Patents

Literature

45results about How to "Short drive line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

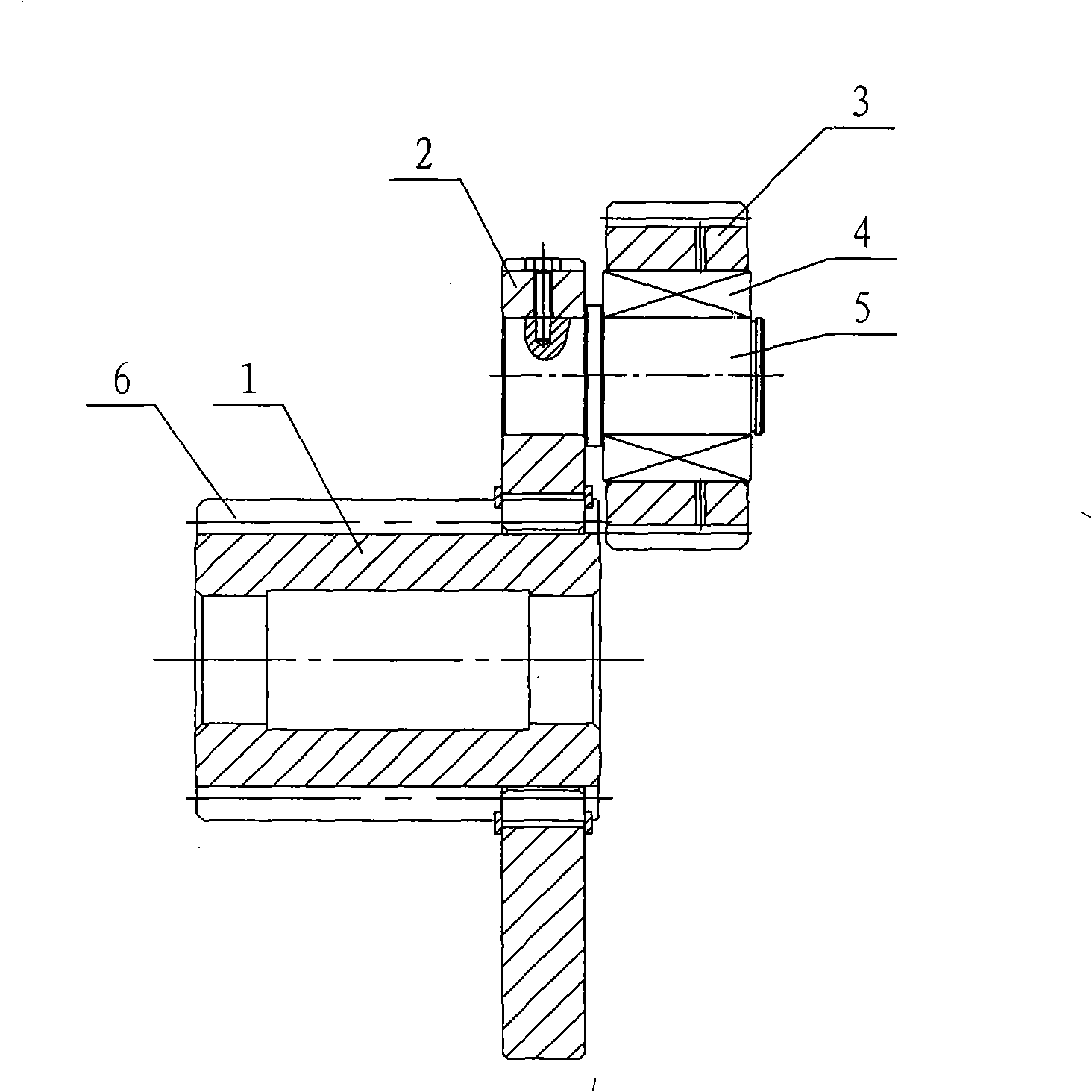

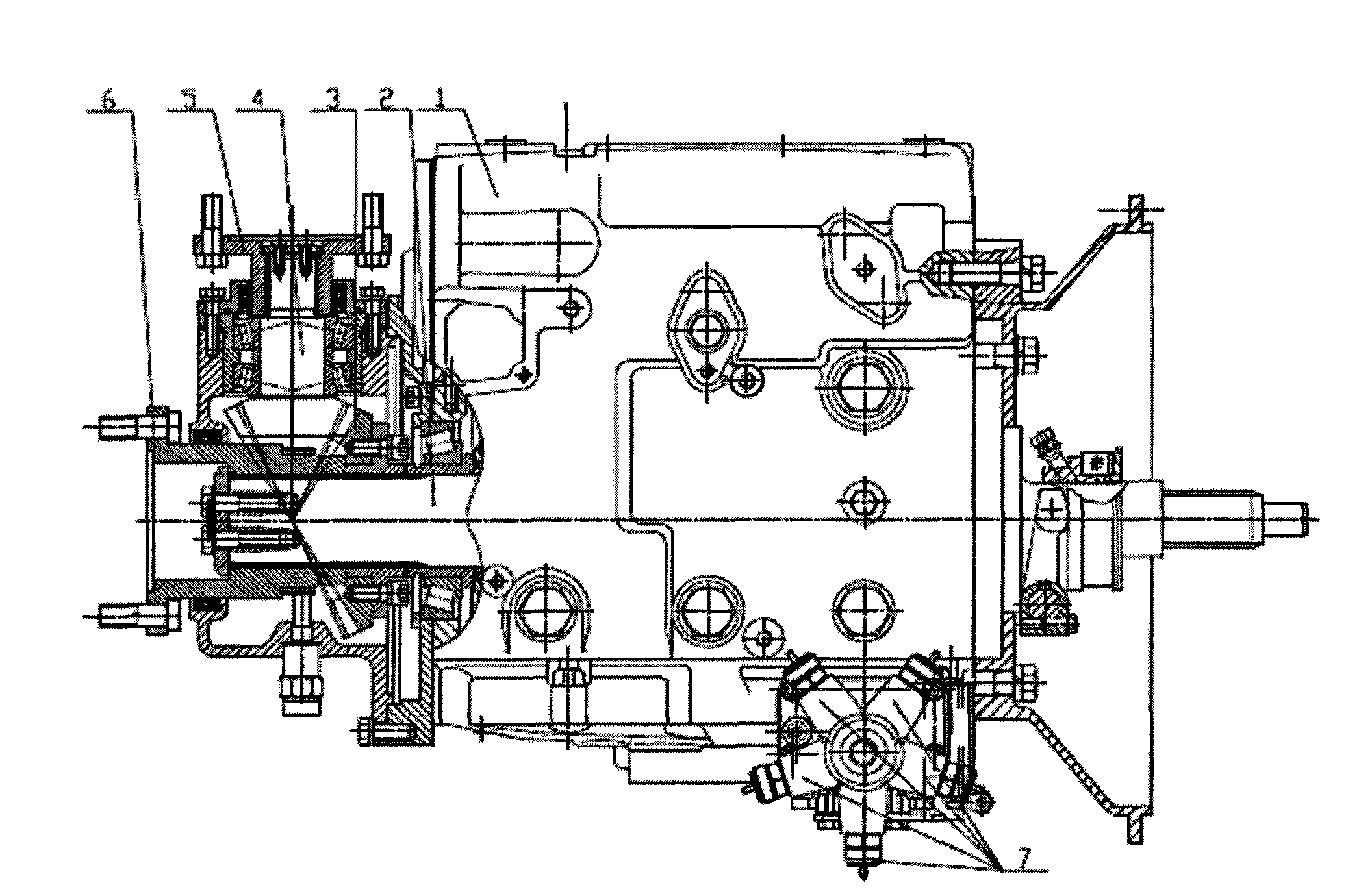

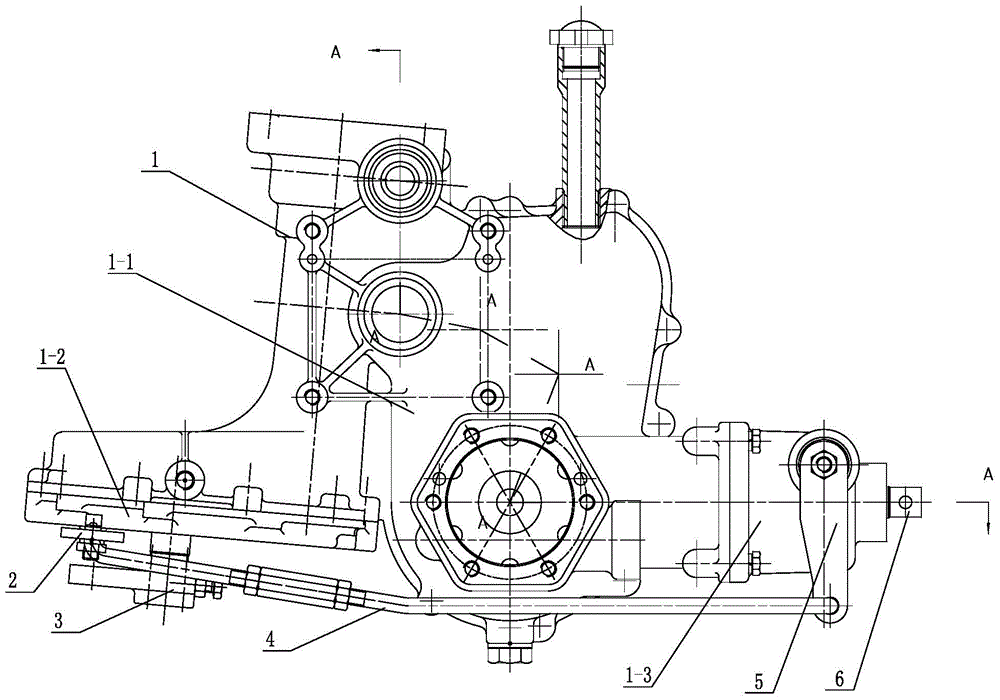

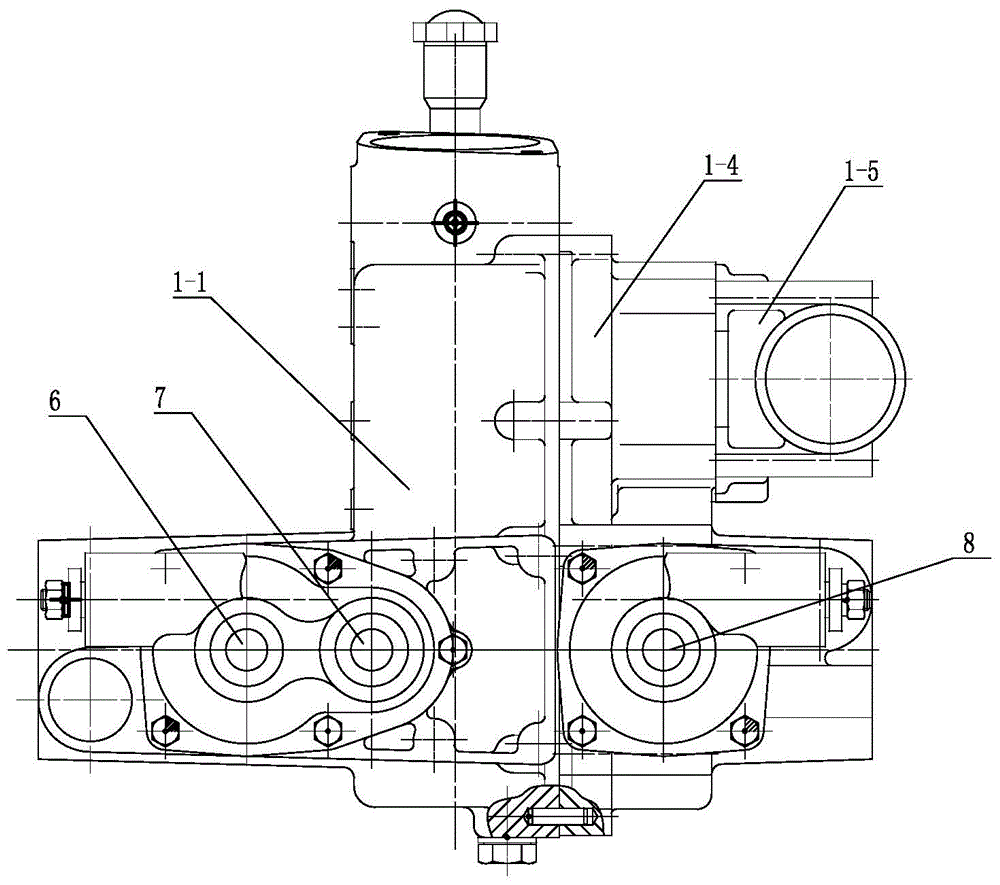

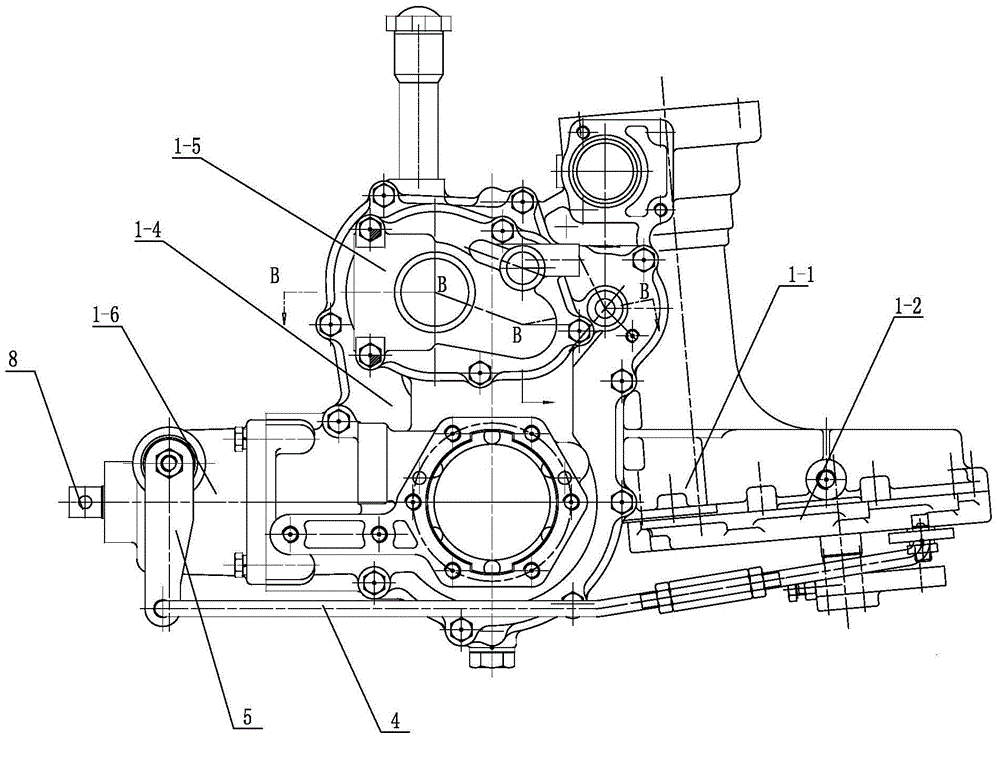

Dynamic gear shifting transmission-gear box suitable for engineering machinery

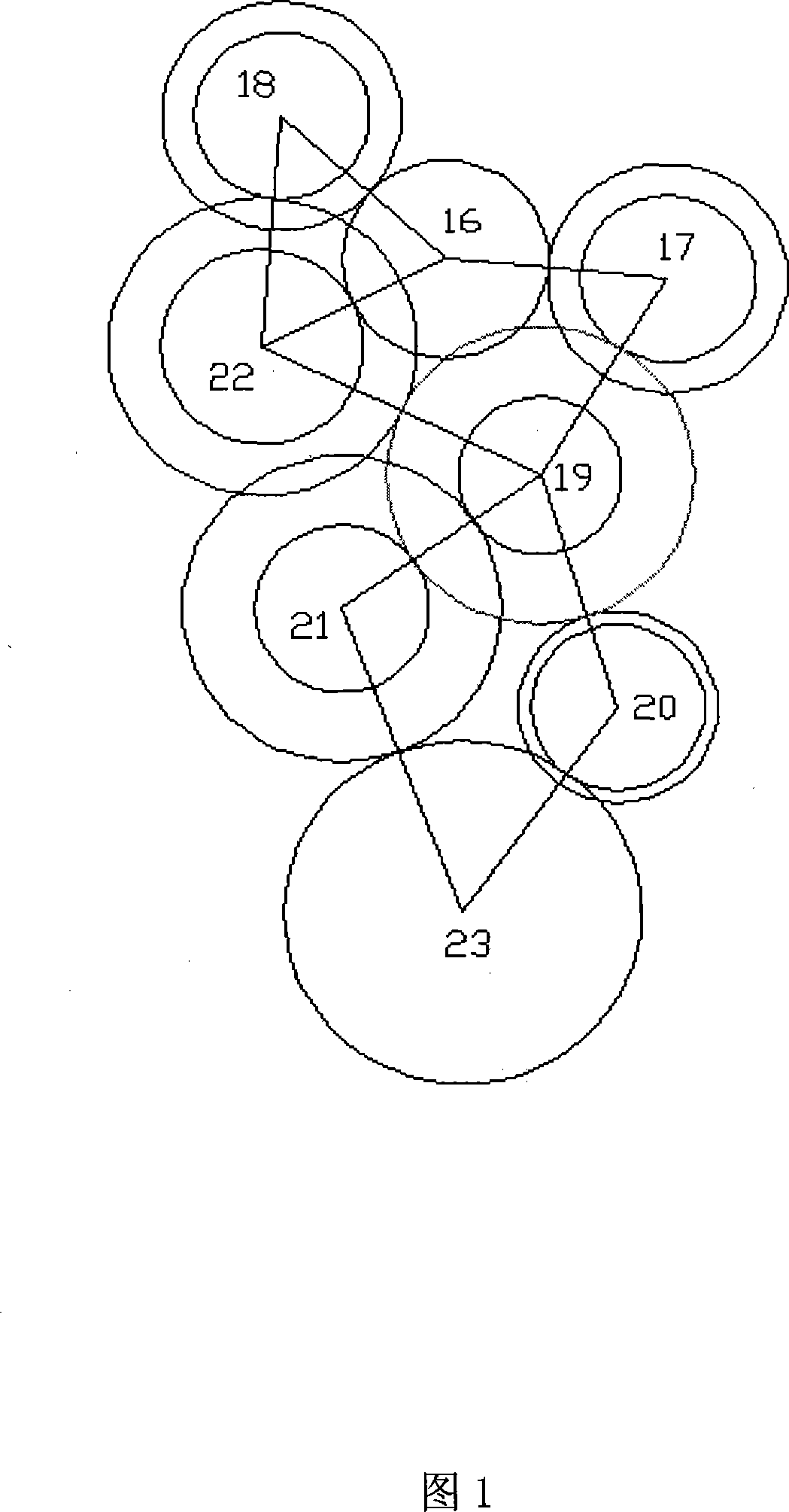

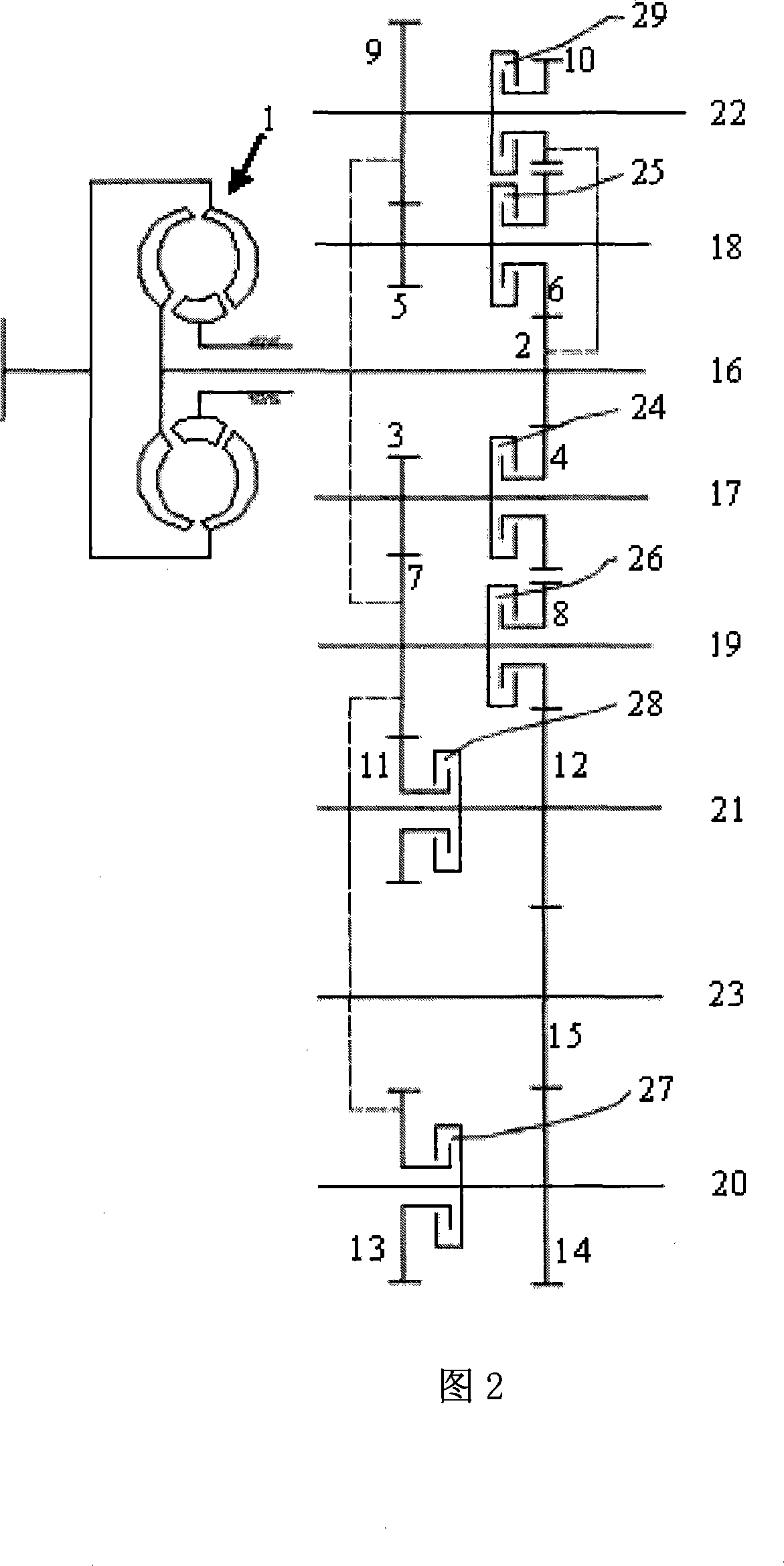

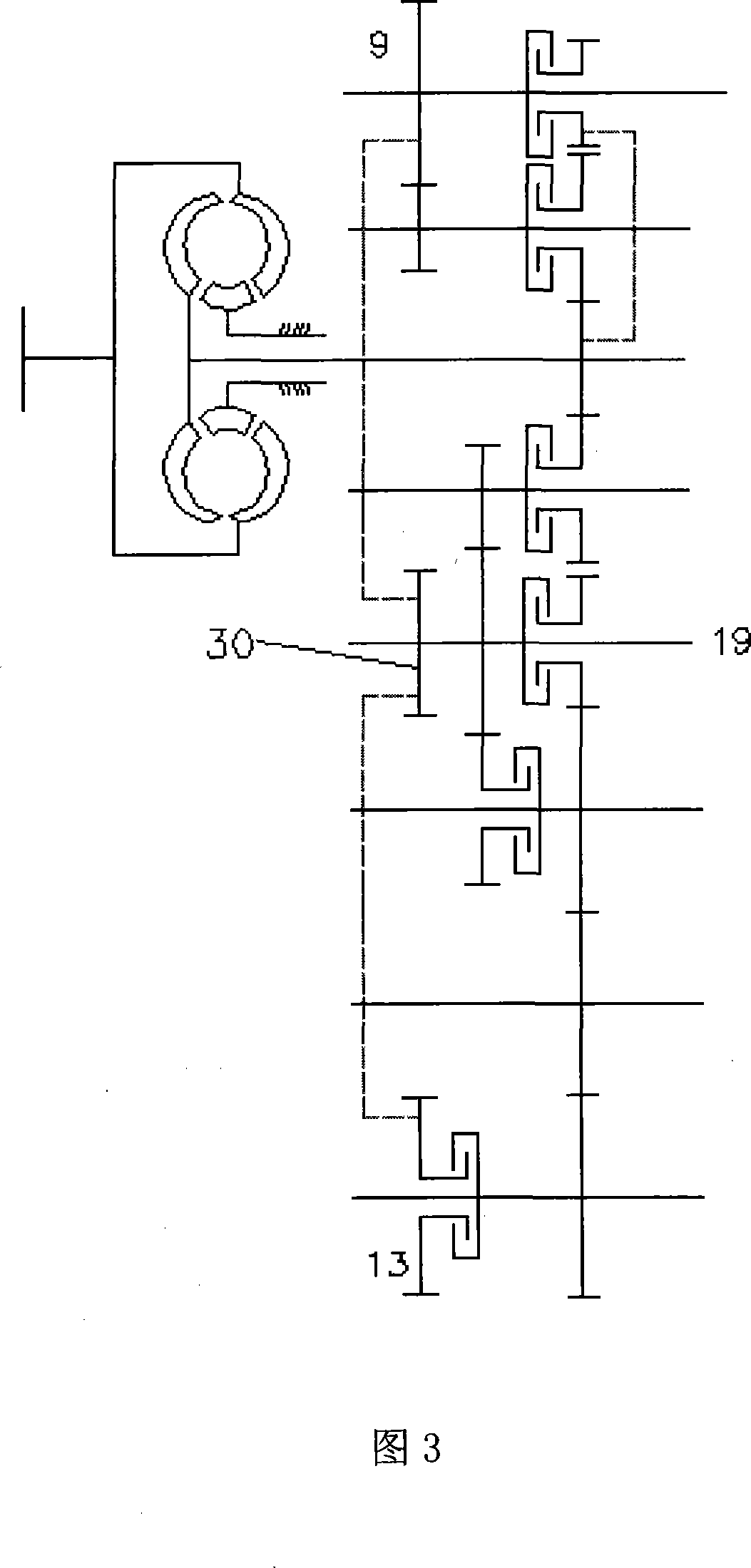

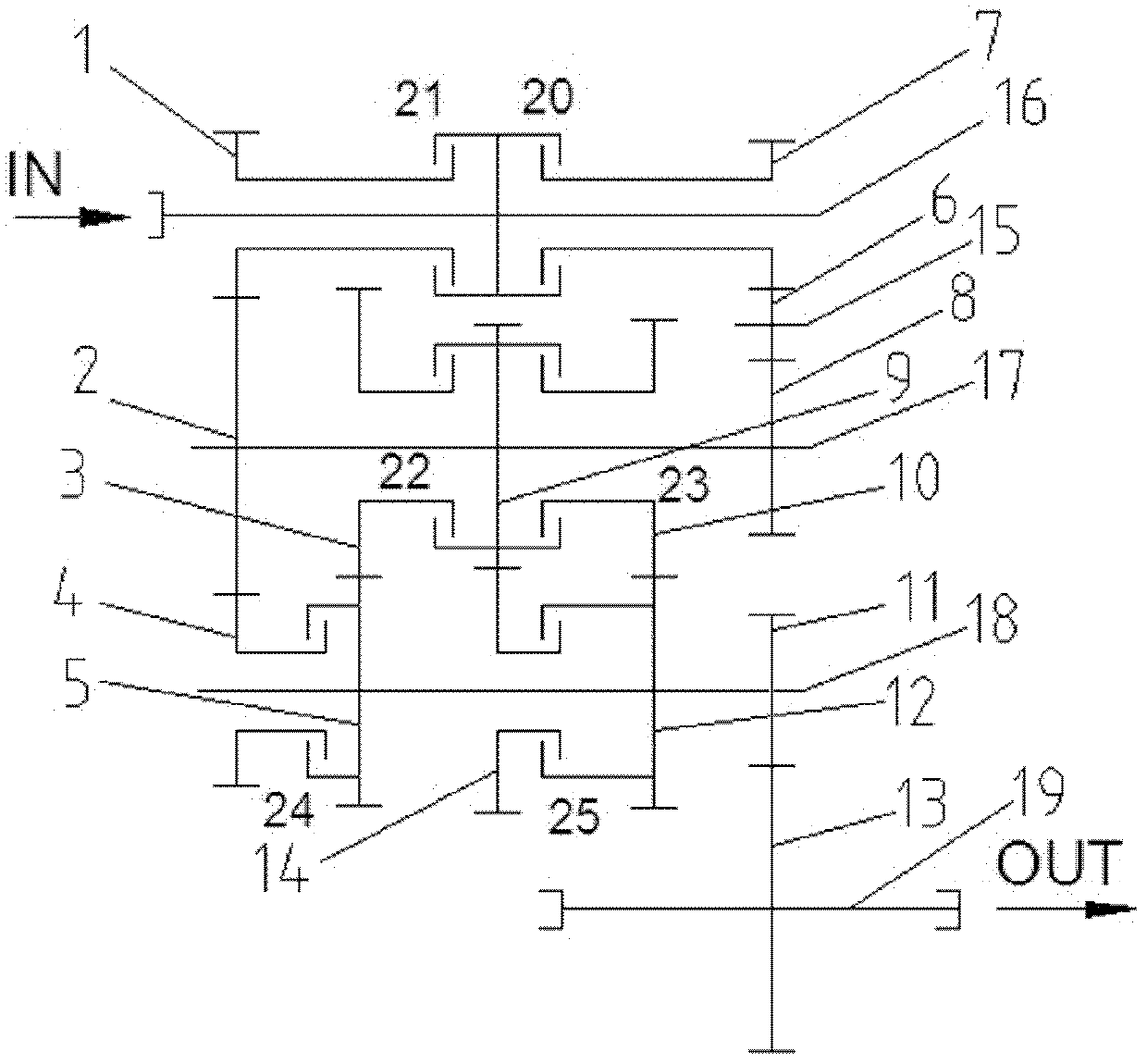

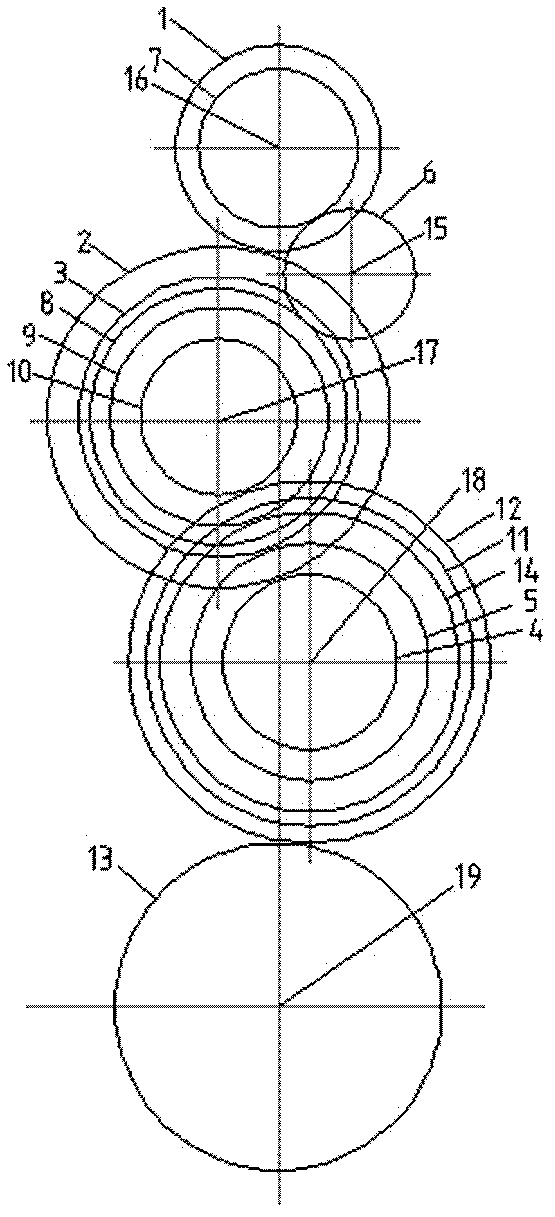

The present invention provides a power shift gearbox fit for engineering plant, mainly resolving complex problem of many gearbox spares and transmission route for present engineering plant. The invention is composed of an input shaft, an output shaft, some center shafts and some clutches and gears, wherein some gears form a reversing gear set, the other gears form a driver gear set, the input shaft and the second, sixth center shafts seen from end show triangle arrangement according to the transmission route of axes, the input shaft and the first, second, sixth middle shafts show quadrilateral arrangement, the output shaft and the third, fouth, fifth center shafts show quadrilateral arrangement. The transmission route of the structure is more compact, using less spares, high transmission efficiency.

Owner:SICHUAN CHENGDU CHENGGONG CONSTR MACHINERY

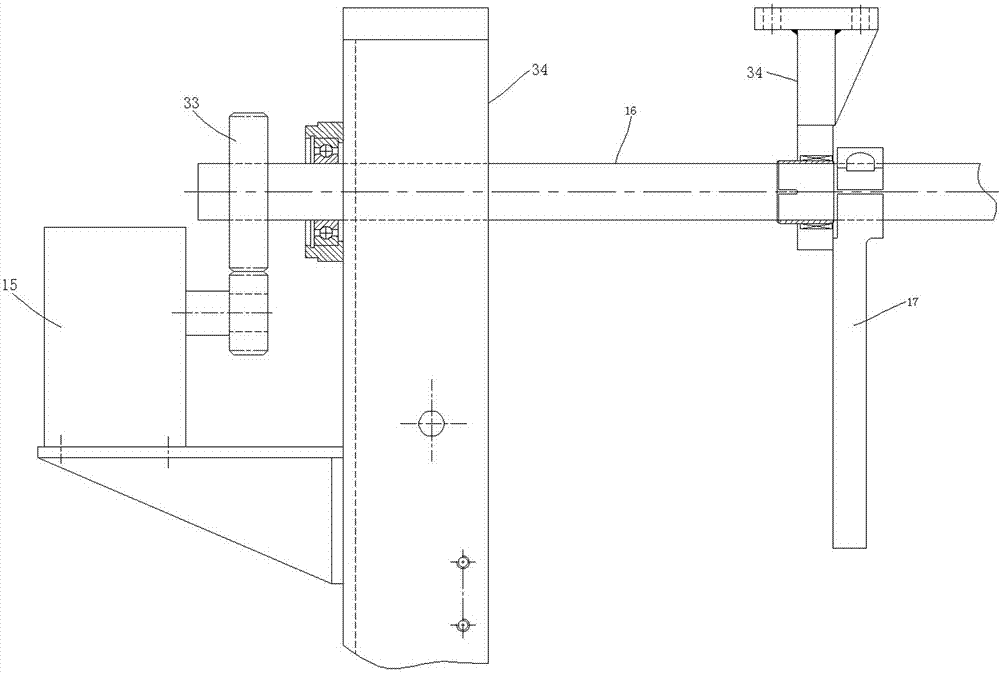

