AMT automatic gear shifting device

A technology for automatic gear shifting and gear shifting motors, which is applied in transmission device control, mechanical control devices, instruments, etc., and can solve problems such as large changes in shift position information, failure of shift selection functions, and failure of the entire mechanism to achieve The effect of compact structure, simple operation and few failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

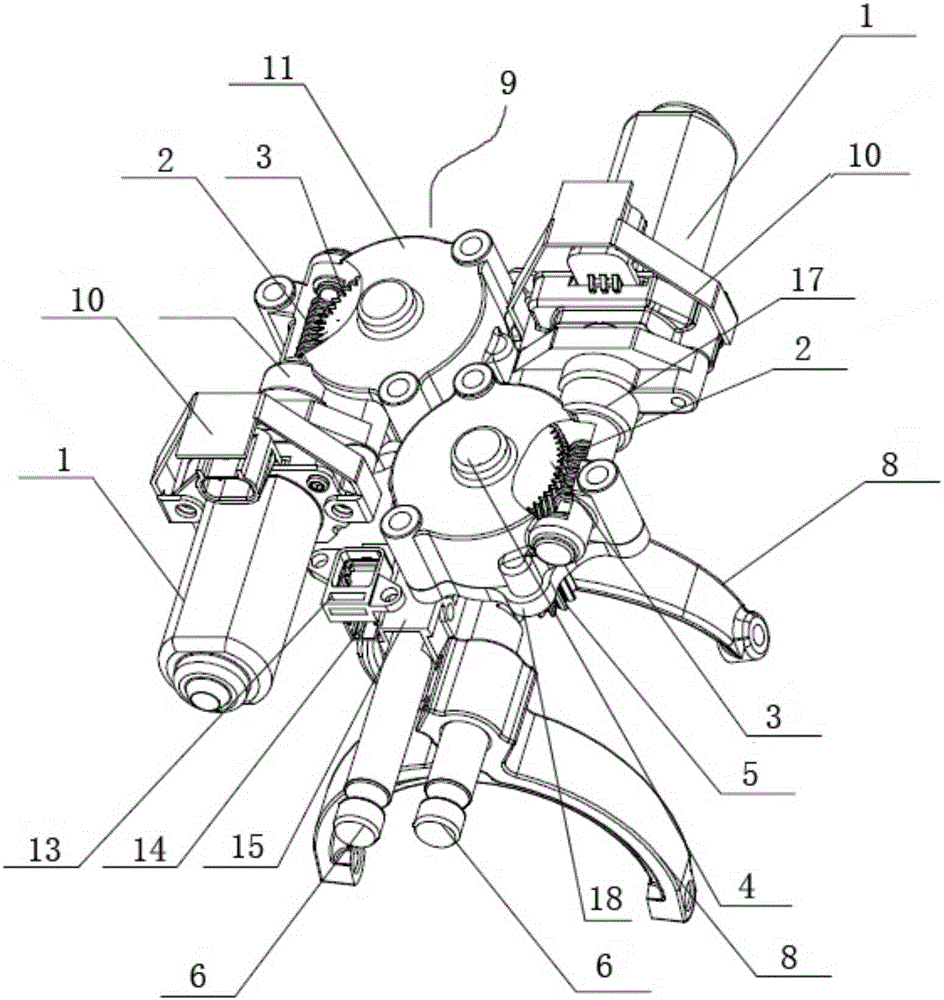

[0021] Specific embodiment one, see figure 1 : Each shift motor 1 is provided with 2 driving strokes, that is, one shift motor 1 corresponds to control 2 gear positions, and when the gear position corresponding to the shift device is 4, 2 shift mechanisms are installed, including 2 A shift support 9, 2 shift motors 1, 2 motor protection frames 10, 2 worm gear placement cavities 11, when the shift position sensor is a linear displacement sensor 13, 2 magnets 14 are fixed respectively through the magnet bracket 15 Corresponding to the shift fork shaft 6, two linear displacement sensors 13 are respectively installed on the transmission case at the corresponding position of the magnet 14 (not shown in the figure, which belongs to the existing mature structure), and the two linear displacement sensors 13 respectively sense the corresponding magnets. 14 linear displacement, the two linear displacement sensors 13 sense the position of the corresponding magnet 14 to collect the shift ...

