Patents

Literature

59results about How to "Less transmission parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

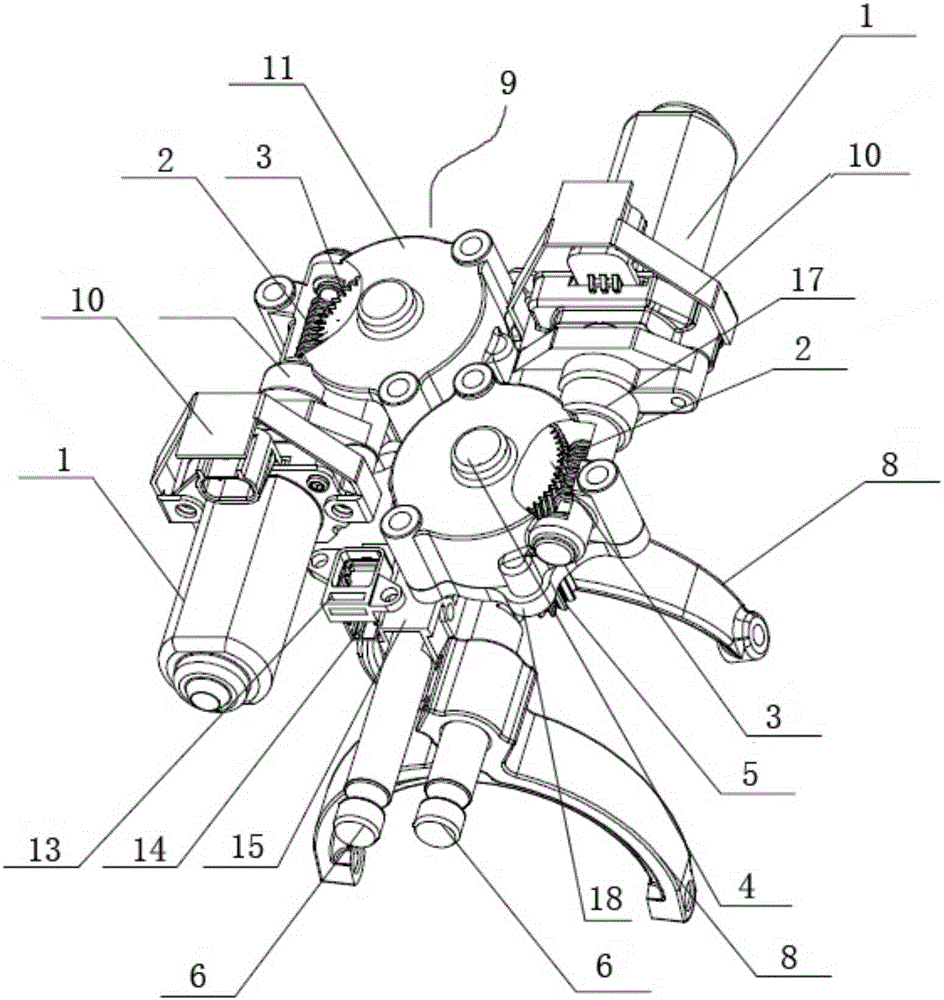

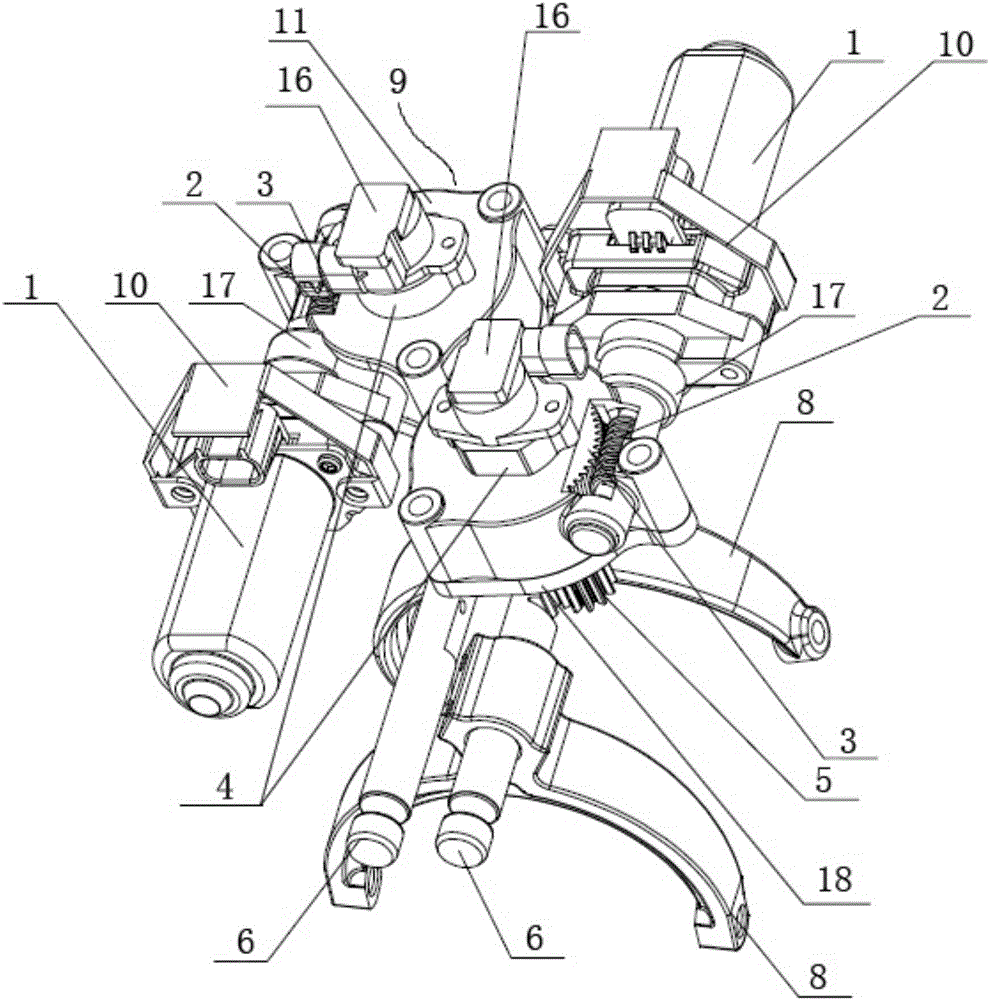

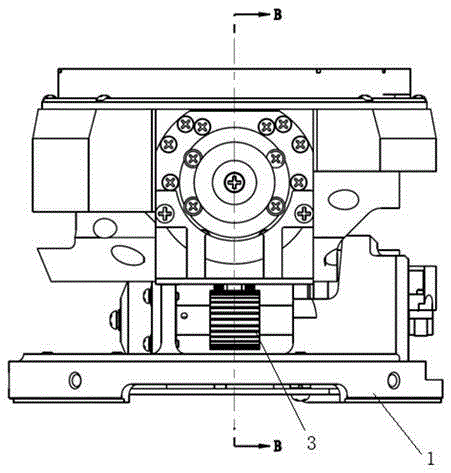

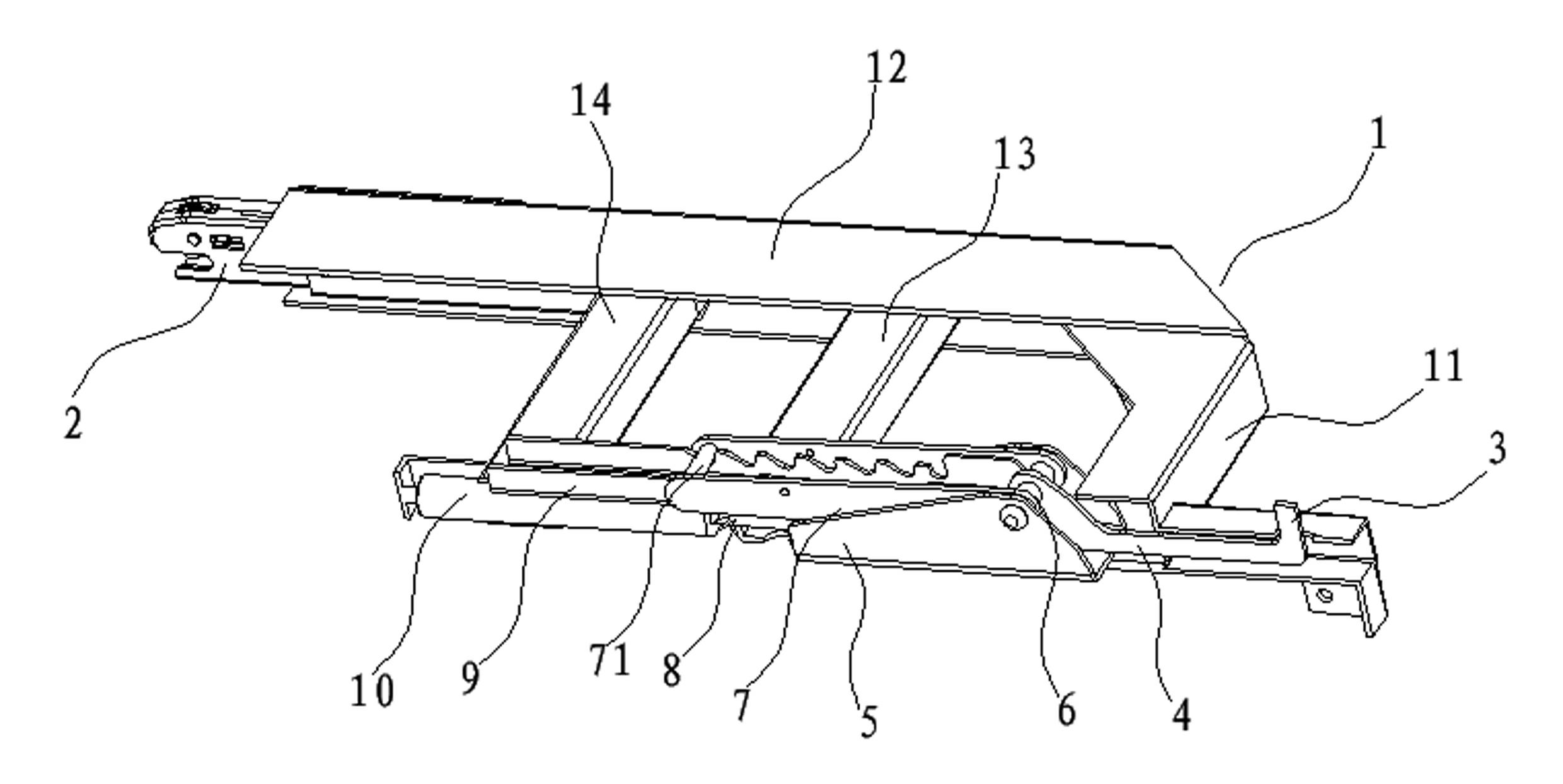

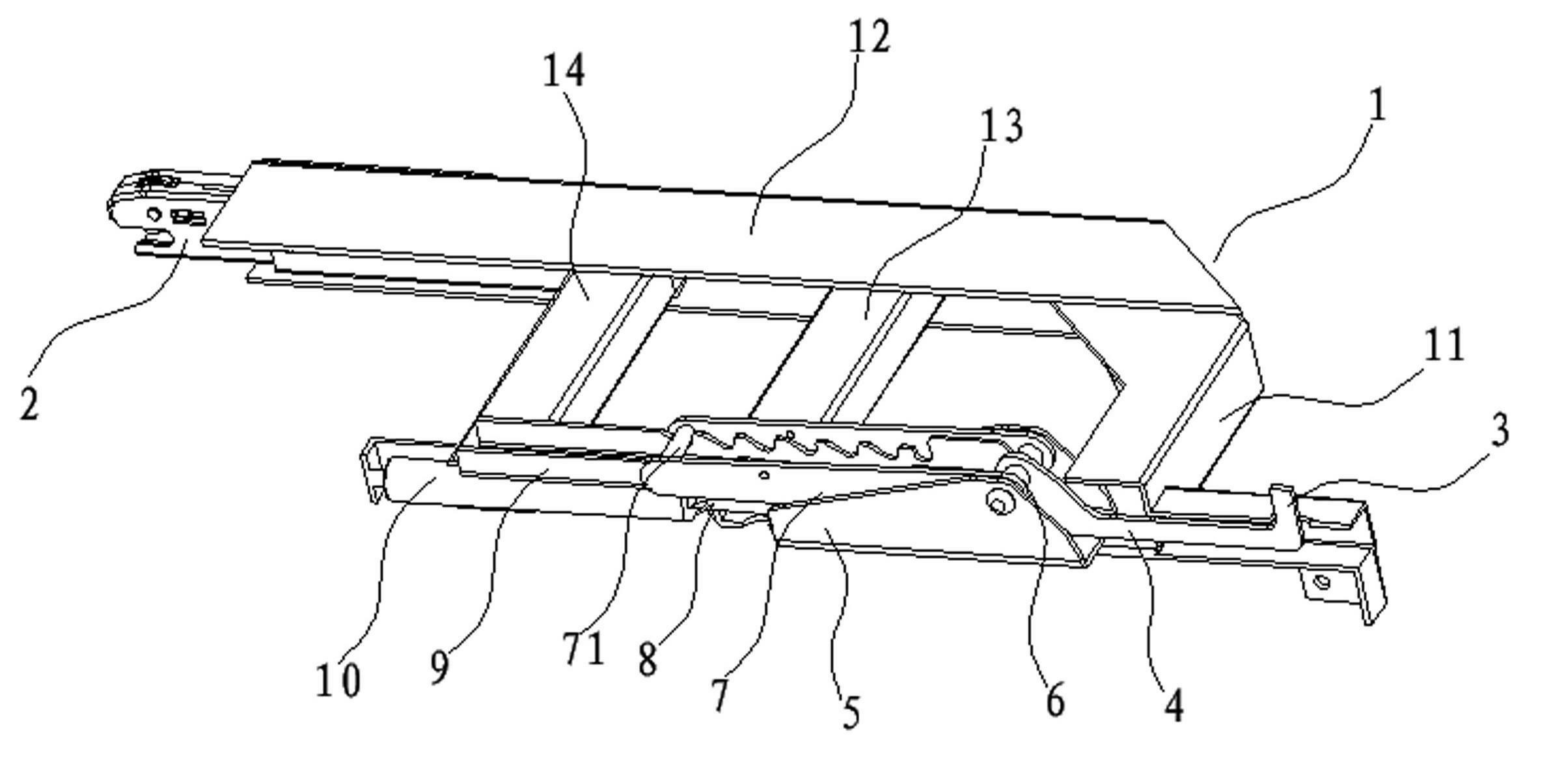

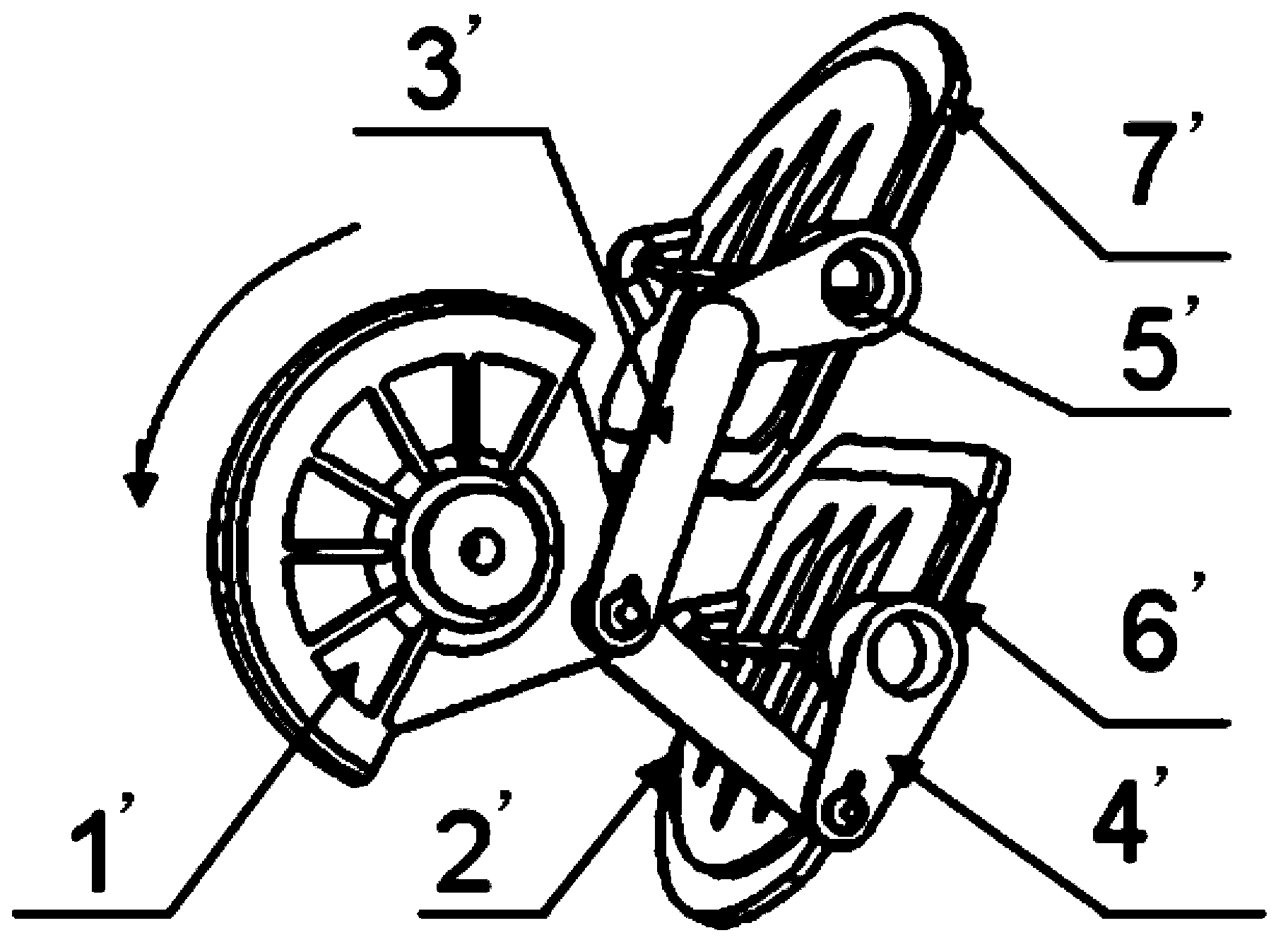

AMT automatic gear shifting device

InactiveCN105782431ASimple actionEasy to controlControlled membersGearing controlGear wheelRack and pinion

The invention provides an AMT automatic gear shifting device. The gear selecting process is omitted through the AMT automatic gear shifting device, and an original gear selecting and shifting mechanism is optimized into several independent gear shifting mechanisms. The AMT automatic gear shifting device comprises gear shifting motors and a shifting fork shaft, the output end of each gear shifting motor is connected with a worm structure, a worm gear structure is connected to one side of each worm structure in a meshed manner, and a main shaft of each worm gear structure is a gear shifting gear wheel shaft; each gear shifting gear wheel shaft comprises a gear shifting gear wheel, the shifting fork shaft is particularly a shifting fork shaft with a rack, the input end of the shifting fork shaft is provided with the rack parallel to the length direction of the shifting fork shaft, and the part of the rack is connected with the gear shifting gear wheels in a meshed manner; the output end of the shifting fork shaft is sleeved with a shifting fork structure, the shifting fork shaft moves in the gear shifting direction, and a sliding sleeve is externally connected to the shifting fork structure; the sliding sleeve comprises a sliding sleeve body with a synchronizer and a sliding sleeve body without a synchronizer; each gear shifting motor has N driving strokes, wherein the N is a natural number larger than or equal to 1, different strokes correspond to different feeding degrees of the shifting fork shaft, and one gear shifting motor correspondingly controls N gears.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

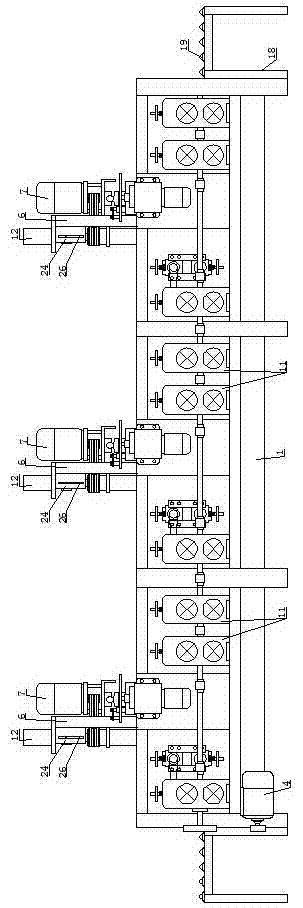

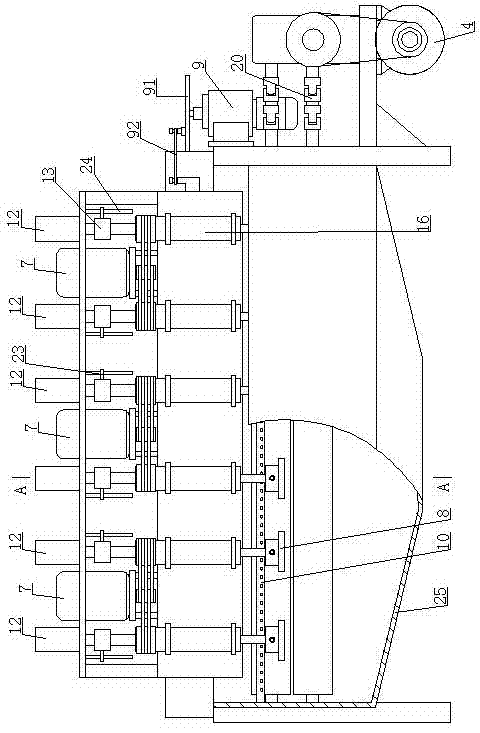

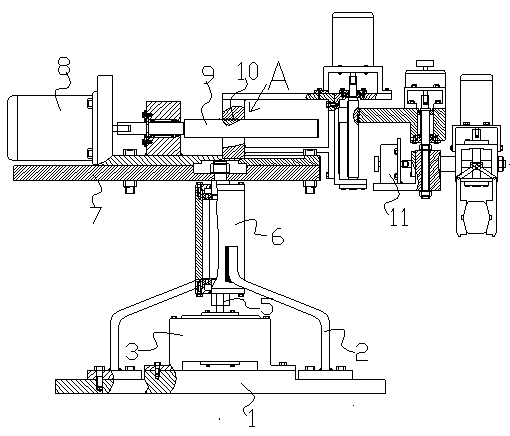

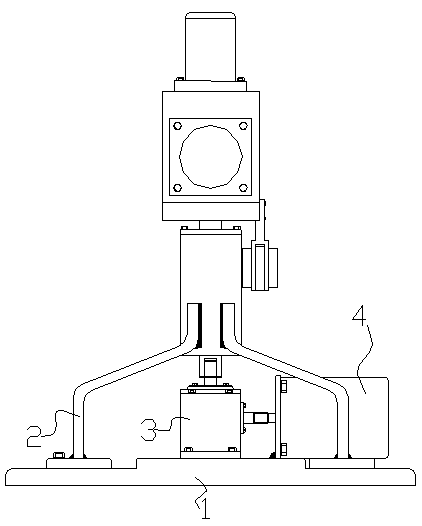

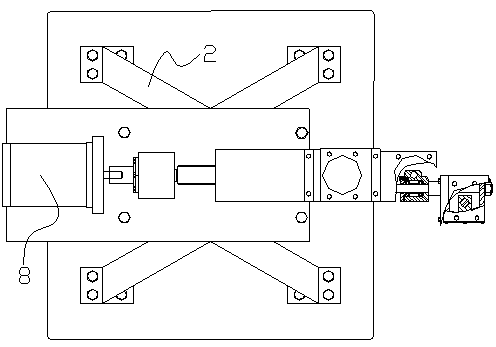

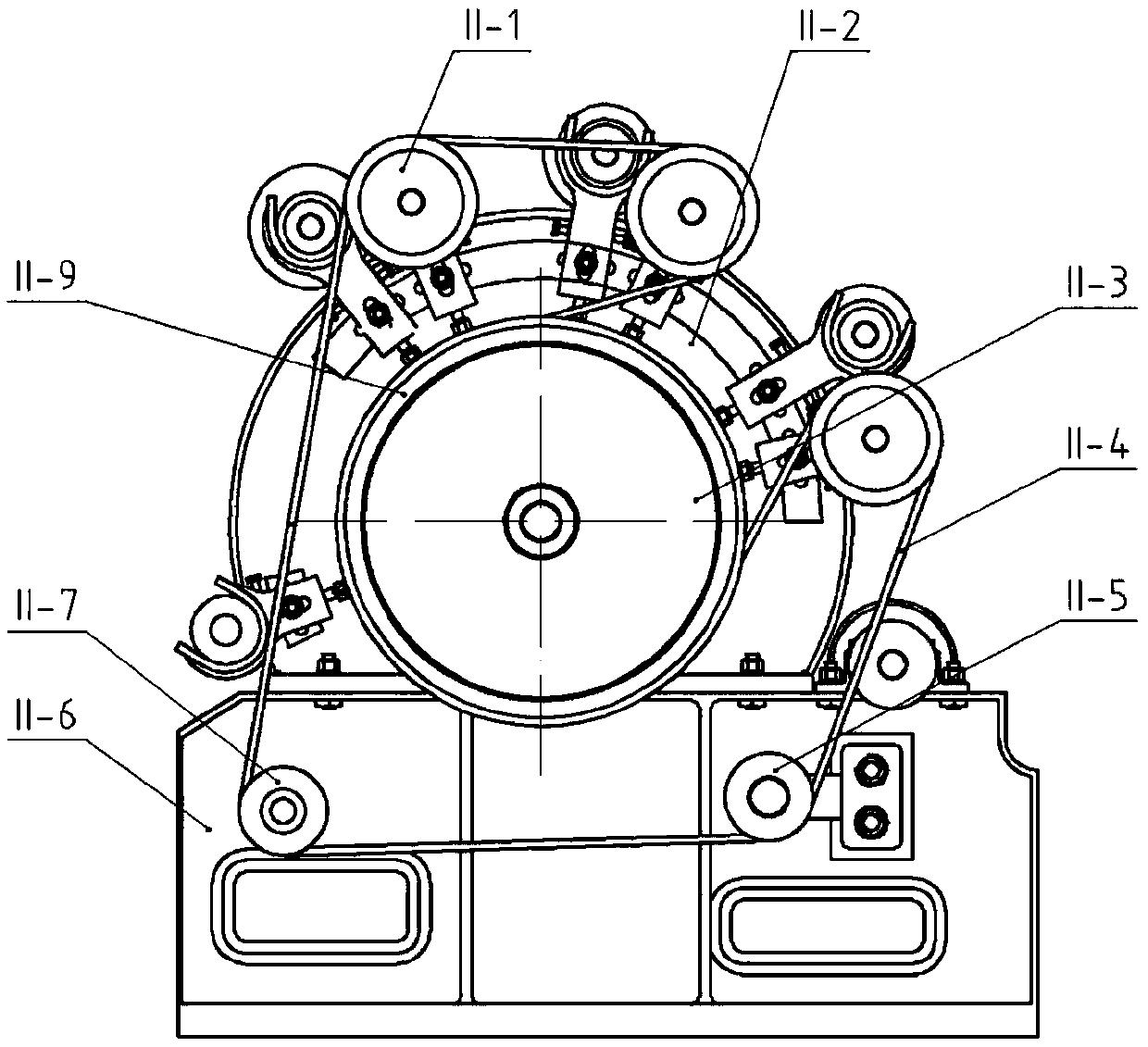

Polishing machine

ActiveCN104842255AAvoid reciprocating scratchesImprove polishing qualityPolishing machinesGrinding feedersMultiple injectionElectric machinery

The invention discloses a polishing machine. The polishing machine comprises a machine frame, wherein multiple mills are installed on the machine frame, conveying roller sets are arranged at the feeding end and discharging end of the each mill, each conveying roller set comprises an upper conveying roller and a lower conveying roller, a main motor is installed on the machine frame, a working table used for supporting a steel plate to be machined is arranged between the feeding end and discharging end of each mill, and grinding head assemblies corresponding to the working tables are arranged on the machine frame. Each grinding head assembly comprises a sliding frame, a polishing motor and a polishing brush driven by the polishing motor to rotate, wherein the sliding frame is driven by a swing motor fixedly installed on the machine frame. The mesh numbers of the polishing brushes of the multiple mills become larger gradually from the feeding end to the discharging end of the machine frame. An injection pipe parallel to the corresponding conveying roller sets is installed on each mill, and multiple injection holes are formed in each injection pipe corresponding to the corresponding working table. Due to the fact that the mesh numbers of the polishing brushes of the multiple mills become larger gradually, polishing process requirements can be met at a time, and reciprocating scratching caused by repeated passing of the steel plates is avoided.

