Internal cooling motor system body with pressure resistance cover body

A technology of motor housing and cover body, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effect of optimizing the mechanical energy adjustment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

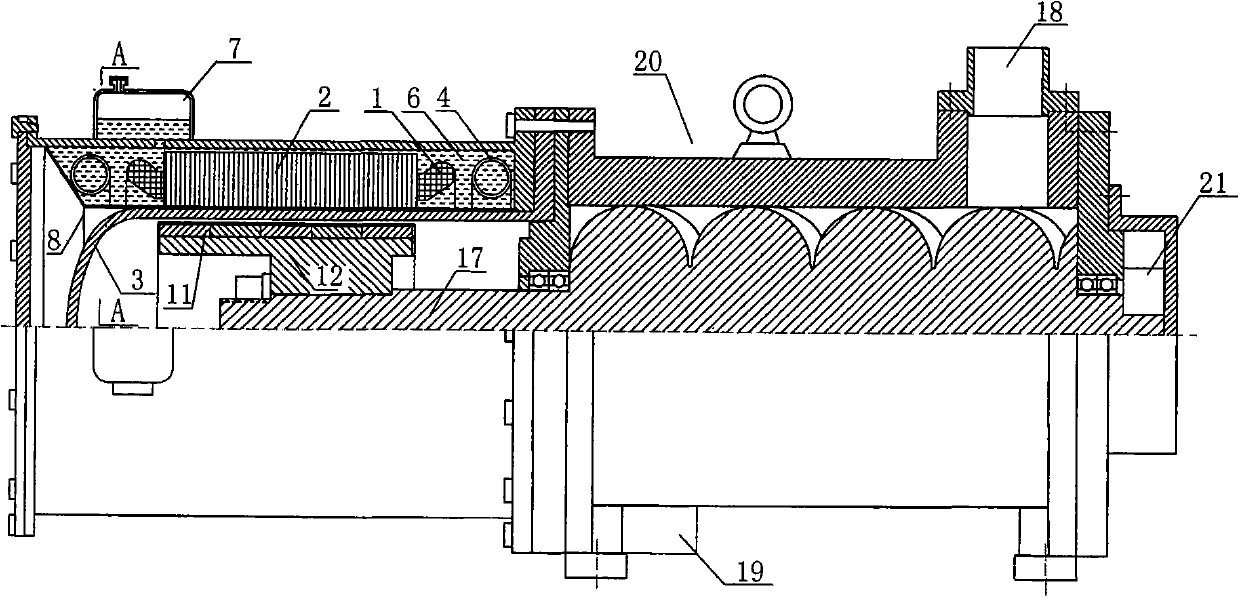

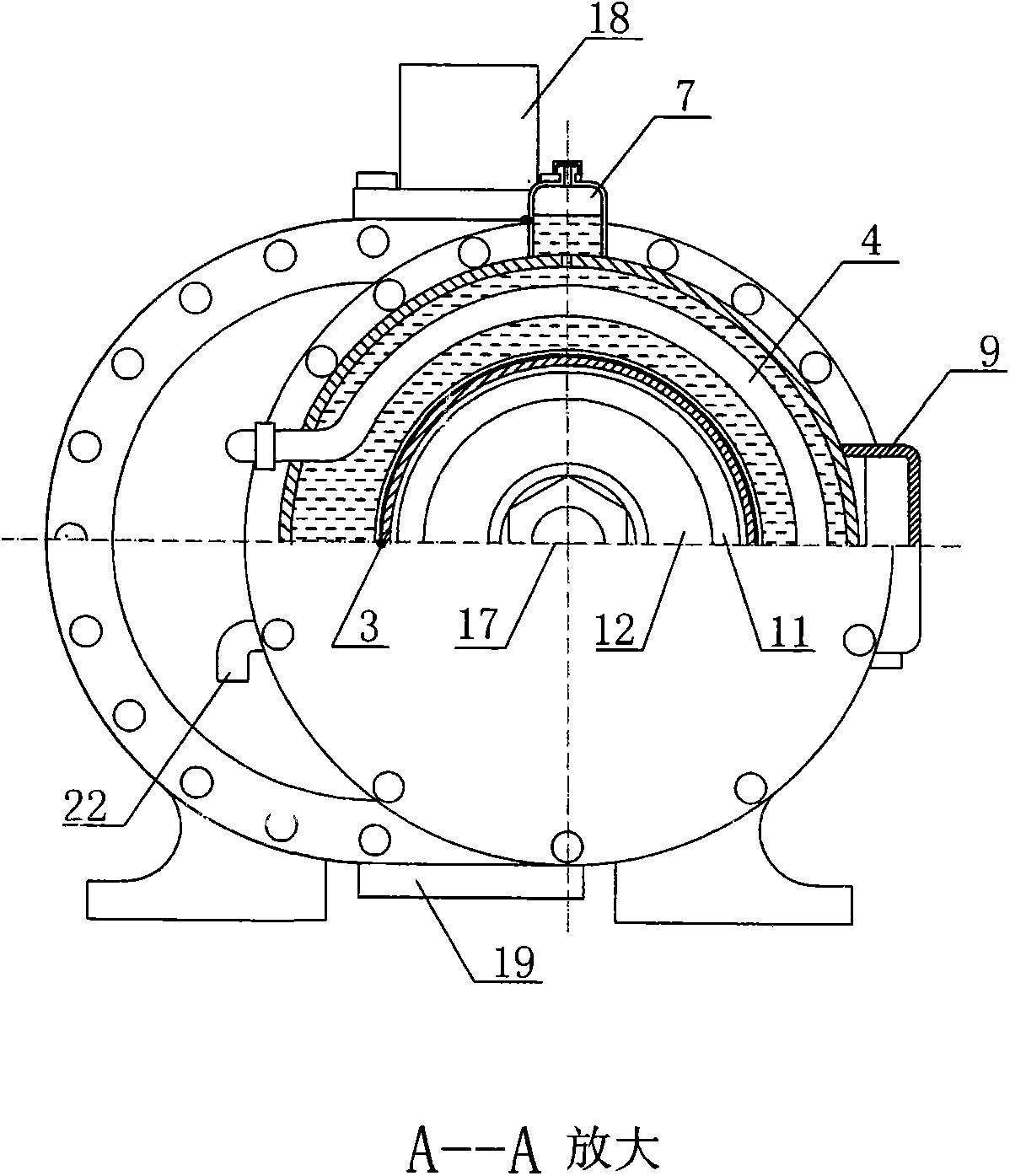

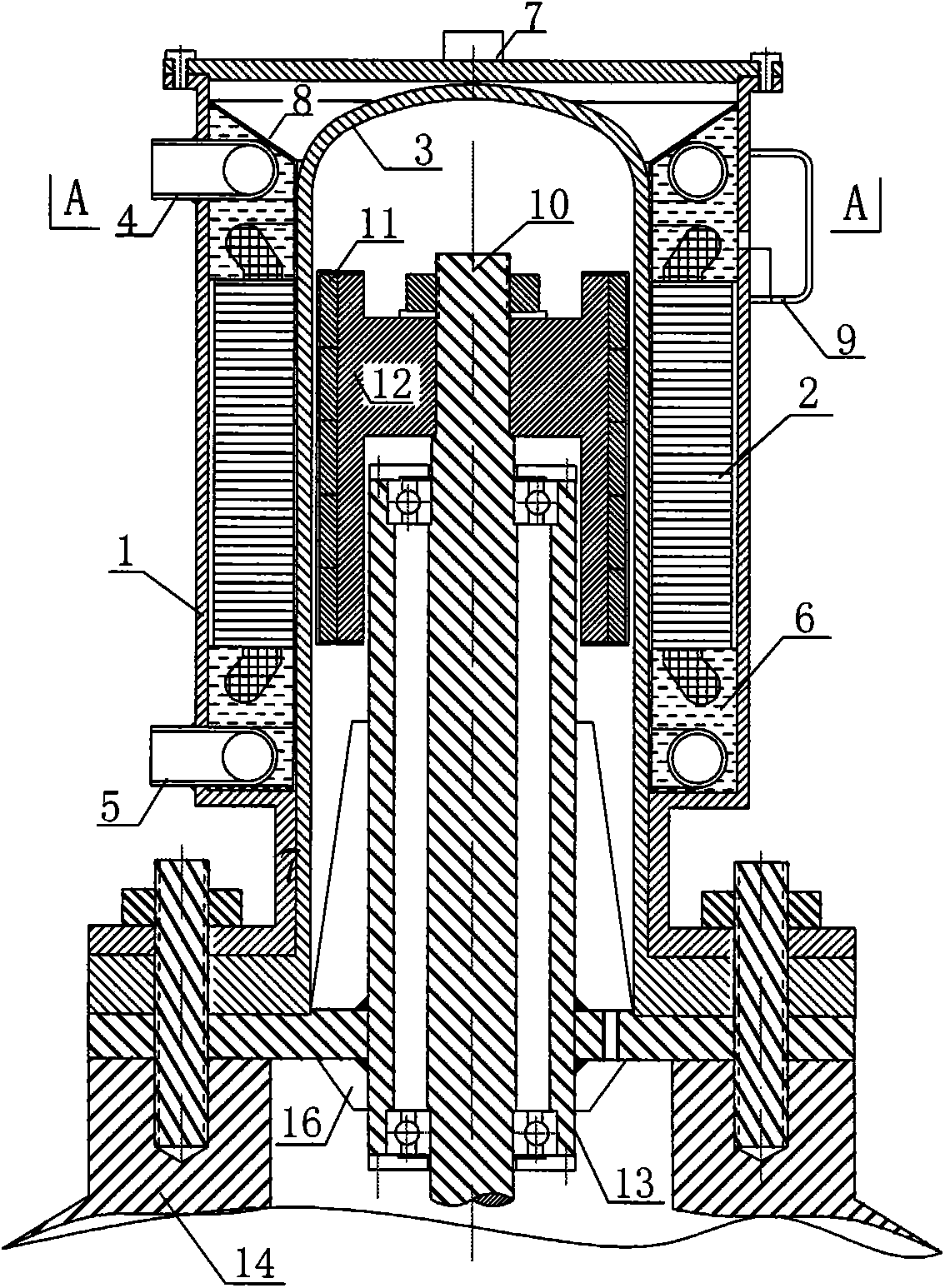

[0018] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0019] An internal cooling motor system body structure with a pressure-resistant cover includes: a motor casing 1 , a motor iron core and a coil 2 , and a motor coil shield 8 . The stator part of the motor is made of two parts, the iron core and the coil, according to the production requirements of the motor. The iron core that will wind the coil winding is packed in the specially-made motor housing, and the upper and lower sides of the stator are respectively packed into the ring cooling water pipes 4 and 5 within a certain safety range from the coil, and the water pipe fixing clips 15 are fixedly welded. The cooling water pipes 4, 5 and the motor casing can be fixed and sealed by welding or wire connection, and the cooling water can be connected in parallel or in series during use. Then use non-magnetic stainless steel to make a tubular shape acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com