Volatile matter leakage preventing reaction barrel

A reaction tube, anti-volatile technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical processes, chemical instruments and methods, etc., to achieve the effect of reducing irritating odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

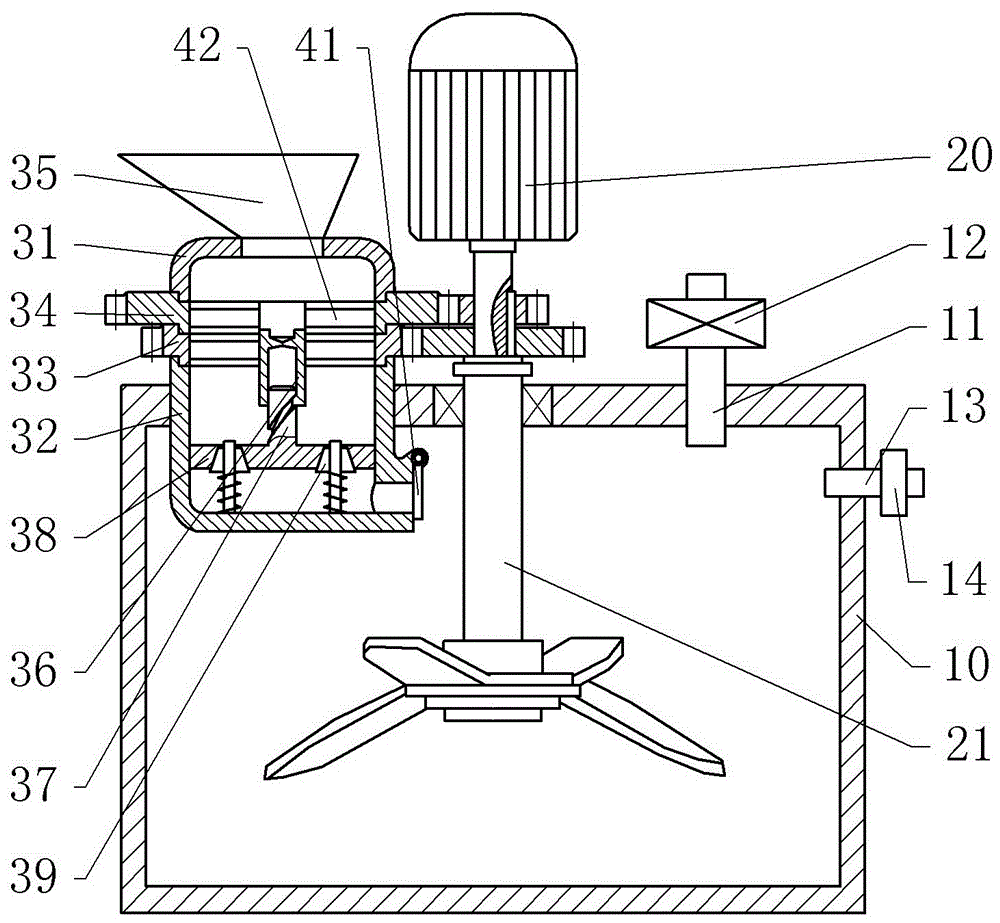

[0021] The reference signs in the drawings of the description include: housing 10, formaldehyde feed port 11, feed valve 12, exhaust pipe 13, formaldehyde absorber 14, motor 20, stirring shaft 21, upper cylinder 31, lower cylinder 32, High-speed crushing impeller 33, low-speed crushing impeller 34, urea feed hopper 35, linkage shaft 36, cylindrical cam 37, piston 38, plug 39, one-way feed valve 41, blade 42.

[0022] The embodiment is basically as figure 1 Shown:

[0023] The anti-volatile reaction cylinder of the present embodiment includes a housing 10, a motor 20, a urea pulverizing part, and a stirring shaft 21 arranged in the housing 10. The upper end of the stirring shaft 21 extends to the outside of the housing 10 and is connected to the motor 20. The output shaft is connected, so that the motor 20 can drive the stirring shaft 21 to rotate. The upper end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com