Owner:山东精鹰机械制造有限公司

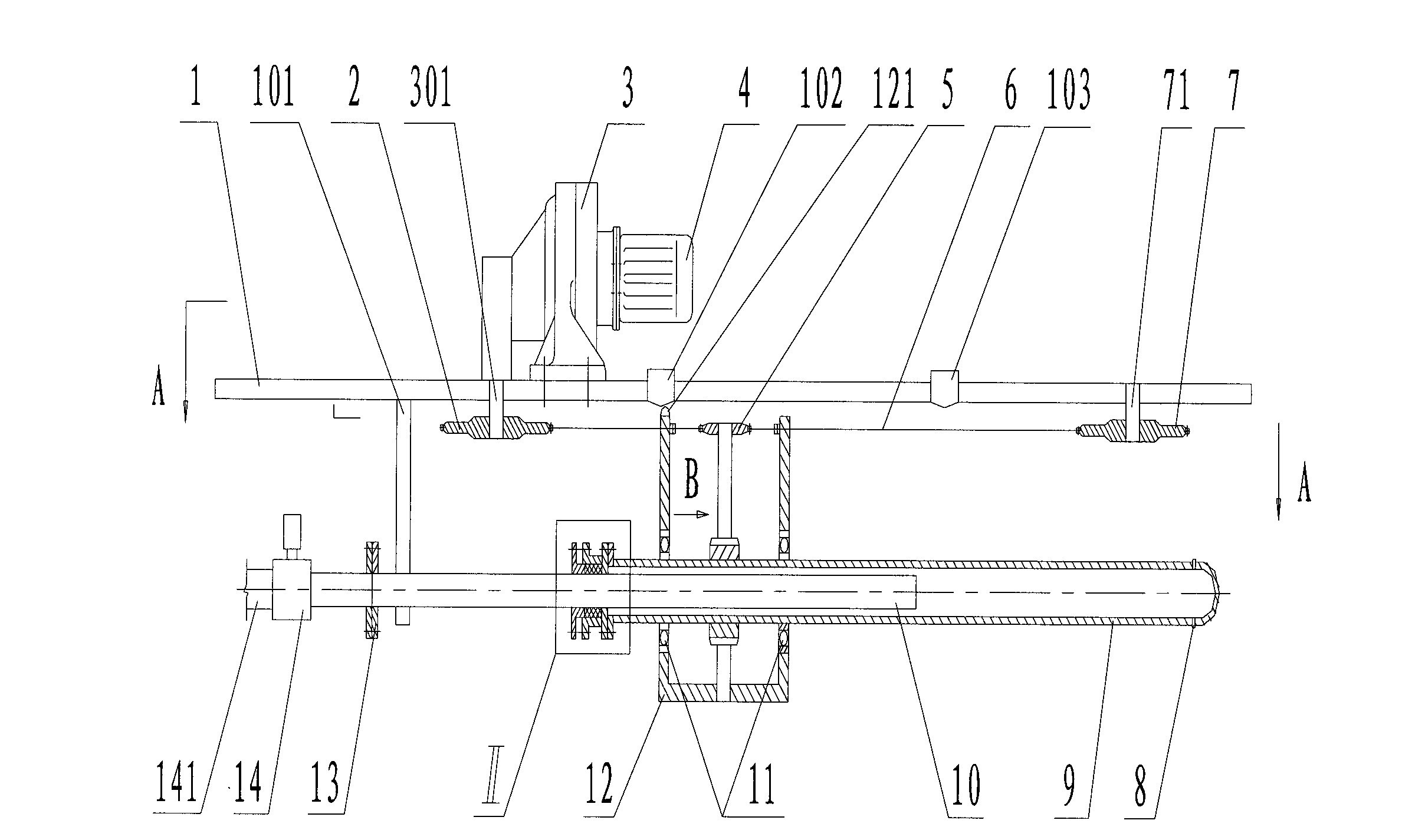

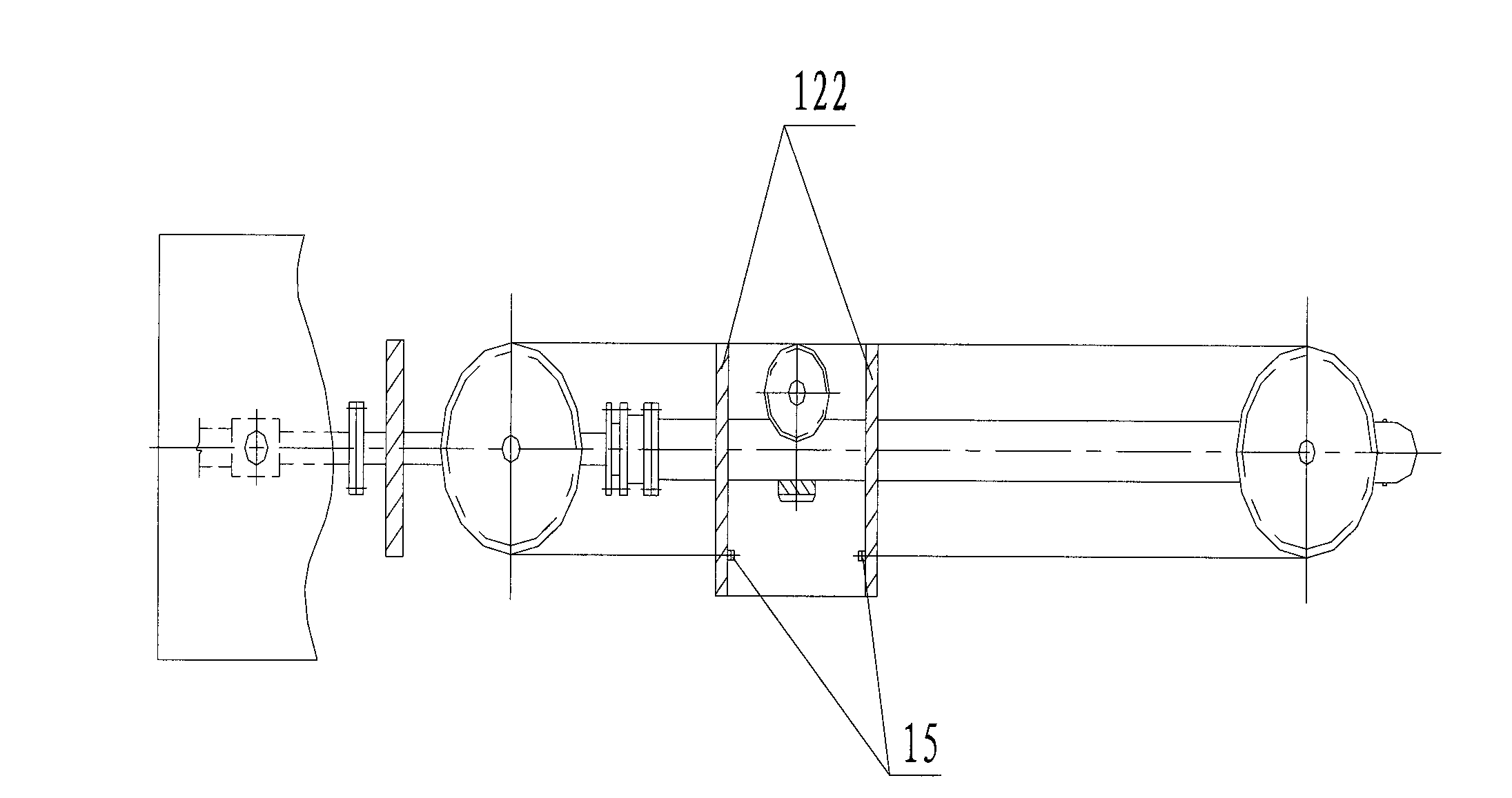

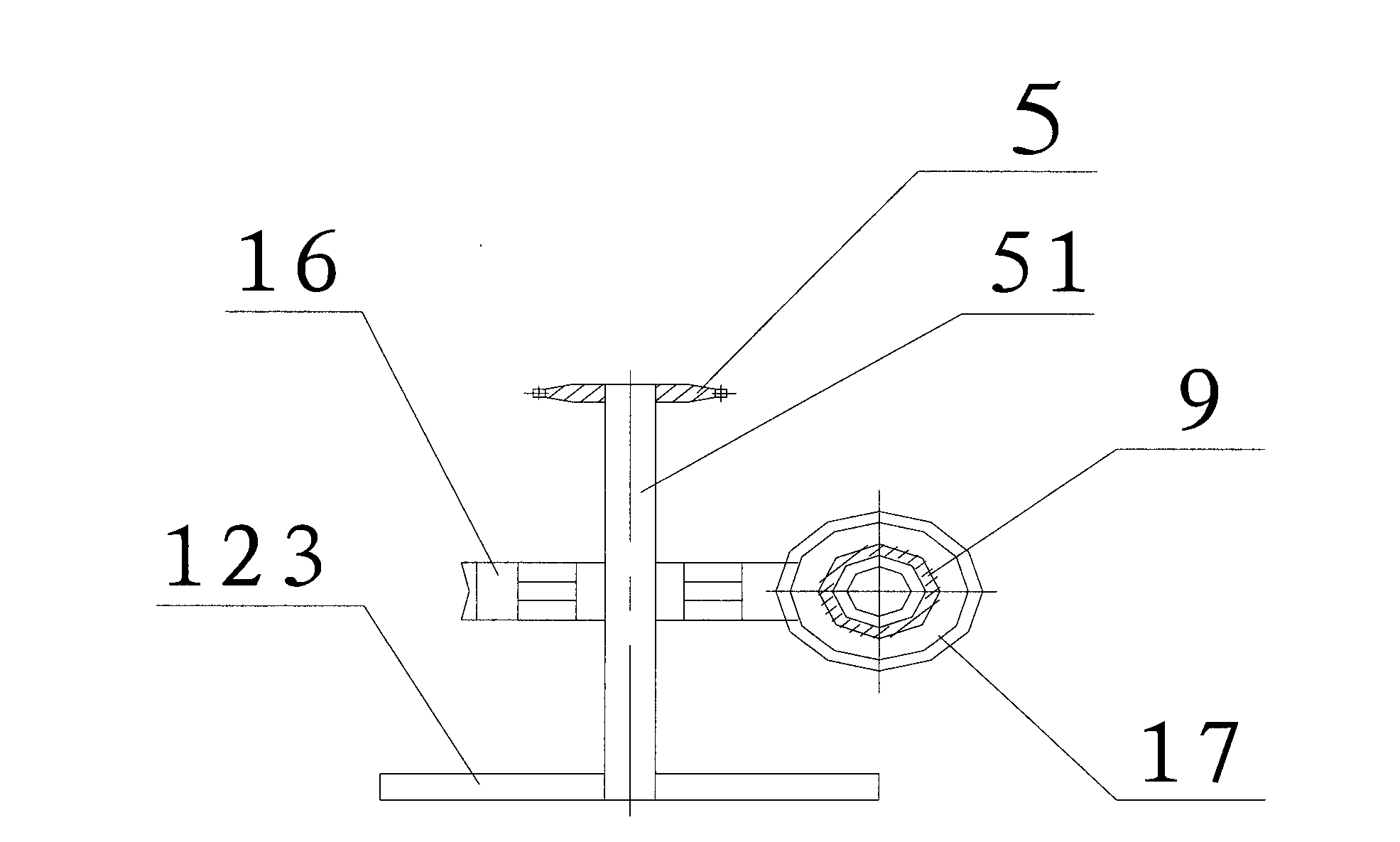

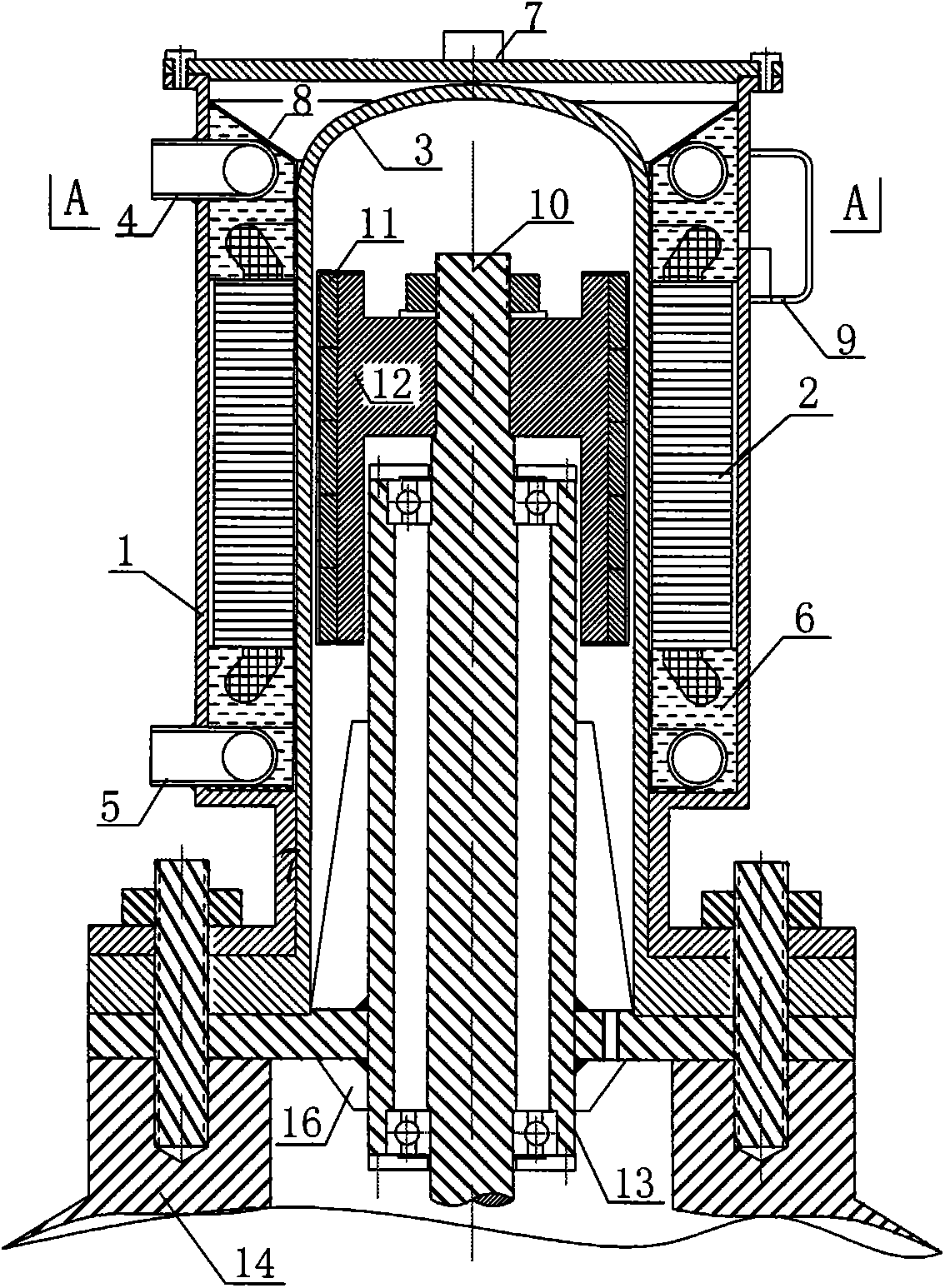

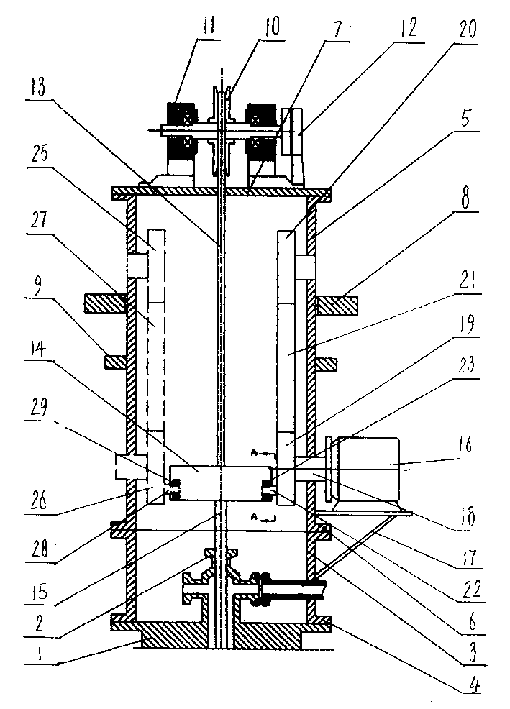

Telescopic gas soot blower

The invention provides a telescopic gas soot blower, which comprises a bracket system, a gas inlet system, a transmission system, a limit system and a soot blowing pipe component, wherein a driving chain wheel, a driven chain wheel, a small chain wheel, a chain, a carriage and an external soot blowing pipe of the transmission system form chain transmission; the chain is disconnected, and both ends of the chain are respectively connected with a sidewall board of the carriage; the external soot blowing pipe is arranged on the sidewall boards of the carriage through bearings; the small chain wheel, a worm wheel, a worm and the external soot blowing pipe of the transmission system form worm wheel and worm transmission; a limit switch of the limit system is arranged on a bracket board; a collision block is arranged on one sidewall board of the carriage; the external soot blowing pipe is sleeved on an internal soot blowing pipe; one end of the internal soot blowing pipe extends out of an opening end of the external soot blowing pipe to be connected with a gas inlet pipe; the internal soot blowing pipe is communicated with the external soot blowing pipe and a soot blowing nozzle on the external soot blowing pipe; and a soot blowing pipe sealing mechanism is arranged between the internal soot blowing pipe and the external soot blowing pipe. Because of few transmission parts of the soot blower, the transmission mechanism of the existing soot blower is prevented from being jammed, rusted and damaged during running.

Owner:CHINA PETROLEUM & CHEM CORP +1

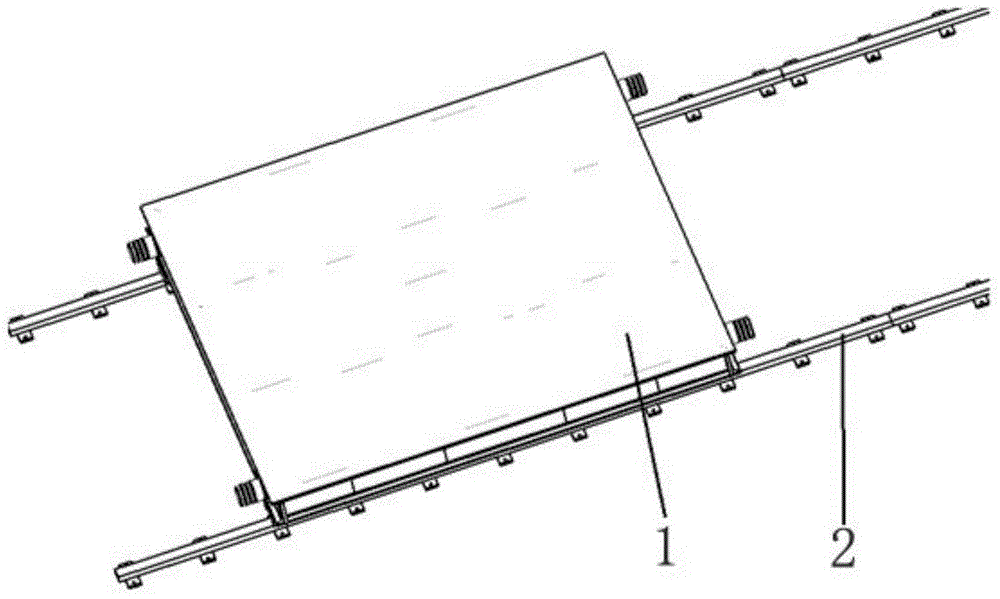

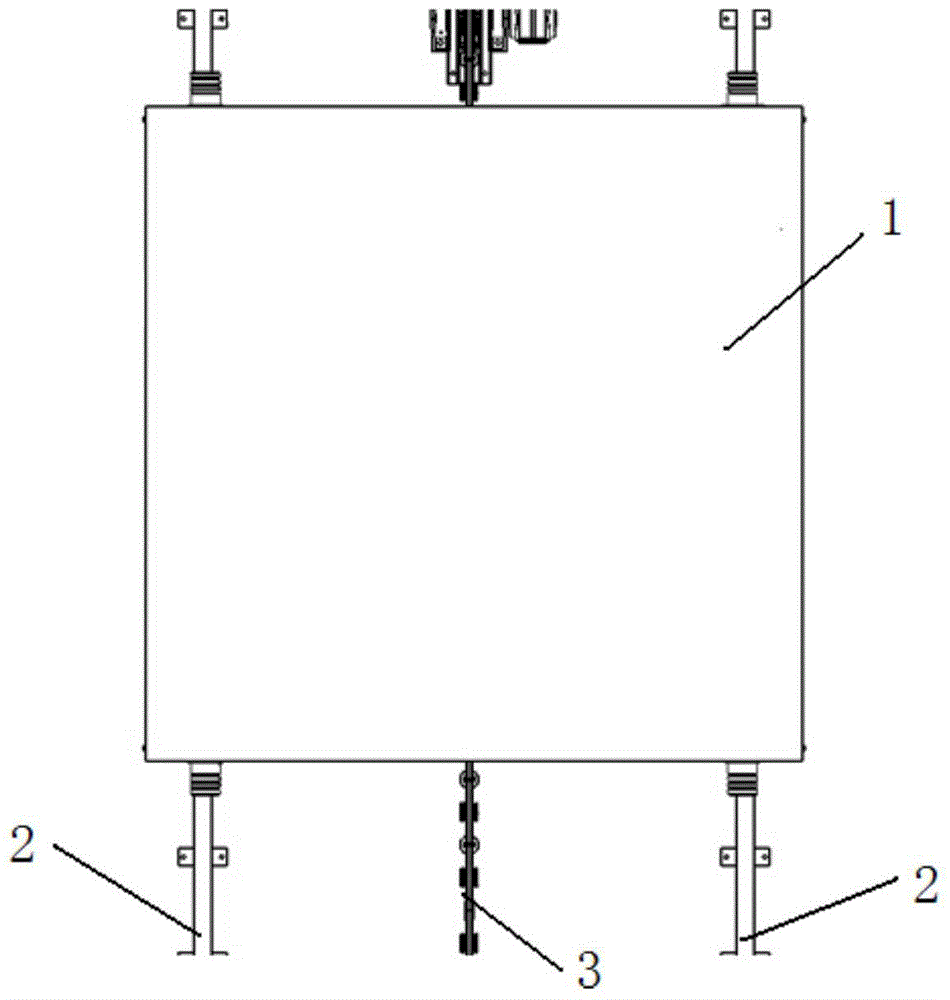

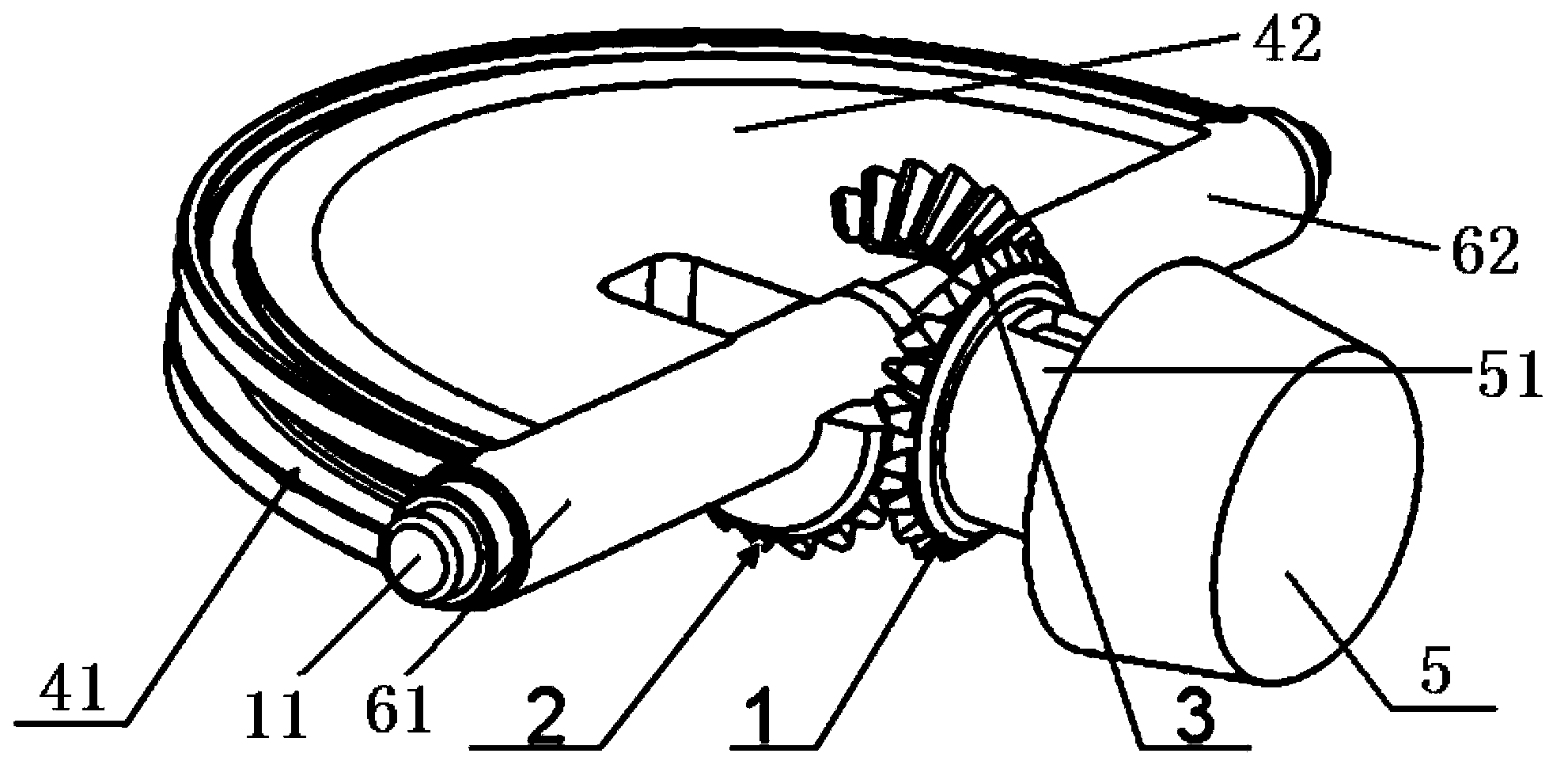

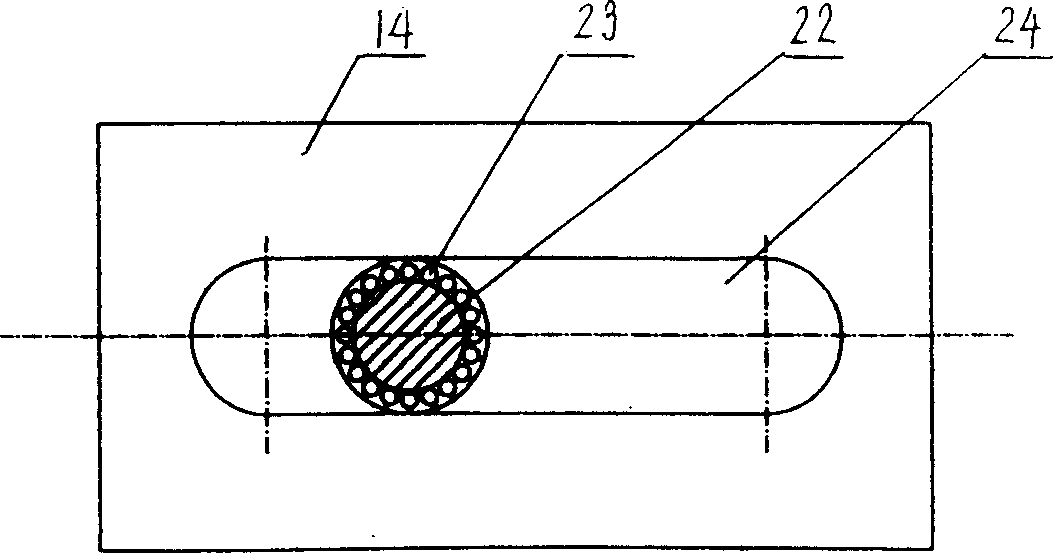

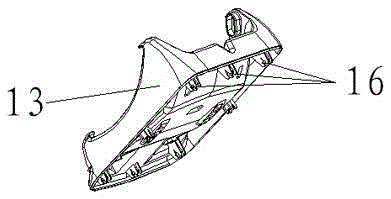

Membrane type material tensioning structure

InactiveCN101537942AEasy to sync and coordinateLess transmission partsWebs handlingEngineeringMembrane configuration

The invention relates to a membrane type material tensioning structure which can adjust tensile force effectively, is stable and comprises a supporting bracket. The main shaft of the supporting bracket is arranged on a plate type part, and the supporting bracket is provided with a tensioning roller. The membrane type material tensioning structure is characterized by comprising a damper-free cylinder which is arranged on a plate type part.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

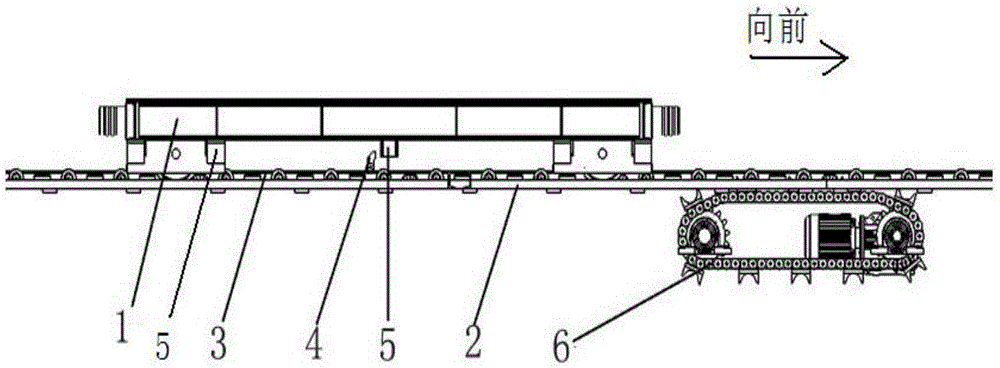

Reciprocating chain driving mechanism

ActiveCN104477589AShort drive lineLess transmission partsMechanical conveyorsReciprocating motionEngineering

Owner:XUZHOU CONSTR MACHINERY

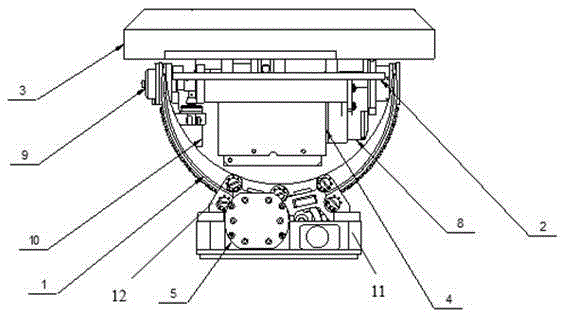

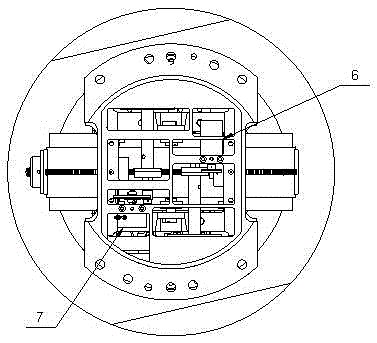

Miniature antenna servo apparatus

The invention discloses a miniature antenna servo apparatus. The miniature antenna servo apparatus comprises a pedestal, an orientation channel motor which is arranged on the pedestal, an orientation channel motor gear which is driven by the orientation channel motor, a pair of sector gears, an orientation channel and a pitching channel, wherein the pair of sector gears are arranged on the upper part of the pedestal and are meshed with the orientation channel motor gear; the orientation channel includes an orientation channel principal axis; the pitching channel includes a pitching channel principal axis which is perpendicular to the orientation channel principal axis; the pitching channel principal axis, the orientation channel principal axis and the pair of sector gears are connected as one body; and the orientation channel motor gear drives the sector gears to rotate so that the orientation channel principal axis and the pitching channel principal axis can also rotate around the hole axis at the upper part of the pedestal synchronously. The miniature antenna servo apparatus is simple in structure and is miniaturized, and has the advantages of being large in the installable detection assembly, being high in the bearable load moment of inertia, being able to realize the maximum compound angle limiting function, and being low in cost.

