Motor with optical fiber communication

An optical fiber communication, self-contained technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of limiting the application field and service life of equipment, large noise and vibration, and high component production costs, saving production costs, reducing Noise, reduce the effect of transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object and advantages of the present invention more clearly understood, the following combined with embodiments of the present invention will be described in detail. It should be understood that the following text is used only to describe one or more specific embodiments of the present invention, and does not strictly limit the specific scope of protection claimed by the present invention. As used herein, the terms "parallel" and "vertical" are not limited to their strict geometric definitions, but include a tolerance for reasonable and inconsistent machining or human errors.

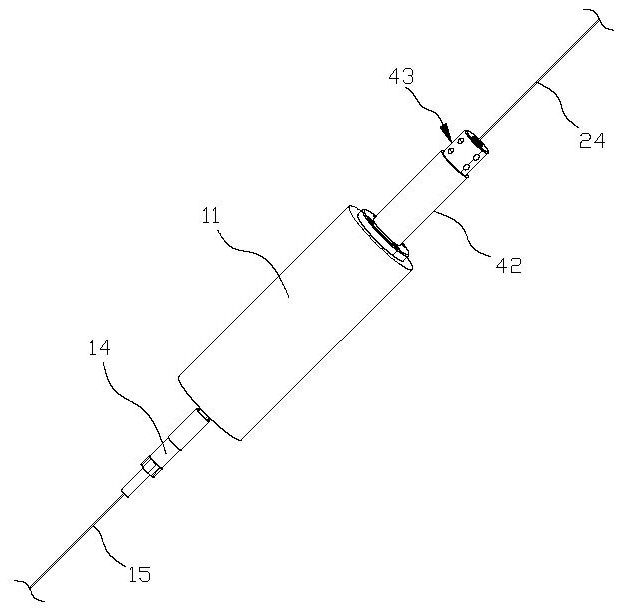

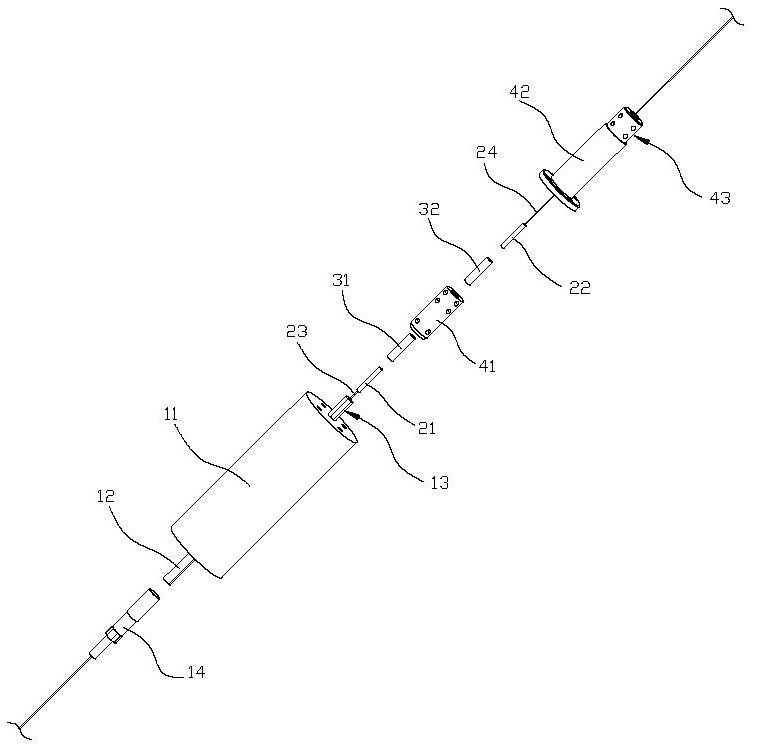

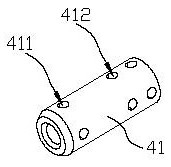

[0027] as Figures 1 to 3 As shown, a motor with its own optical fiber communication, comprising a slip ring part and a drive part, the drive part has a rotating mounted drive shaft 12, the slip ring part has a stator unit and a rotor unit, the drive shaft 12 and the rotor unit are arranged along the centerline of the drive shaft 12 and the two are fixedly connected. The above sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com