specific Embodiment 2

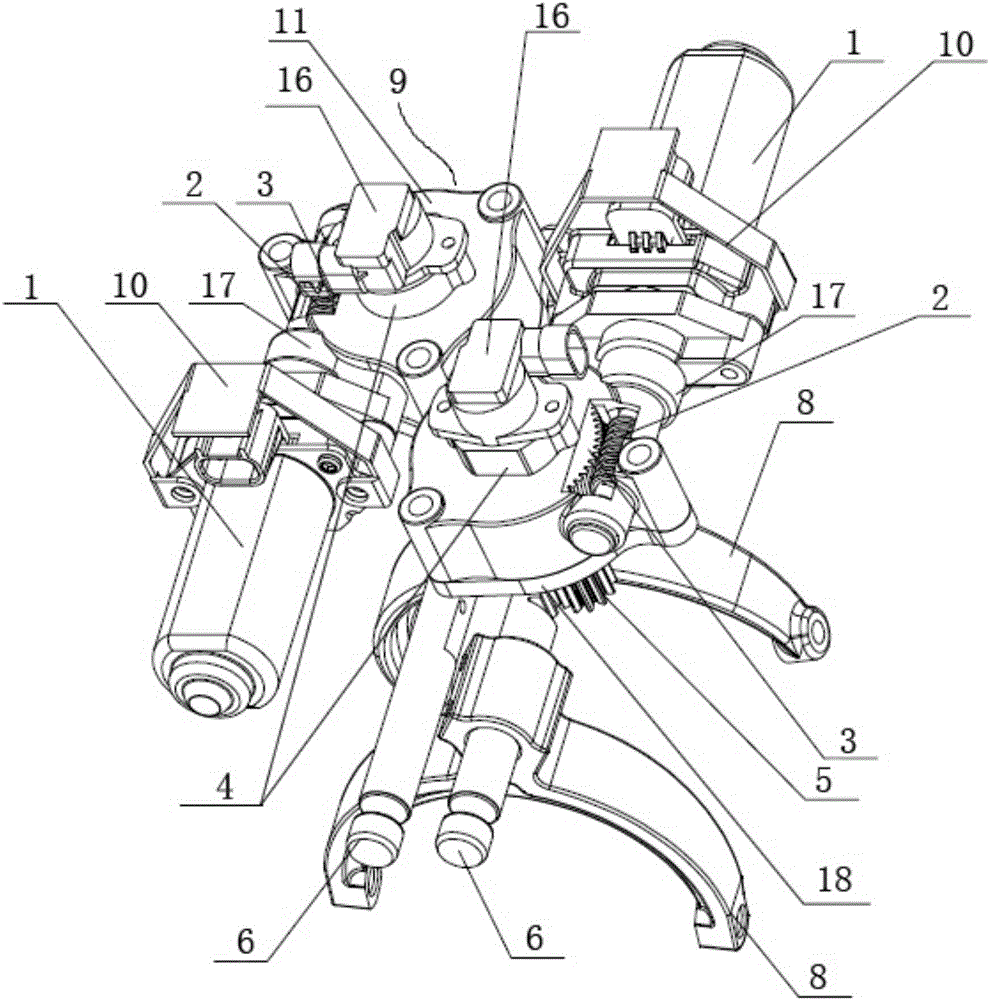

[0022] Specific embodiment two, see figure 2 : Each shift motor 1 is provided with 2 driving strokes, that is, one shift motor 1 corresponds to control 2 gear positions, and when the gear position corresponding to the shift device is 4, 2 shift mechanisms are installed, including 2 1 shift support, 2 shift motors 1, 2 motor protection frames 10, 2 worm gear placement cavities 11, 2 shift motors 1 are respectively arranged on the corresponding shift support 9, and the shift position sensor is Angular displacement sensor 16, two angular displacement sensors 16 are respectively set on the part of the corresponding main shaft 4 exposed to the worm gear placement chamber 11; since the main shaft 4 of the worm gear structure 3 and the main shaft of the shift gear 5 are the same main shaft, the angular displacement sensor 16 By collecting the angle information of the main shaft 4 of the worm gear structure 3, that is, the rotation angle information of the shift gear 5 is collected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com