Owner:SHANGHAI RADIO EQUIP RES INST

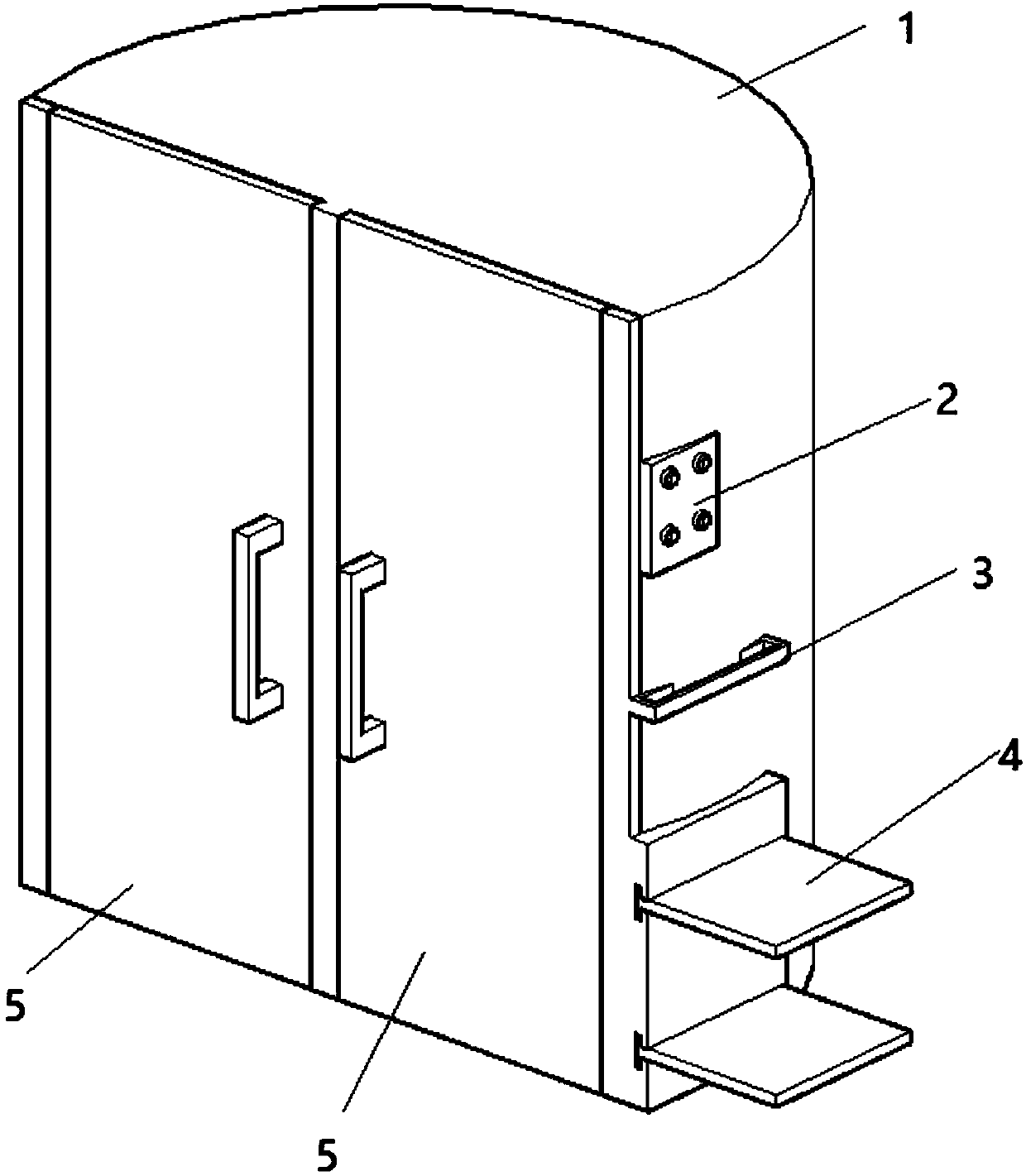

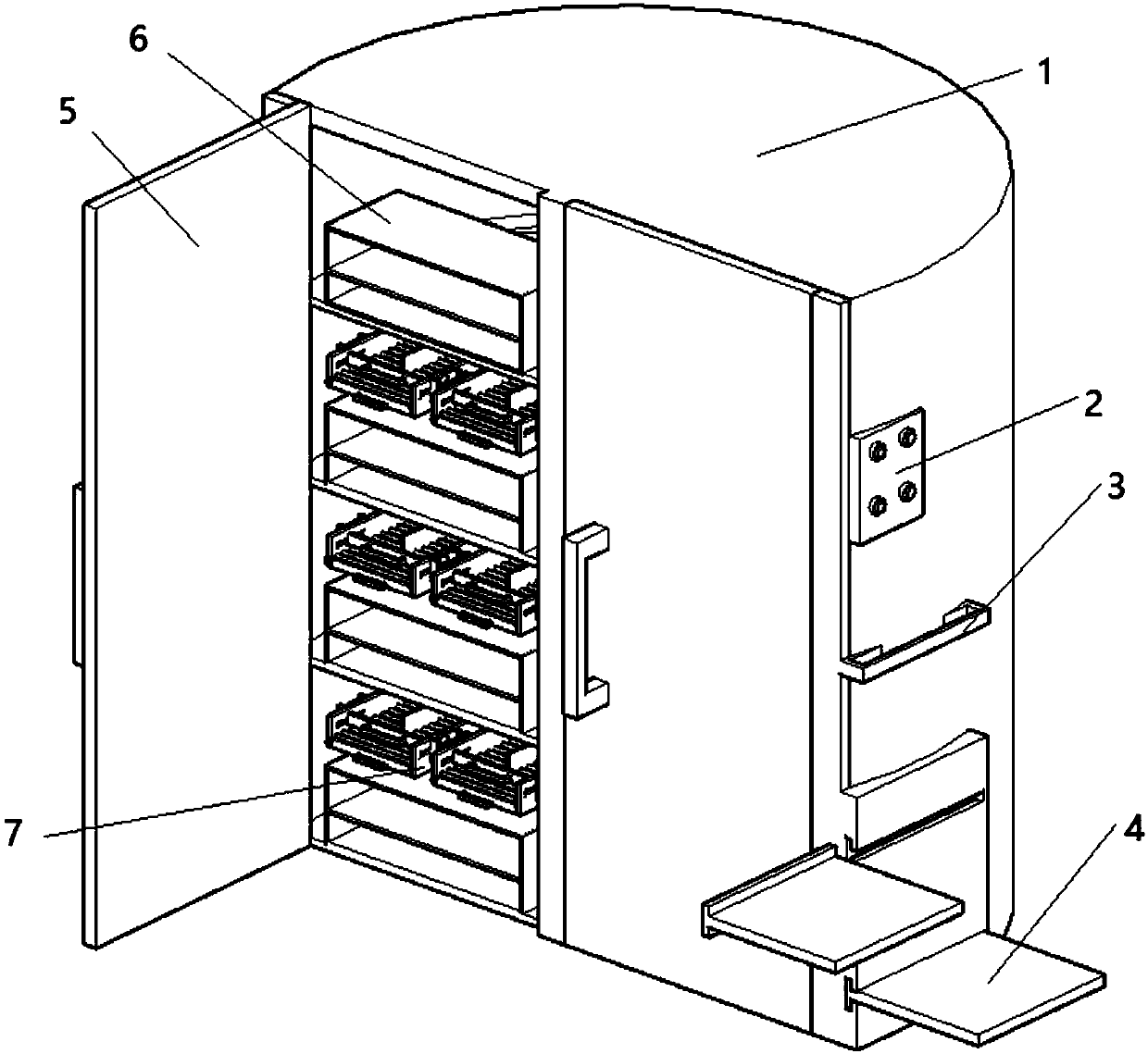

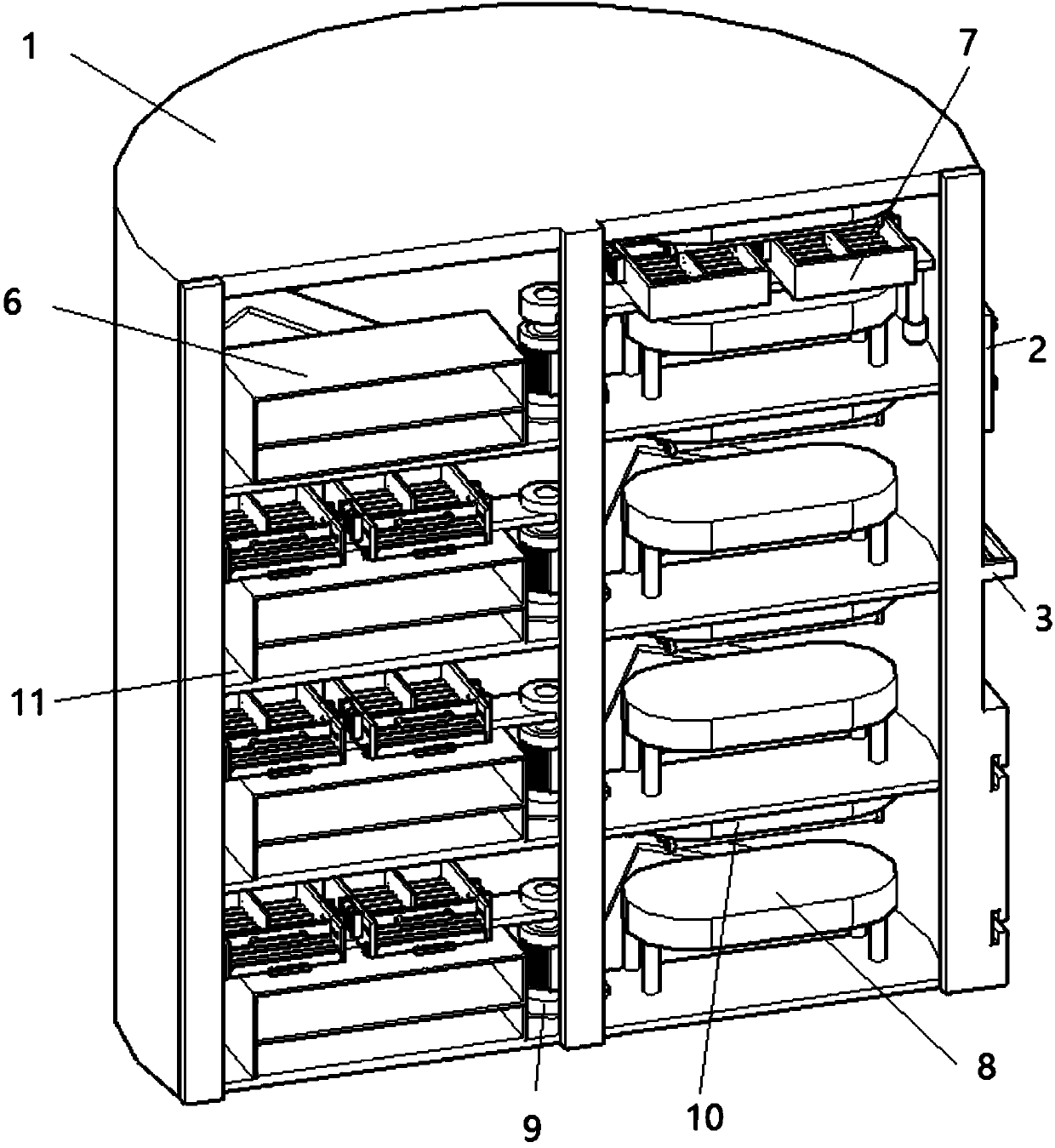

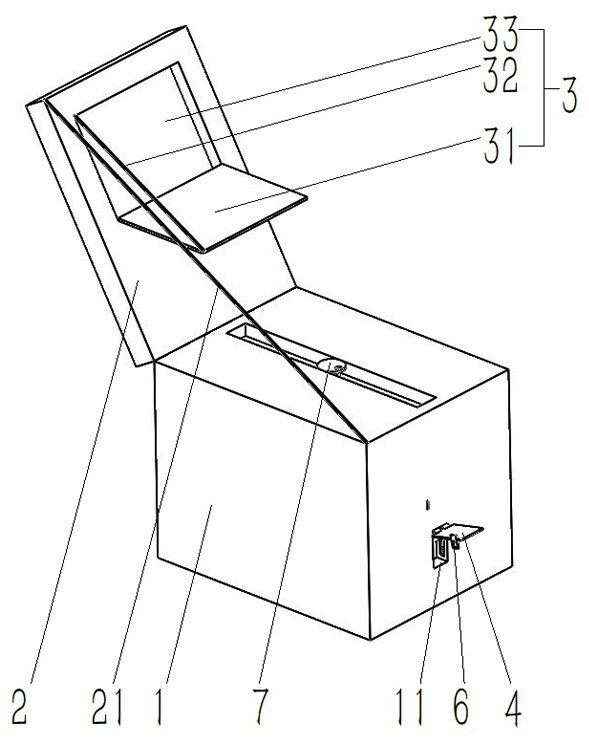

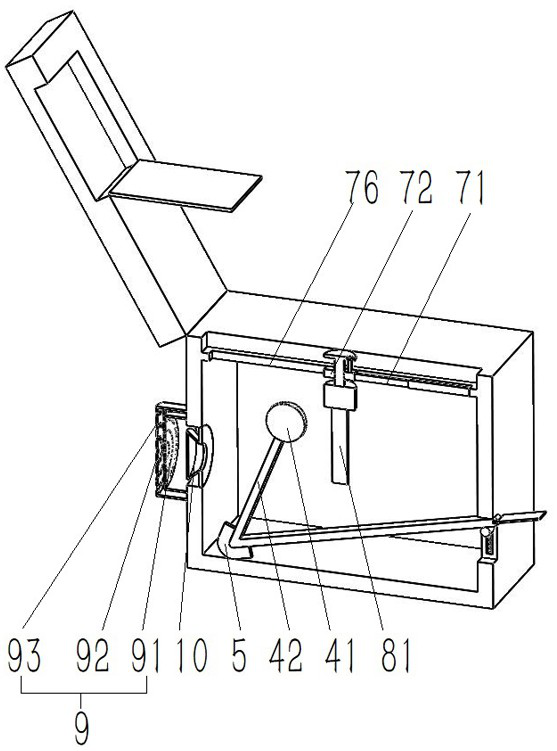

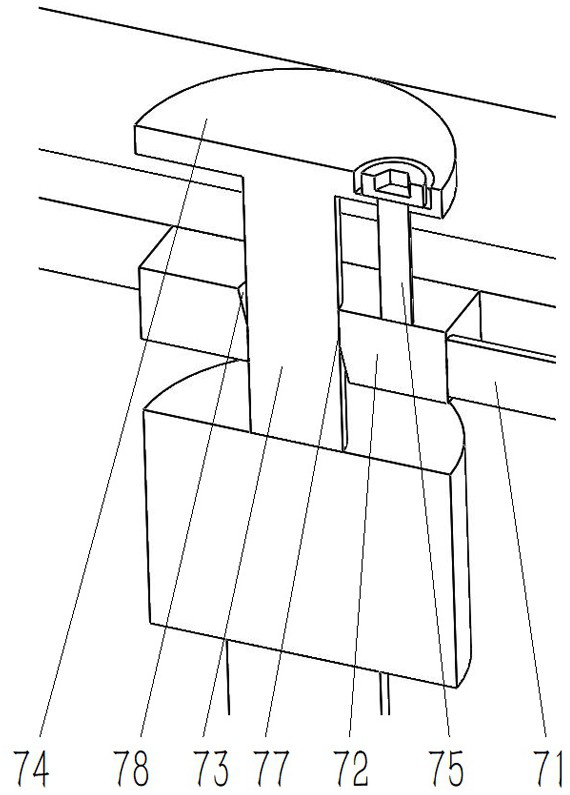

Household sterilization drying cabinet achieving full-automatic shoe storing

The invention provides a household automatic shoe sterilization and drying cabinet, which includes a sliding top plate, a heating oil tank, a servo motor, a second oil tank, a support mounting plate, a rotating support plate, a support shaft and an ultraviolet light tube. The shoe box There is a fixed plate protruding from the middle of the left and right side walls. The two fixed plates are vertically welded to support two telescopic rods, and the tops of the two telescopic rods are welded and fixed with the sliding top plate, and then slide The top plate and the fixing plate are telescopically connected together; the middle part of the rear end side wall of the shoe box extends to the inner side of the shoe box with a spacer plate, which is welded and supported on the shoe bracket, and Its front end leans against the inner side of the pressing plate; five ultraviolet light tubes are suspended in an equidistant arrangement at the bottom of the second oil tank. The setting of the positioning bolts in the present invention, the positioning bolts can tighten and fix the tray, so as to prevent the tray from sliding and falling off from the inside of the sliding cavity during the process of following the rotation of the rotating support plate.

Owner:闻玉华

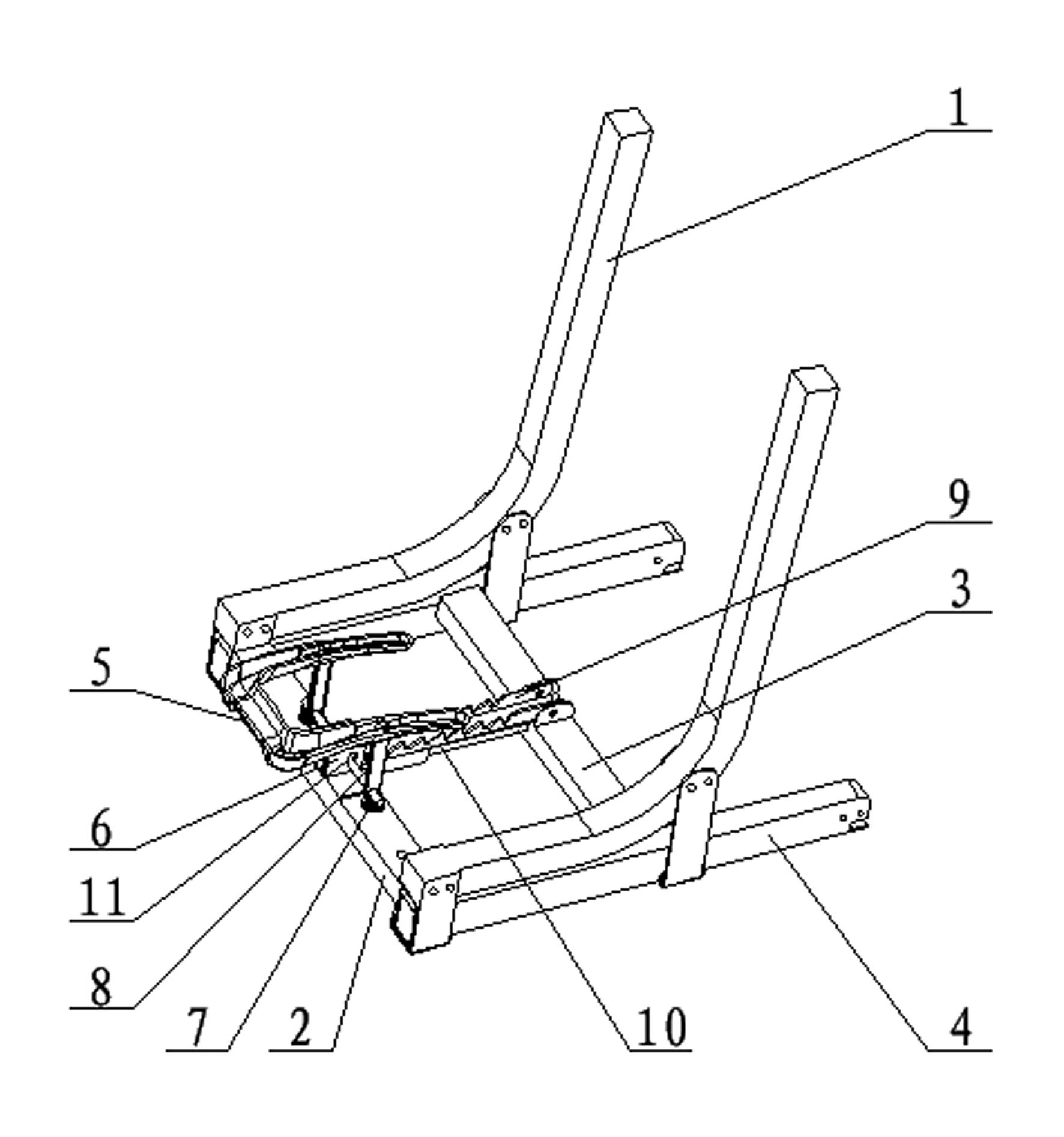

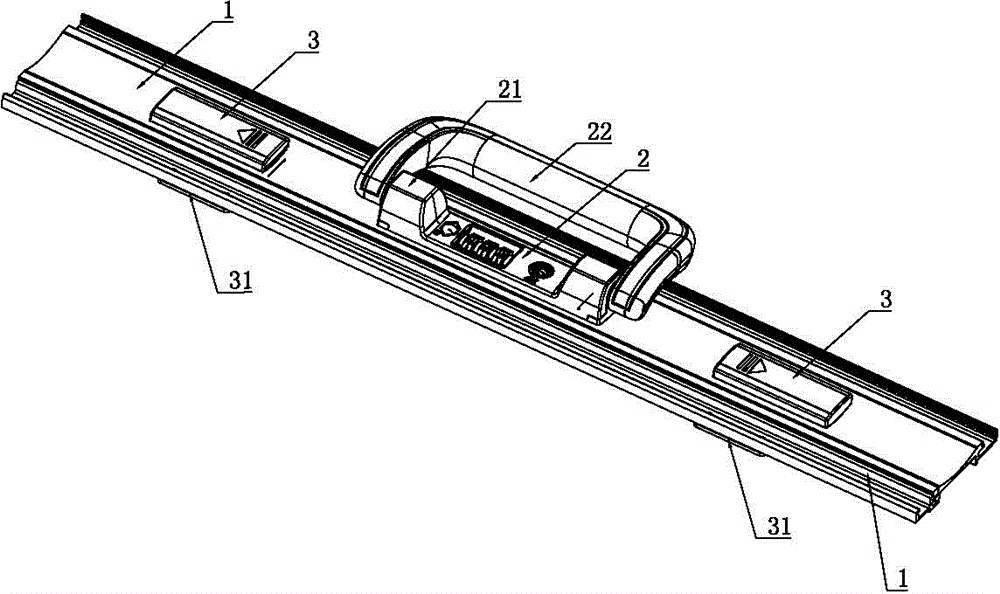

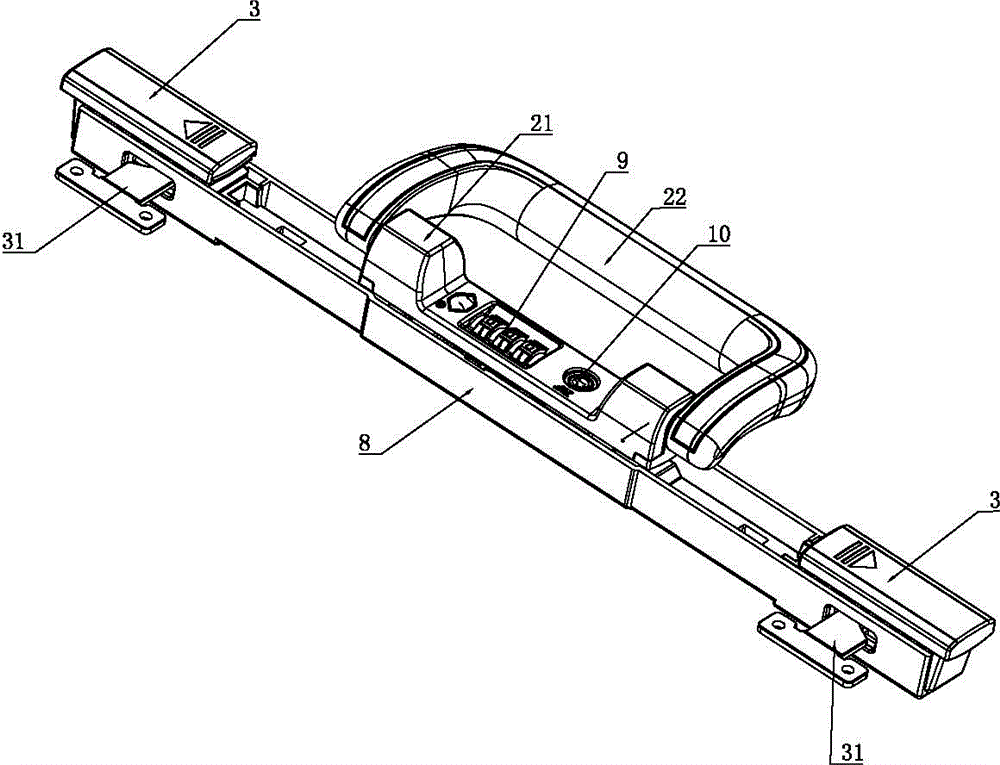

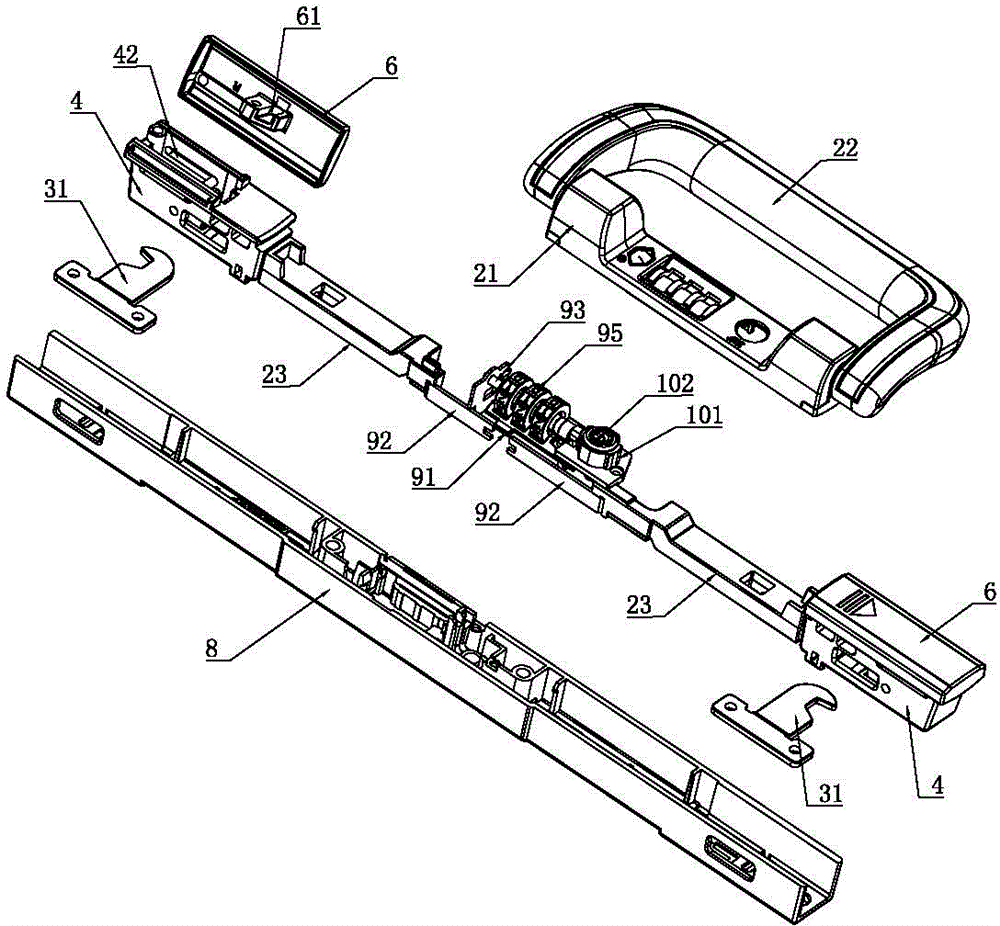

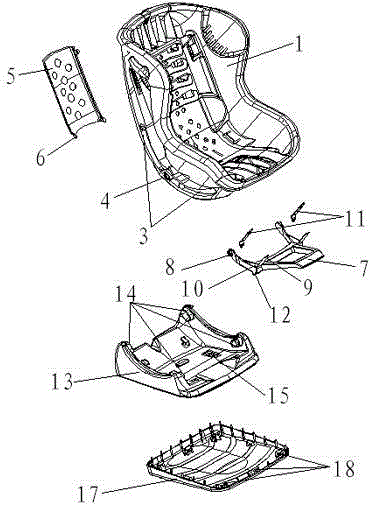

Seat-adjustable ISOFIX (International Standards Organisation FIX) system of vehicle-mounted children safety-restraint system

The invention relates to a seat-adjustable ISOFIX (International Standards Organisation FIX) system of vehicle-mounted children safety-restraint system. The seat-adjustable ISOFIX system comprises a base frame, a FIX connector, an adjusting stirring plate and an adjusting mechanism. The adjusting stirring plate is connected with a FIX connector supported on the bottom of the base frame in a sliding way through an adjusting mechanism; the adjusting mechanism comprises a front support plate, a rear sliding plate, a gear shifting slide gear, a pneumatic spring, a gear locking post and a gear locking plate, wherein the front support plate is fixedly connected with the front end of the base frame, the gear locking plate is arranged on the front support plate, one end of the gear shifting slide gear is supported in the shift locking plate and is in a state of sliding along a front-to-back direction of the base frame, the other end of the gear shifting slide gear is connected with the FIX connector via the rear sliding plate, the front support plate and the rear sliding plate are connected by the pneumatic spring, the lower end of the adjusting stirring plate is connected to the front support plate via the spring, and the adjustment stirring plate is provided with the gear locking post corresponding to the notch of the shifting slide gear. The seat is adjustably mounted and fixed, and the seat is simple and compact in structure, less in transmission components, steadily locked and time-saving and labor-saving in operation.