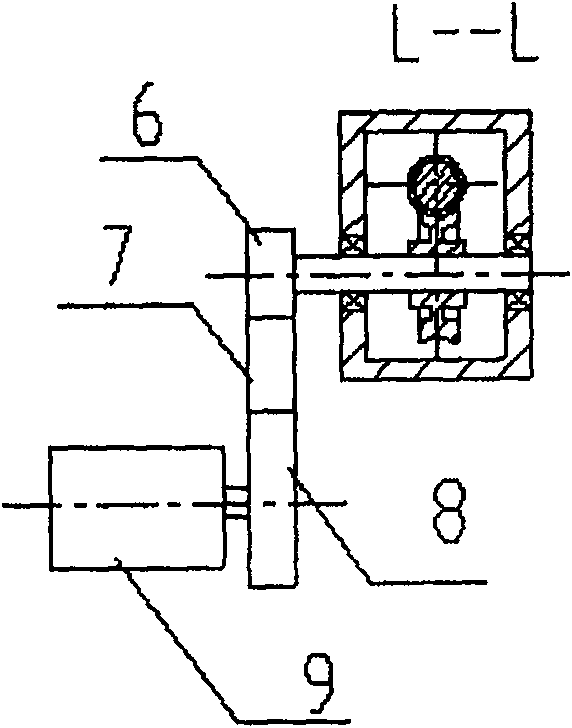

Schlagblech moving device for computer type tricot machine

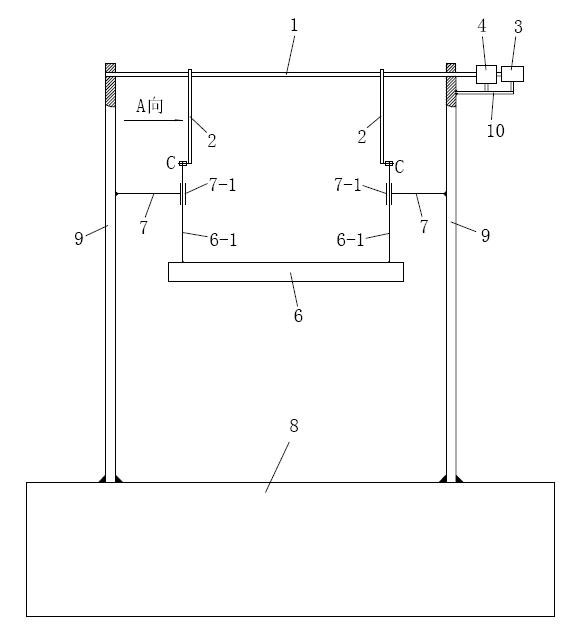

The invention relates to a schlagblech moving device for a computer type tricot machine, which comprises a schlagblech , two wall plates respectively fixed at the left side and the right side of the top of an oil tank of the tricot machine, and a pressing input shaft positioned between the two wall plates, wherein both ends of the pressing input shaft are respectively inserted into holes of the two wall plates and are connected in the mode of rotating pairs; a bracket is fixed on the outer side face of one of the wall plates and is provided with a servo motor and a speed reducer; one end of the pressing input shaft is connected with an output shaft of the speed reducer after extending out of the wall plates; the pressing input shaft drives the schlagblech to move through two same transmission mechanisms which are provided with eccentric wheels and connecting rods; the eccentric wheels are fixed on the pressing input shaft; the upper ends of the connecting rods and the eccentric wheels are connected in the mode of rotating pairs, and the lower ends of the connecting rods and a connecting piece fixed on the schlagblech are connected in the mode of rotating pairs; and the connecting piece is connected with a schlagblech guiding piece fixed on the side wall plate in the mode of rotating pairs. The invention has the advantages of simple structure, convenient regulation and high-speed operation fit.

