Polishing machine

A polishing machine and polishing brush technology, which is applied in the field of polishing machines, can solve problems such as scratches, customer dissatisfaction, and affecting the health of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

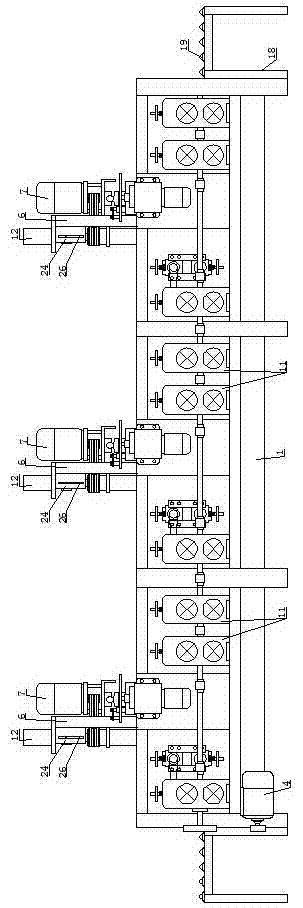

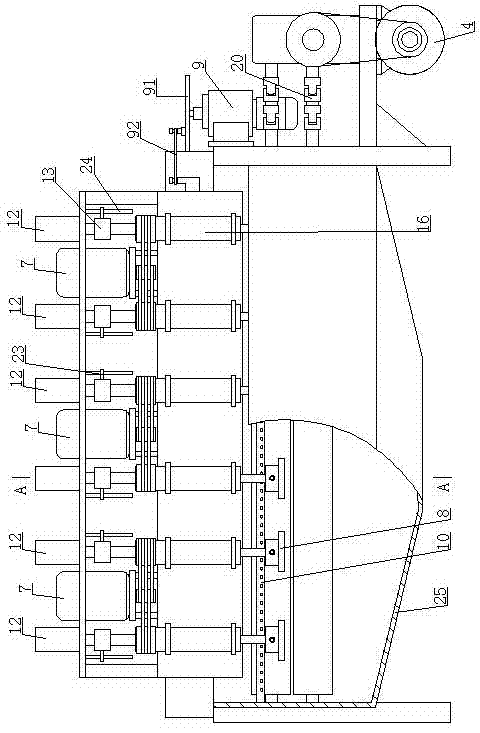

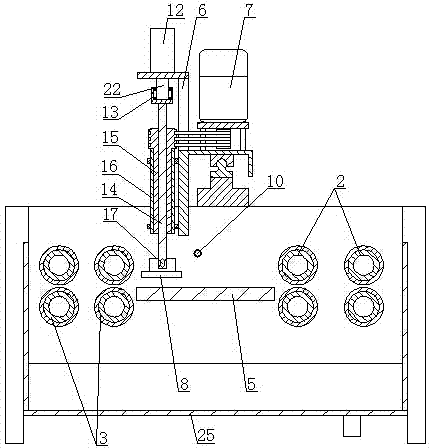

[0019] Such as Figure 1 to Figure 3 As shown, the polishing machine includes a frame 1, and the frame 1 is sequentially installed with three groups of mills from the feed end to the discharge end, and the frame 1 is respectively provided with a support frame 18 at the feed end and the discharge end, and the support frame The upper surface of 18 is fixed with universal support ball 19. Each group of mill feed end and discharge end are respectively equipped with two sets of conveying rollers to facilitate the smooth conveying of the steel plate. And the lower conveying roller 3 is a rubber roller, wherein the upper conveying roller 2 can be adjusted up and down, and the structure of up and down adjustment is a prior art, so it will not be repeated here. The main motor 4 used to drive the upper conveyor roller 2 and the lower conveyor roller 3 to rotate synchronously is installed on the frame 1. The conveyor roller groups at the feed end of each group of mills are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com