Owner:JIANGSU LUCKY BABY SAFETY SYST MFG

Side lock for coded lock and coded lock

ActiveCN104912395AEasy to openSimple structurePuzzle locksPermutation locksElectrical and Electronics engineeringCipher

The invention relates to the technical field of locks, in particular to a side lock for a coded lock and the coded lock. The coded lock comprises a central lock and the side lock. The side lock comprises a lock shell, a lock hook, a lock block and a push brake, wherein the lock block is provided with a first protruding part buckled with the lock hook, a second protruding part in sliding connection with the push brake and a third protruding part connected with the central lock. The lock block integrates multiple transmission and control relationships, a transmission component of the side block is omitted, and the transmission relationship is simplified, so that the transmission and control performance is more stable and reliable. The side lock is simpler and more compact in structure, and convenient to assemble. Compared with a brake part with one turnup end in the prior art, the push brake is convenient to operate, is not prone to being damaged and will not scratch clothes.

Owner:YIFENG MFG

Industrial mechanical arm

InactiveCN105500342ASimple structureEasy to grabProgramme-controlled manipulatorReduction driveDrive shaft

The invention discloses an industrial mechanical arm and belongs to the field of mechanical arms. The mechanical arm comprises a base and further comprises a stepping motor, a speed reducer and a connecting seat. The stepping motor is connected with the speed reducer, the stepping motor and the speed reducer are arranged on the base, the stepping motor is connected with the connecting seat through a rotating shaft, a shell is arranged on the periphery of the rotating shaft, the speed reducer drives the rotating shaft to rotate, the rotating shaft drives the connecting seat to rotate, the motor is arranged on the connecting seat and connected with an arm support through a transmission shaft, and the tail end of the arm support is connected with a mechanical arm body. The industrial mechanical arm is simple in structure, all power is provided by the motor, the number of transmission components is small, maintenance cost is small, and the industrial mechanical arm is capable of rotating by 360 degrees, high in degree of freedom and capable of conveniently clamping cargos.

Owner:WUHU QIU HUA INSULATION MATERIALS

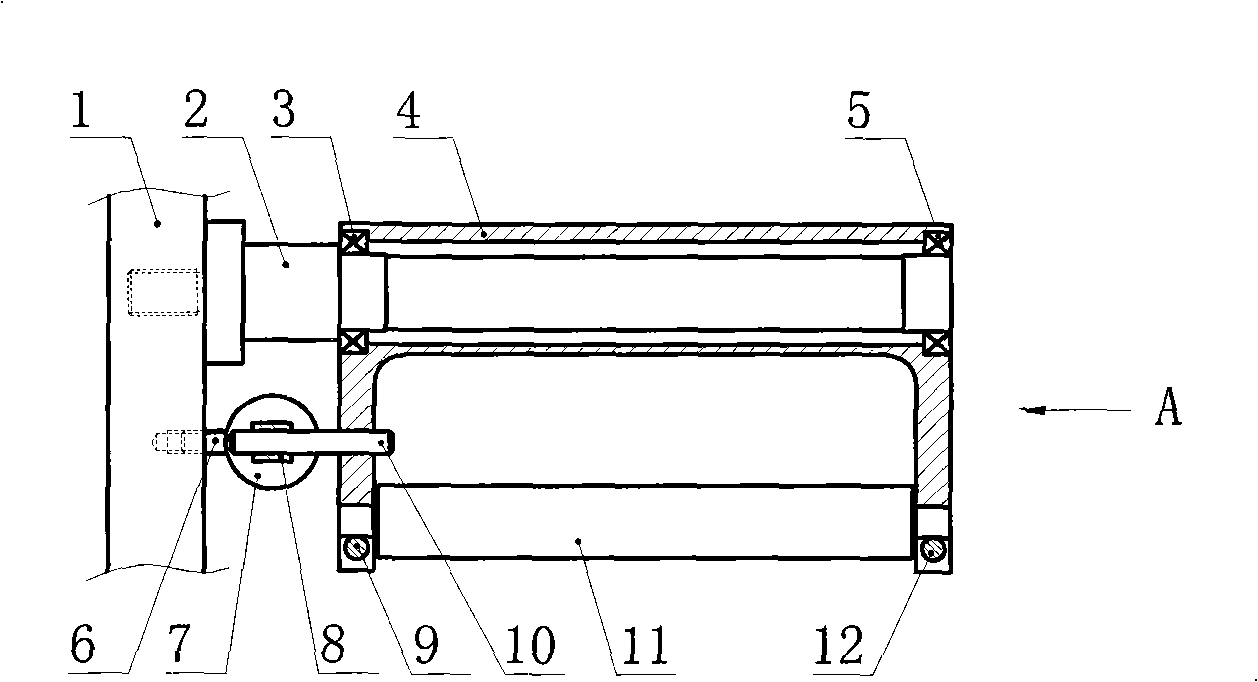

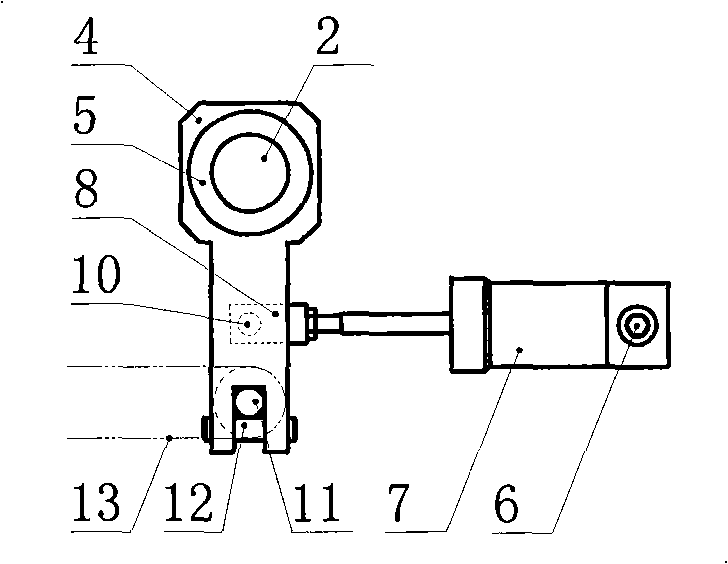

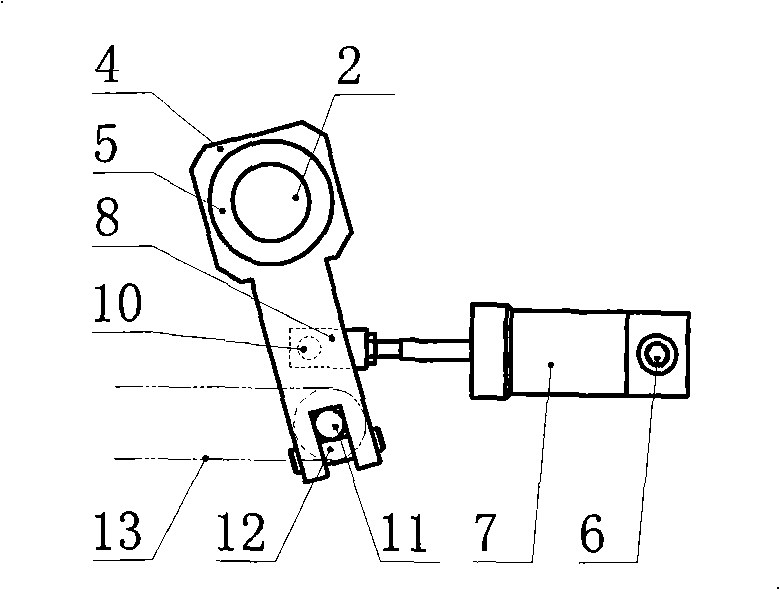

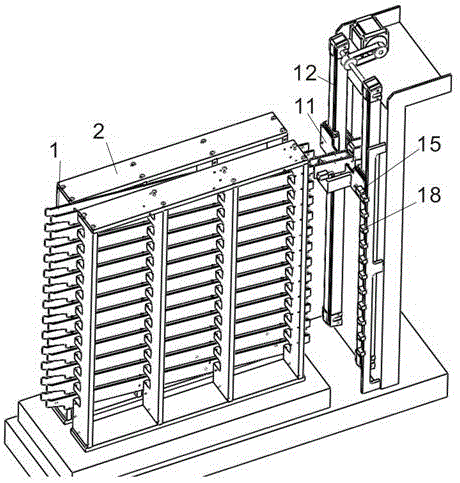

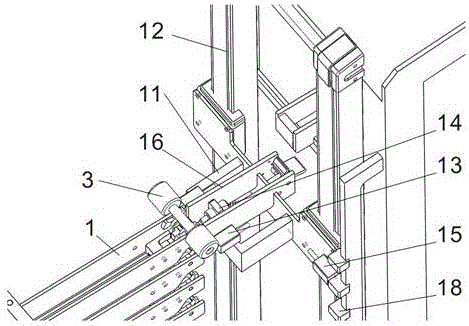

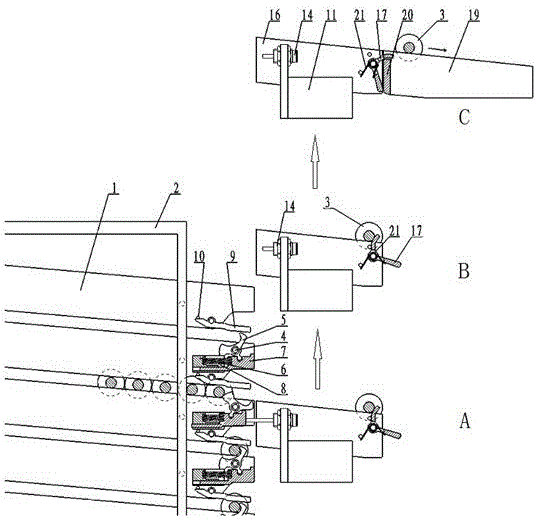

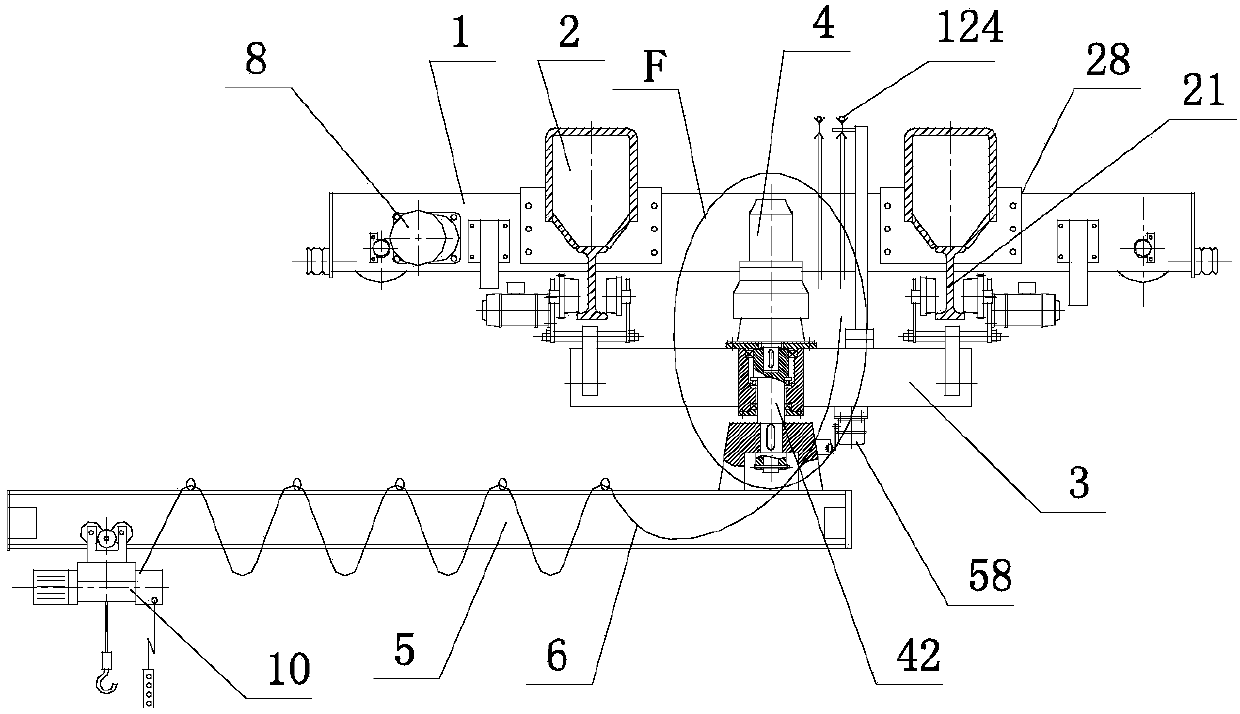

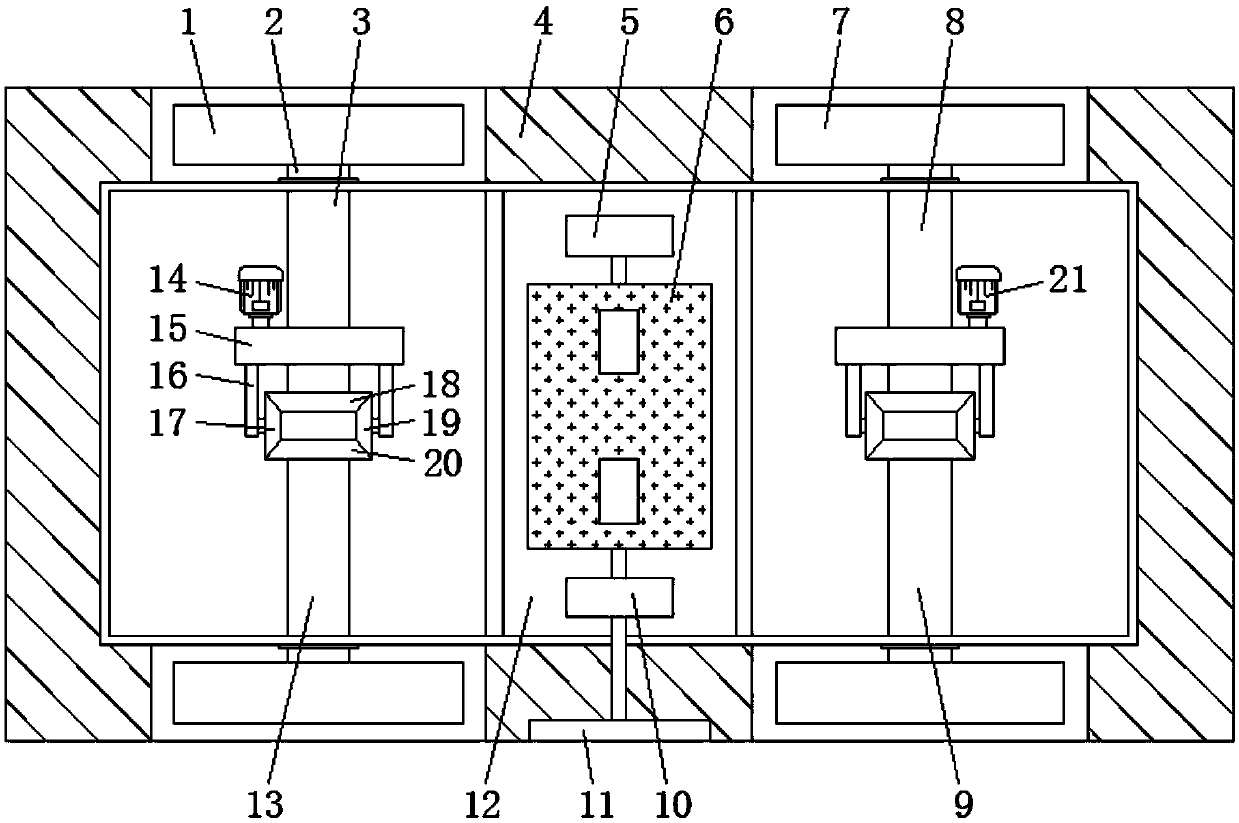

Automatic feeding device for spinning roller grinding machine

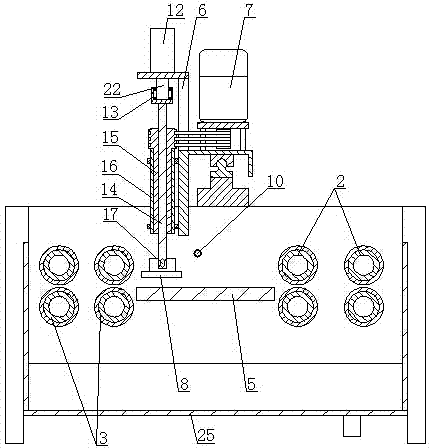

InactiveCN106276151ASimple structureLess transmission partsConveyorsRevolution surface grinding machinesVehicle frameEngineering

The invention discloses an automatic feeding device for a spinning roller grinding machine. The automatic feeding device comprises a multi-roller storage cabin unit, a picking dolly unit and a discharging roller unit, wherein the multi-roller storage cabin unit comprises a storage roller plate set, a roller plate bearing frame and a baffle transferring mechanism; the storage roller plate set is composed of a plurality of storage roller plates which are vertically and parallelly arranged in the roller plate bearing frame in an inclined manner; the baffle transferring mechanism is arranged at the outlet of each storage roller plate; the picking dolly unit comprises a picking dolly frame, a material moving roller, a rail and a sensing detection unit; the rail is vertically mounted on one side of the discharging roller unit; the picking dolly frame is arranged on the rail and is capable of moving up and down along the rail; the picking dolly frame and the rail are both provided with sensing detection units; the material moving roller is arranged on the picking dolly frame; the roller surface of the material moving roller is inclined; the discharging roller unit comprises a discharging roller. The automatic feeding device has the beneficial effects that the structure is simple, the transmission components are few, the efficiency is greatly increased, the device has few parts, the mounting is convenient and the cost is low.

Owner:无锡立达纺织机械器材有限公司

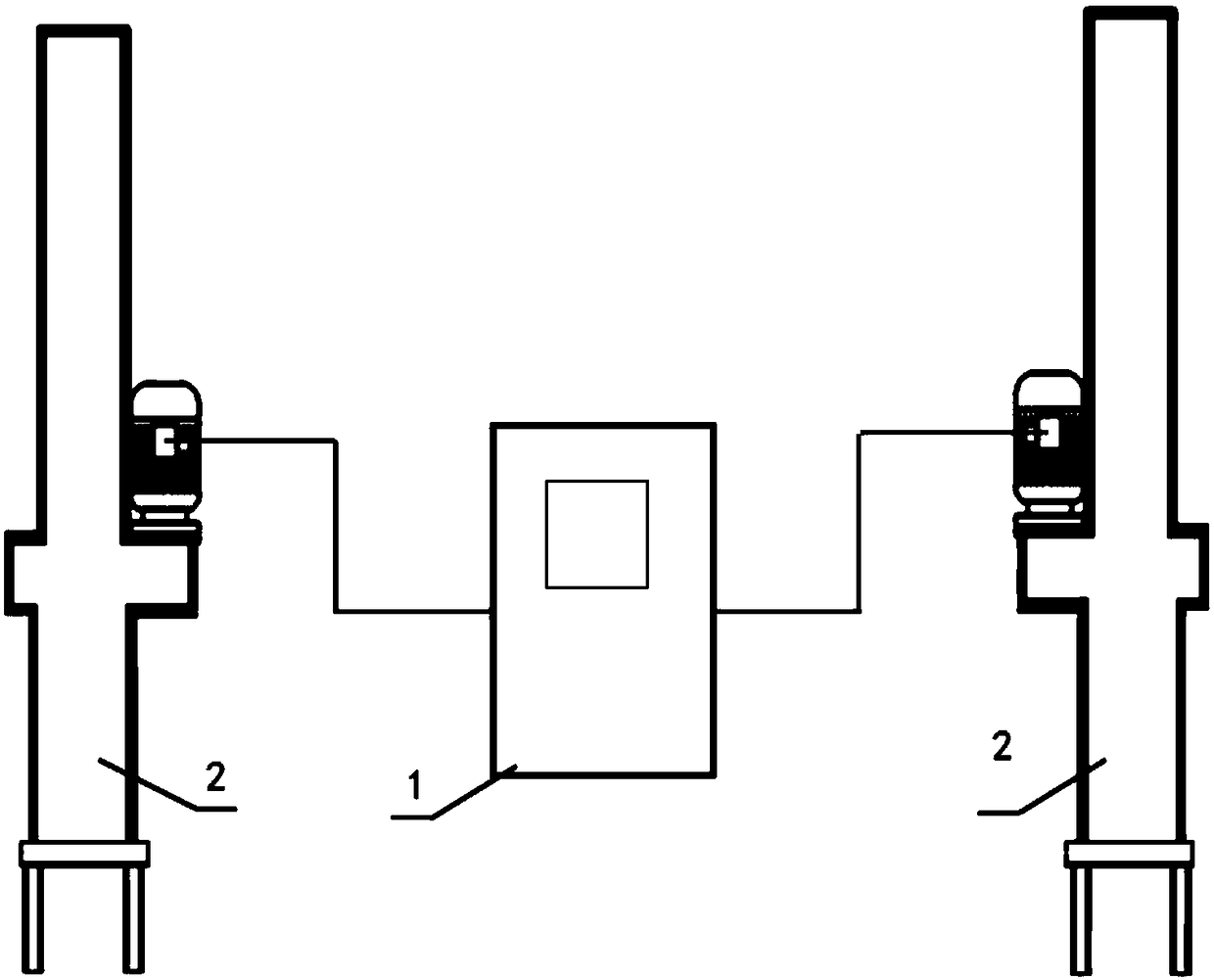

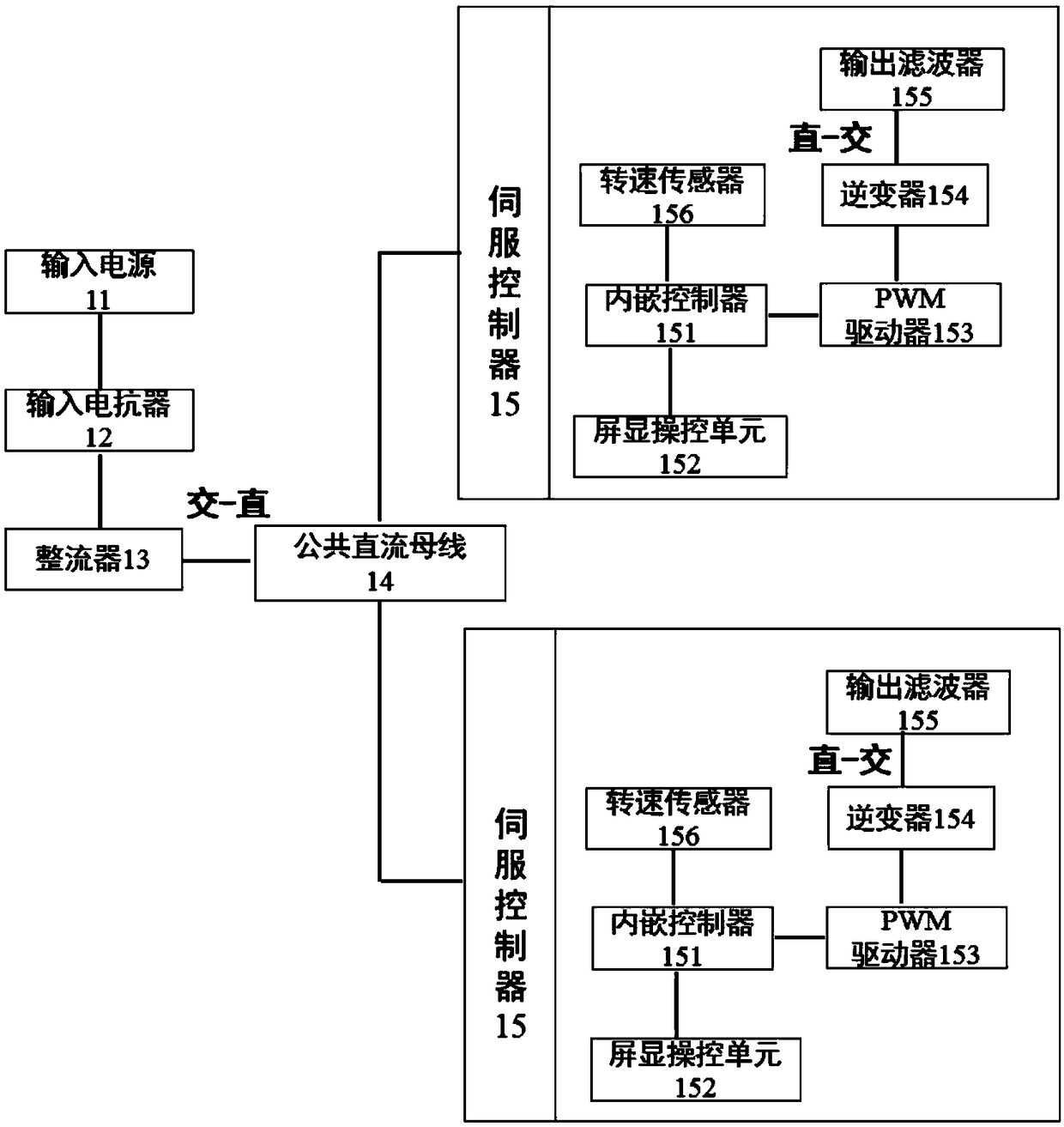

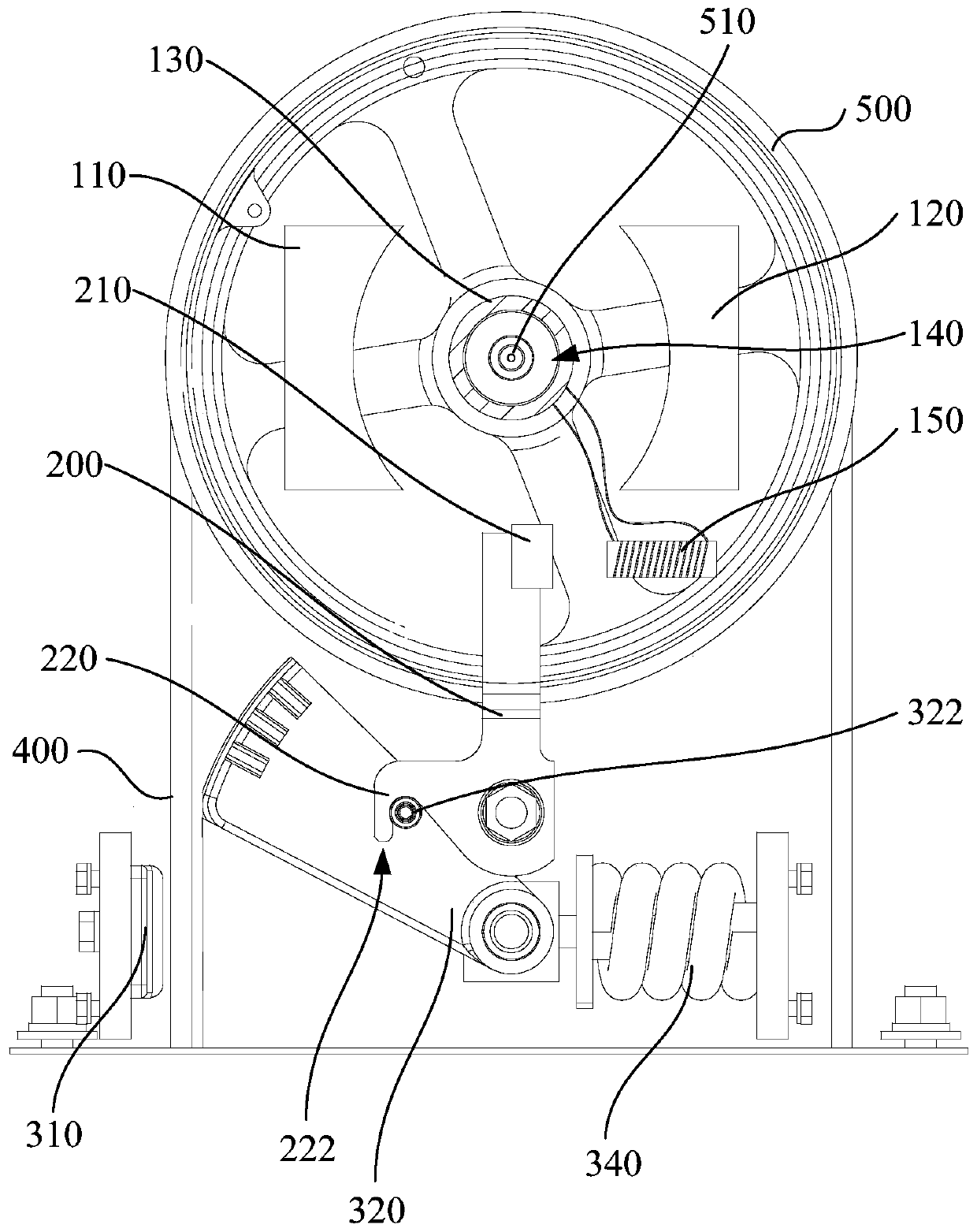

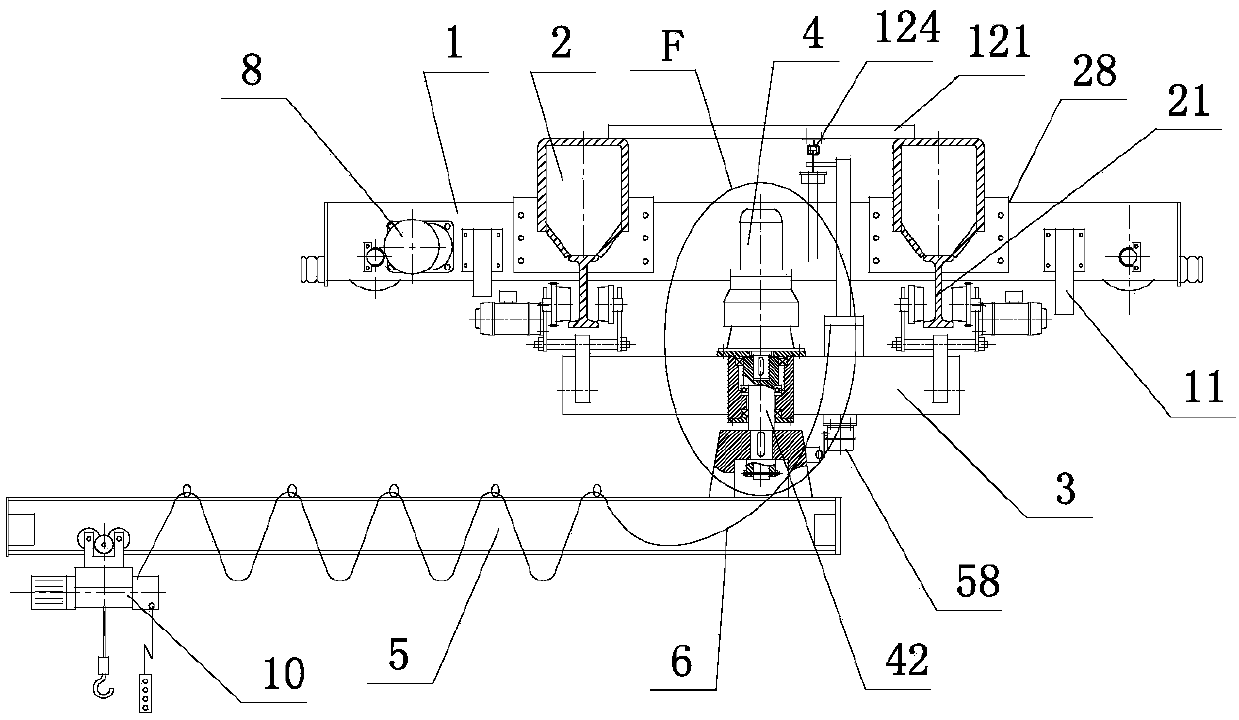

Double-well mutually balanced type direct drive oil pumping machine control system and oil pumping device

