Shaftless propeller

A thruster and shaftless technology, which is applied in the direction of rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of increased difficulty in ship design and maintenance costs, low space utilization, increased use costs, etc., to achieve easy installation and Maintenance, improvement of space utilization, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

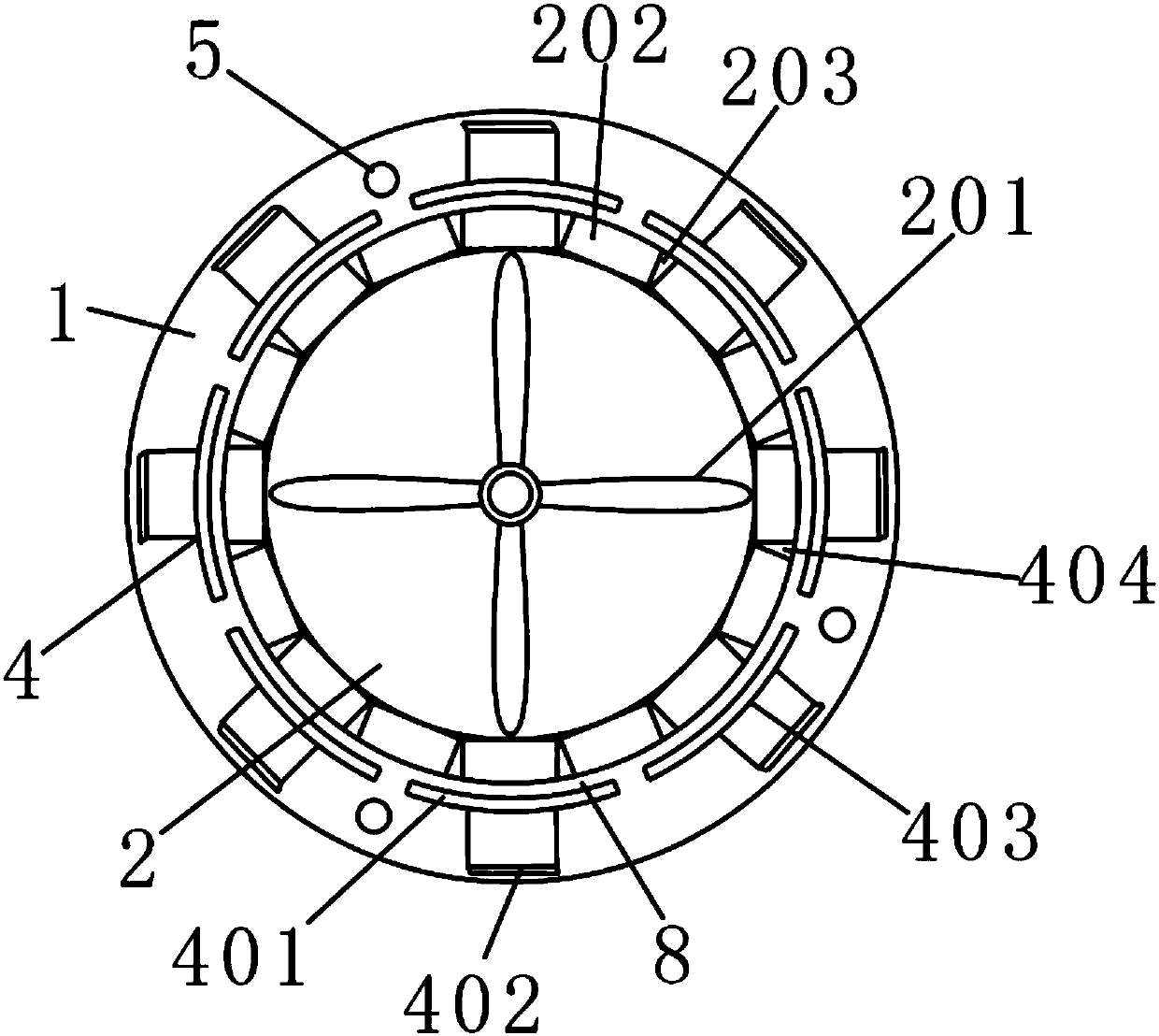

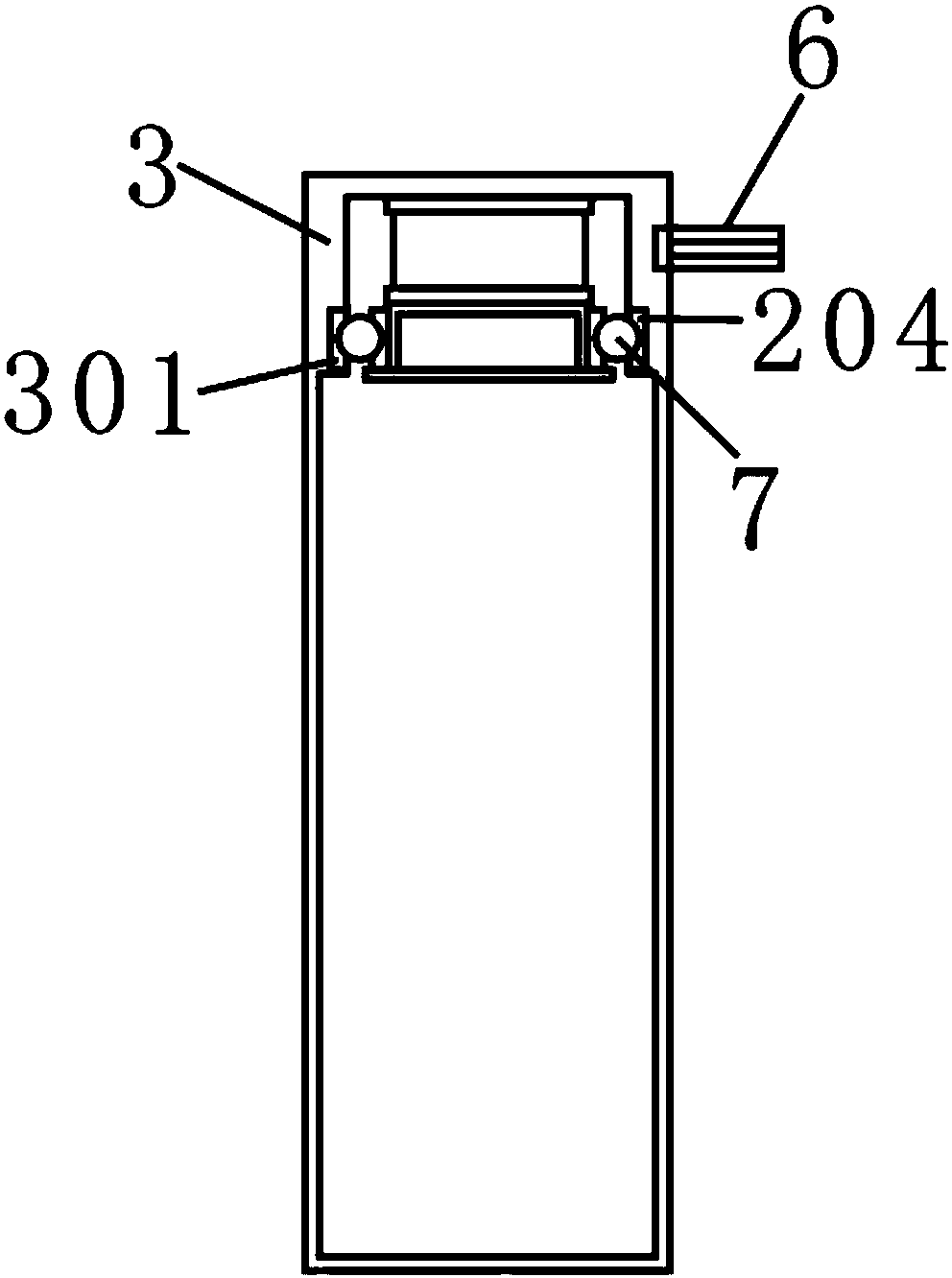

[0026] Such as figure 1 and figure 2 As shown, the present invention provides a shaftless propeller, including a casing 1, a rotor 2 and two end covers 3, a stator 4 and three Hall sensors 5 are fixedly installed inside the casing 1, and the Hall sensors 5 is symmetrically fixed on the housing 1 at an angle of 120° to the center of the housing 1, and is used to detect the motion state of the rotor 2. The rotor 2 includes a blade 201, a permanent magnet 202 and a ring 203. The blade 201 is different from the previous blades and is Based on the traditional blade, a circular ring 203 is added to the outer edge of the blade 201. The blade 201 forms an integrated structure with the circular ring 203 by casting, welding or screwing, and there is a permanent magnet on the 203 circular ring. The cavity, the blade 201 is fixedly installed inside the ring 203, and several pairs of the permanent magnets 202 are alternately embedded in the groove on the ring 203 according to the N pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com