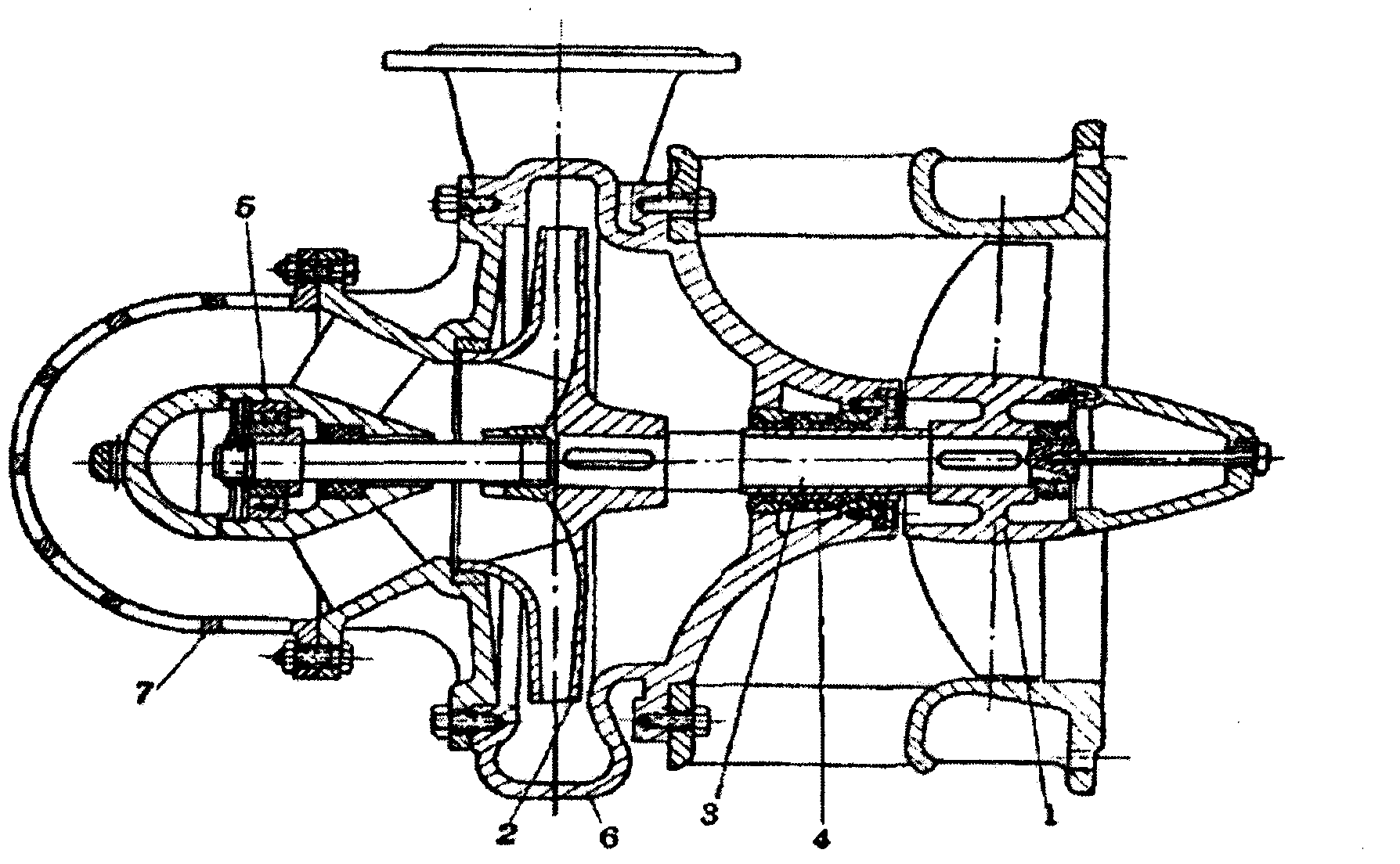

[0010] figure 1 Among them, the whole pump body is divided into five parts, with openings on both sides of the pump body turbine, so as to facilitate the loading and unloading of the impeller and the runner, and the coaxial connection between the impeller and the runner. Sliding bearings are arranged on the left and right sides of the hydraulic turbine pump to support the shaft, and thrust plates are respectively arranged to realize axial limit, and the transmission mechanism and shaft seal (mechanical seal or skeleton seal, etc.) are omitted to realize no shaft seal and avoid shaft seal leakage. The cavity where the sliding bearing is located and the inlet of the hydraulic turbine are connected with a flushing pipe, and a filter is set to form a cooling and lubricating liquid circulation circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com