InactiveCN109488581ASimple structureLess transmission partsFlexible member pumpsFluid removalMachine controlControl system

The invention relates to the technical field of the oil extraction project, and particularly belongs to a double-well mutually balanced type direct drive oil pumping machine control system and an oilpumping device used in the oil field. The problems that a tower type direct drive oil pumping machine is complex in structure, short in integral service life and poor in safety, an oil pumping machinefoundation needs to be prefabricated, and reverse power generation cannot be effectively utilized are solved. The oil pumping device is composed of one direct drive oil pumping machine control system(1) and two direct drive oil pumping machines (2). The double-well mutually balanced type direct drive oil pumping machine control system and the oil pumping device have the advantages that the structure is simple, few transmission components are adopted, transportation and installation are easy, oil pumping machine foundation prefabrication is not needed, the reverse power generation in the oilpumping machine running process can be effectively utilized, the running life of the system can be prolonged, energy consumption is reduced, equipment reliability is high, and the running cost is low.

Owner:PETROCHINA CO LTD +1

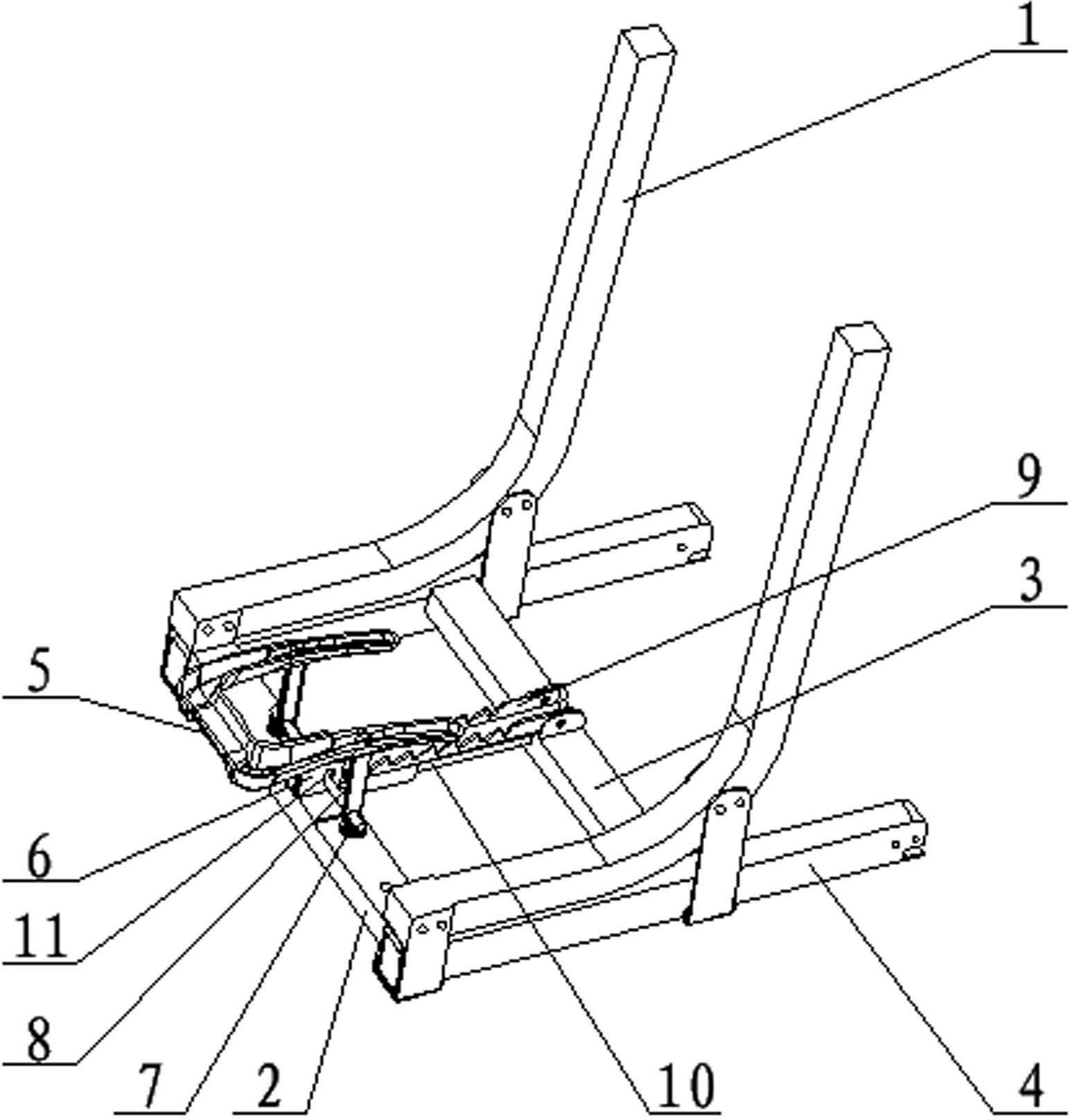

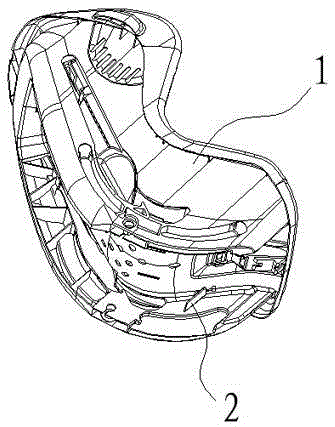

Automobile safety constraint system adjustable ISOFIX system seat in child car

ActiveCN102627079ARealize adjustable installation and fixationSimple structureChild seatsEngineeringAutomobile safety

The invention relates to an automobile safety constraint system adjustable ISOFIX system seat in a child car. The seat comprises a base, a FIX joint, an adjusting button, and an adjusting mechanism. The adjusting mechanism comprises a transmission rod, a pin support plate, a pin roll, a locking rod, a locking shaft, a tooth bar, and a pneumatic spring. The pin support plate is fixedly supported by a front frame and a crossbeam. The pin roll is arranged on the pin support plate. The adjusting button is fixedly connected to the pin roll through the transmission rod. The pin roll penetrates and is connected with one end of the locking rod. The other end of the locking rod is provided with the locking shaft. An offsetting spring is arranged on the other end of the locking shaft. The tooth bar is fixedly connected to a transmission beam. The tooth mouth of the tooth bar is set corresponding to the locking shaft to present a locking state or a disengaging state. The pneumatic spring is fixed between the transmission beam and the crossbeam or the pin support plate. The adjustable mounting and fixing of the seat are realized by using the adjusting button to control the pneumatic spring such that the FIX joint snaps into or disengages from an automobile FIX joint in the disengaging state of the tooth bar and the locking shaft. The seat has a simple and compact overall structure, and few transmission parts, and is stable in locking, and timesaving and laborsaving in operation.

Owner:JIANGSU LUCKY BABY SAFETY SYST MFG

Lifting equipment, speed limiting device and triggering mechanism

InactiveCN111532932AImprove securityLess transmission partsElevatorsHoisting equipmentsMagnetic polesElectrical connection

The invention discloses lifting equipment, a speed limiting device and a triggering mechanism. The triggering mechanism comprises a first magnetic pole, a second magnetic pole, a conductive part, a transmission unit and a coil, the second magnetic pole and the first magnetic pole are separated and arranged to form a magnetic field, the conductive part is movably arranged, and the conductive part comprises a first end and a second end; the transmission unit comprises a connecting part used for being in fixed transmission connection with a rotating shaft and is used for driving the conductive part to cut the magnetic field, or the transmission unit is used for driving the first magnetic pole and the second magnetic pole to move and cutting the magnetic field by the conductive part; and the coil comprises a first wiring end electrically connected with the first end and a second wiring end electrically connected with the second end. The triggering mechanism can directly utilize the runningspeed of a lift car to carry out triggering control, and the sensitivity is higher. The triggering mechanism is adopted in the speed limiting device, the number of transmission parts is small, and the sensitivity is further improved under the condition that the reliability is guaranteed. A speed limiter is applied to the lifting equipment, so that the operation safety of the lift car is favorablyimproved.

Owner:HITACHI ELEVATOR CHINA

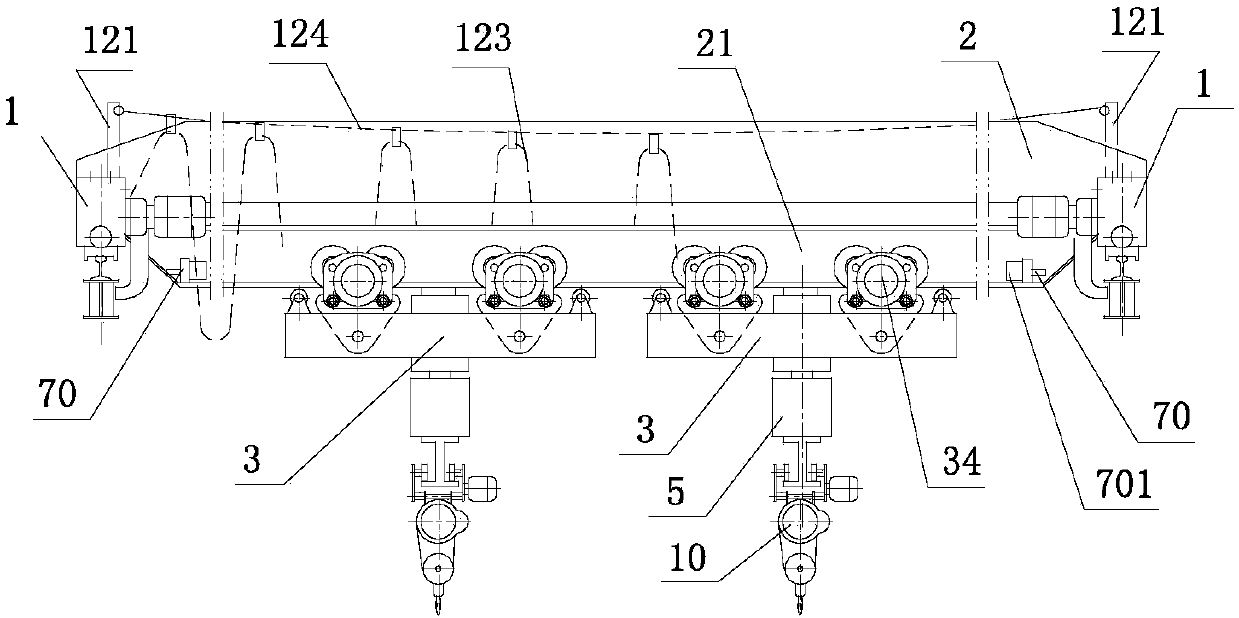

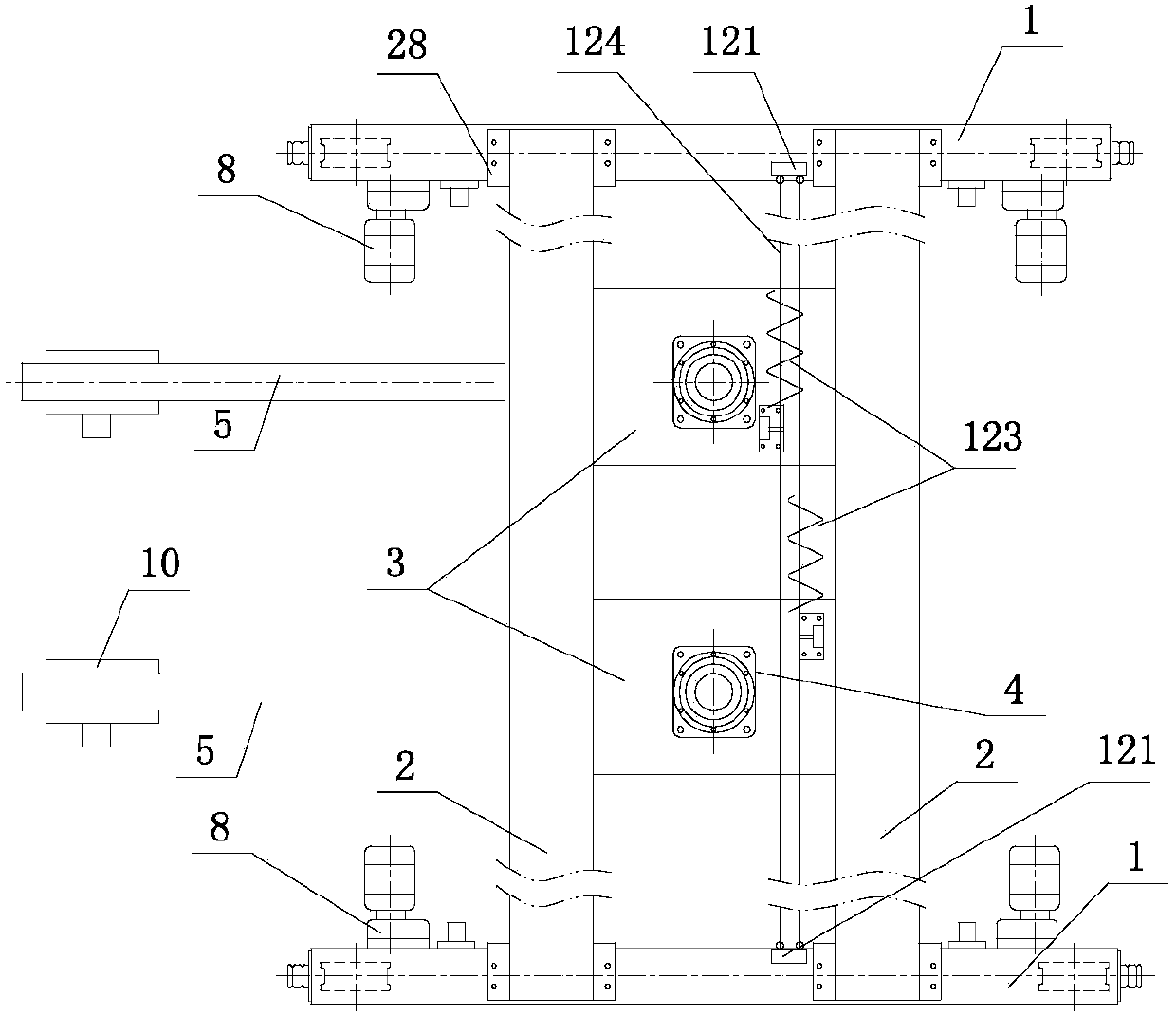

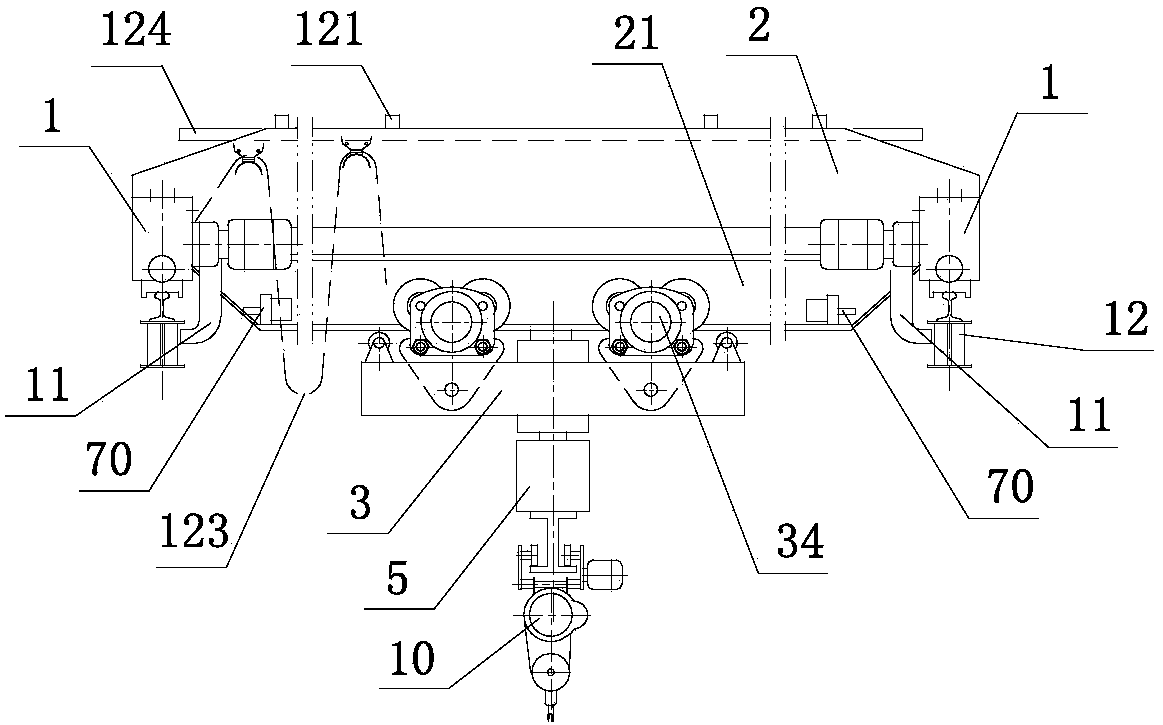

Bridge type cantilever crane with two suspended trolleys

InactiveCN107867646AImprove efficiencyConvenient supportingTravelling cranesTravelling gearCantilevered beamBogie

The application discloses a bridge-type cantilever crane with two suspended trolleys, including a double-girder bridge; the double-girder bridge includes an end beam and a main beam; the end beam is provided with a cart running device; the main beam A rail is arranged below; two suspension trolleys are connected on the two rails and can run along the rails; a rotation mechanism is arranged on the suspension trolley; the boom shaft in the rotation mechanism is connected with the cantilever member; the A rotation limiting device is arranged between the cantilever member and the suspension trolley; an electric hoist is installed on the cantilever member, and the electric hoist can move back and forth horizontally along the cantilever beam; the cantilever beam is under the main beam and can rotate; the double-girder bridge An electrical pick-up frame is arranged on the end beam, two steel cable rails are connected between the two electrical pick-up frames, and the hanging cables on the two steel cable rails are respectively electrically connected with the two suspension trolleys.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

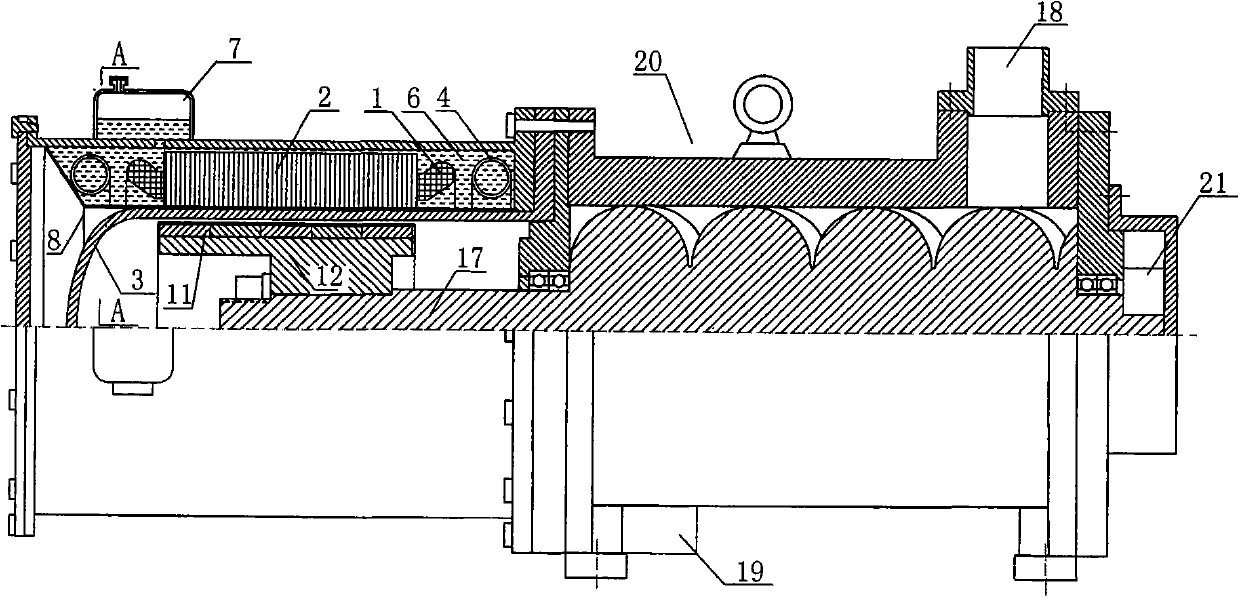

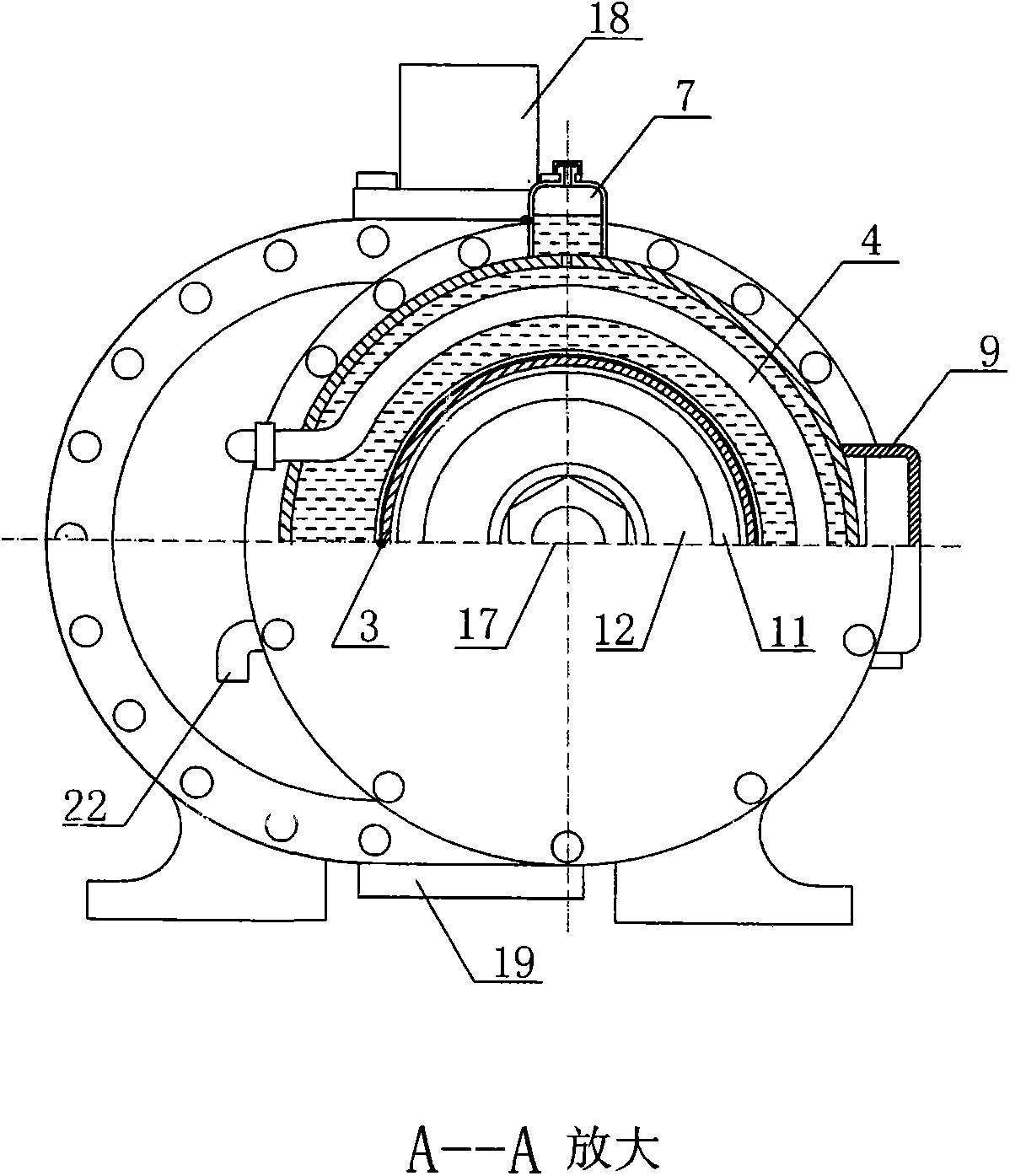

Internal cooling motor system body with pressure resistance cover body

InactiveCN103401352ASolve the sealing problemSolve the cooling effectPrevention/reducing eddy-current losses in winding headsMechanical energy handlingBrushless motorsEngineering

The invention provides an internal cooling motor system body with a pressure resistance cover body, and belongs to a motor in a special structure. The pressure resistance cover body is arranged among a motor rotor, an iron core and a coil, the iron core and the coil parts of the motor stator are arranged beyond the pressure of the pressure resistance cover body, the rotor part is arranged in the pressure resistance cover body, and the magnetic field of the motor stator is utilized for driving the motor rotor. Through the technical scheme, the mechanical transmission problem inside and outside pressure containers of large-size refrigerators, reaction kettles and the like is preferably solved. In order to solve the motor coil heating problem, a mode of wetting the coil by oil and adopting a built-in cooling water pipe in the oil is adopted, and a brushless motor structure is adopted in the technology.