Owner:临沂高新区金蓝领劳务有限公司

Device of utilisation of waste gases for automobile engine

InactiveCN1959076AStable outputEfficient deliveryInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

A utilization device of waste gas from engine on automobile consists of volute, blade set in volute, power transmission unit and speed reduction unit. It is featured as setting power transmission unit and speed reduction unit to be a unified unit and erecting said unified unit between volute and generator.

Owner:CHERY AUTOMOBILE CO LTD

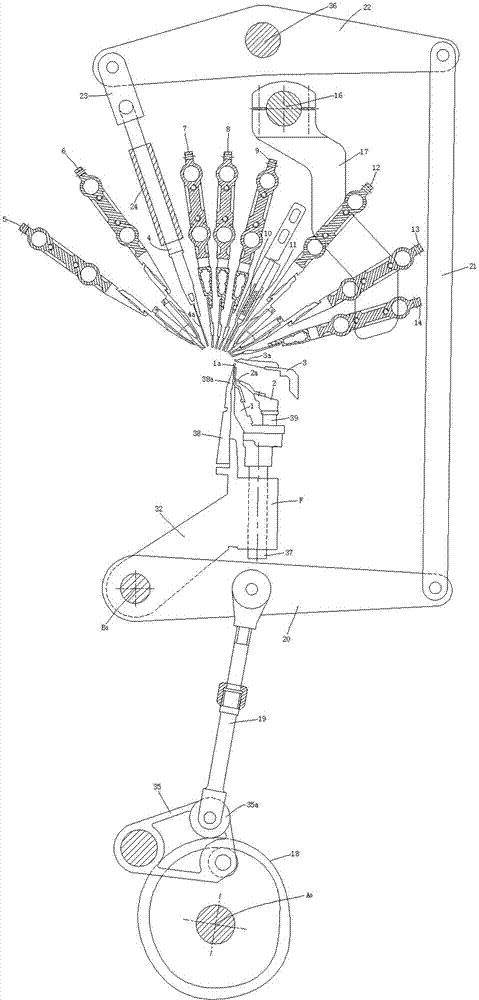

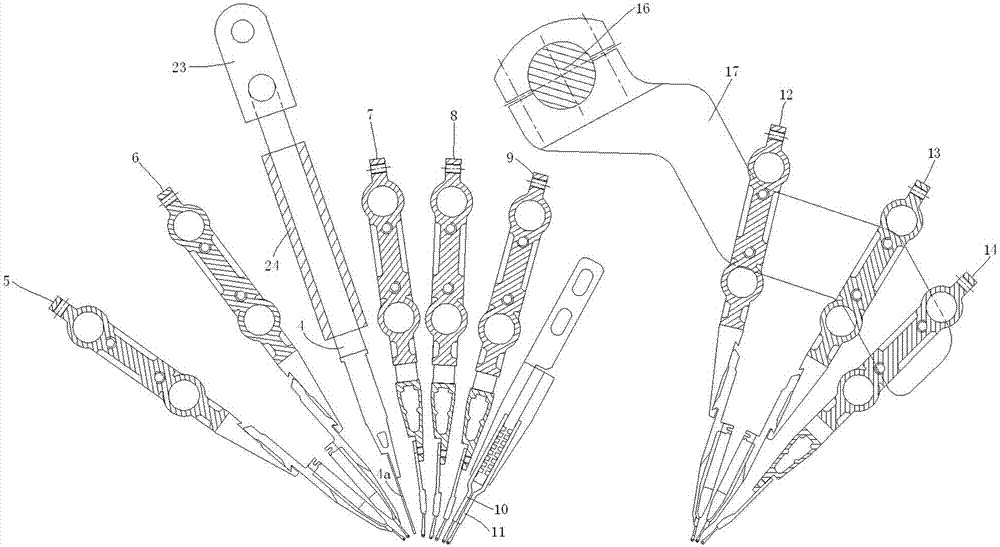

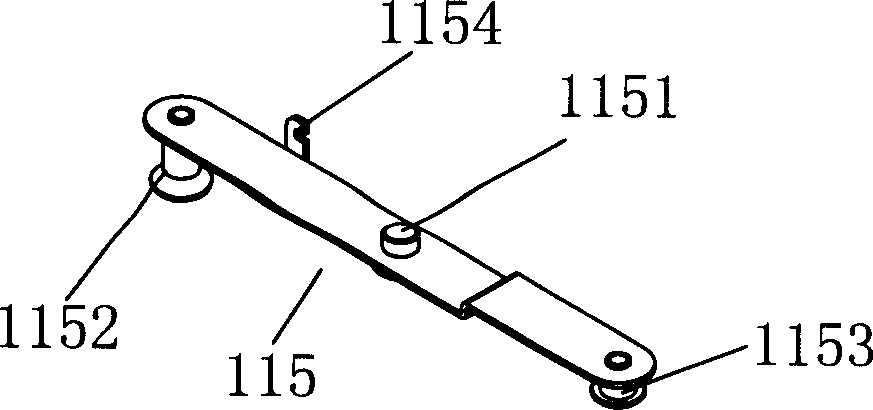

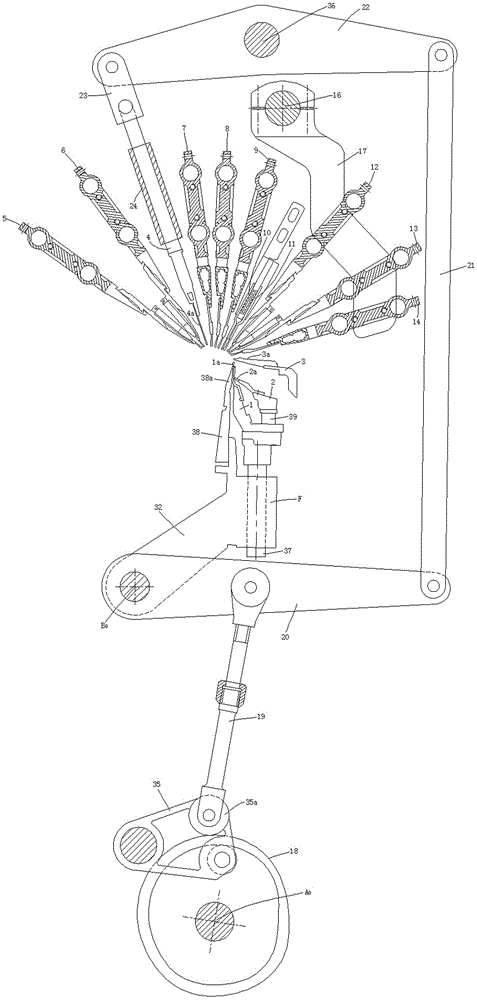

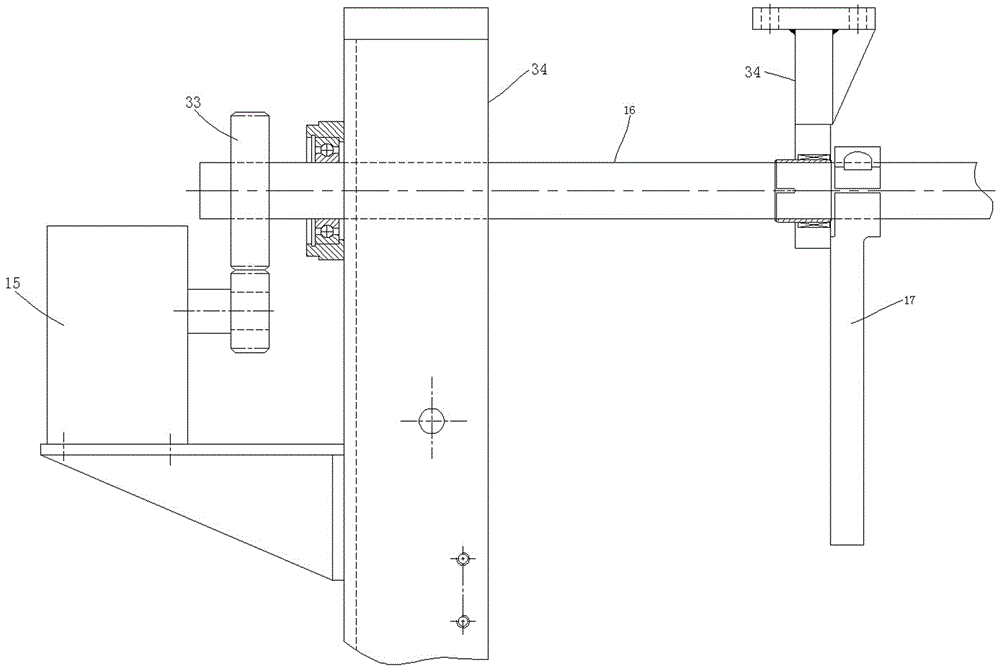

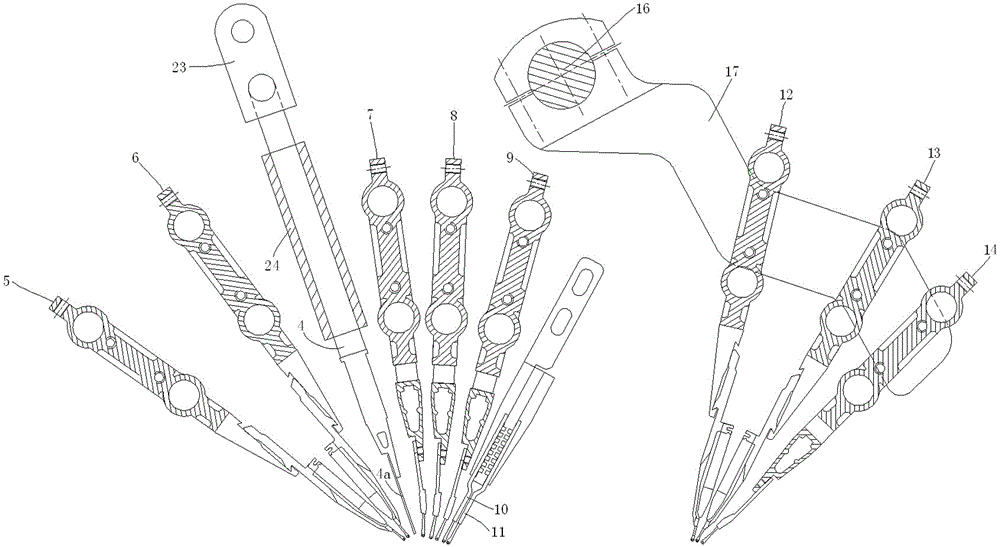

Loop-forming mechanism of few-guide-bar yarn-pressing warp knitting machine

InactiveCN104499181ARich fabric patternsSatisfy the variety of flower patternsWarp knittingEngineeringLinear motion

The invention discloses a loop-forming machine of a few-guide-bar yarn-pressing warp knitting machine. The loop-forming machine comprises a groove pin fixedly mounted on a groove pin bed, a pin core fixedly mounted on a pin core bed, a sinker fixedly mounted on a sinker bed, a yarn pressing plate and groove pin up-down movement mechanism fixedly mounted at the lower end of a yarn pressing plate mounting base, a groove pin swing mechanism, and a guide bar mechanism provided with a plurality of guide bars, wherein the guide bar mechanism is provided with at least ten guide bars which are a first jacquard guide bar, a second jacquard guide bar, a first ground guide bar, a second ground guide bar, a third ground guide bar, a first grouped pattern guide bar, a second grouped pattern guide bar, a third jacquard guide bar, a fourth jacquard guide bar and a spandex guide bar in the direction from the front to the rear of the machine; the yarn pressing plate is positioned between the second jacquard guide bar and the first ground guide bar, and is driven by the yarn pressing plate up-down movement mechanism to do up-down linear motion. The loop-forming mechanism is reliable in yarn-pressing action, is rich in fabric pattern, and can meet the development trend of pattern diversity.

