Lawn ventilator

A kind of ventilator and grassland technology, which is applied in the direction of lawn treatment machinery, agricultural machinery, agricultural machinery lifting device, etc. It can solve the problems that the grassland ventilator cannot work, the motor volume becomes larger, and the weight increases, so as to improve the grassland ventilation effect, High transmission efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

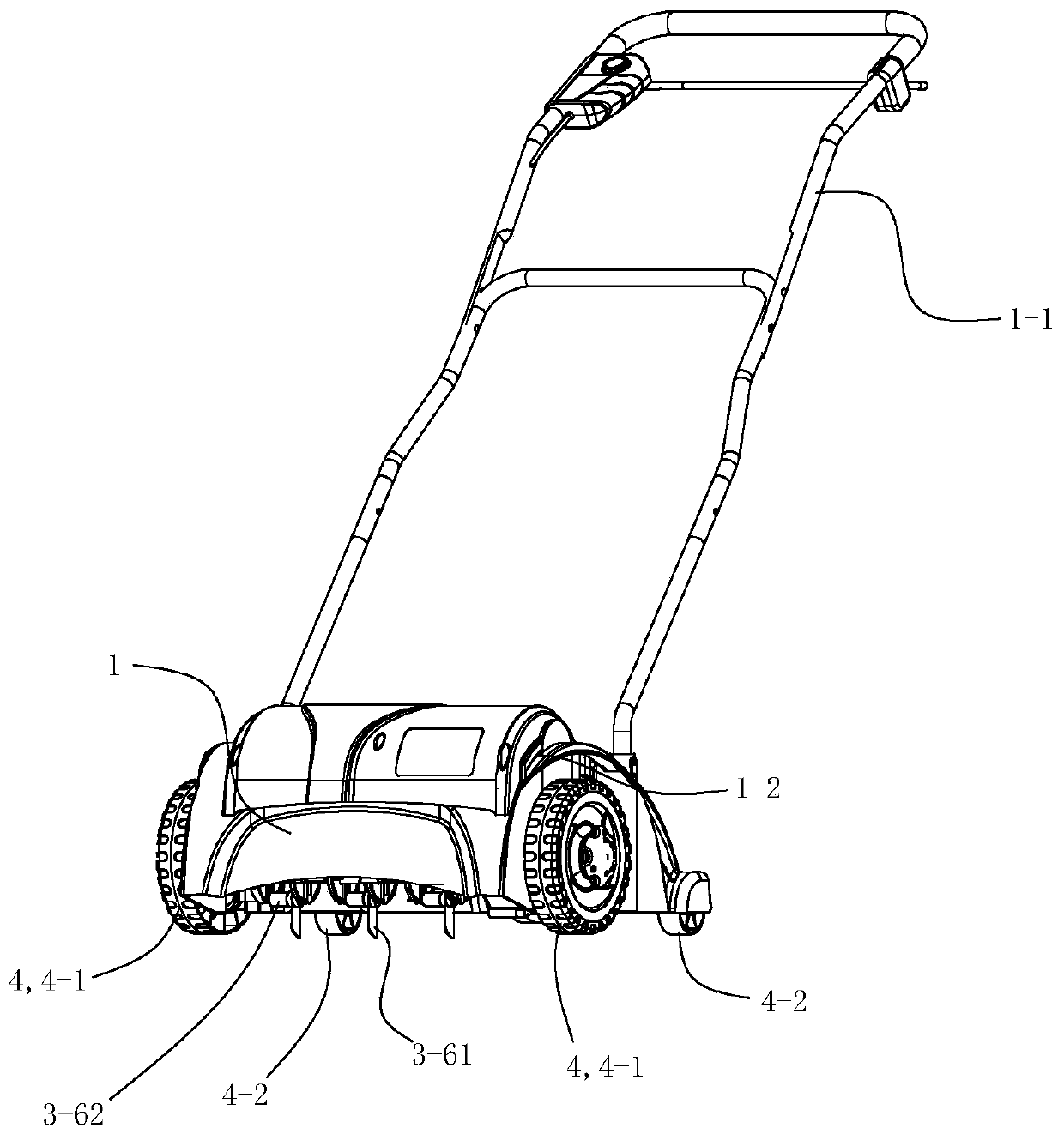

[0047] See Figure 1 to Figure 15 , The grass aeration machine of the present invention comprises a casing 1, a motor 2, a soil loosening cutter 3, a traveling mechanism 4, a depth adjustment mechanism 5 and a battery pack.

[0048] See figure 1 , the casing 1 is provided with an armrest 1-1. Handrail 1-1 top is provided with operation switch. The detachable fixed connection of the battery pack is arranged in the upper part of the casing 1, and the battery pack adopts a rechargeable lithium battery.