Owner:李少龙

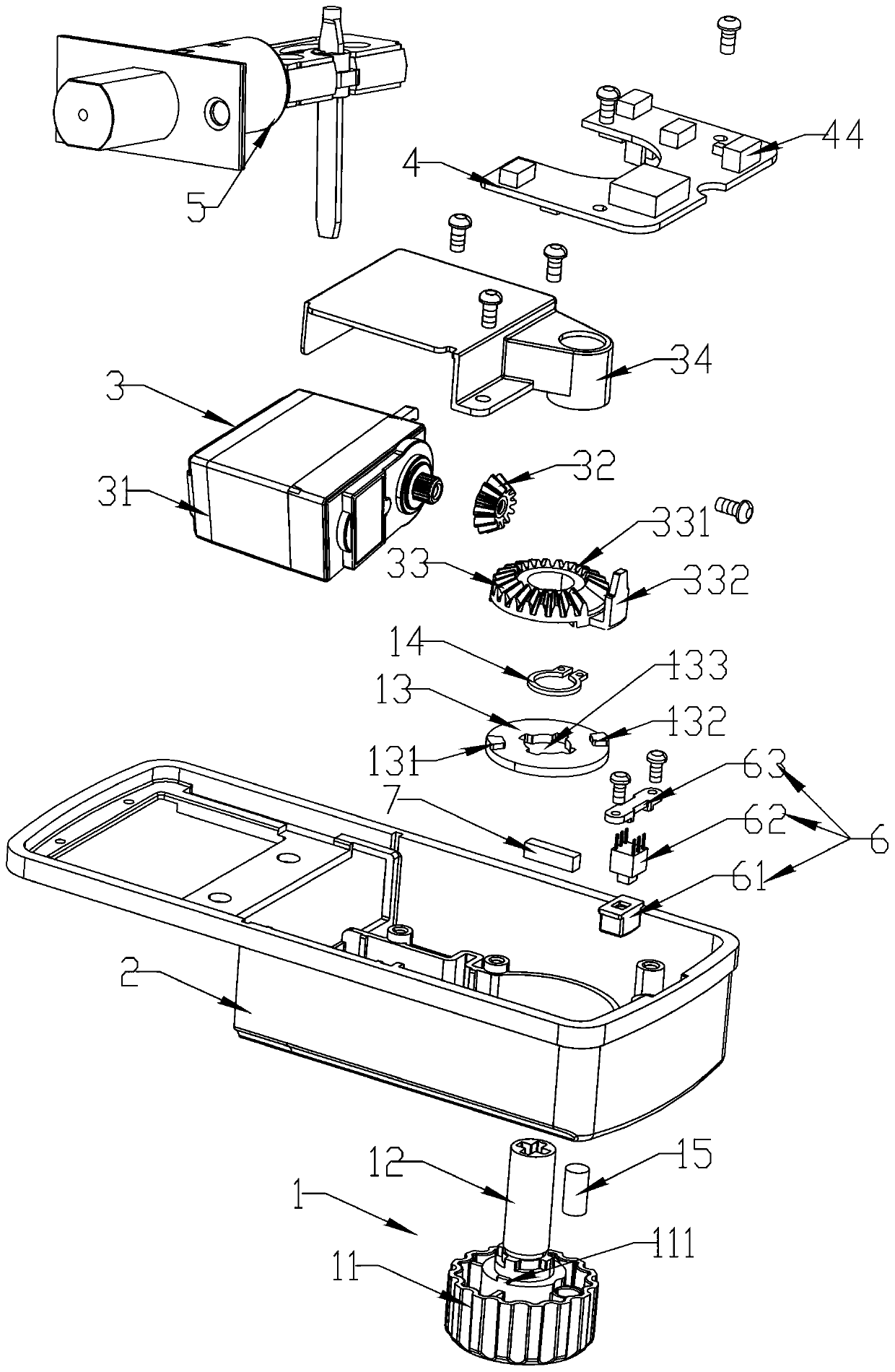

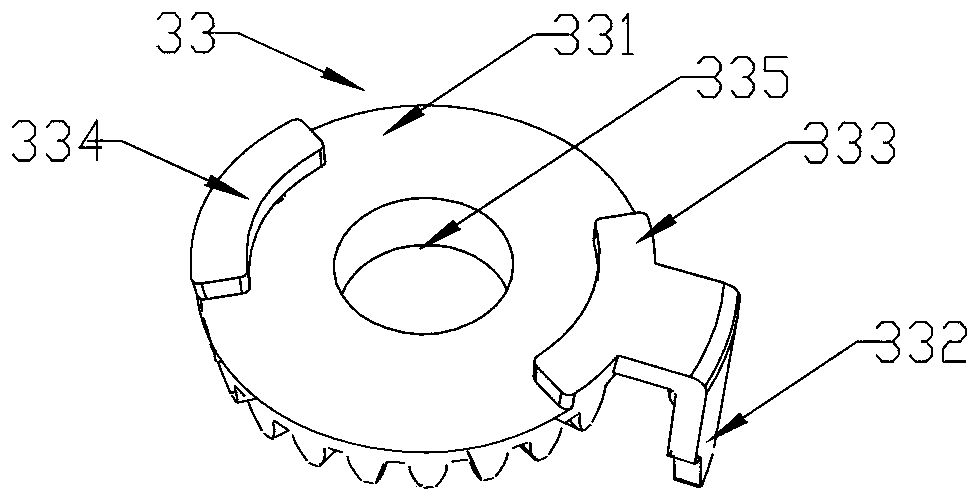

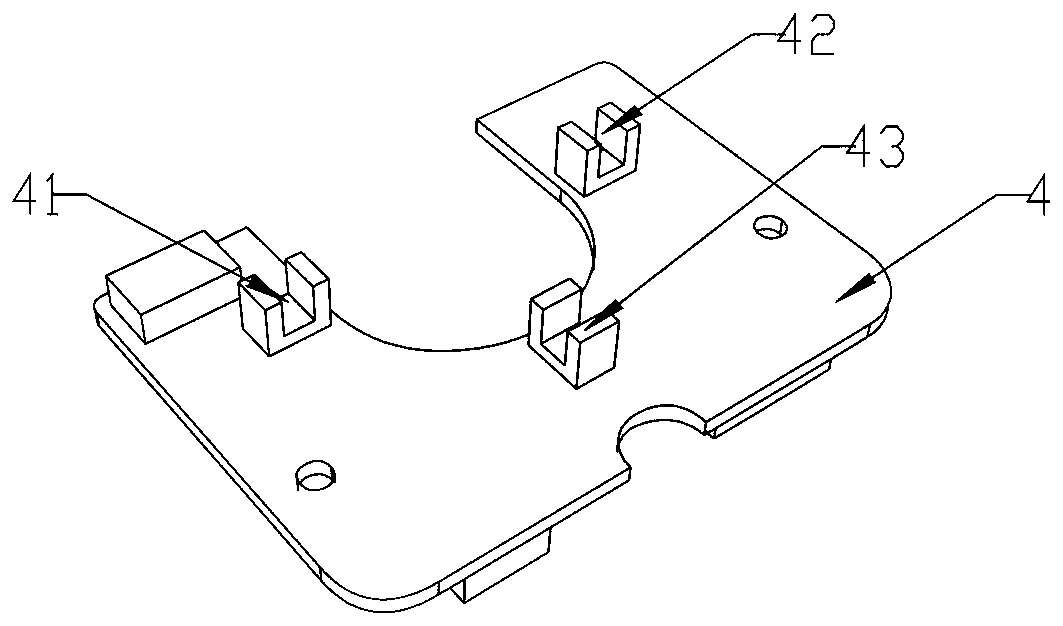

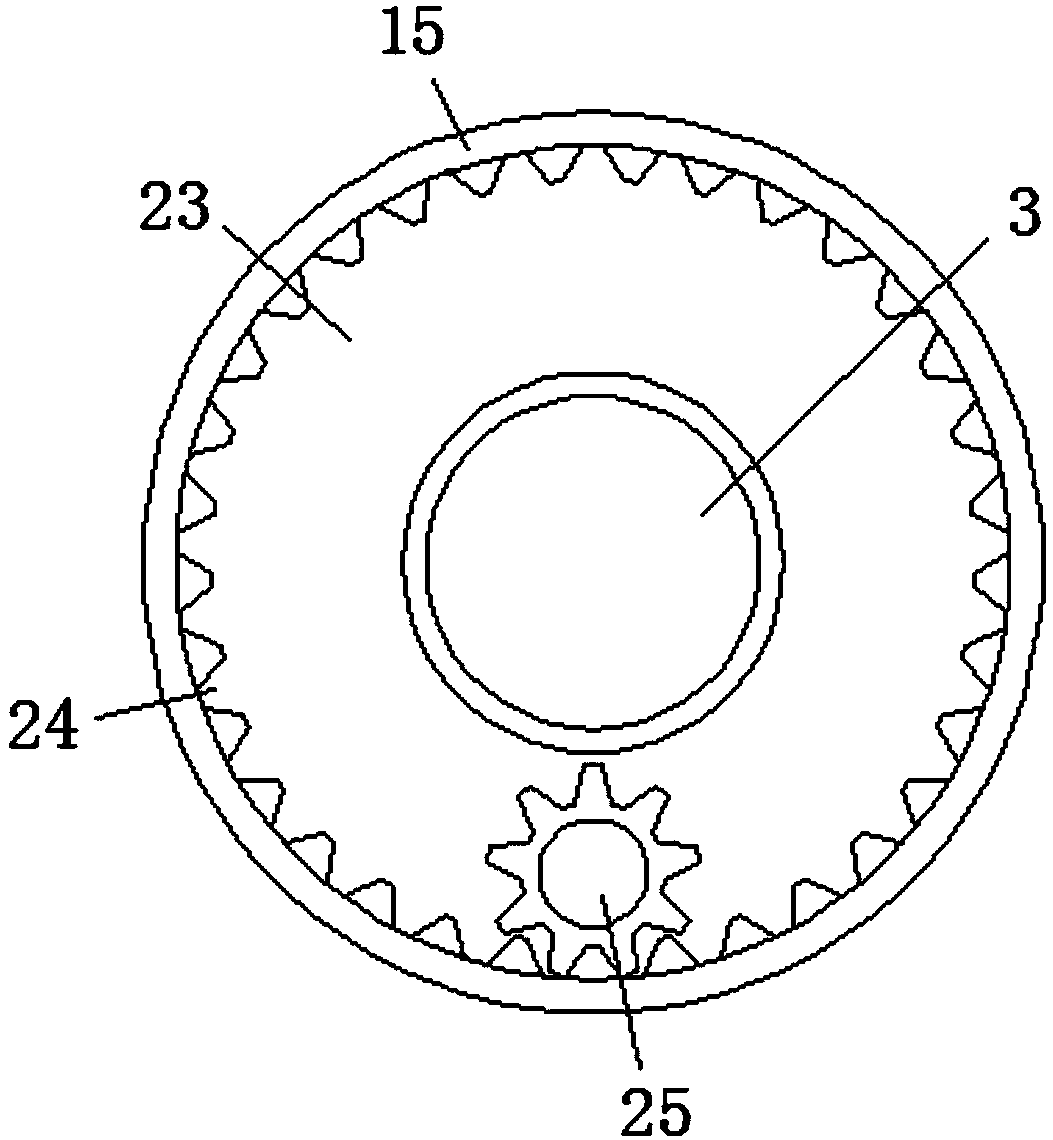

Electronic lock

PendingCN110485821AReduce wearLess transmission partsNon-mechanical controlsMotherboardMechanical engineering

The invention provides an electronic lock which comprises a lock shell, a bolt mechanism, a control main board, a rotary knob mechanism and a variable speed transmission mechanism. The rotary knob mechanism comprises a rotary knob linkage part rotating synchronously with a rotary knob. The variable speed transmission mechanism comprises a driven gear disc arranged coaxially with the rotary knob linkage part. A gear disc body is provided with a first gear disc boss, a second gear disc boss, and a gear disc swing arm arranged vertically, wherein the first gear disc boss and the second gear discboss are arranged symmetrically. A first rotary knob boss and a second rotary knob boss are arranged on one side of the rotary knob linkage part and arranged symmetrically. Two symmetrical stroke tracks are formed between the first gear disc boss and the second gear disc boss. The first rotary knob boss and the second rotary knob boss are located on the two opposite stroke tracks correspondingly.The control main board is further provided with a first resetting induction switch, a second resetting induction switch and a resetting-in-place induction switch, wherein the first resetting inductionswitch and the second resetting induction switch are used for inducting the gear disc swing arm. The electronic lock has the advantages of being little in transmission disturbance, little in part abrasion and precise in transmission and resetting.

Owner:陈海英

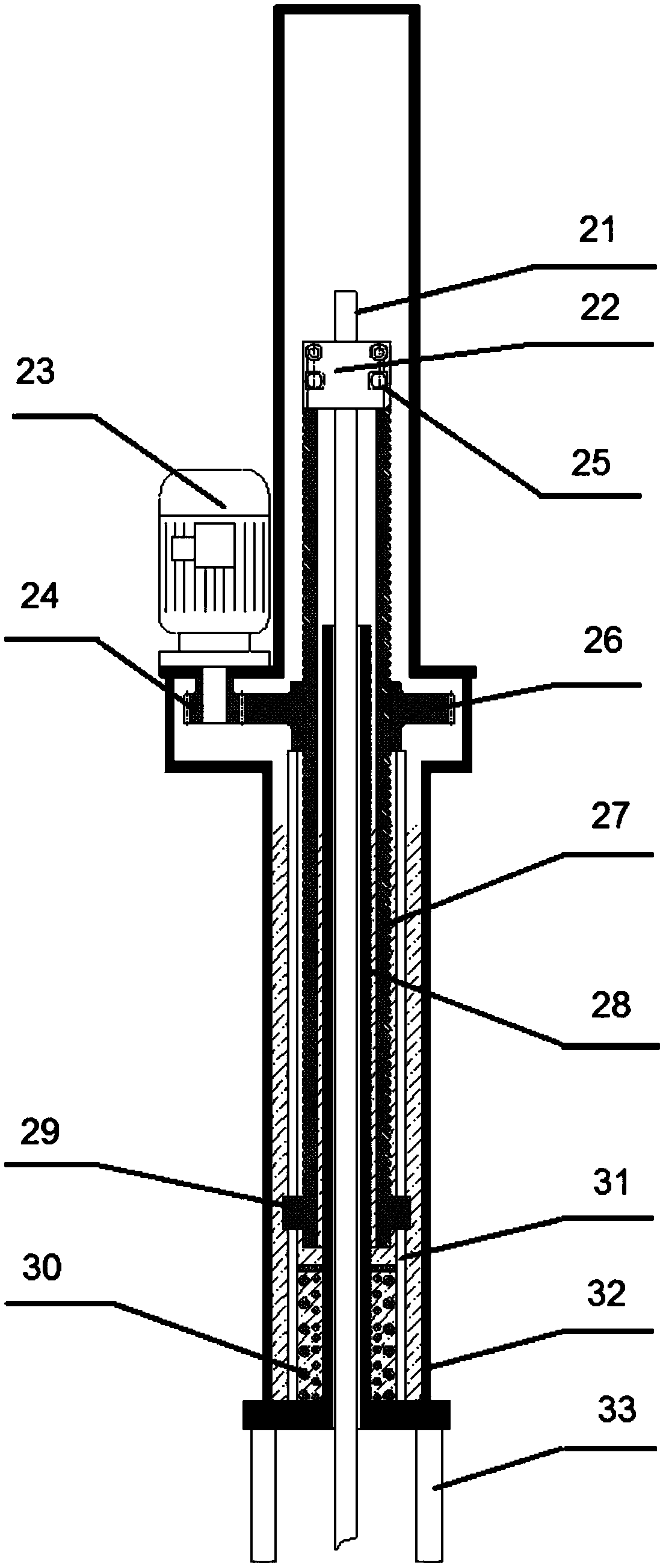

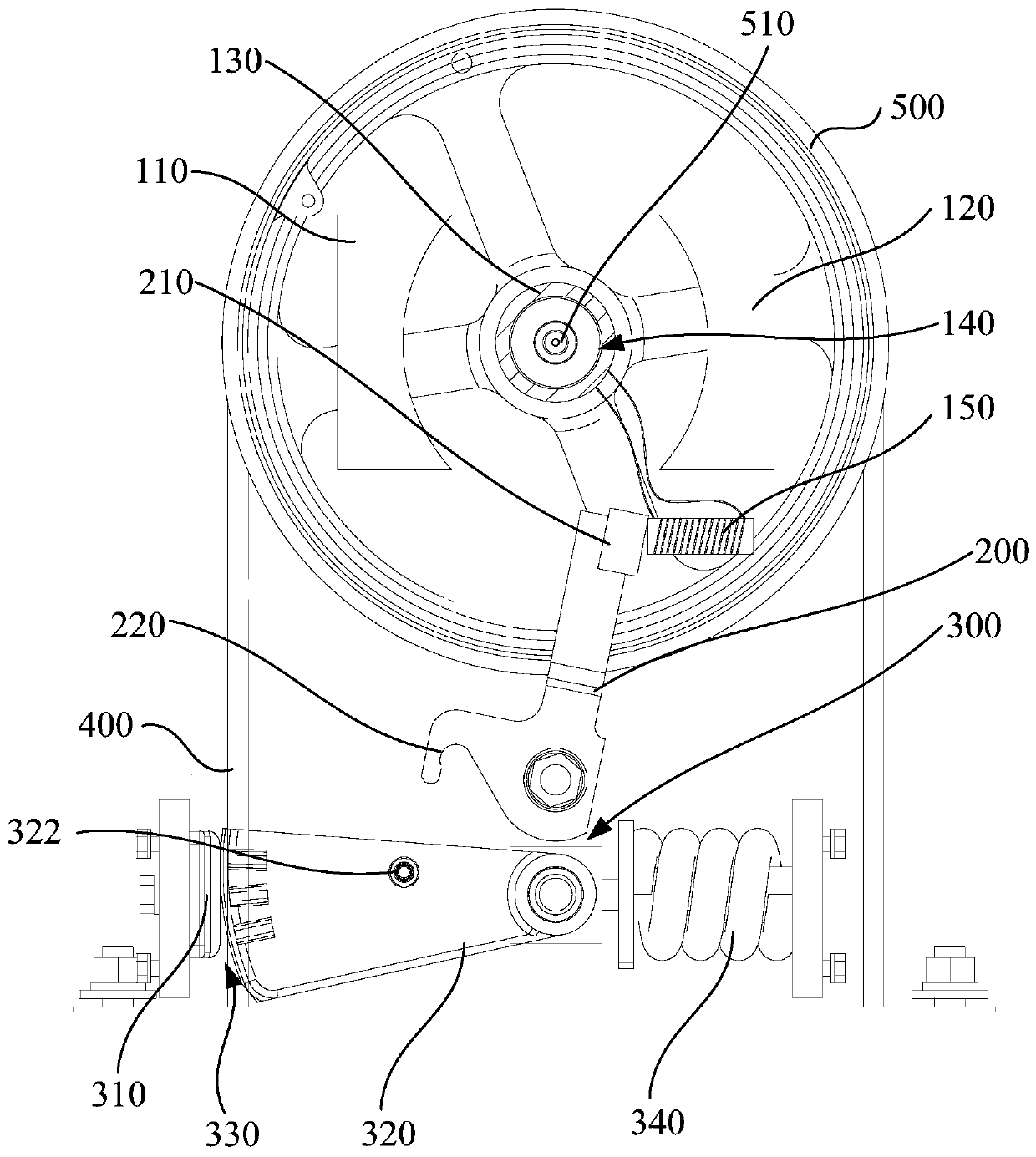

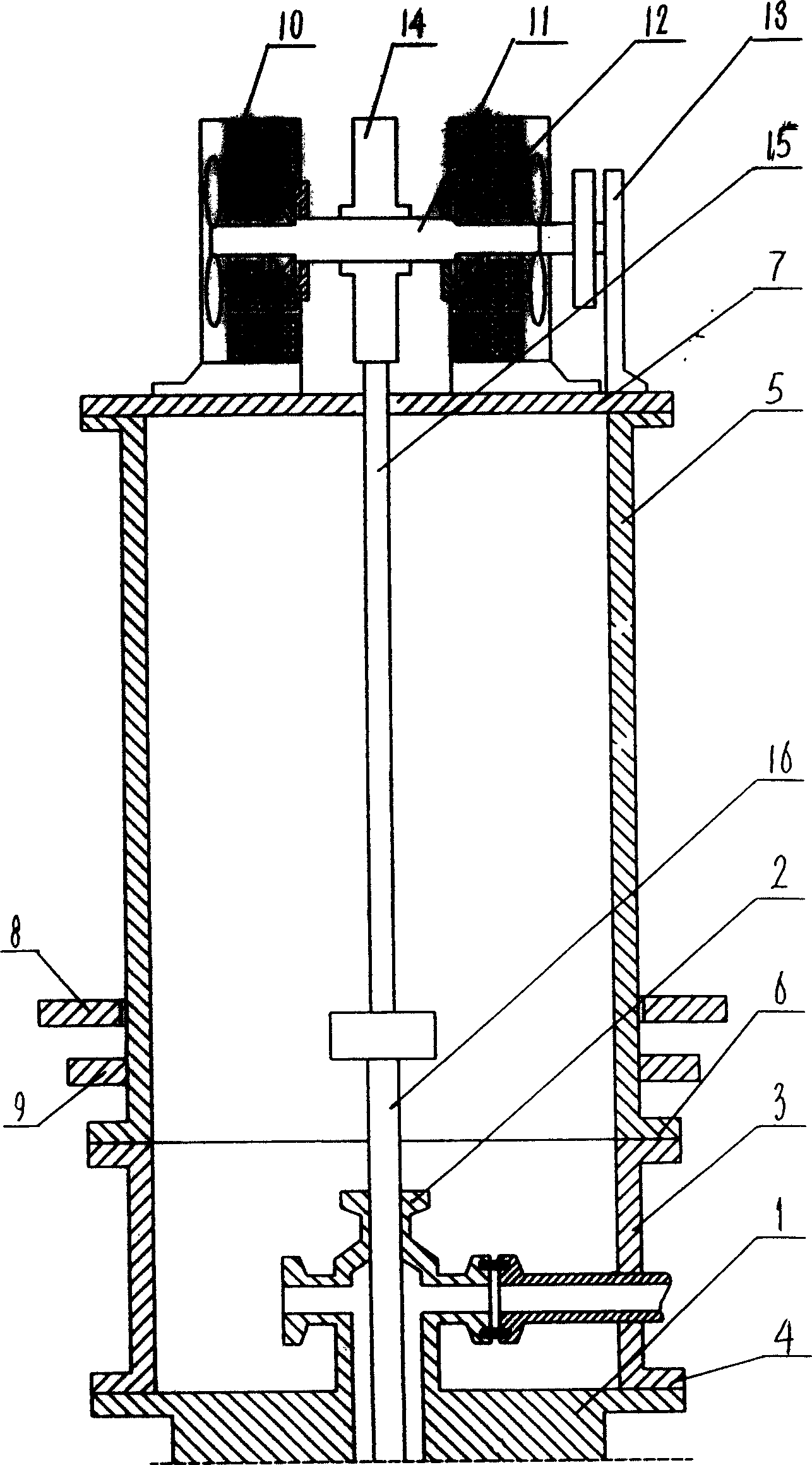

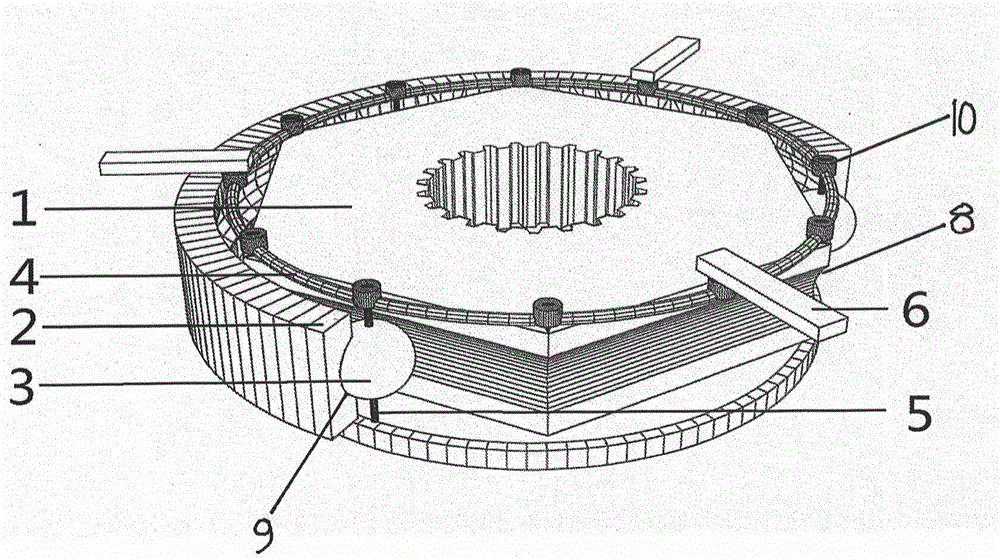

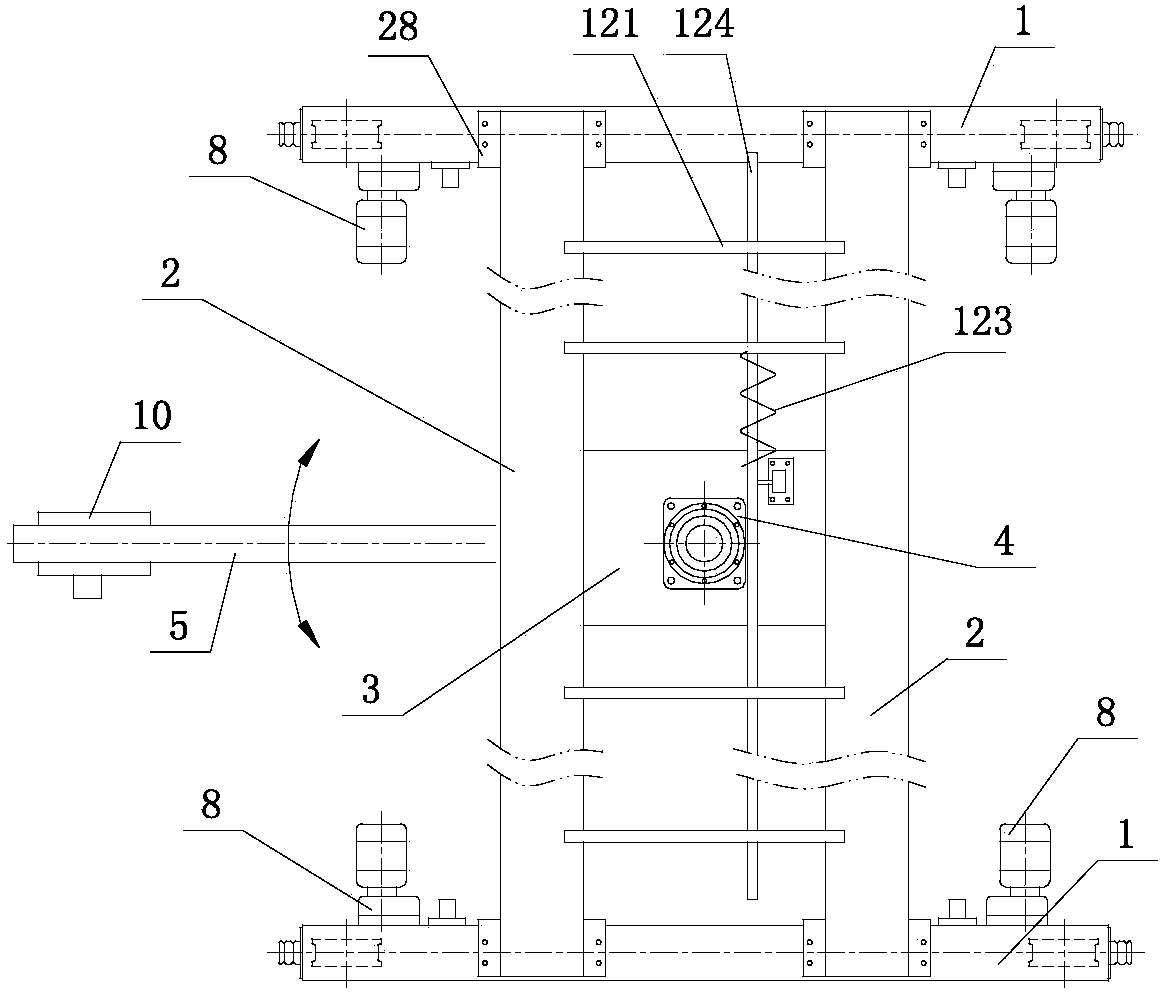

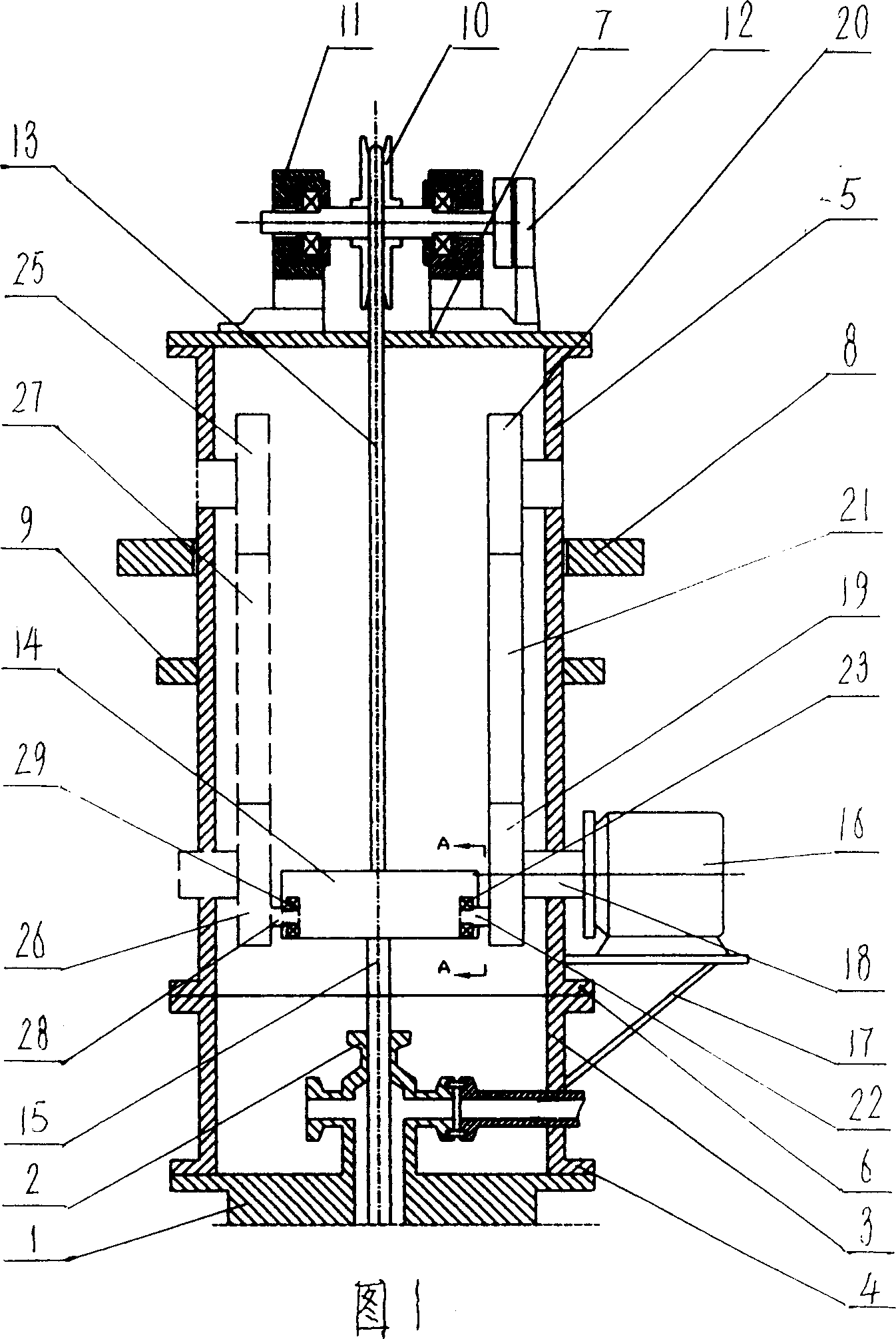

Split motor-drived vertical-pipe reciprocating chain pumping unit

The invention is a two-piece electric-machine drive vertical-tube type reciprocating-chain oil pumping unit, a beam-free one composed of wellhead large four-way, wellhead short section, vertical tube, electric machine, chain wheel and oil pumping rod. The large four-way is fixed at the wellhead and set with wellhead small four-way at the center; the well short section situated on the large four-way; the vertical tube situated on the short section, the top of the vertical tube set with a cap, and a ring balance weight slipping over the periphery of the vertical tube and able to slide upwards and downwards along the vertical tube; the electric machine is a two-piece permanent-magnet low-speed synchronous one, fixed on the cap and the output shaft supported on the right and left pieces by bearings; the chain wheel connected to the center of the output shaft by bond and able to rotate forwards and reversely under the electric machine drive; one end of the chain linked with the balance weight, and the other one linked with the upper end of the oil pumping rod round the chain wheel; the lower end of the oil pumping rod passing through the small four-way to link up with the underground reciprocating pump.