Owner:江苏润源控股集团有限公司

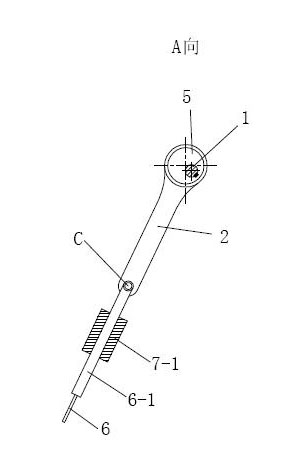

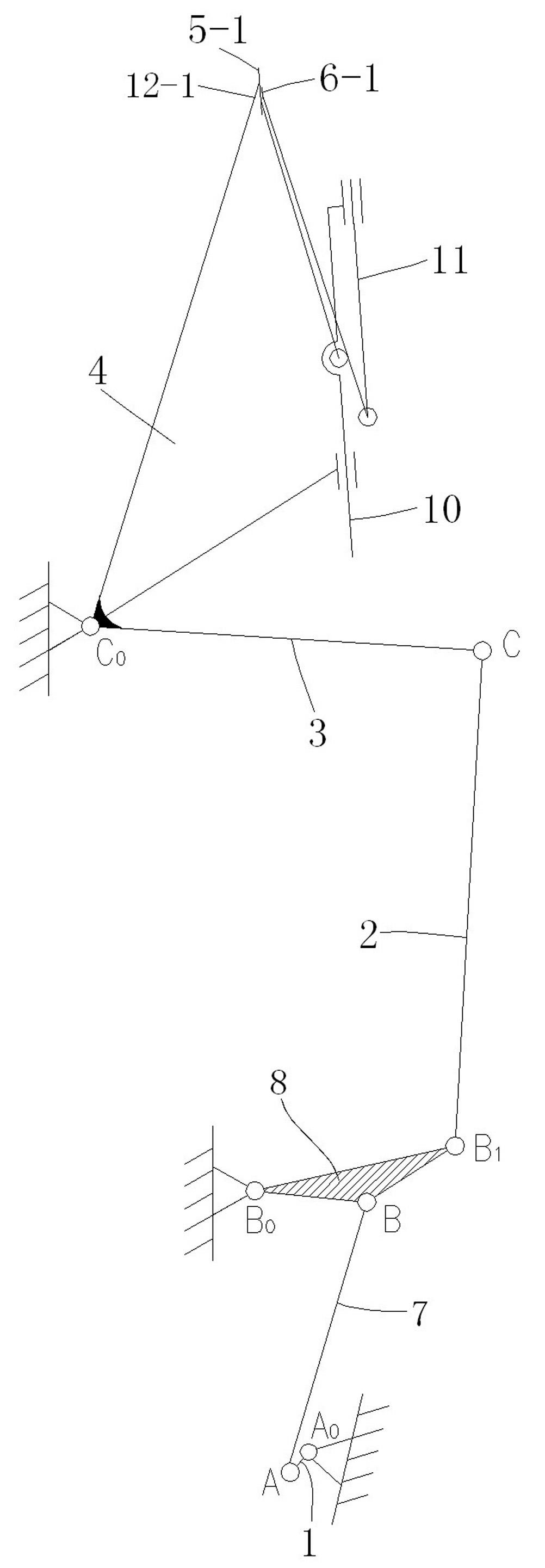

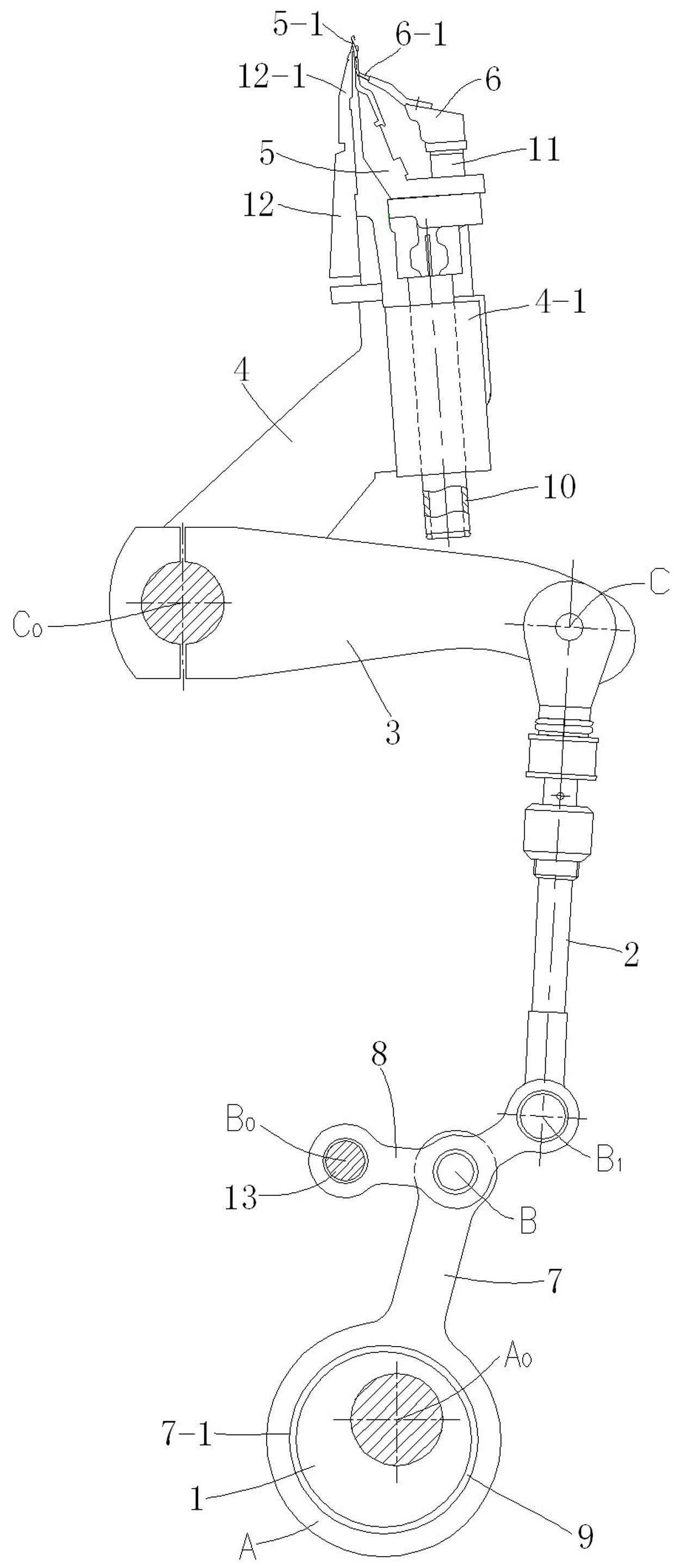

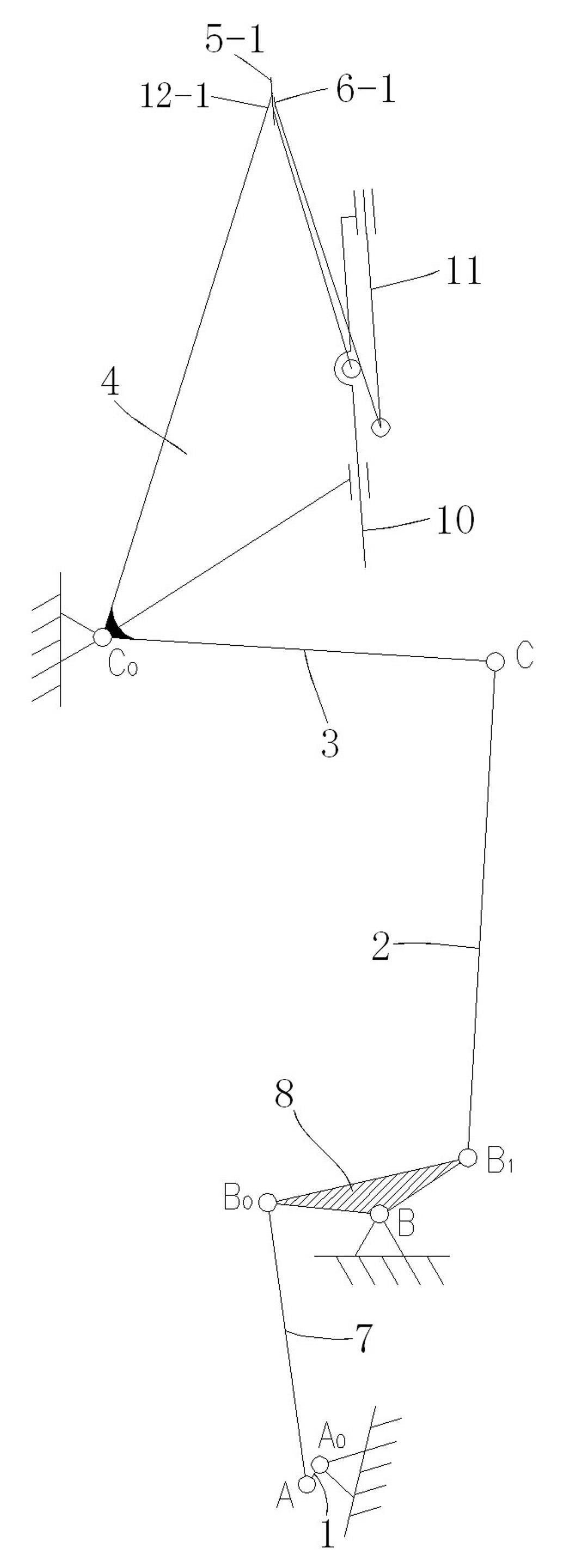

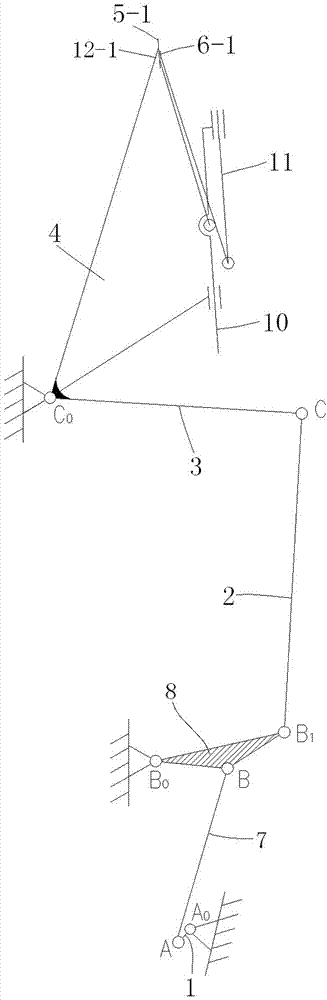

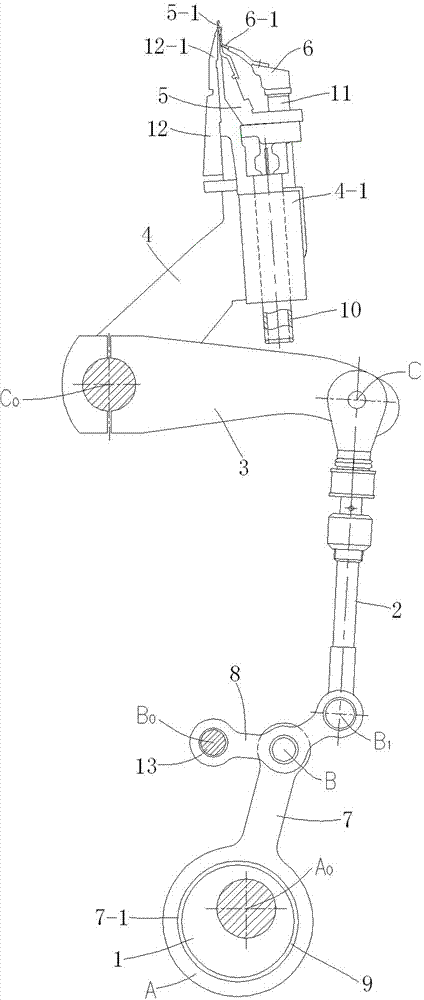

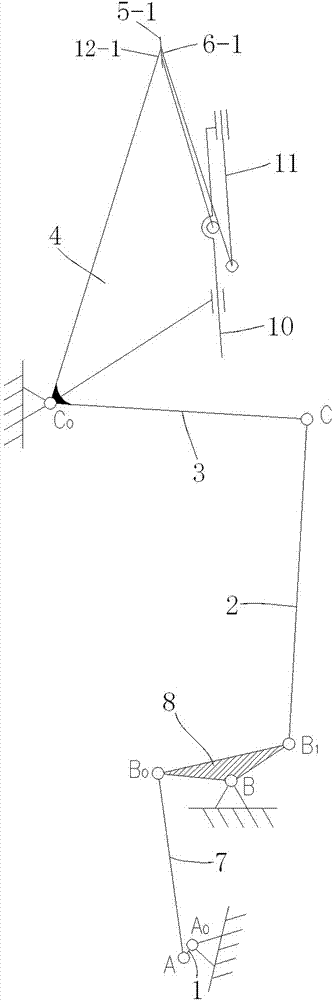

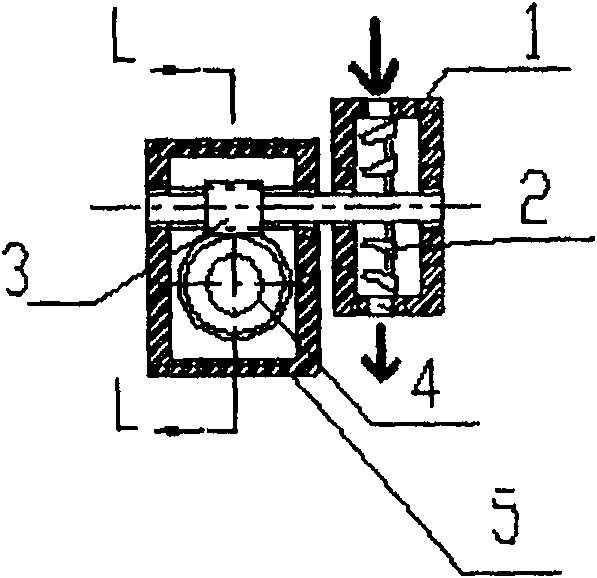

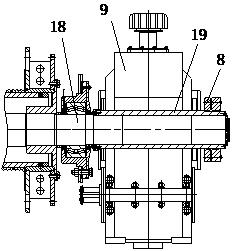

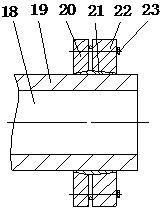

Needle bed swing mechanism for multi-bar Raschel warp knitting machine

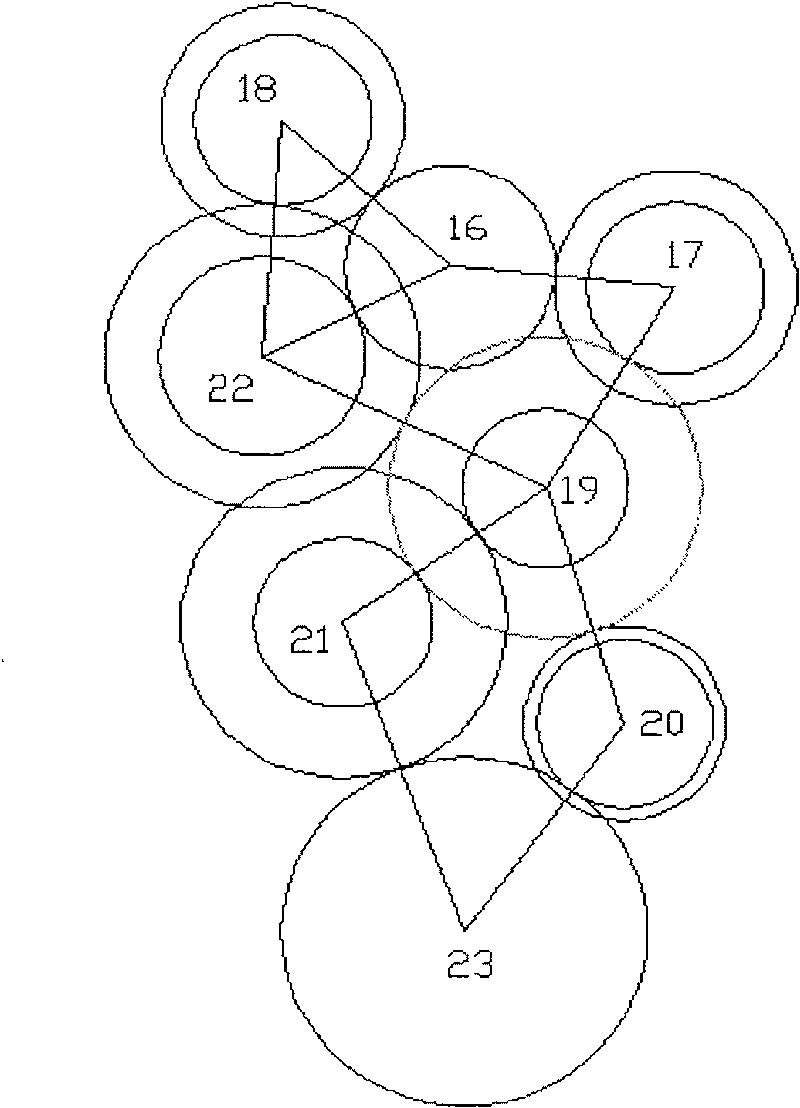

The invention discloses a needle bed swing mechanism for a multi-bar Raschel warp knitting machine, which comprises a transmission spindle, an eccentric wheel fixedly mounted on the transmission spindle, an oil tank output bar, an upper swing arm, a looping swing arm shaft, a guide arm and a connecting rod support. One end of the upper swing arm is fixedly connected with the looping swing arm shaft, the other end of the upper swing arm is rotatably connected with the upper end of the oil tank output bar, the upper end of the guide arm is slidably connected with a grooved needle bed, the lower end of the guide arm is fixedly connected with the looping swing arm shaft, a stylet bed is slidably connected with the grooved needle bed, an eccentric bushing connecting rod and a triangular connecting rod are arranged between the eccentric wheel and the oil tank output bar, the lower end of the eccentric bushing connecting rod is sleeved on the eccentric wheel, the upper end of the eccentric bushing connecting rod is rotatably connected with the bottom end of the triangular connecting rod, the left upper end of the triangular connecting rod is rotatably connected with the connecting rod support, and the right upper end of the triangular connecting rod is rotatably connected with the lower end of the oil tank output bar. The coefficient of swing travel speed ratio of the needle bed swing mechanism is approximate to 1:1, the needle bed swing mechanism is well applicable to high-speed warp knitting and is simple in structure and reliable in operation, and a transmission circuit of the needle bed swing mechanism is short.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

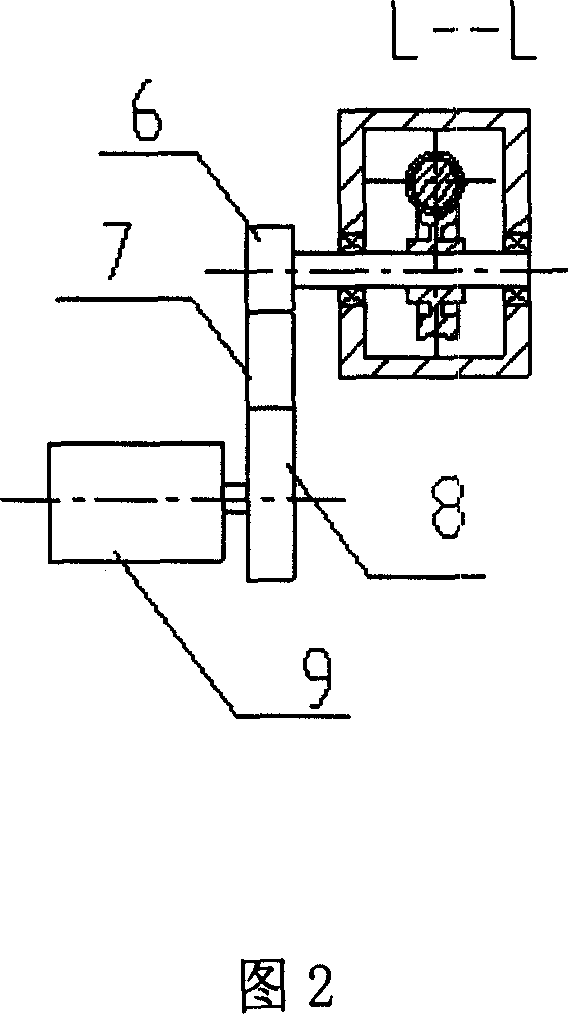

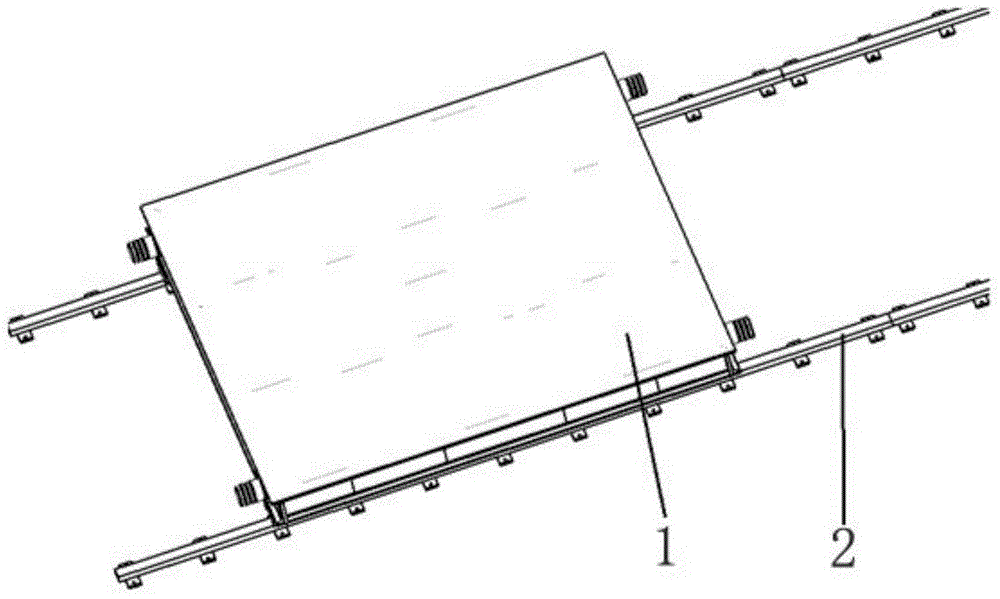

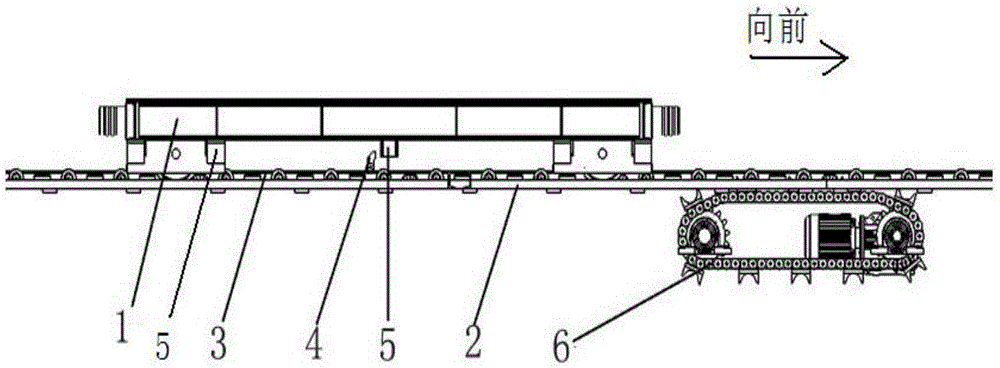

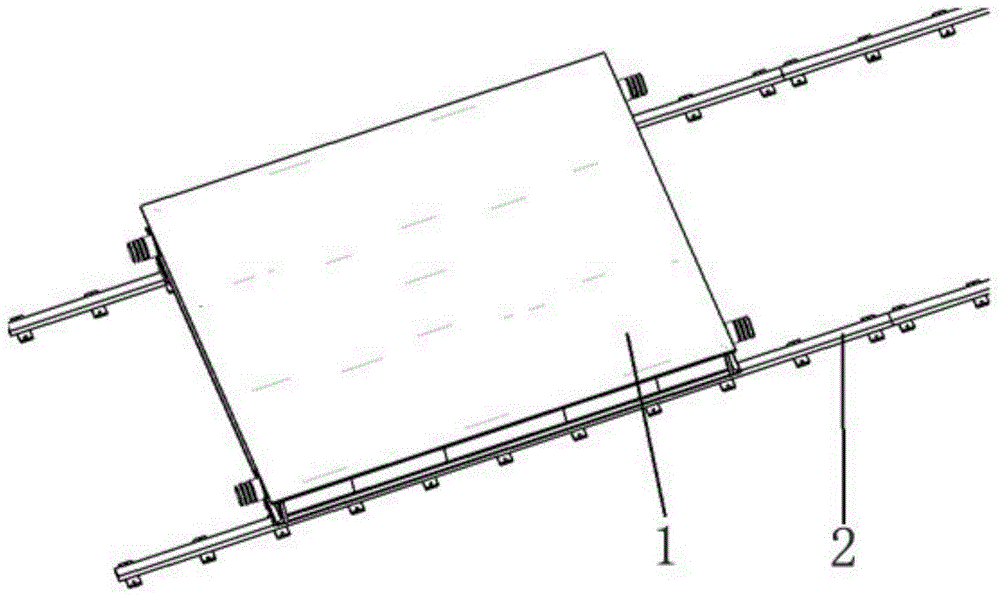

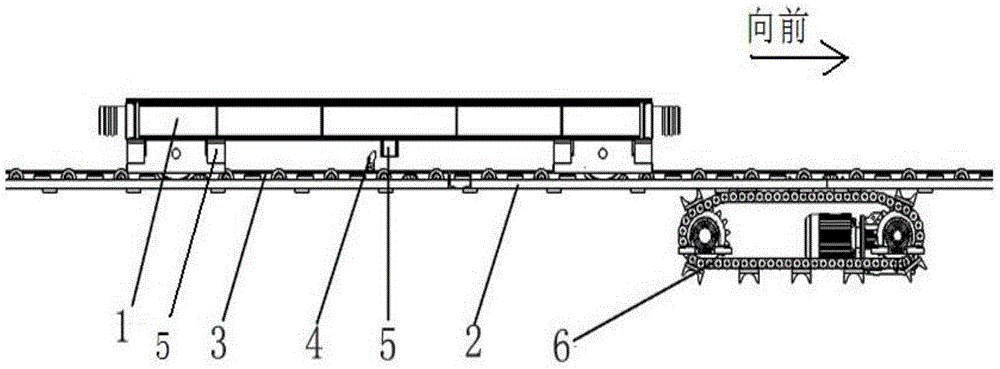

Reciprocating chain driving mechanism

ActiveCN104477589AShort drive lineLess transmission partsMechanical conveyorsReciprocating motionEngineering

