High automatic feeding device

An automatic feeding, high-level technology used in transportation and packaging, load hanging elements, roller tables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described:

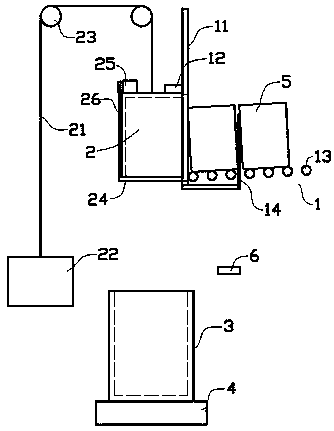

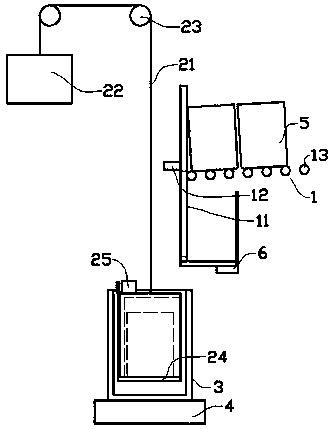

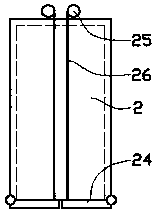

[0018] Such as figure 1 with figure 2 As shown in the embodiment, this high-position automatic feeding device includes a feed track 1, a feed box 2, a discharge box 3, and a discharge track 4; the feed track 1 is placed to be installed in the discharge box 3 Component 5, the feed box 2 is connected to the counterweight 22 through a rope 21, the upper part of the feed box 2 and the counterweight 22 is fixedly equipped with a runner 23, and the rope 21 is wound through the runner 23, The feeding track 1 is placed obliquely, and the element 5 is put in from the inclined upper end of the feeding track 1 and slides out from the lower part of the feeding track 1 . The low-end outlet position of the described feed rail 1 is designed with a material stopper 11 that can slide up and down, such as Figure 5 As shown, the material retaining block 11 is divided into two parts: an upper material r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com