Owner:李华林

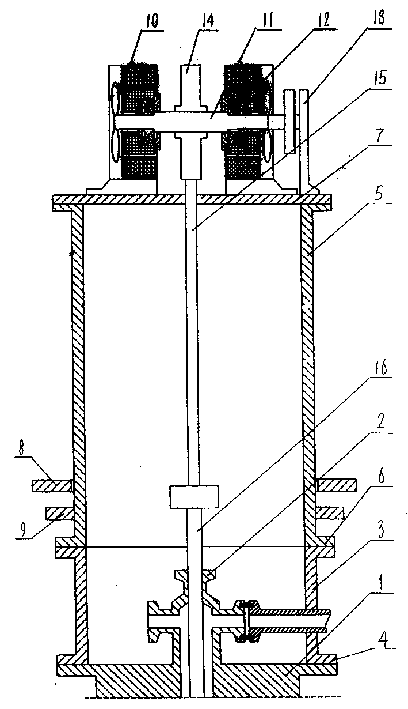

Volatile matter leakage preventing reaction barrel

InactiveCN106732272APrevent proliferationAvoid flowChemical/physical/physico-chemical stationary reactorsFeed devicesImpellerEngineering

The invention discloses a volatile matter leakage preventing reaction barrel and relates to fertilizer producing equipment. The volatile matter leakage preventing reaction barrel comprises a shell, a urea smashing part and a stirring shaft, wherein a formaldehyde feeding opening is formed in the upper end of the shell; the urea smashing part comprises a smashing barrel, a smashing impeller, a linkage mechanism and a feeding piston; the smashing barrel is fixed to the upper end of the shell, the lower portion of the smashing barrel is arranged in an inner cavity of the shell, and a one-way feeding valve is arranged at the lower portion of the smashing barrel; a urea feeding hopper is arranged at the upper end of the smashing barrel, the feeding piston is in slide connection in the smashing barrel, the smashing impeller is in rotary connection with the smashing barrel, and the stirring shaft can drive the smashing impeller to rotate through the linkage mechanism; the smashing impeller rotates to drive the feeding piston to slide up and down in a reciprocating mode, a material leaking hole in a reversed frustum shape is formed in the feeding piston, a plug matched with the material leaking hole is arranged under the material leakage hole, and the lower end of the plug is connected with a spring. In material feeding, the urea smashing part of the device can prevent irritant volatile gas from diffusing outwards through the urea feeding hopper.

Owner:CHONGQING YONGCHUAN DISTRICT TIANTANG CHEM PLANT

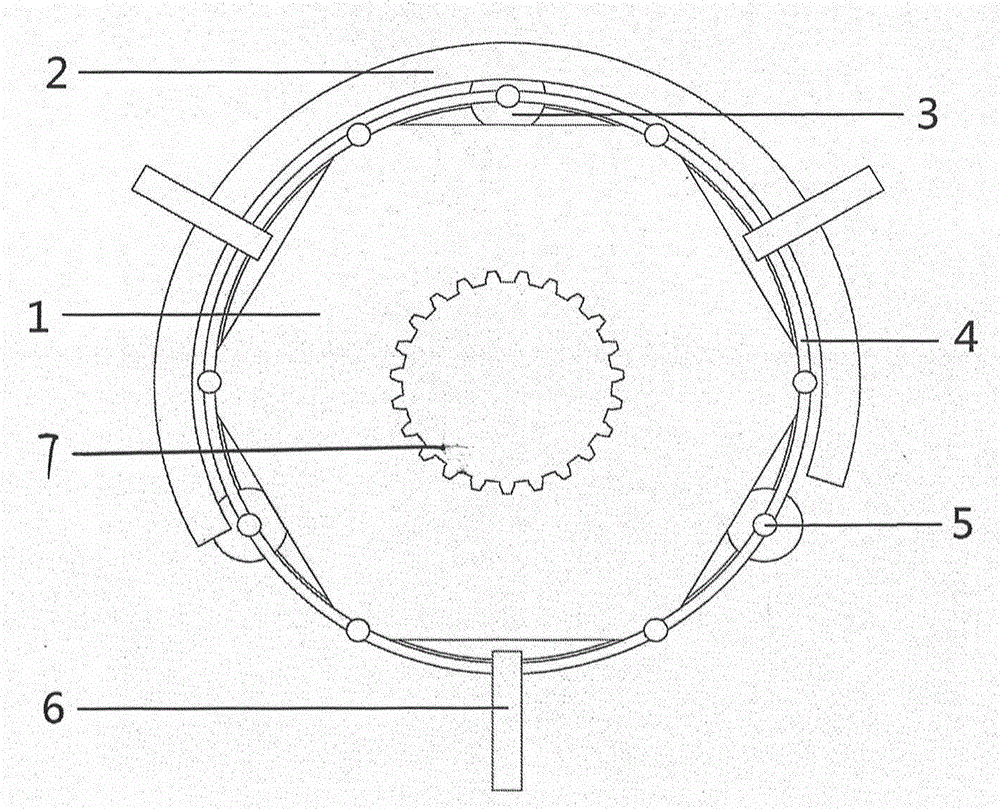

Bothway self-adaptation three-axis transmission system

InactiveCN104455075ASimple structureLess transmission partsFreewheel clutchesDrive shaftSelf adaptive

The invention belongs to a bothway self-adaptation three-axis transmission system. The bothway self-adaptation three-axis transmission system is composed of a driving shaft and a driven shaft, and a self-adaptation wedge shaft transmission device is arranged between the driving shaft and the driven shaft, wherein the wedge shaft transmission device is formed by a wedge shaft, a wedge shaft center shaft, a damping rod and a wedge shaft damping support. The periphery of the driving shaft is of an equilateral hexagonal-prism structure, panels for the wedge shaft to slide are arranged on at least three cylindrical surfaces, which are arranged at intervals, of the hexagonal-prism faces of the driving shaft, or main wedge grooves penetrating through the cylindrical surfaces and allowing the wedge shaft to slide therein are longitudinally formed in the middles of the at least three cylindrical surfaces which are arranged at intervals. The bothway self-adaptation three-axis transmission system has the capacity that the rotating speed of the driven shaft freely surpasses the inertia rotating speed of the driving shaft, has the capacity of power self-adaptation distribution according to resistance of the driven shaft and has the characteristic that a power transmission terminal is relatively independent; and the motility of inertia energy recycling of the driven shaft is used; in addition, the bothway self-adaptation three-axis transmission system has the advantages of being simple in structure, fewer in transmission piece, rapid in reaction, small in operation noise, high in durability and low in manufacturing and maintaining cost.

Owner:杨德利

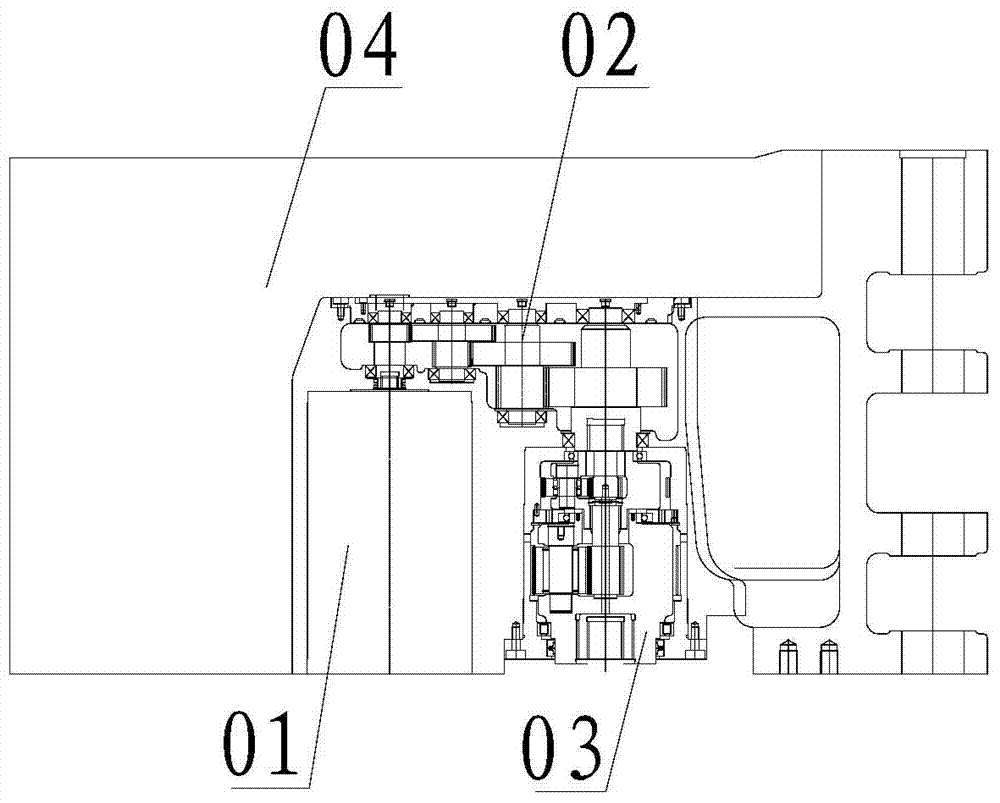

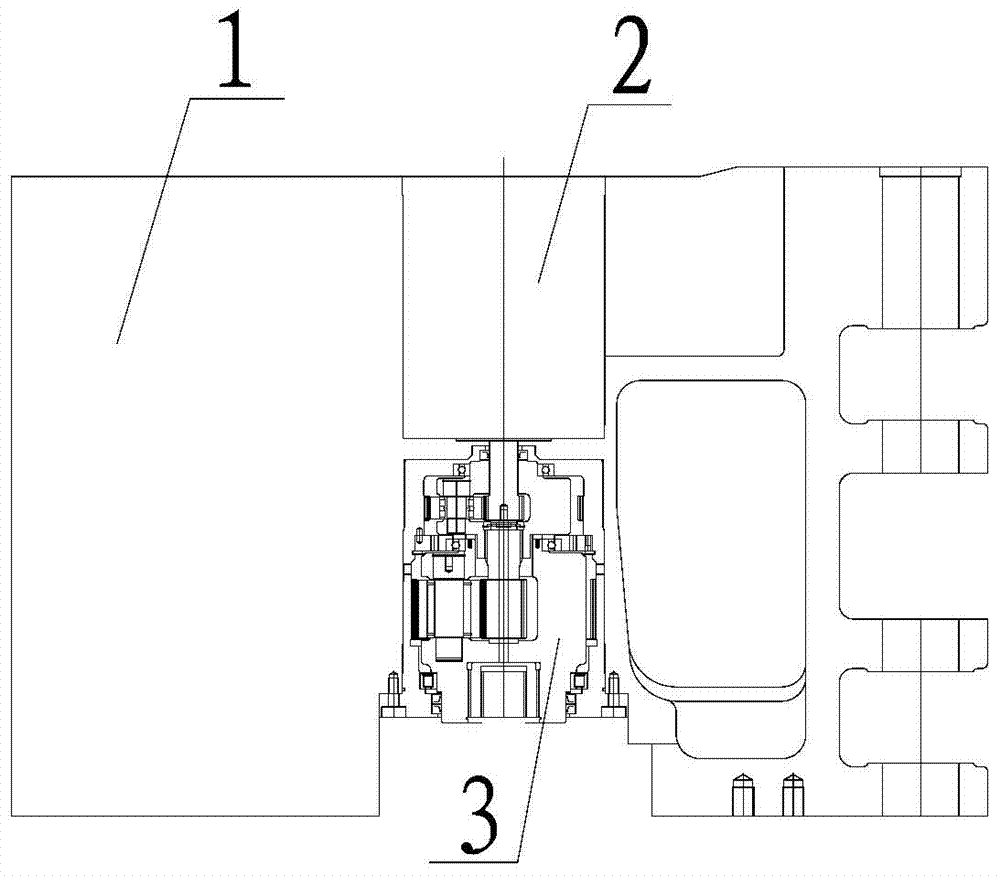

Coal mining machine and traction part thereof

InactiveCN103924972ALess transmission partsReduce costs and points of failureDriving meansPropulsionCoal miningAutomotive engineering

The invention provides a coal mining machine and a traction part thereof. The traction part of the coal mining machine comprises a traction part shell and a two-stage planetary speed reduction device arranged in the traction part shell, wherein a driving motor with a rotating speed lower than a preset rotating speed is arranged in the traction part shell; the driving motor is axially arranged at the input end of the two-stage planetary speed reduction device; an output shaft of the driving motor is connected with the two-stage planetary speed reduction device in a driving manner. The driving motor is configured to be a preset high-torque and low-rotating-speed motor, so that traction force can be directly output to a traveling part of the coal mining machine after the rotating speed output by the driving motor passes through the two-stage planetary speed reduction device; the number of transmission components is reduced, the cost is lowered, and fault points are reduced; the reliability is improved.

Owner:SANY HEAVY EQUIP

Air door adjusting structure, air outlet assembly and automobile air conditioning system

InactiveCN103383135ACompact layoutLow costNoise suppressionAir-flow control membersGear wheelAutomobile air conditioning

The invention provides an air door adjusting structure, an air outlet assembly and an automobile air conditioning system. In the air door adjusting structure, the edge of one side of a first blade of an air door is connected with a first semi-axle of a center axle through a first sleeve; the edge of one side of a second blade of the air door is fixedly connected with a second sleeve which is arranged on a second semi-axle of the center axle in a sleeved mode; a first half bevel gear is fixedly arranged on the circumferential surface of the first sleeve through the inner side of the first half bevel gear; a second half bevel gear is fixedly arranged on the circumferential surface of the second sleeve through the inner side of the second half bevel gear; a bevel gear is engaged with the first half bevel gear and the second half bevel gear respectively; the bevel gear is engaged with the first half bevel gear and the second half bevel gear all the time in a process that the angle between the first blade and the second blade is increased from zero to a set maximum angle. According to the air door adjusting structure, the air outlet assembly and the automobile air conditioning system, a device with the air door adjusting device is smooth in operation without vibration or abnormal sound; the arrangement of transmission mechanisms is compact; transmission parts are fewer, so that mould costs and product costs are reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

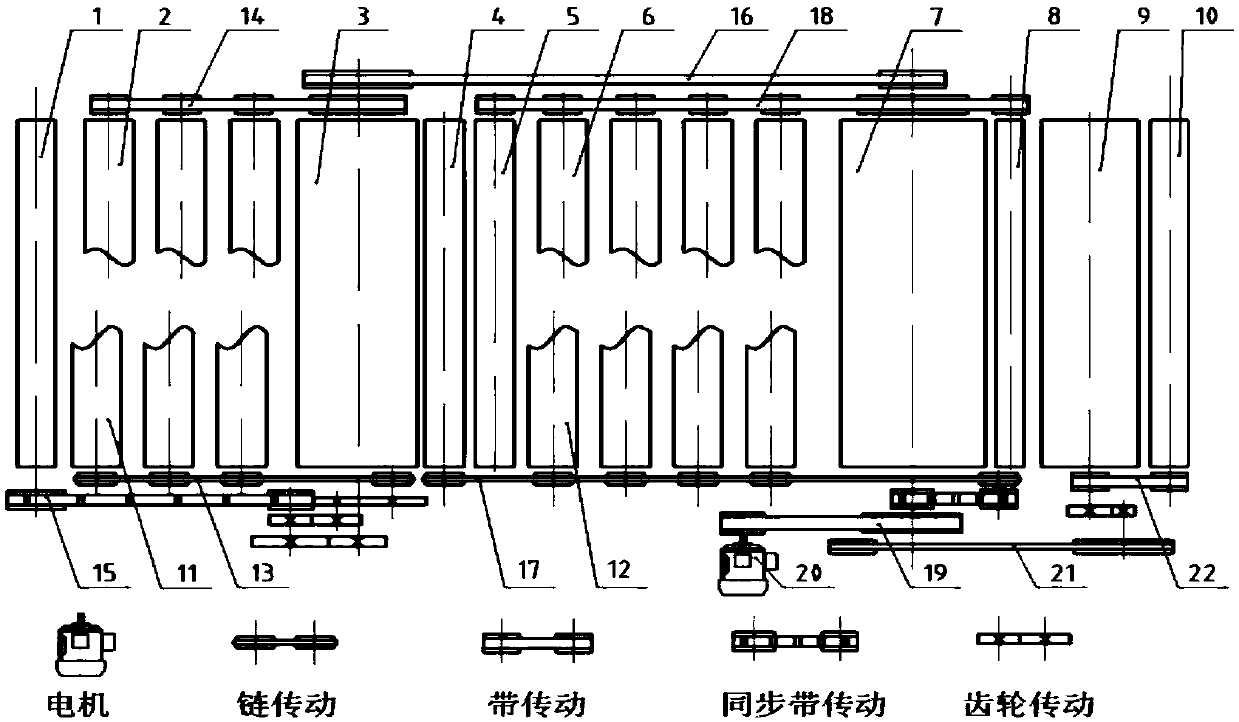

Cashmere wool carding machine transmission system and carding machine

The invention discloses a cashmere wool carding machine transmission system and a carding machine, which have the effects that a transmission process has good synchronism and the energy utilization rate of a transmission mechanism is improved. According to the technical scheme, the cashmere wool carding machine transmission system comprises a breast cylinder, wherein one end of the breast cylinderis connected with a plurality of breast cylinder working rollers through a first chain transmission mechanism; the other end of the breast cylinder is connected with a plurality of breast cylinder stripping rollers through a first belt transmission mechanism; the breast cylinder is further connected with the breast cylinder through a first synchronous belt transmission mechanism; the breast cylinder is further connected with a primary carding roller through a second belt transmission mechanism; one end of the primary carding roller is connected with a plurality of primary carding cylinder working rollers and a first wind wheel through a second chain transmission mechanism; the other end of the primary carding roller is connected with a plurality of primary carding cylinder stripping rollers, a transferring roller and a second wind wheel through a third belt transmission mechanism; the primary carding roller is connected with a motor through a fourth belt transmission mechanism; the primary carding roller is further connected with a doffer through a fifth belt transmission mechanism; the doffer is connected with a cleaning roller through a sixth belt transmission mechanism.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Cantilever crane with suspended car

The application discloses a cantilever crane with a suspended trolley, which includes a double-girder bridge frame; the double-girder bridge frame includes an end beam and a main beam; both ends of the end beam are provided with cart driving devices and safety hooks; Rails are provided; the two ends of the rails are connected with car stoppers; the two rails are connected with suspension trolleys and can run along the rails; the suspension trolleys are provided with a rotation mechanism; the boom shaft in the rotation mechanism is connected to the cantilever member; A rotation limit device is connected to the cantilever member; an electric hoist is installed on the cantilever member, and can move back and forth horizontally along the cantilever beam; The guide cable rail is connected under the frame; the hanging cable on the guide cable rail is electrically connected with the suspension trolley.

