Driving system of seedling transplanter

A technology for a drive system and a rice transplanter, applied in the field of a rice transplanter drive system and drive system, can solve the problems of not being able to store and recover the kinetic energy or potential energy of the system, unfavorable to automation, intelligent control, and not meeting the requirements of light weight, etc., so as to achieve a lightweight transmission system. , optimized layout flexibility, easy to intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

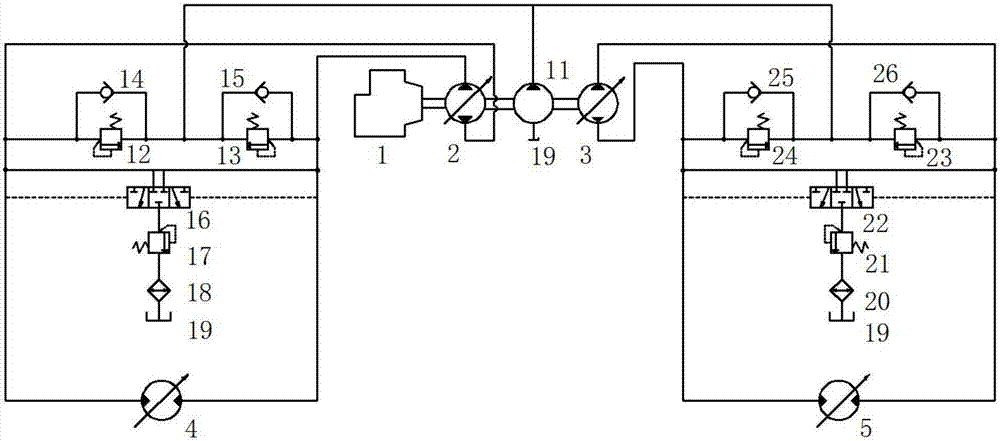

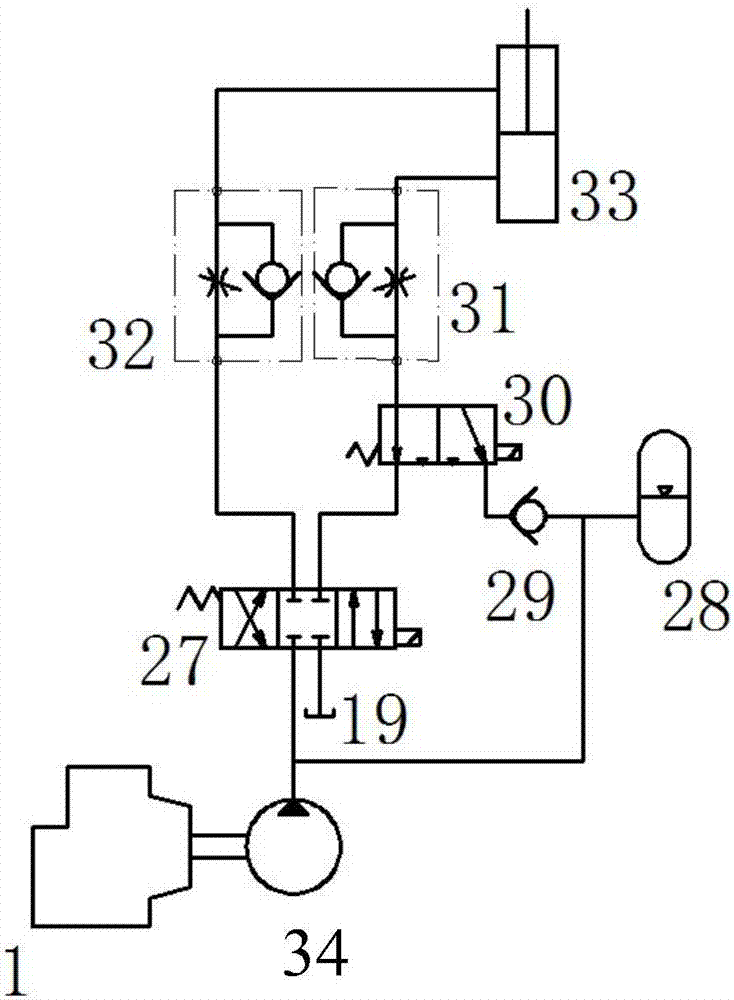

[0033] see Figure 1-Figure 4 :

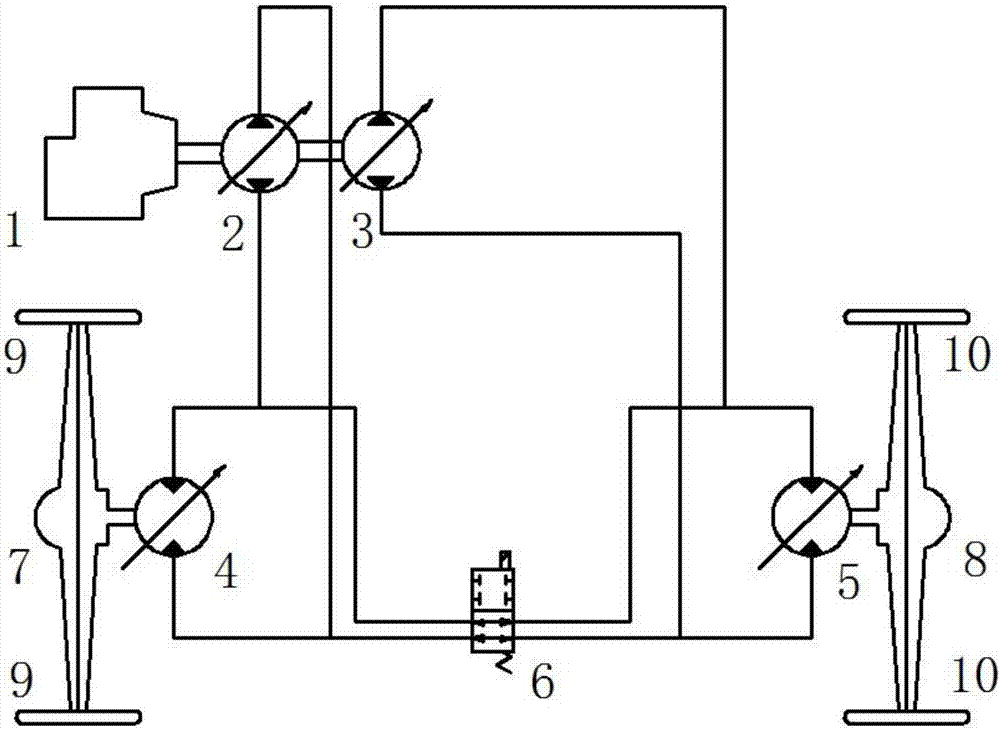

[0034] figure 1 Shown is the layout of the travel drive system.

[0035] Diesel engine 1 provides power for the entire walking drive system. Two-way variable plunger pumps 2 and 3 are connected to the engine through a belt. The two plunger pumps are respectively connected to the front wheel drive motor 4 and the rear wheel drive motor 5 through a closed circuit. The output shaft of the drive motor is connected to the front axle, and the output shaft of the rear wheel drive motor is connected to the rear axle. The main reducer and the planetary gear differential are arranged in the front and rear axles. By rationally configuring the motor speed and the reduction ratio of the axles, the uniformity of each wheel is ensured. There is no parasitic power, and an inter-axle differential lock valve is set between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com