Owner:XUZHOU CONSTR MACHINERY

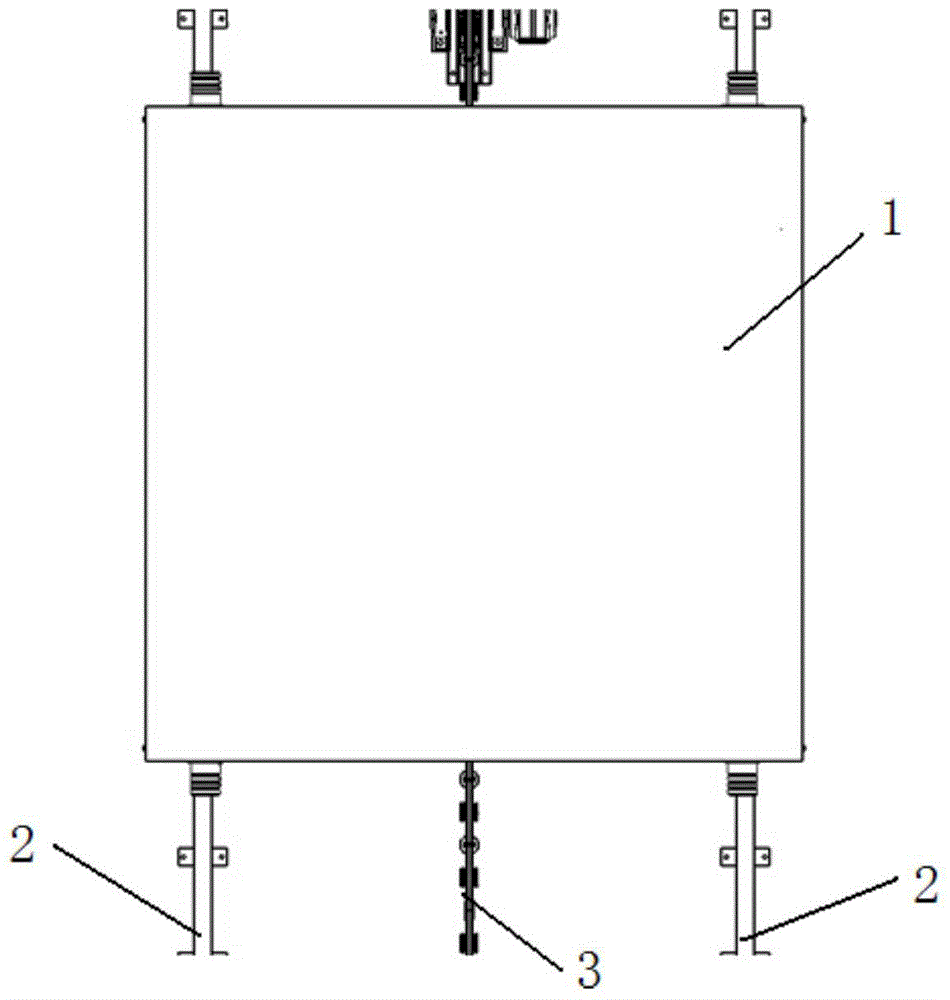

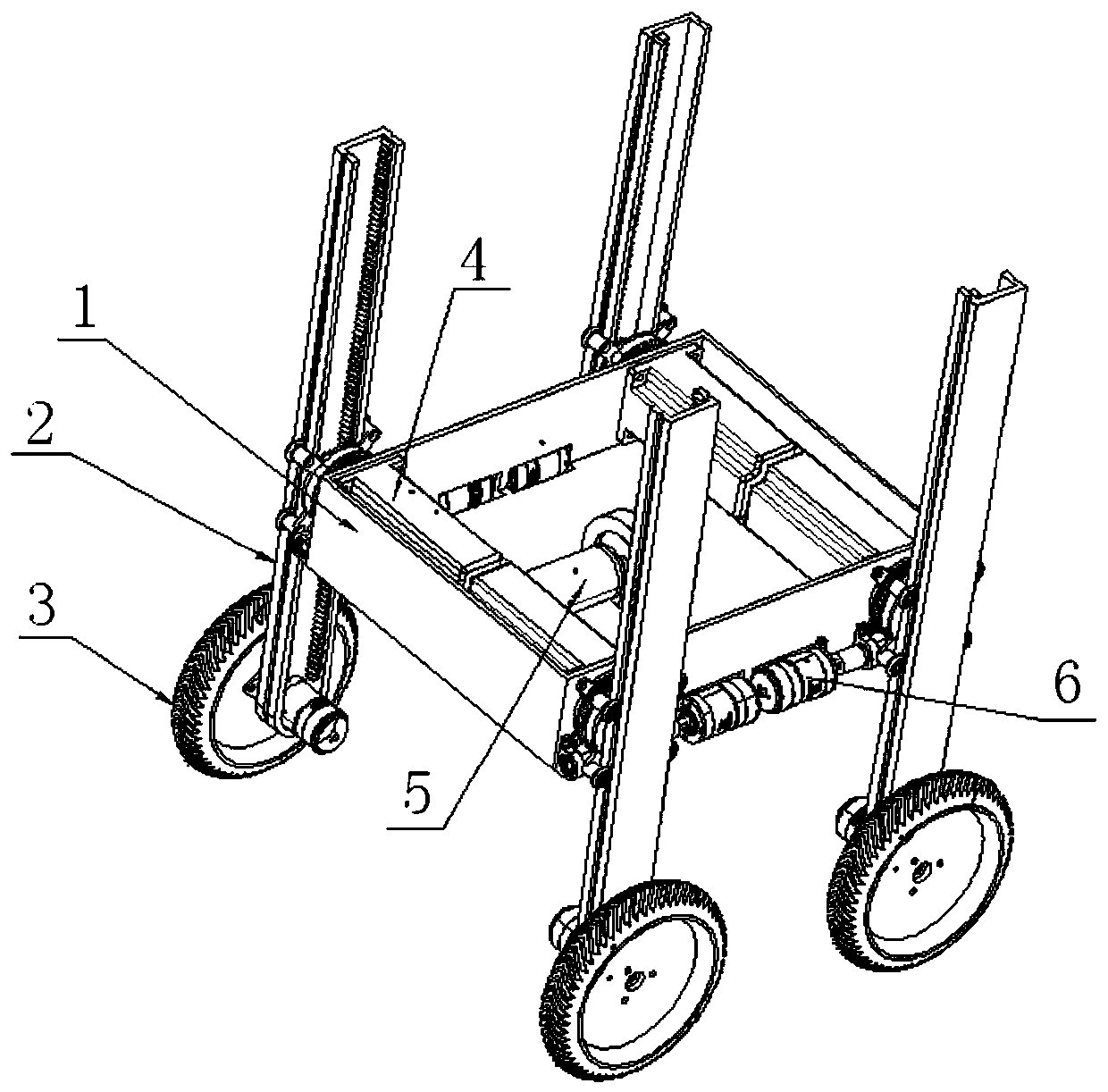

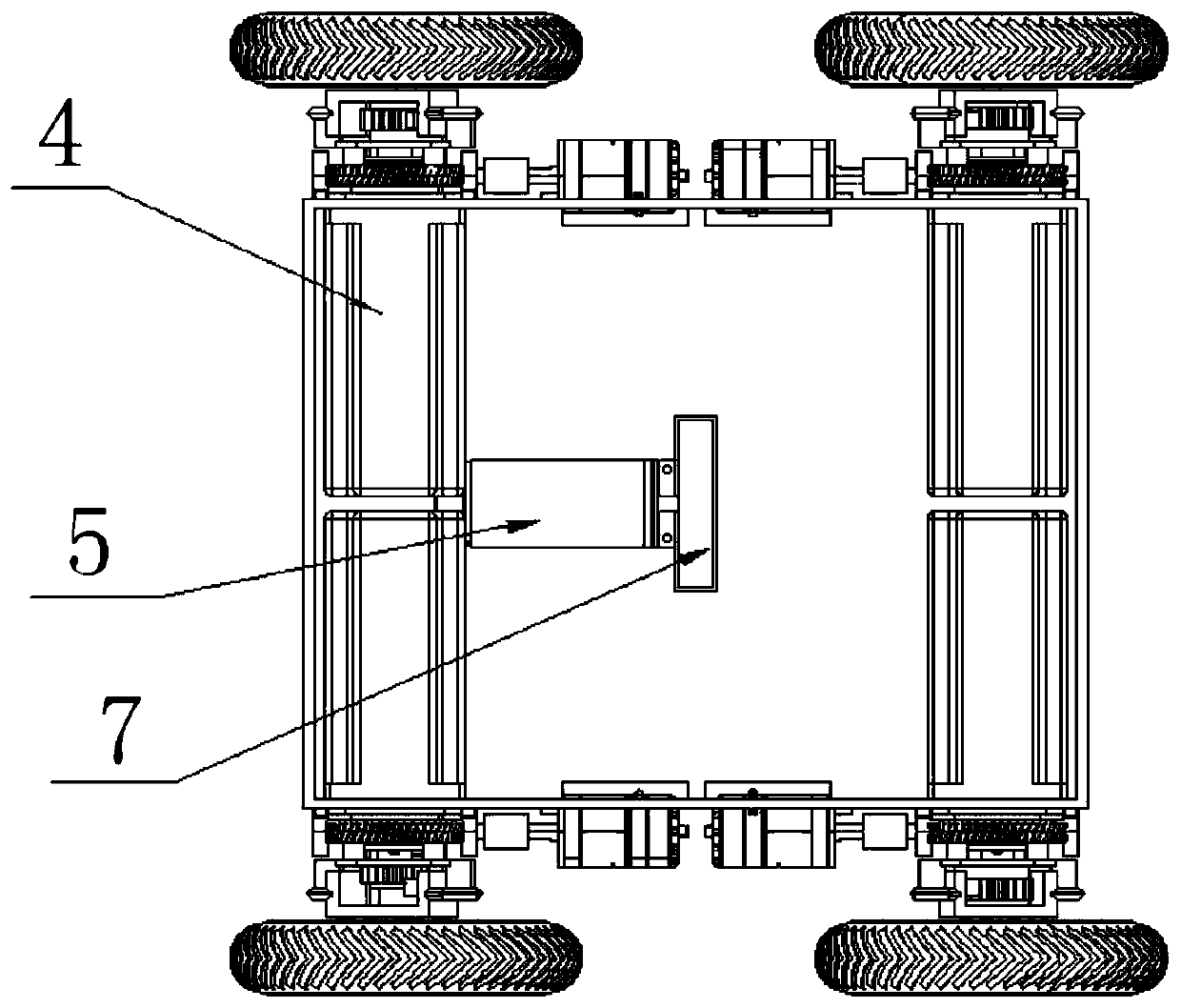

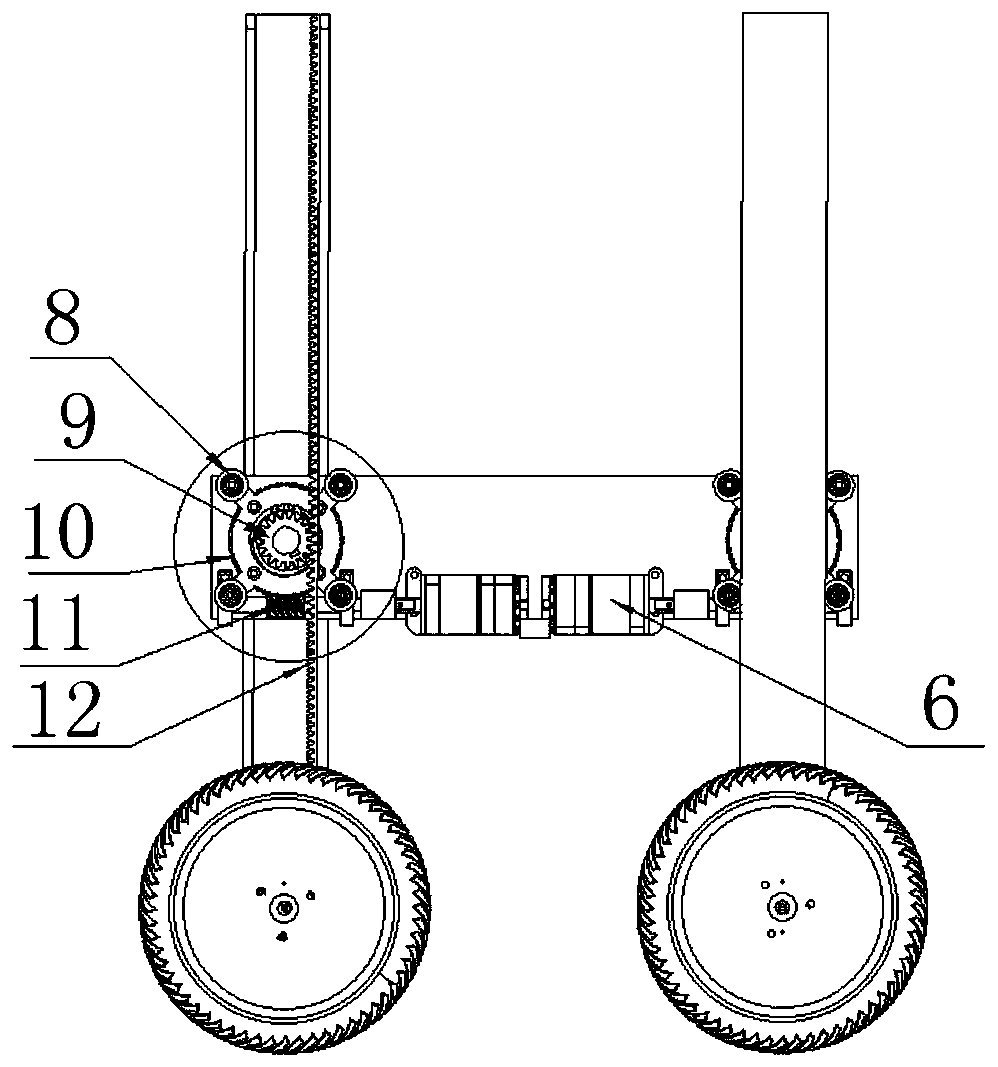

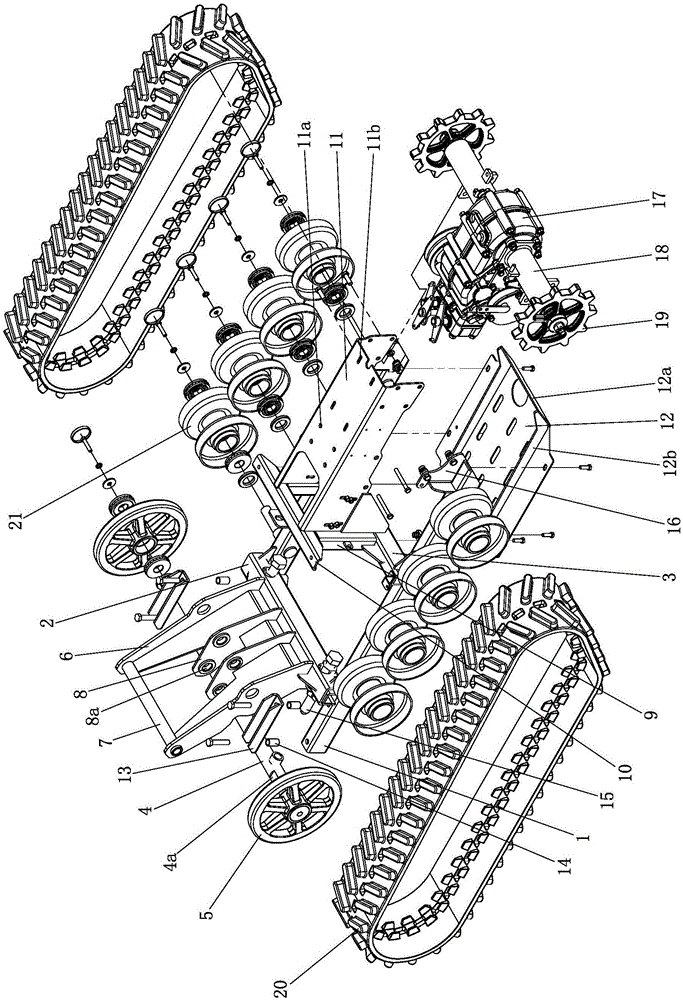

Bouncing mobile robot with gear-rack structure

The invention discloses a bouncing mobile robot with a gear-rack structure. The robot comprises a vehicle body and at least one vehicle leg, racks are arranged on the vehicle legs in the direction ofthe vehicle legs, the vehicle body is provided with gears meshed with the racks, and the gears are provided with first driving devices for driving the gears to rotate. The vehicle legs are provided with worm wheels, the worm wheels are provided with worms driving the worm wheels to rotate, the vehicle body is provided with a second driving device driving the worms to rotate, rails are arranged onthe two sides of the vehicle legs, idler wheels matched with the rails are arranged on the rails, and the idler wheels are fixed to the worm wheels through installation frames. The advantages of a wheeled robot and a jumping type robot are combined, so that the application range of the mobile robot is wider, and the mobile robot can be applied to more occasions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

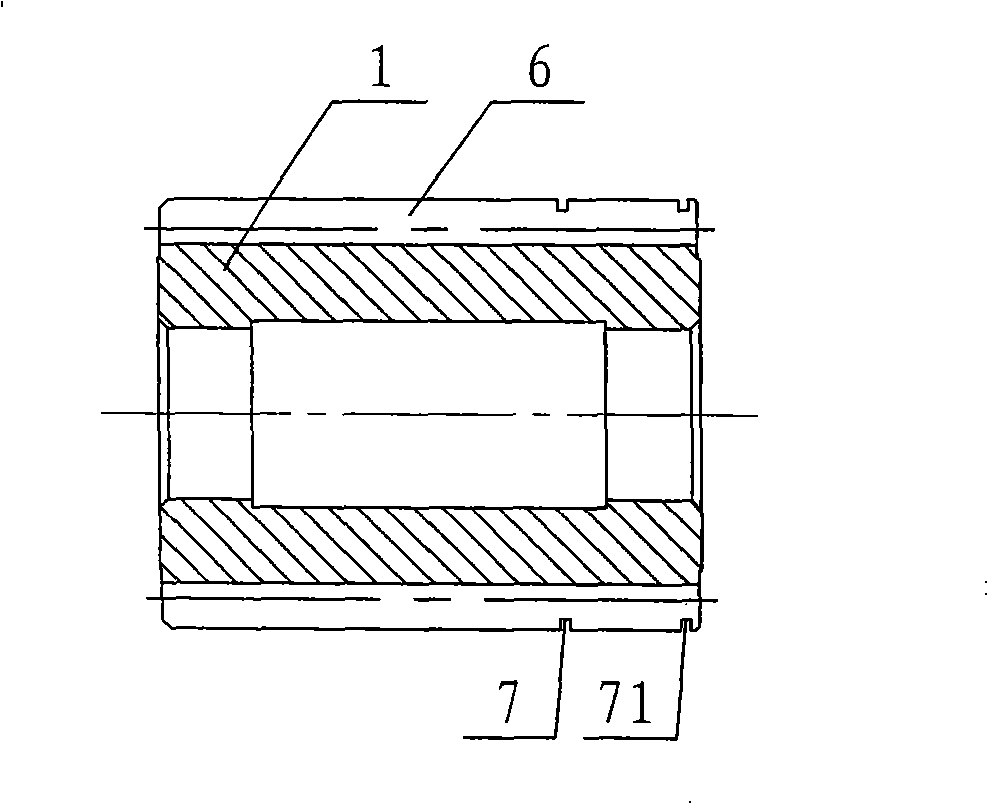

High-efficiency energy-saving hoist gear change device for vessel

InactiveCN101319702AImprove rigidityReduce volumeToothed gearingsPortable liftingGear wheelEngineering

The invention relates to a high-efficient energy-saving winding speed adjusting device, comprising a sun wheel, a planet carrier and a planet wheel. One end of the sun wheel is vertically arranged in an annular gear of the planet carrier; the planet carrier is connected with the planet wheel through a planet shaft by a bearing; the outer diameter of the sun wheel is processed into a full-length tooth part; the outer diameter of one end of the tooth part is processed into two spaced clamping spring grooves; the planet carrier is a single-leaf disc-shape forged member. The outer diameter of the sun wheel of the device leaves out the processing of a tool recess and a two-tooth part; the processing technique is simplified, the cost is lowered, the size of the overall speed adjusting device is reduced; the noise of transmission is lowered and the efficiency and reliability are improved to a large extent.