Owner:谢新华

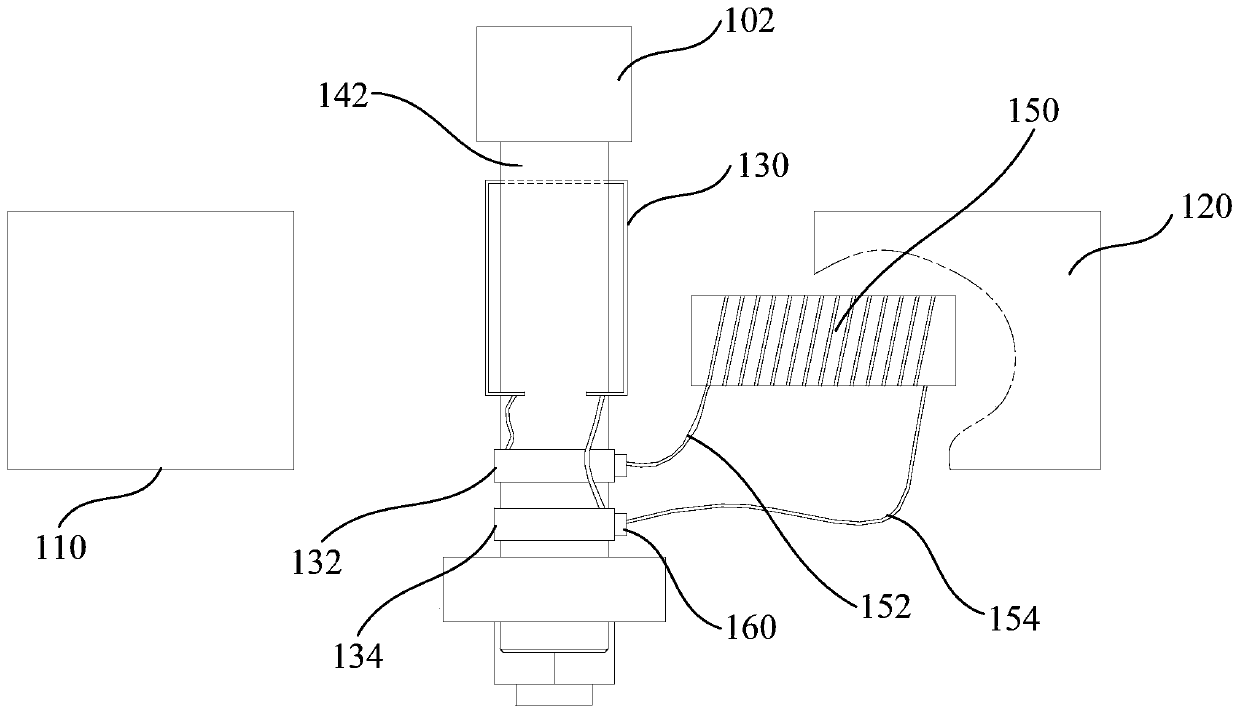

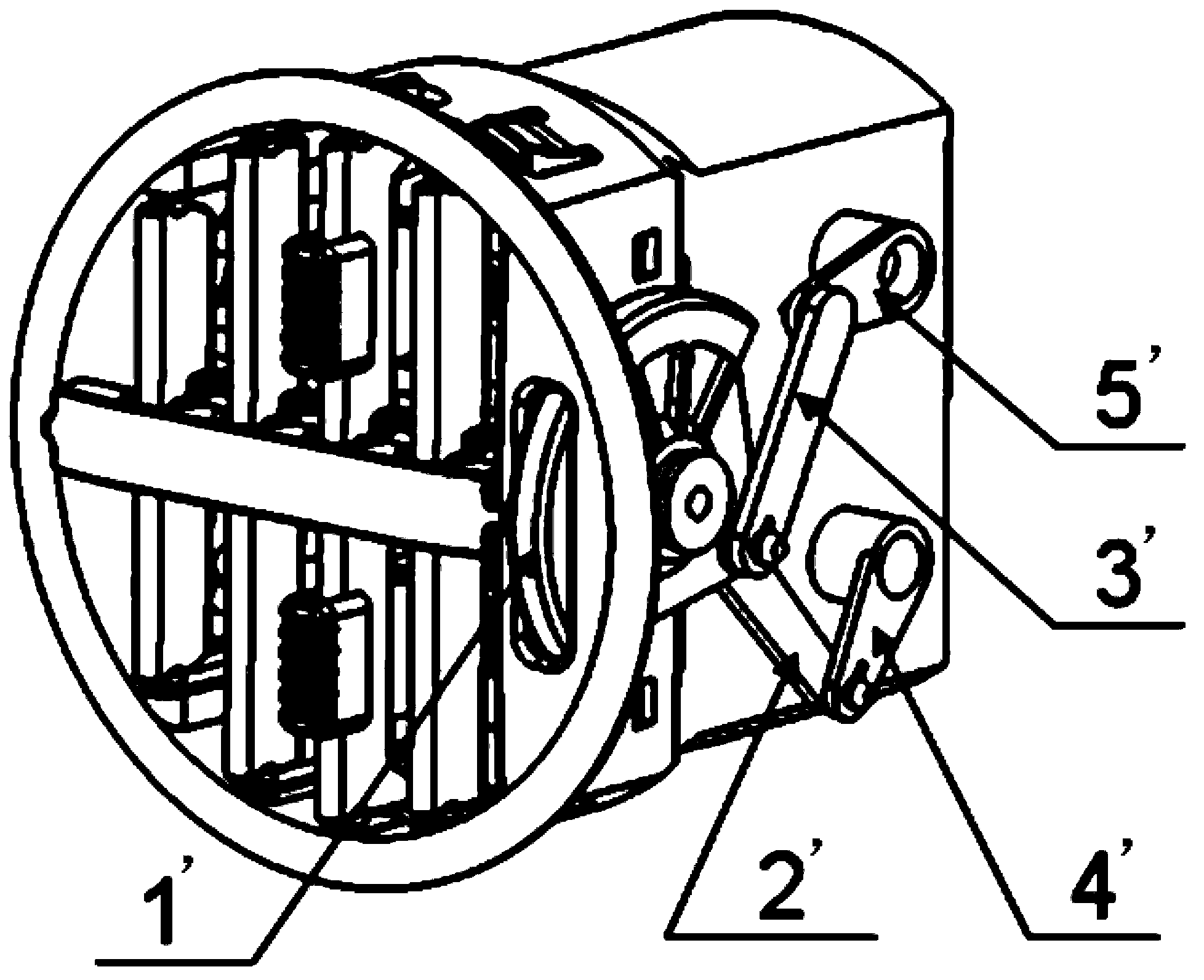

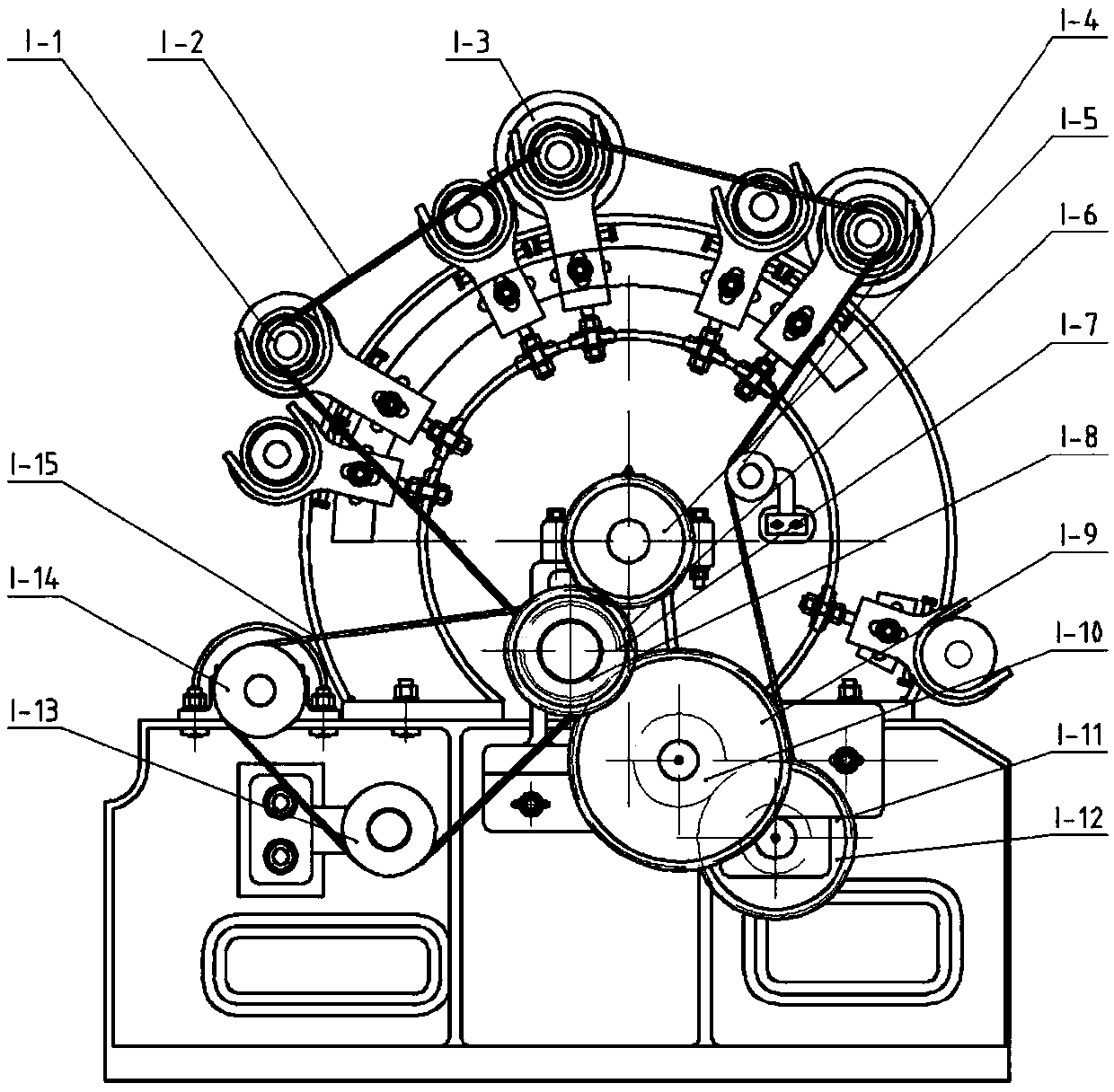

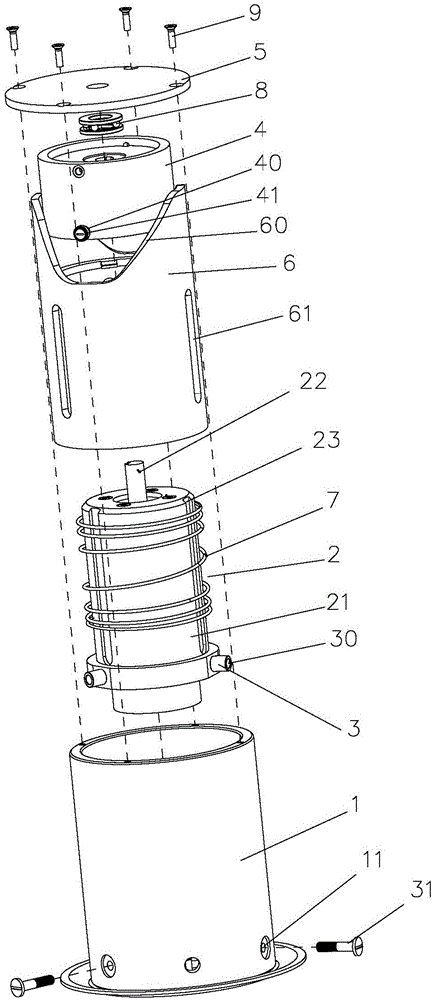

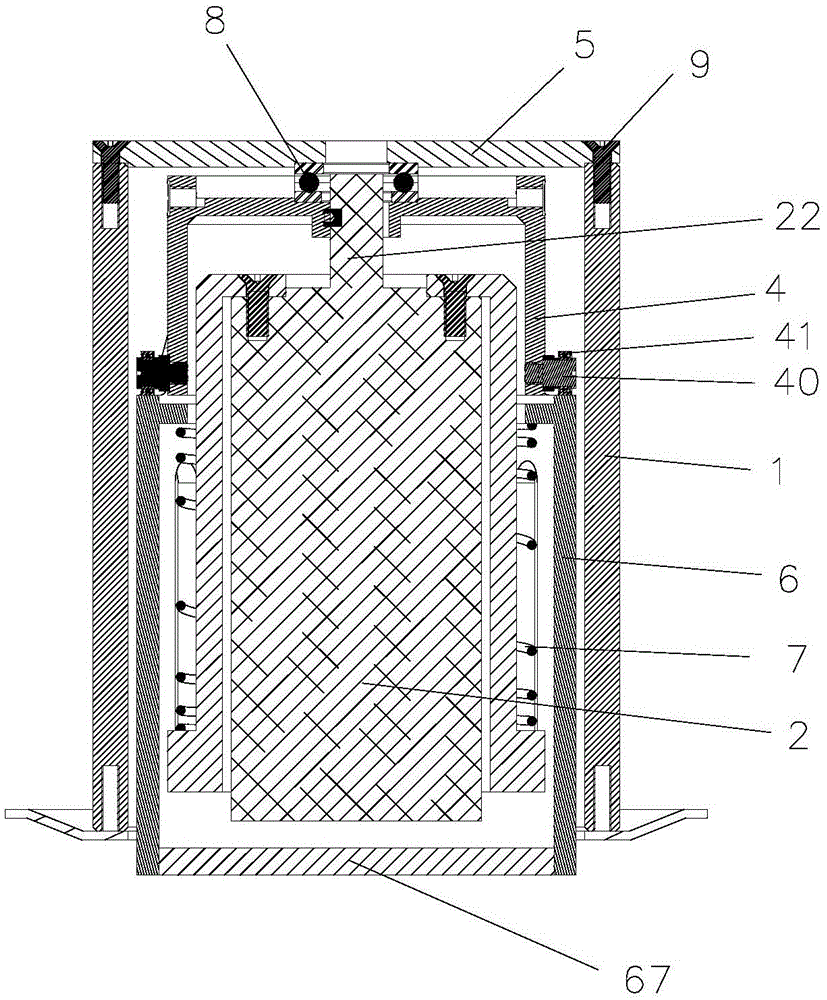

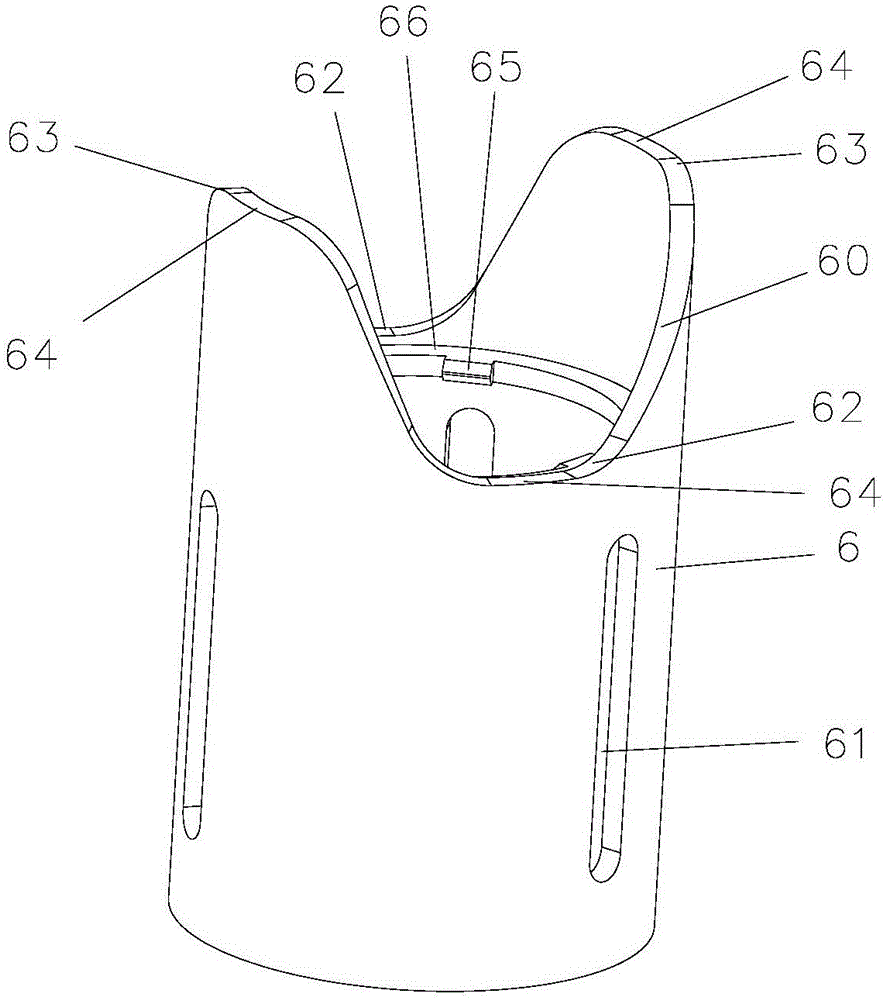

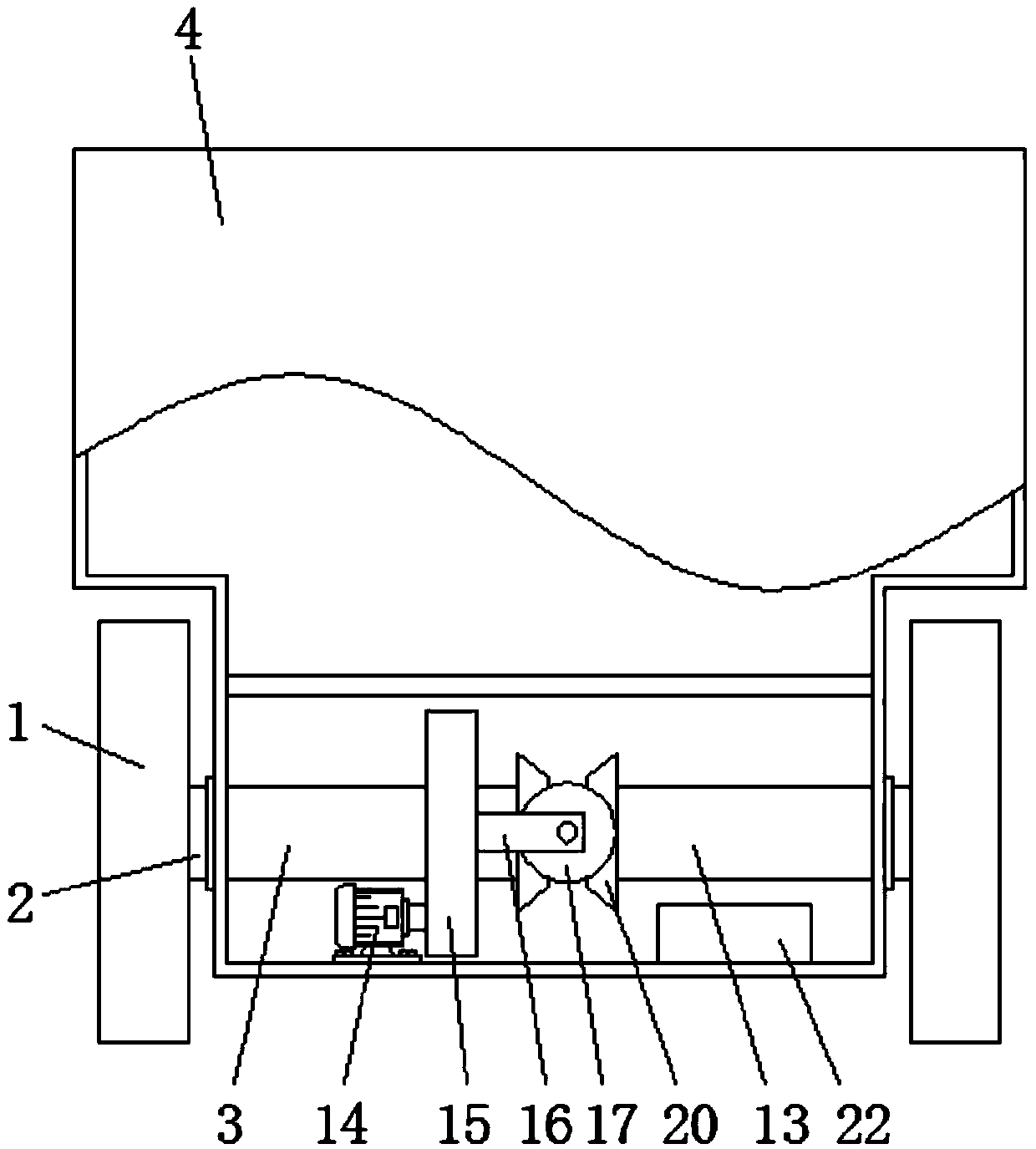

Mechanical type external chest compression device

ActiveCN105106005ASimple structureCompact structureElectrotherapyHeart stimulationCompression deviceEngineering

The invention discloses a mechanical type external chest compression device. The device comprises an outer barrel, a driving device is arranged inside the outer barrel, the lower end of the driving device is fixed to the bottom of the outer barrel through connecting pieces which are arranged in the radial direction, the upper end of an output shaft of the driving device is connected with a revolving shaft, two driving protrusions are arranged on the outer side face of the revolving shaft in the circumferential direction, and the upper end of the outer barrel is connected with a top cover; a cam jacking rod is arranged between the driving device and the outer barrel, the upper end face of the cam jacking rod is a concave-convex curved surface, long-strip holes are formed in the side wall of the cam jacking rod, the connecting pieces are placed in the long-strip holes so that the connecting pieces can be adapted to the axial motion of the cam jacking rod, a return spring is arranged in an inner chamber of the cam jacking rod, and the lower end of the cam jacking rod extends out of the outer barrel and is connected with a compression plate. The mechanical type external chest compression device is simple in structure, easy to machine and produce, low in cost, small in size, compact in structure, low in weight, convenient, fast, few in transmission components, high in transmission efficiency, low in energy loss and beneficial to battery life.

Owner:SUNLIFE SCI SUZHOU INC

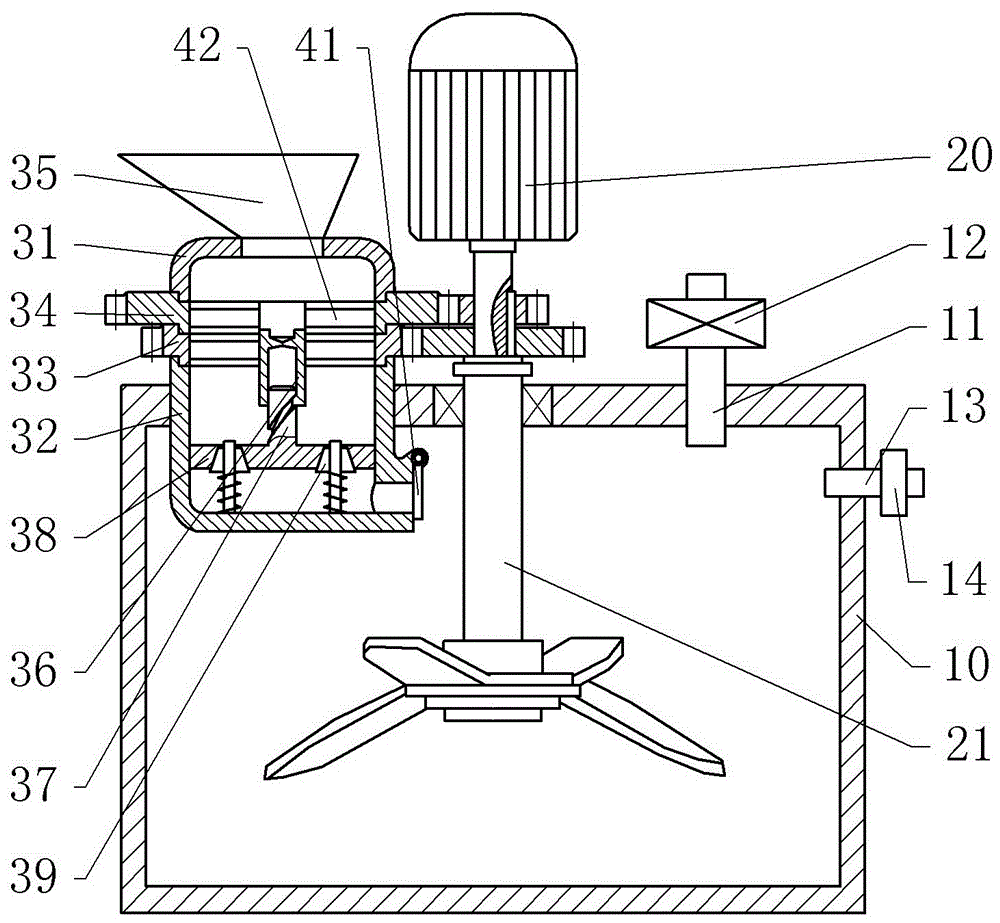

Vertical pipe chain pumping unit

The invention is a vertical tube type chain oil pumping unit, a beam-free one composed of wellhead large four-way, wellhead short section, vertical tube, hoisting sheave, suspension weight rope, return frame, oil pumping rod and chain drive mechanism. The large four-way is fixed at the wellhead and set with wellhead small four-way at the center; the well short section situated on the large four-way; the vertical tube situated on the short section, the top of the vertical tube set with a cap, and a ring balance weight slipping over the periphery of the vertical tube and able to slide upwards and downwards along the vertical tube; the hoisting sheave installed on the cap through the bracket and able to rotate forwards and reversely; one end of the suspension weight rope linked with balance weight and the other one linked with the upper end of the return frame round the chain wheel; the lower end of the return frame linked with the upper end of the oil pumping rod and able to reciprocate upwards and downwards; and the lower end of the oil pumping rod passing through the small four-way to link up with the underground reciprocating pump.

Owner:李华林

An adjustable tilting child safety seat

ActiveCN103538504BSatisfy the requirements of tilt shiftingSimple structureKids chairsChild seatsEngineeringMechanical engineering

The invention relates to an adjustable inclined type child safety seat. The adjustable inclined type child safety seat comprises a body and a base, wherein the body is supported on the base in an adjustable mode through an inclined rail, a gear shifting device is arranged between the body and the base, a plurality of gear shifting grooves in the forward and backward direction of the base are formed in the upper end surface of the base, a sheet table is arranged on the bottom surface of the body, the gear shifting device is connected with the bottom surface of the body in a rotary mode and correspondingly connected with the gear shifting grooves in a clamping mode, and an elastic reset device attached with the sheet table is arranged on the gear shifting device. The sheet table which abuts against a gear shifting board on the body through the elastic reset device is arranged on the body of the seat, a gear shifting clamping table of the gear shifting board comes off the gear shifting grooves of the base by overcoming the acting force of the elastic reset device, the gear shifting clamping table of the gear shifting board is correspondingly connected with the gear shifting grooves of the base in a clamping mode under the acting force of the elastic reset device, and therefore the body can be adjusted on the base in an inclined mode or the body can be positioned on the base after adjustment, and the requirements for inclined gear shifting of the seat from different users and under different use environments are met.

Owner:JIANGSU LUCKY BABY SAFETY SYST MFG

Quick drive device of pure electric passenger vehicle

InactiveCN108674161ACompact structureImprove driving efficiencyElectric propulsion mountingVehicular energy storageDrive wheel

Owner:常德中车新能源汽车有限公司

Metronome for music teaching

A metronome for music teaching comprises a metronome box, the top of the metronome box is rotationally connected with a box cover, and a music score placing assembly is arranged on the inner side of the box cover; a pedal hole is formed in the rear side wall of the beat box in a penetrating mode, a pedal beating device is installed in the beat box, one end of the pedal beating device extends to the outside from the pedal hole, a beaten shifting device is installed on the top of the beat box, and a beaten device is installed on the beaten shifting device. A loudspeaker is arranged on the front side wall of the metronome; a sound changing device is arranged on the metronome outside the loudspeaker; the invention has the following advantages: a pedal-type beat striking mode is adopted, so that the hands of a user are liberated, and the user can conveniently play musical instruments or command at the same time; the position of the hit device can be adjusted through the hit shifting device, after the device is used for a long time, the hit device can be shifted, then the trigger distance of the beat is increased, the hit device can be moved to the initial position through the hit shifting device, and then the normal trigger distance is recovered.

Owner:河南经贸职业学院

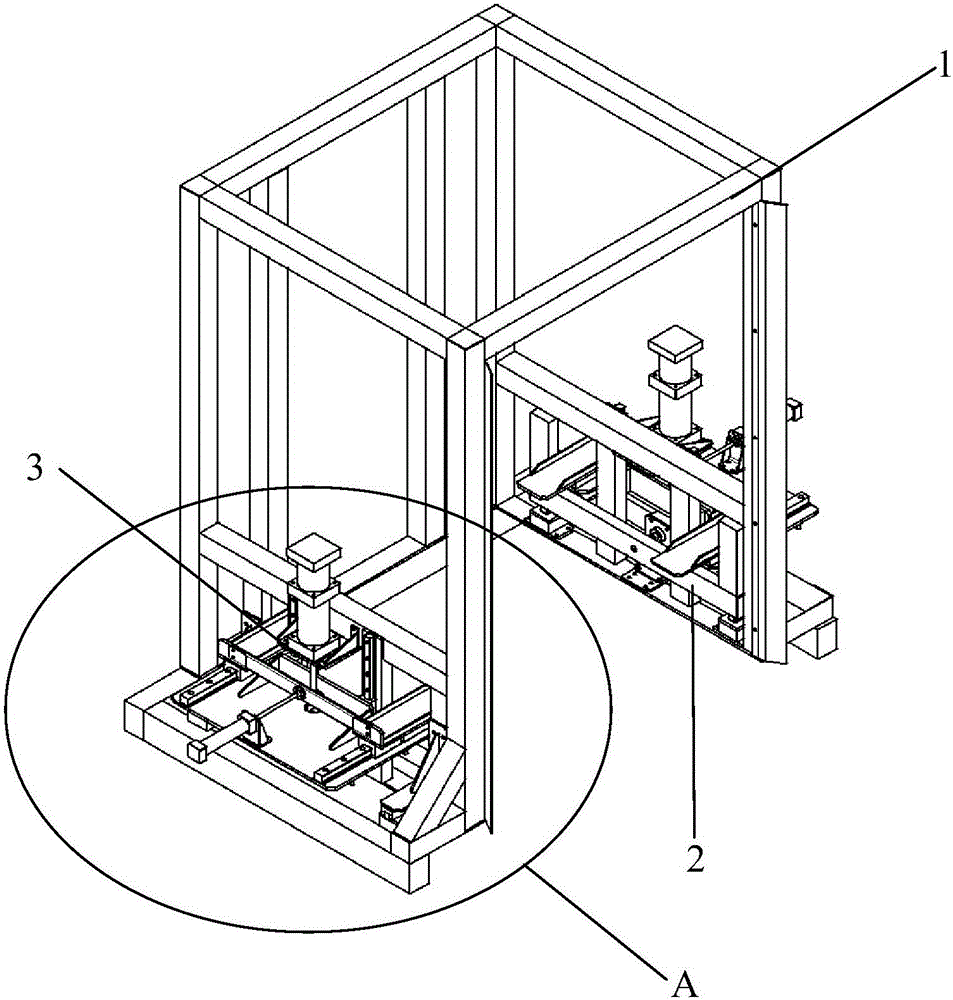

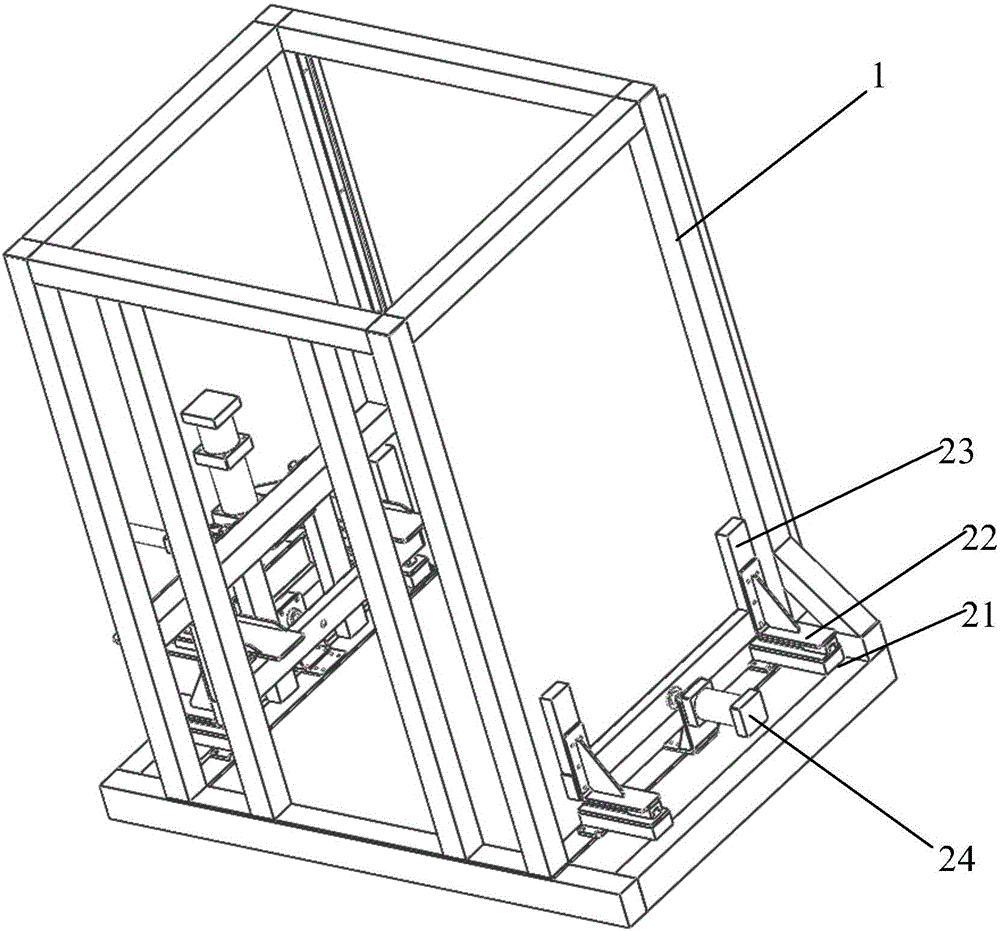

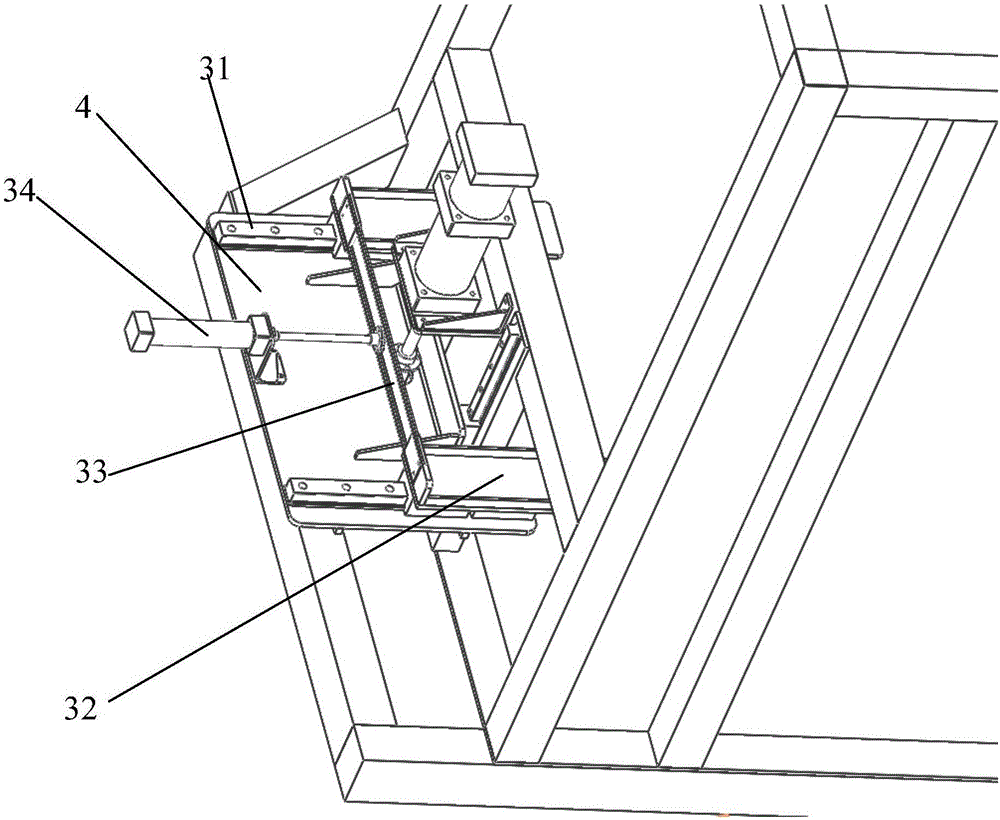

Tray unstacking/stacking machine

PendingCN106743686ACompact structureLess transmission partsConveyorsStacking articlesMechanical transmissionStack machine

The invention discloses a tray unstacking / stacking machine which is aimed at solving the technical problems that the existing tray unstacking / stacking machine mentioned in the background art mostly adopts a mechanical transmission structure and a motor for driving and is characterized by huge structure, complicated transmission and inconvenience in maintenance. The technical scheme is as follows: the tray unstacking / stacking machine comprises an n-shaped rigid bracket placed on the ground, wherein tray entrance and exit are formed at the front and back of the rigid bracket; pneumatic beating and finishing mechanisms are arranged on the left side surface and right side surface of the rigid bracket respectively; the two pneumatic beating and finishing mechanisms are symmetrically arranged; tray fork mechanisms are arranged above the two pneumatic beating and finishing mechanisms; and a hanging plate is glidingly arranged on the rigid bracket and is vertical to the side surface of the rigid bracket. The tray unstacking / stacking machine disclosed by the invention has the following advantages: with an air cylinder serving as a motion execution component and by replacing the transmission way and adopting a pneumatic component to execute motion, the structure is simple, compact and not complicated and neater than that of traditional machinery.

Owner:江苏保力自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com