Automatic feeding device for spinning roller grinding machine

An automatic feeding and top roller technology, which is applied to grinding machines, machine tools designed for grinding the rotating surface of workpieces, transportation and packaging, etc., can solve the problems of less storage, unstable work, deformation of top rollers, etc., and achieve high efficiency Improvement, simple structure, less transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

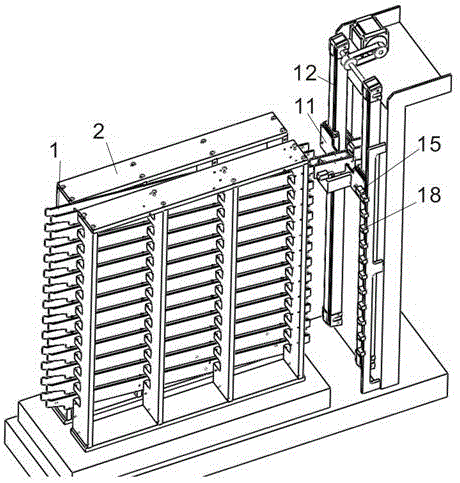

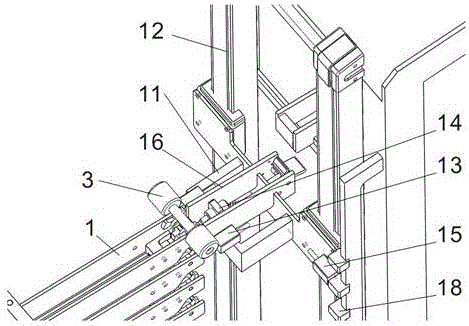

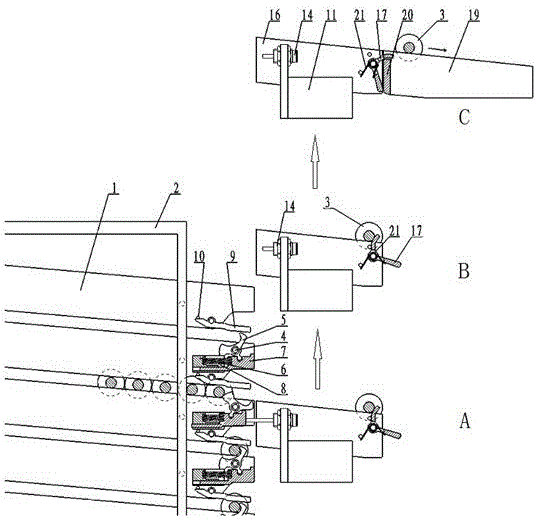

[0021] Such as Figure 1 to Figure 5 Shown are respectively the overall three-dimensional structure schematic diagram of the automatic feeding device of the textile top roller grinder of the present invention, the partial three-dimensional structure schematic diagram of the pick-up trolley unit, the structural schematic diagram of the pick-up trolley unit feeding, transporting, and discharging states and its retrieving, Enlarge the schematic diagram of the structure when discharging.

[0022] In this embodiment, multiple groups of storage raceway plates 1 are arranged in the raceway plate support frame 2 to form a multi-raceway storage bin unit. The rollers 3 are concentrated at the outlet to facilitate rolling out; at the outlet of each group of storage raceway plates 1, a push block 5 is respectively installed through a shaft pin 4, and the push block 5 has a front block, a rear block, and a convex structure. A slide plate seat 6 is fixed on any storage raceway plate 1 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com