Owner:JIANGSU TAILAI REDUCER

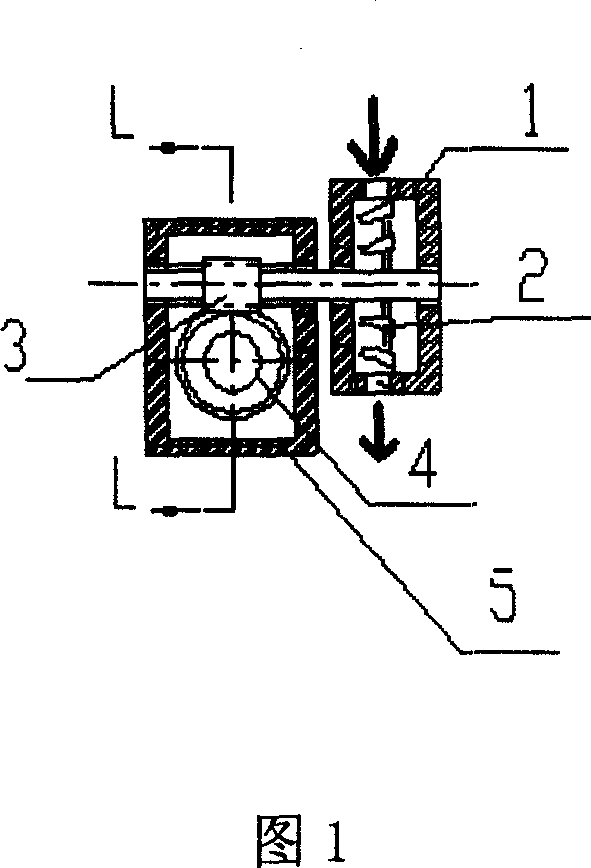

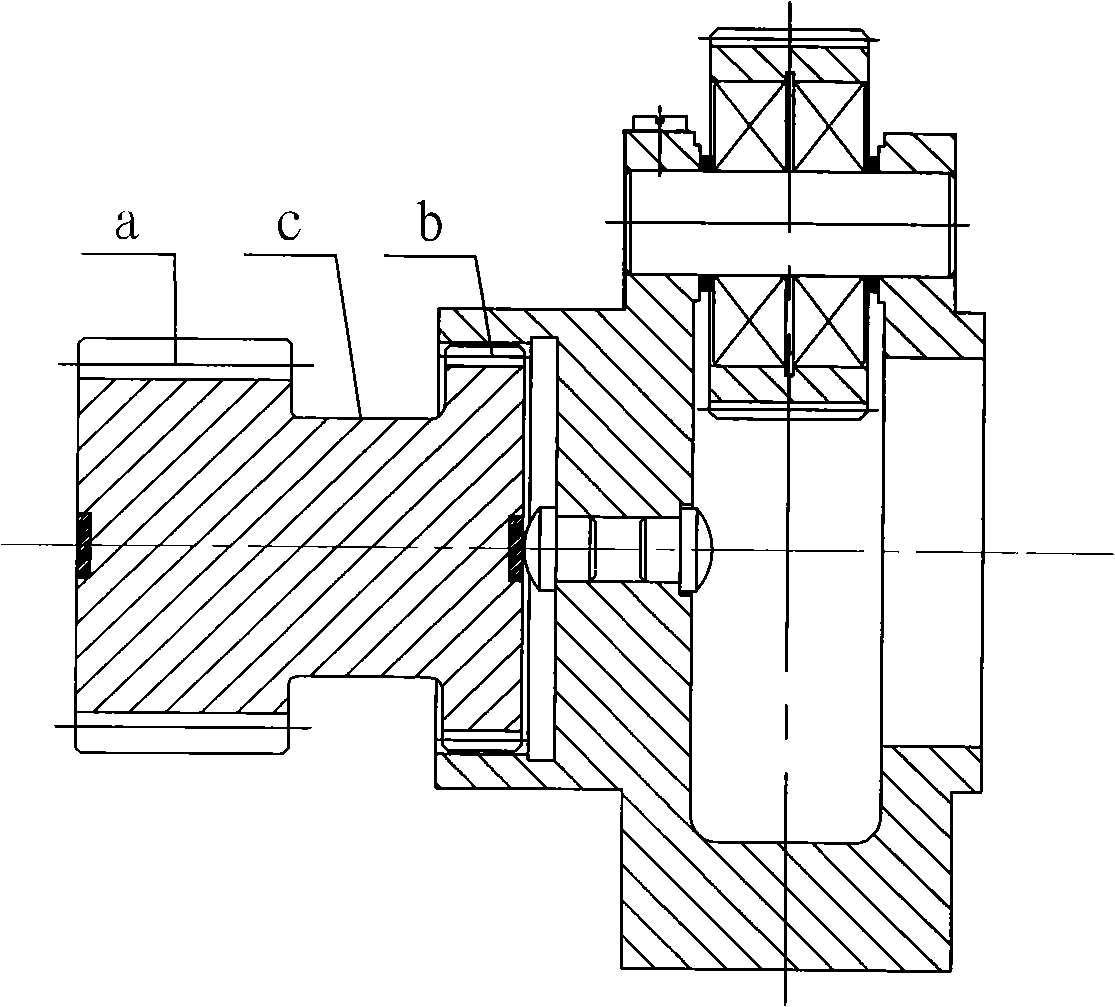

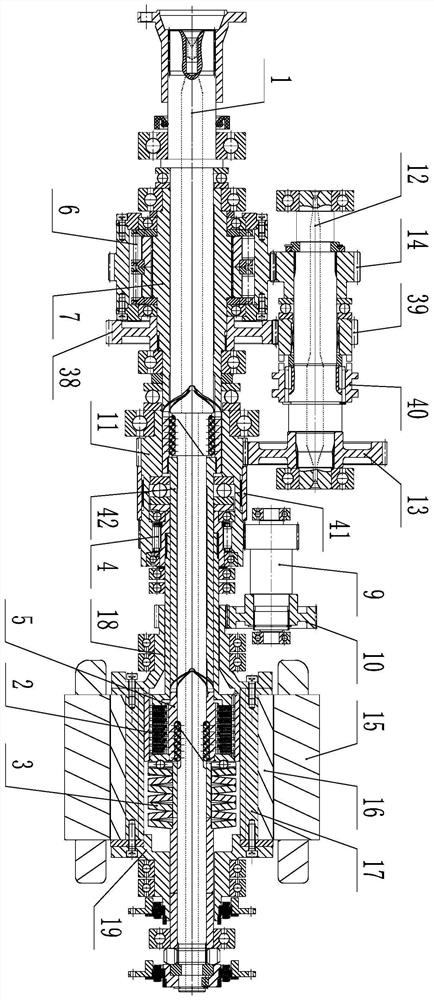

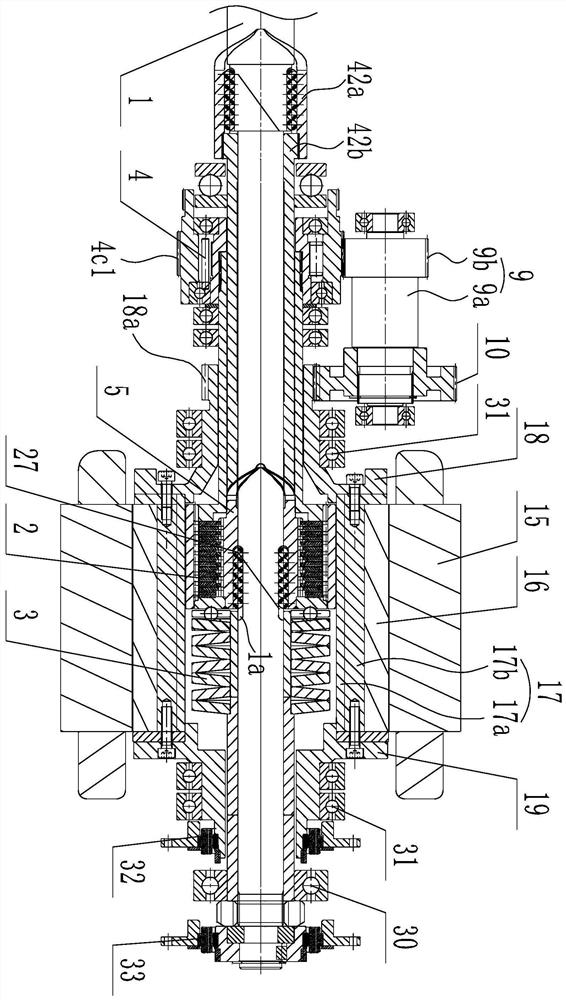

Method for shift and power coupling of hybrid powered vehicle and device thereof

ActiveCN101513828ALower installation heightShort drive lineGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingVariatorEngine power

The invention discloses a method for shift and power coupling of a hybrid powered vehicle and a device thereof. Power of an engine and a motor is coupled by a bevel gear and output by an output flange; an input axis of the motor power is perpendicular to that of the engine power, and coupled by the bevel gear. The shift and power coupling device of the hybrid powered vehicle comprises a vehicle transmission, a lengthened transmission output shaft, a driven bevel gear, a drive bevel gear shaft, a motor power input flange, a coupled power output flange and the like. The engine power and the motor power are coupled by the bevel gear and output by the output flange; the input axis of the motor power is perpendicular to that of the engine power, the driving is a single-stage driving, and a drive gear switch is arranged on a gear selection shaft.