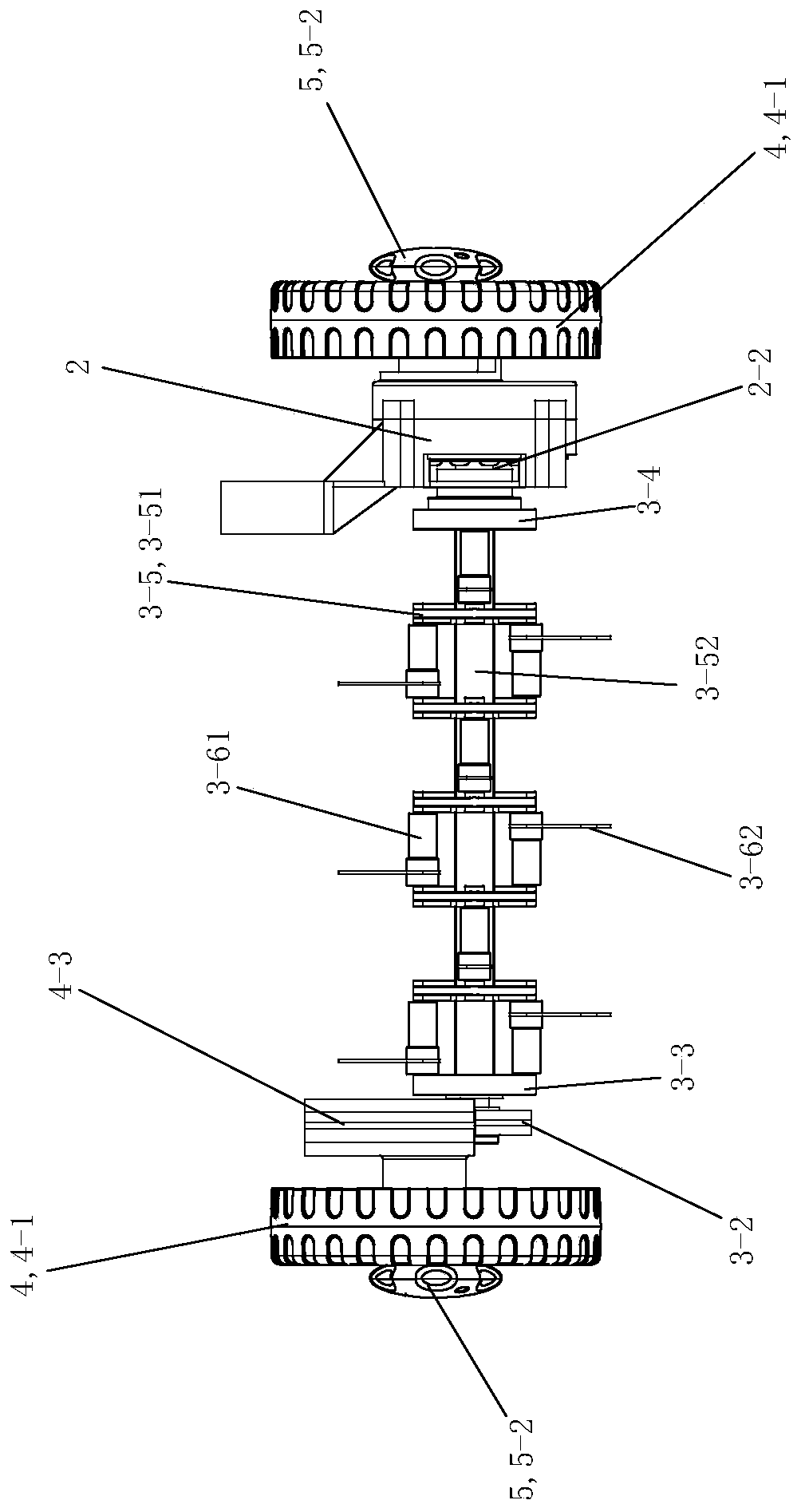

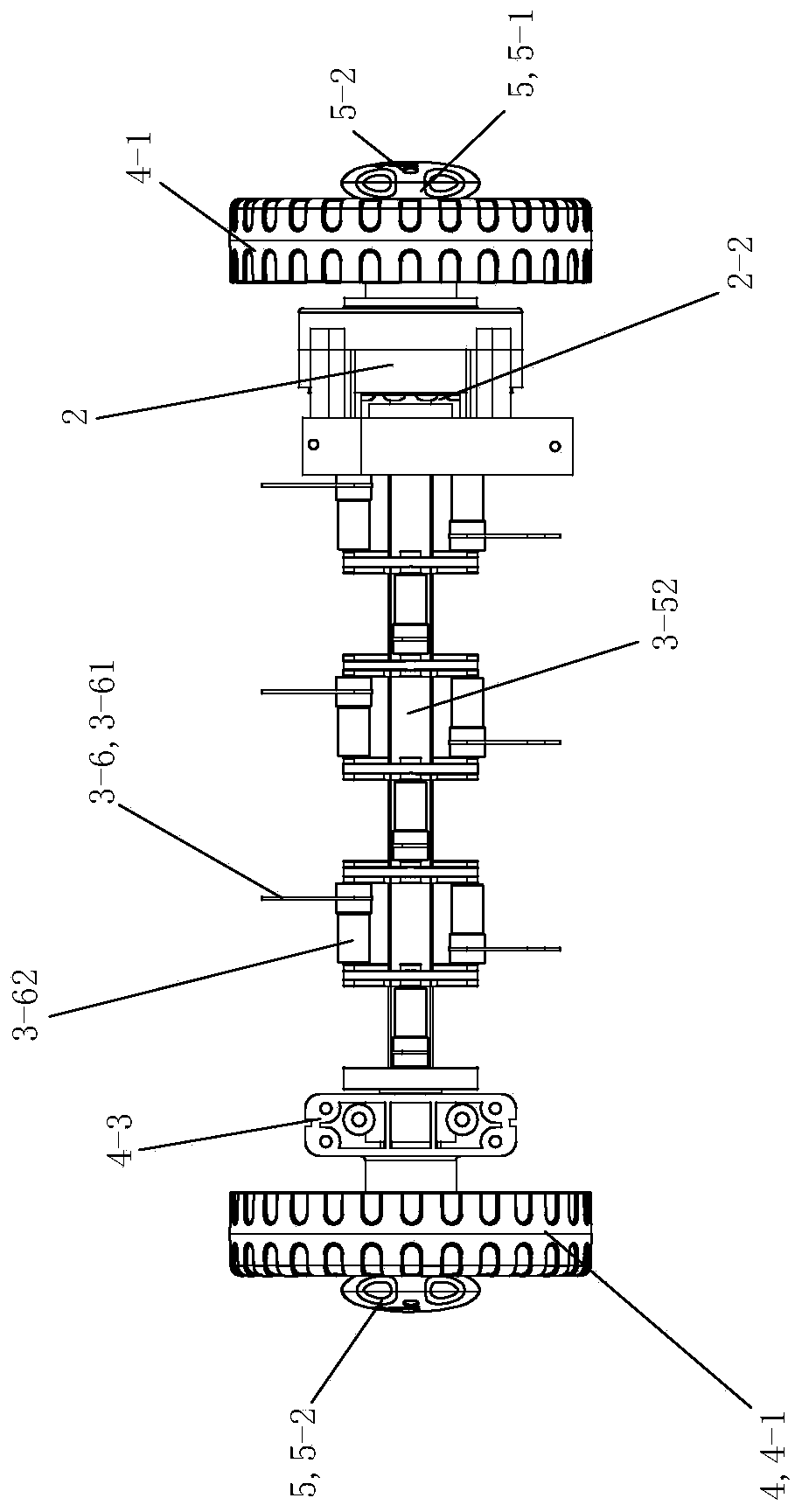

[0049] See Figure 2 to Figure 9 , The motor 2 is fixedly arranged in the motor compartment in the right part of the front part of the casing 1, and the upper part of the motor compartment is provided with a vent 1-2. The motor 2 adopts a brushless DC motor, and the motor 2 is powered by a battery pack. The motor shaft 2-1 of the motor 2 stretches out of the motor compartment to the left, and the left end output end of the motor shaft 2-1 is a square shaft. The motor 2 is p...

Embodiment 2)

[0060] The remainder of this embodiment is the same as that of Embodiment 1, the difference being that the middle knife seat 3-5 of the soil loosening tool 3 adopts a split structure, and the middle knife seat shaft 3-51 of the middle knife seat 3-5 is connected to the center The square shaft spacer part 3-52 is two independent parts; the left end tool seat 3-3 also adopts a split structure, the tool seat shaft part 3-31 of the left end tool seat 3-3 and the square shaft spacer part 3-32 It is two independent parts, so that the distance between two adjacent intermediate tool holder shaft parts 3-51 can be adjusted by replacing the intermediate square shaft spacer part 3-52 and the square shaft spacer part 3-32 of different lengths , the distance between the tool seat shaft part 3-31 of the left end tool seat 3-3 and the middle tool seat shaft part 3-51 and the distance between the middle tool seat shaft part 3-51 and the right end tool seat 3-4, there are It is beneficial to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com