Bothway self-adaptation three-axis transmission system

A three-axis transmission, self-adaptive technology, applied in one-way clutches, clutches, mechanical equipment and other directions, can solve the problems of high production cost, lag in response, cumbersome use procedures, etc., to achieve low manufacturing and maintenance costs, low operating noise, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

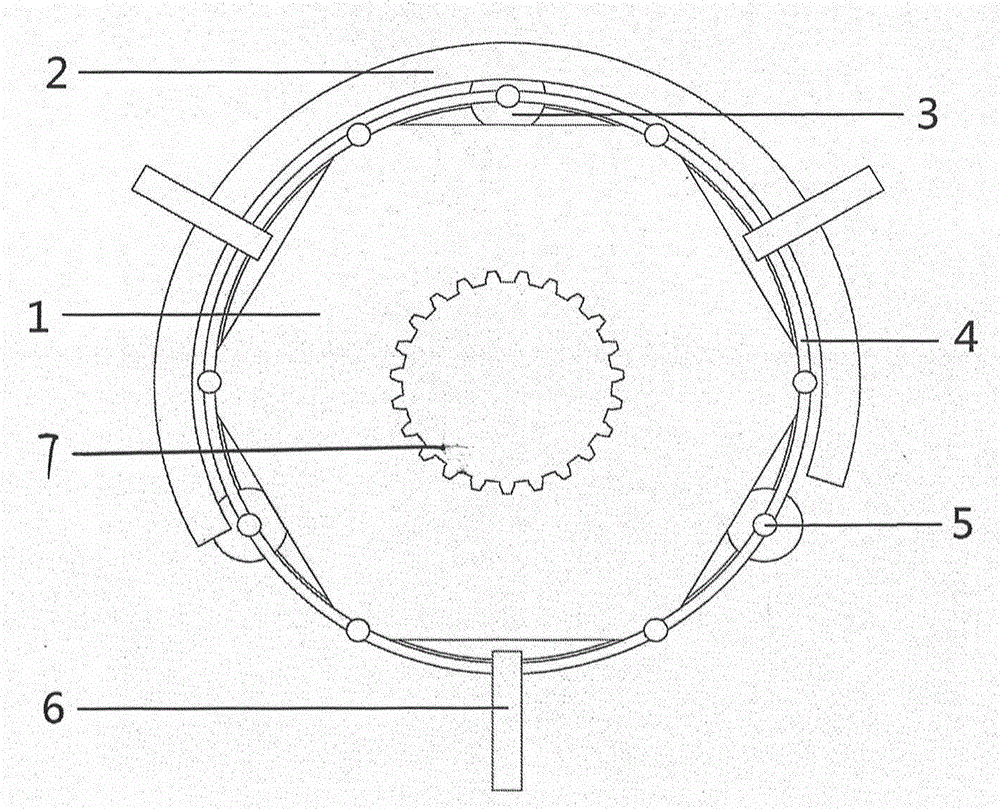

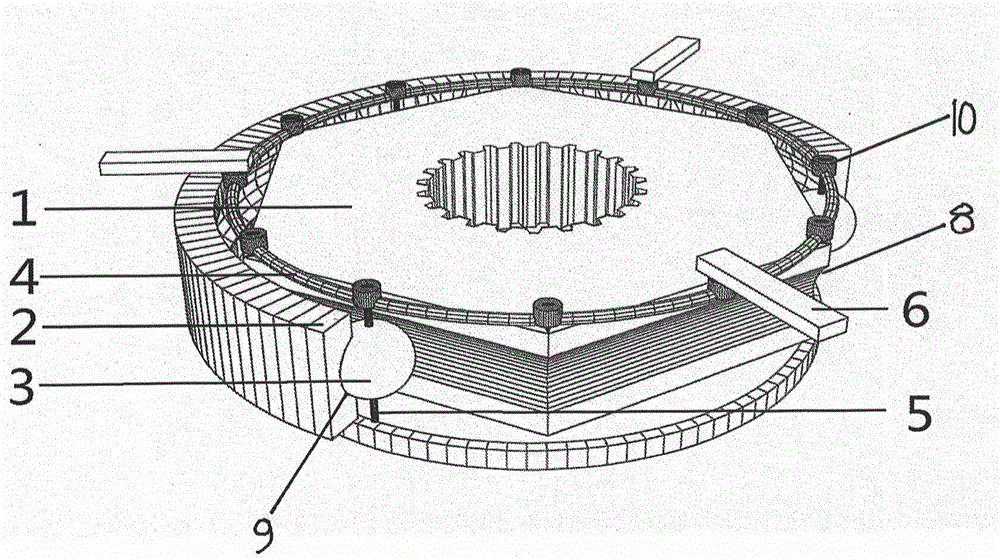

[0012] like figure 1 and figure 2 As shown, a two-way self-adaptive three-axis transmission system is composed of a driving shaft 1 and a driven shaft 2 . An adaptive wedge shaft transmission device is provided between the driving shaft and the driven shaft, or an adaptive wedge shaft transmission device is provided between the driving shaft and the driven shaft sleeve. The self-adaptive wedge shaft transmission includes:

[0013] The driving shaft 1, the outer periphery of the driving shaft is in an equilateral hexagonal prism structure. Its middle part is provided with the spline shaft hole 7 that joins with power source or connects the plate that connects basin tooth. The hexagonal cylinder surface of the driving shaft is provided with a plane on which the wedge shaft 3 slides on at least three cylindrical surfaces distributed at intervals or at least at least in the middle of the three cylinders distributed at intervals. The main wedge groove 8 in which the wedge shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com