Owner:长沙中车智驭新能源科技有限公司

Dynamic gear shifting transmission-gear box suitable for engineering machinery

Owner:SICHUAN CHENGDU CHENGGONG CONSTR MACHINERY

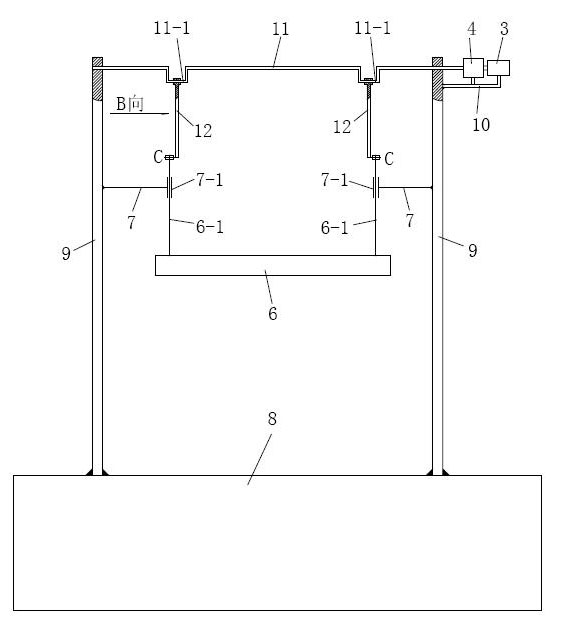

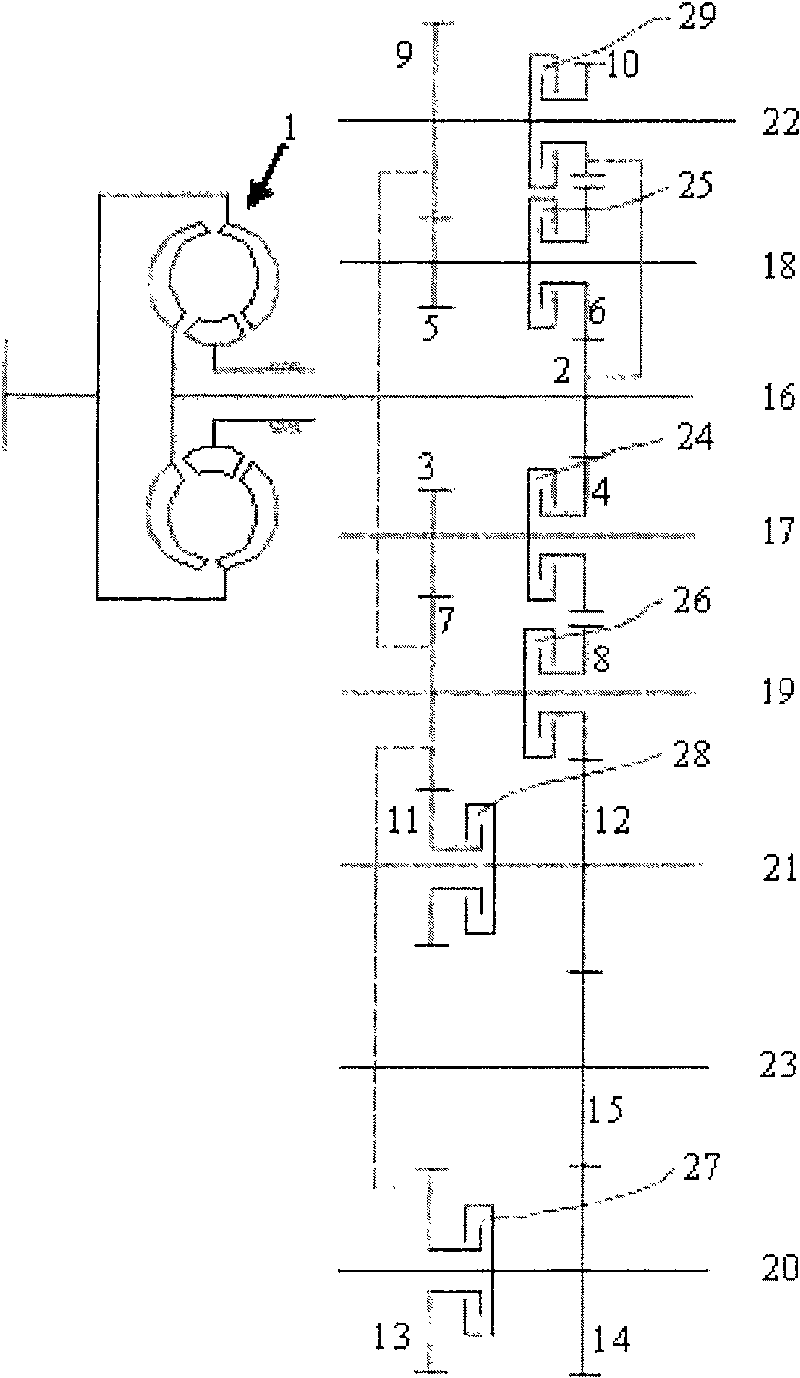

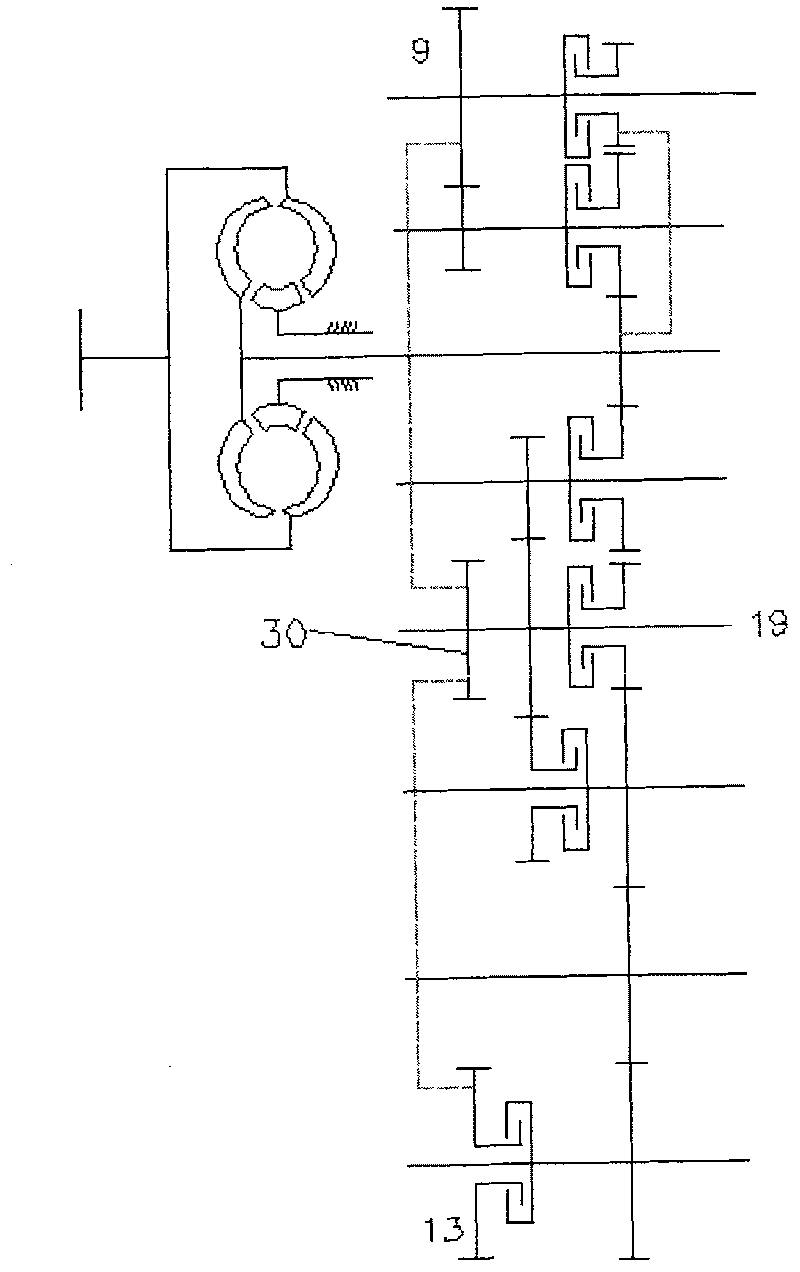

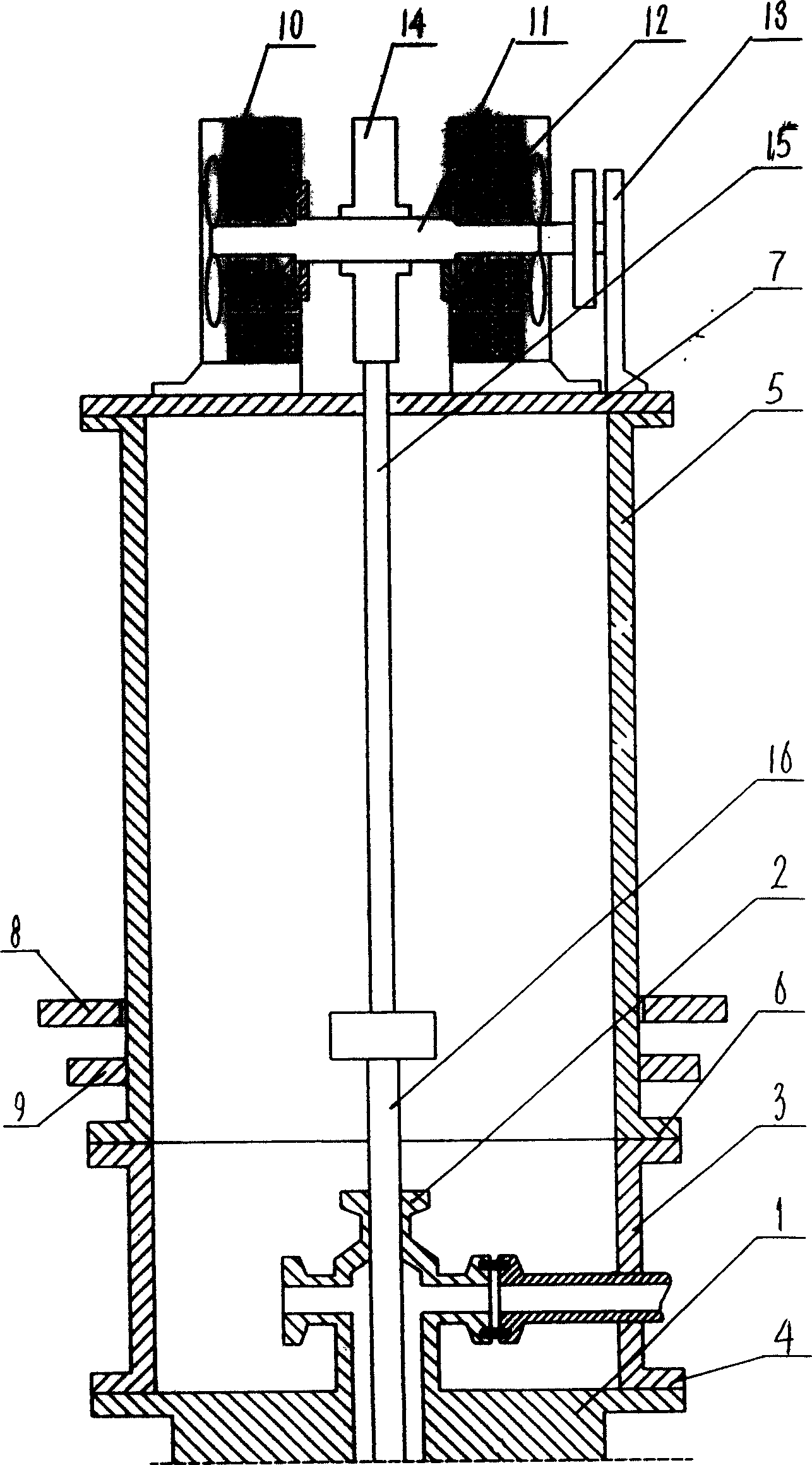

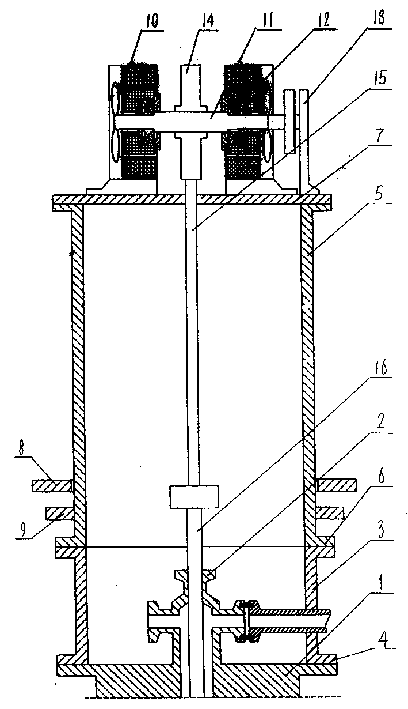

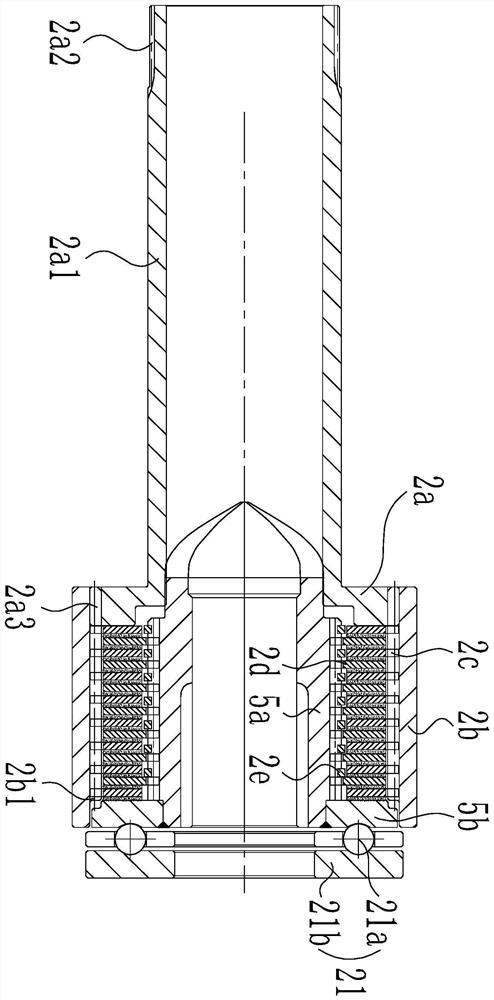

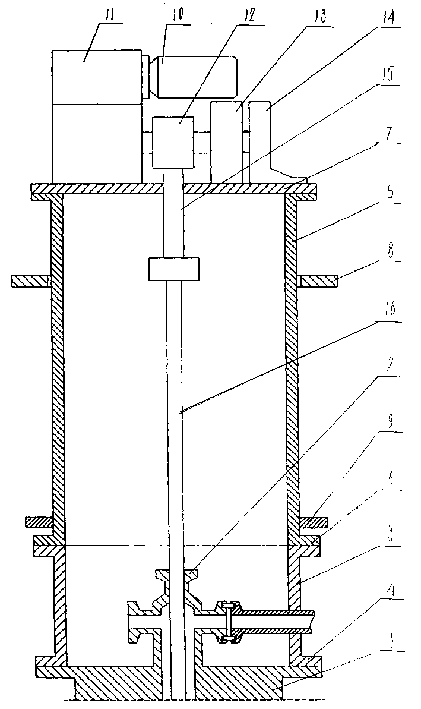

Split motor-drived vertical-pipe reciprocating chain pumping unit

The invention is a two-piece electric-machine drive vertical-tube type reciprocating-chain oil pumping unit, a beam-free one composed of wellhead large four-way, wellhead short section, vertical tube, electric machine, chain wheel and oil pumping rod. The large four-way is fixed at the wellhead and set with wellhead small four-way at the center; the well short section situated on the large four-way; the vertical tube situated on the short section, the top of the vertical tube set with a cap, and a ring balance weight slipping over the periphery of the vertical tube and able to slide upwards and downwards along the vertical tube; the electric machine is a two-piece permanent-magnet low-speed synchronous one, fixed on the cap and the output shaft supported on the right and left pieces by bearings; the chain wheel connected to the center of the output shaft by bond and able to rotate forwards and reversely under the electric machine drive; one end of the chain linked with the balance weight, and the other one linked with the upper end of the oil pumping rod round the chain wheel; the lower end of the oil pumping rod passing through the small four-way to link up with the underground reciprocating pump.

Owner:李华林

Rice transplanter type vehicle transmission

The invention relates to a rice transplanter type vehicle transmission, comprising a transmission cabinet, a differential, steering clutches, a brake, and a steering transmission mechanism. The differential is installed on the transmission cabinet and is connected with a left half axle and a right half axle. The transfer-drive sliding variable gear of a transmission shaft is corresponding to a transfer-drive duplicate gear which is installed on a transfer-drive transmission shaft. A transfer-drive driving taper gear on the transfer-drive transmission shaft is meshed with a transfer-drive output taper gear shaft. Half-shaft output driving taper gears are respectively connected with a left tail end output shaft and a right tail end output shaft through a half-shaft output driven taper gear and respective steering clutches. A differential lock installed on the left half axle is opposite to a differential housing. The brake is installed on a right housing and a differential transmission shaft. The second transfer-drive taper gear on the differential housing is meshed with a second transfer-drive taper gear shaft. The rice transplanter type vehicle transmission is characterized by compact structure, good installation and maintainability, and reliable use, and adapting to multifunctional configuration requirements.

Owner:CHANGZHOU DONGFENG AGRI MACHINERY GROUP

a flying car

ActiveCN109968931BReduced curb weightImprove transmission efficiencyEfficient propulsion technologiesAircraft power transmissionGear wheelElectric machinery

The invention provides a flying car, which has the function of four-wheel independent electric drive, and includes a chassis, a wheel propeller assembly installed on the chassis, and an overturning mechanism assembly. The belt brake is used to control the planetary gear mechanism to realize the hub motor to drive the wheel or propeller to rotate. The turning mechanism assembly can be used to turn the wheel propeller assembly vertically or parallel to the ground. When switching between car mode and flight mode, the planet carrier or the wheel can be fixed by controlling the tightening of the brake band of the planet carrier or the ring gear, so that the output power of the hub motor can be transmitted to the wheel or the propeller shaft , to enter car mode or airplane mode. In addition, the propeller blades can be retracted under the action of the return spring, which is convenient to be integrated with the wheels. It can perform in-situ vertical lift and fly smoothly without affecting other vehicles, and at the same time, it can also improve the problem of poor passability of existing vehicles.

Owner:XIAN UNIV OF SCI & TECH

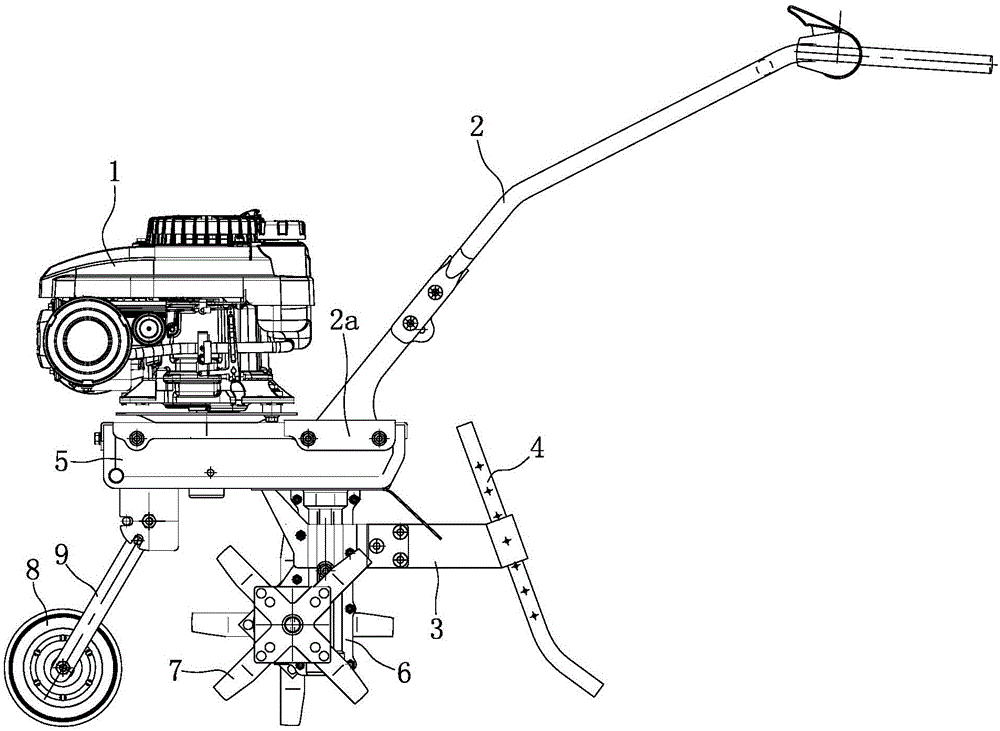

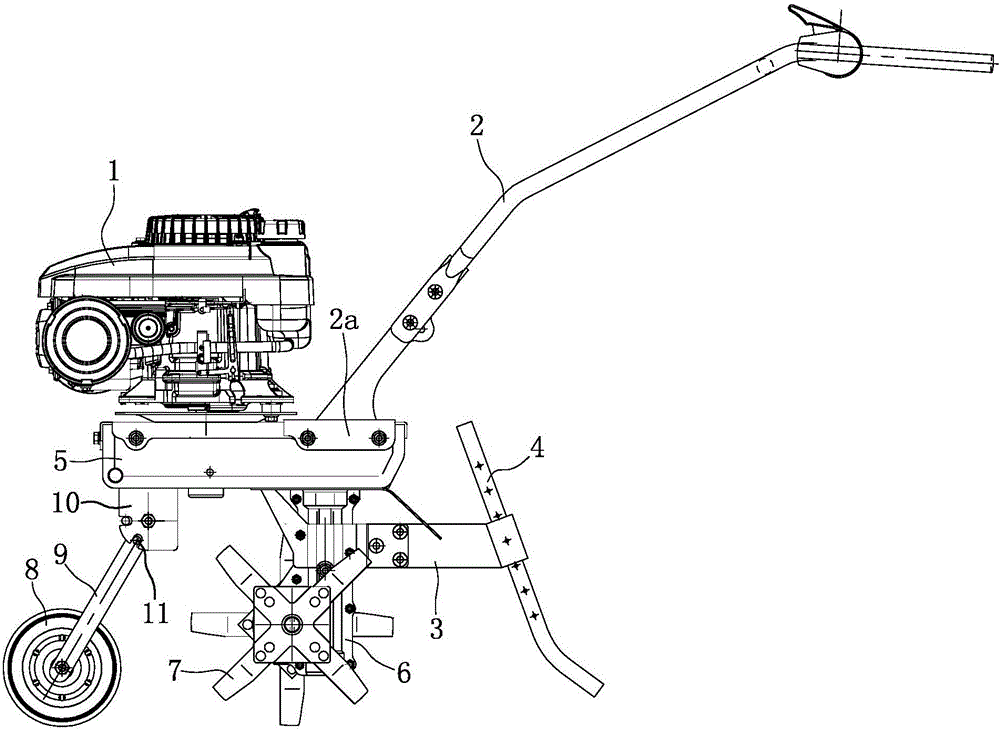

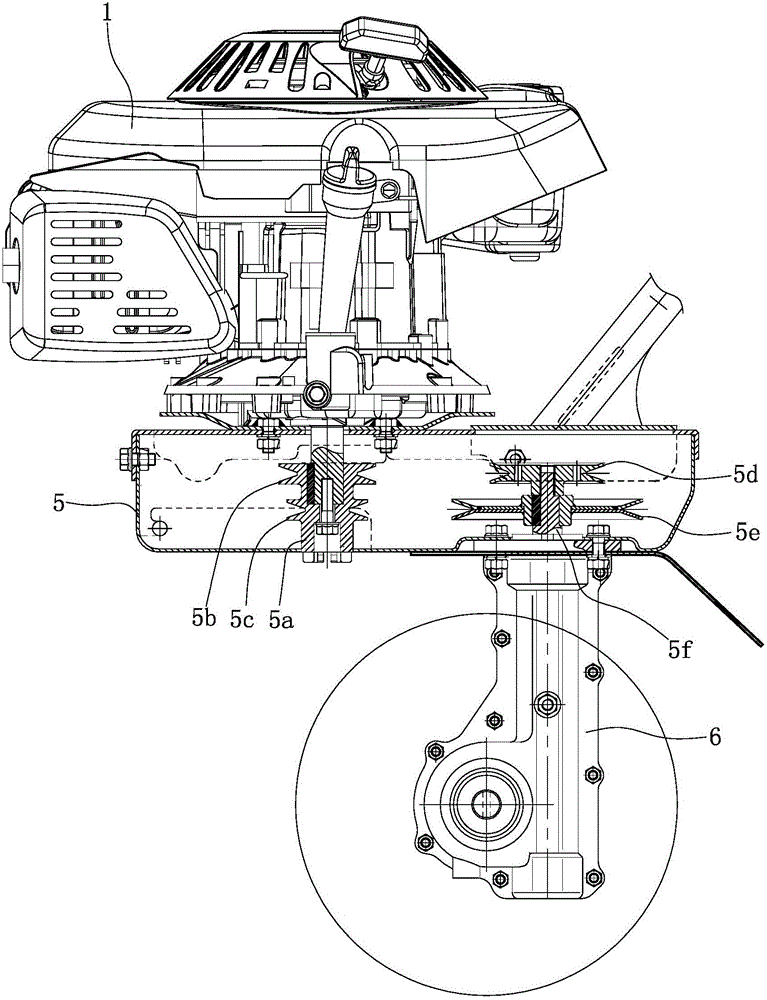

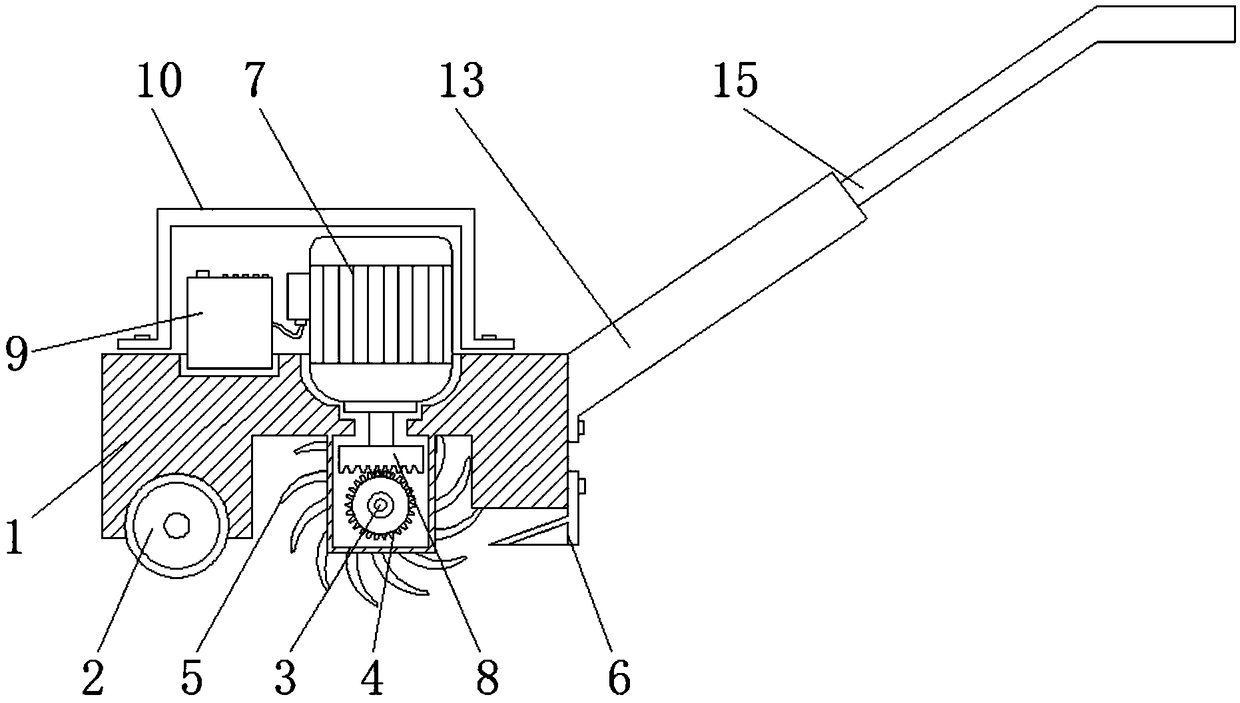

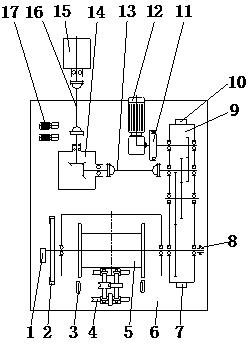

Portable micro-cultivator

InactiveCN105052259ASimple structureCompact structureTilling equipmentsEngineeringMechanical engineering

The invention discloses a portable micro-cultivator. An engine (1) is mounted at the front end of the top of a main transmission case (5), a handle assembly (2) is mounted at the rear end of the top of the main transmission case (5), and an output shaft of the engine (1) extends into the main transmission case (5) and is connected with the input end of the main transmission case (5); the output end of the main transmission case (5) is connected with the input end of a worm wheel transmission case (6), cultivating cutters (7) or travelling wheels are mounted on the output shaft of the worm wheel transmission case (6), a front wheel (8) is arranged in front of the worm wheel transmission case (6) and mounted at the lower end of a sloped pipe (9), the upper end of the sloped pipe (9) is connected with the bottom of the front end of the main transmission case (5) through bolts, and a resistance rod (4) is arranged behind the worm wheel transmission case (6). The portable micro-cultivator disclosed by the invention is few in parts, simple and compact in structure, small in size, low in cost, easy to assemble, convenient to operate and labor-saving.

Owner:CHONGQING JIAMU MACHINERY

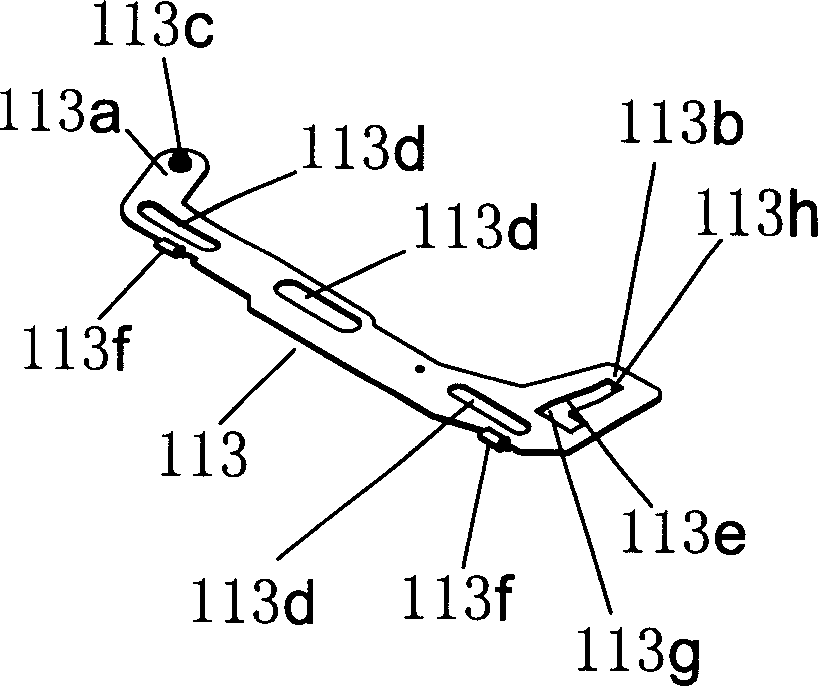

Dual suction type mechanical core

InactiveCN1873806ASimple structureImprove reliabilityRecord information storageEngineeringLocking plate

The invention discloses a double-suction machine core, comprising substrate, disc suction driving mechanism, press disc mechanism, active piece, push plate, planetary plate, locking plate and limiting piece, where the active piece is installed on the substrate and able to laterally make horizontal movement under the drive of the disc, and the active piece makes the push plate reversely move through linkage piece, the push plate is made with limiting groove, the planetary plate is in a lever structure and the pivot of the lever is located in the limiting groove and the force bearing end of the lever is located on the moving track of the disc, and the forcing end of the lever drives the locking plate to move, the locking plate has a first locking piece whose moving track is provided with a second locking piece, the limiting piece is between the press disc and planetary plate and can be rotatablely arranged on the substrate and has a limiting column and spring piece to reset the limiting column, the push plate is equipped with a push part to rotate the limiting column, and the position on the substrate corresponding to the limiting column is equipped with channel. And the machine core has high location accuracy and can implement suction of large and small discs.

Owner:ASA IND SHENZHEN +2

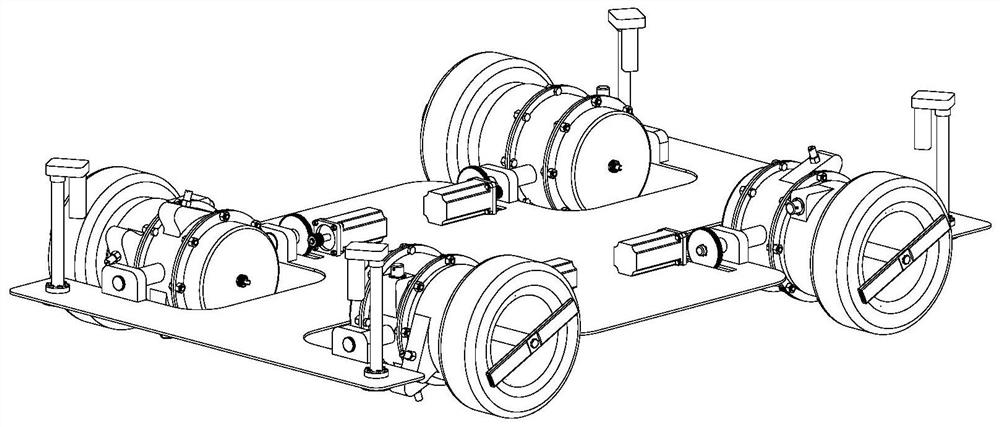

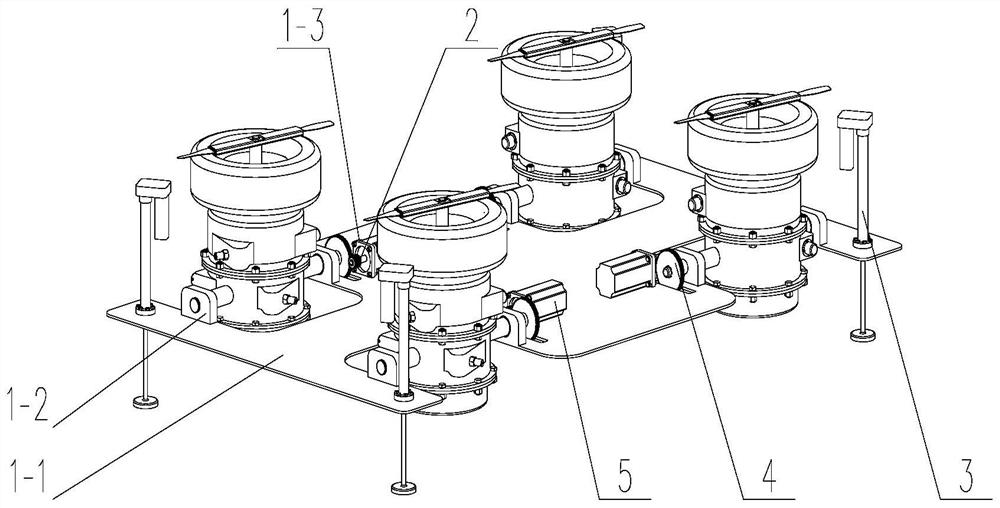

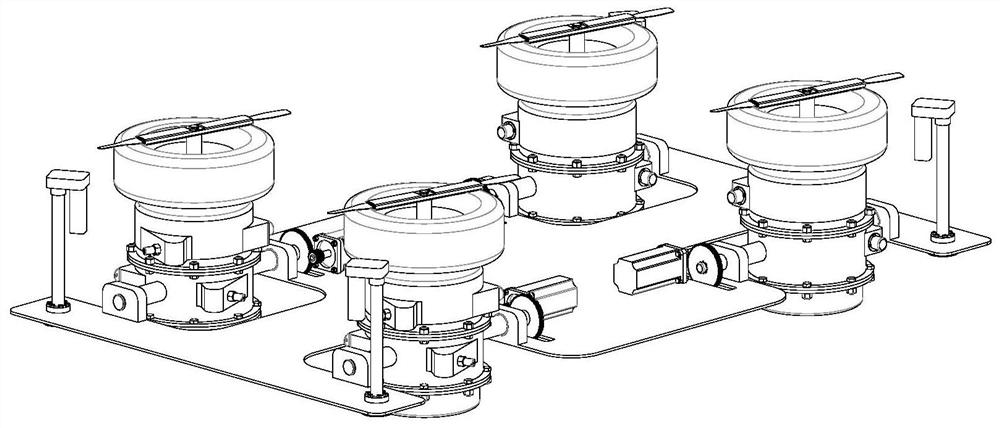

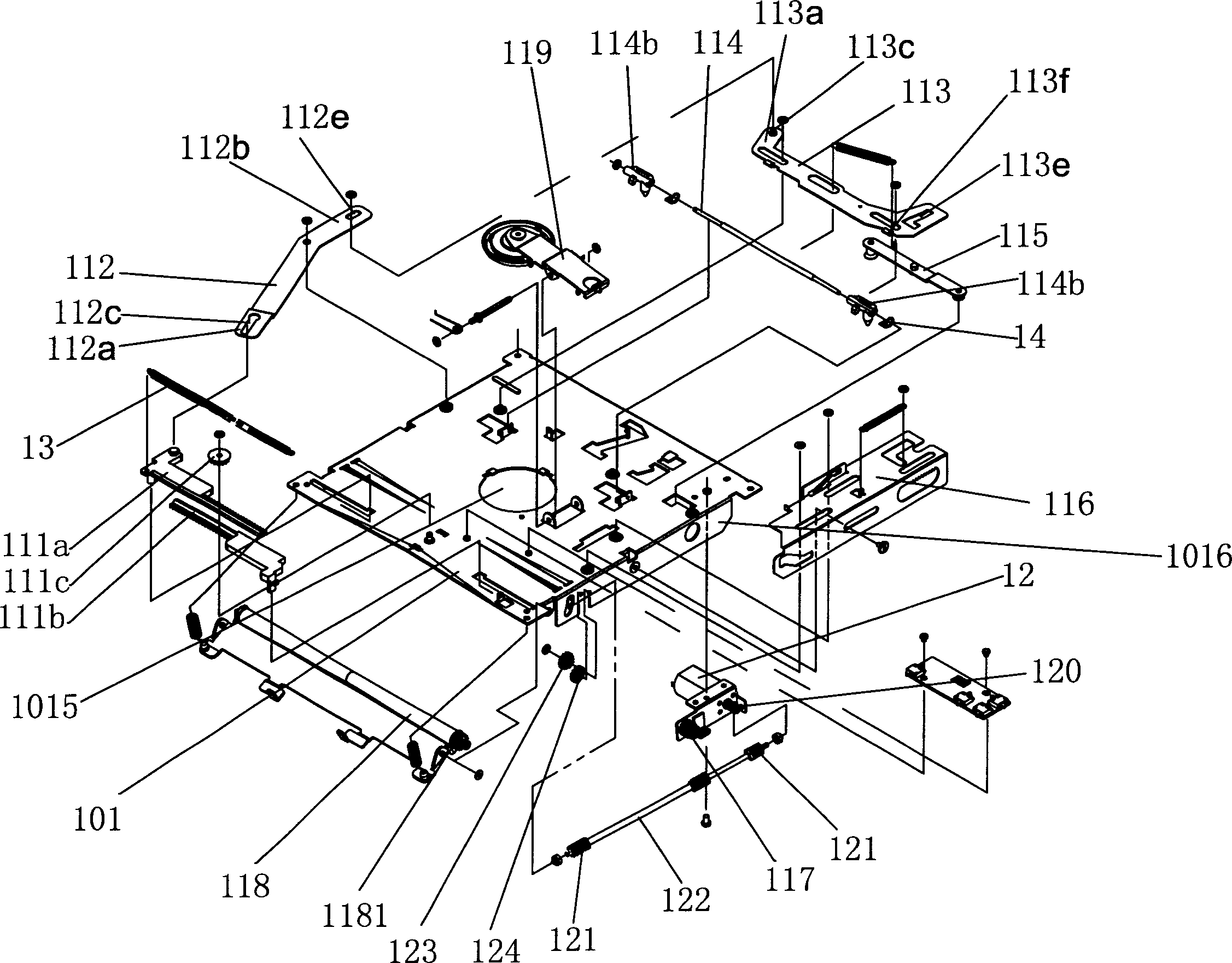

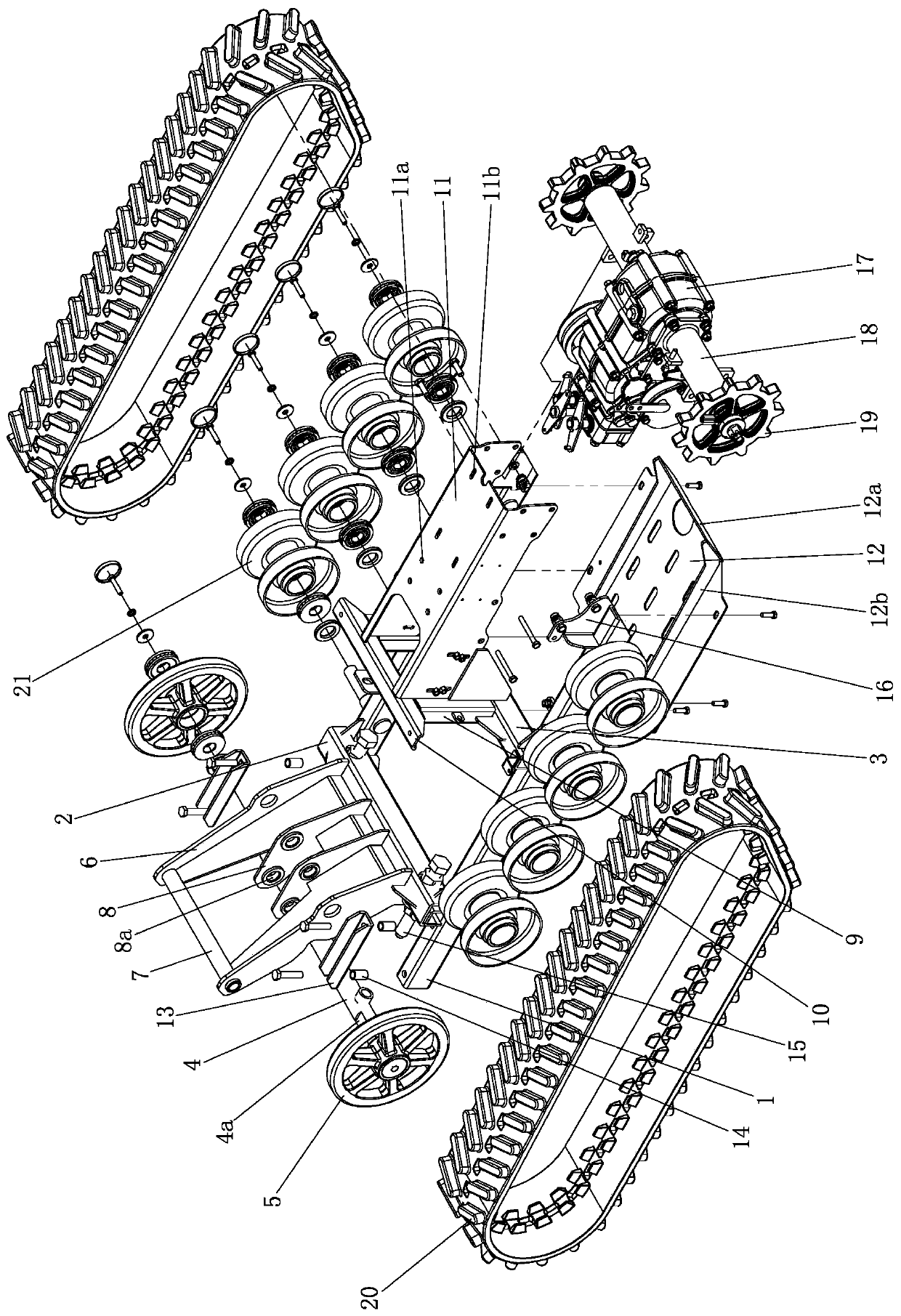

Chassis of multifunctional agricultural management machine

ActiveCN106576468AReasonable designSimple structureAgricultural undercarriagesAgricultural engineeringCarrying capacity

The invention discloses a chassis of multifunctional agricultural management machine. A guiding wheel axle which is parallel with a front cross beam is arranged in front of the front cross beam. The front cross beam is provided with two side plates which are bilaterally symmetrical. A container front installing tube is connected between the upper ends of the two side plates. Two oil cylinder support plates which are parallel on left and right are arranged between the two side plates. A gearbox is arranged on a gearbox supporting plate. The gearbox is provided with two output ends which are symmetrical on left and right. Each output end is connected with an output axle shaft. The output axle shaft is provided with a driving wheel. The driving wheel is connected with the guiding wheel on the same side through a crawler belt. A plurality of track rollers are arranged from front to back between the driving wheel and the guiding wheel which are on the same side. The chassis is simple and compact in structure, small in volume, and low in production cost. On one hand, the chassis is beneficial for arrangement and installation for other functional components, and the chassis can carry a large volume container, effectively improving carry capacity, on the other hand, the crawler belt is used to travel, so passing ability is good, gradeability is good, and the chassis does not hurt earth's surface and vegetation.

Owner:CHONGQING JIAMU MACHINERY

Knitting mechanism of warp knitting machine with fewer combs

The invention discloses a loop-forming machine of a few-guide-bar yarn-pressing warp knitting machine. The loop-forming machine comprises a groove pin fixedly mounted on a groove pin bed, a pin core fixedly mounted on a pin core bed, a sinker fixedly mounted on a sinker bed, a yarn pressing plate and groove pin up-down movement mechanism fixedly mounted at the lower end of a yarn pressing plate mounting base, a groove pin swing mechanism, and a guide bar mechanism provided with a plurality of guide bars, wherein the guide bar mechanism is provided with at least ten guide bars which are a first jacquard guide bar, a second jacquard guide bar, a first ground guide bar, a second ground guide bar, a third ground guide bar, a first grouped pattern guide bar, a second grouped pattern guide bar, a third jacquard guide bar, a fourth jacquard guide bar and a spandex guide bar in the direction from the front to the rear of the machine; the yarn pressing plate is positioned between the second jacquard guide bar and the first ground guide bar, and is driven by the yarn pressing plate up-down movement mechanism to do up-down linear motion. The loop-forming mechanism is reliable in yarn-pressing action, is rich in fabric pattern, and can meet the development trend of pattern diversity.

Owner:江苏润源控股集团有限公司

Transmission mechanism for mini-tiller

The invention discloses a transmission mechanism for a mini-tiller. An output shaft of an engine (1) extends into a main transmission box (5) and is connected with a driving wheel shaft (5a); a highs speed driving wheel (5b) and a low speed driving wheel (5c) are arranged on the driving wheel shaft (5a); a high speed driven wheel (5d) and a low speed driven wheel (5e) are arranged on a driven wheel shaft (5f); the lower end of the driven wheel shaft (5f) is connected with the input end of a worm transmission box (6); the worm transmission box (6) is positioned below the rear end of the main transmission box (5); and a raker (7) or a travel wheel is mounted on the output shaft of the worm transmission box (6). The transmission mechanism for the mini-tiller disclosed by the invention is few in parts, simple and compact in structure, small in volume, low in cost and easy to assemble. The transmission mechanism for the mini-tiller disclosed by the invention has two gear positions: high speed and low speed gear positions. The transmission mechanism for the mini-tiller is transmitted by using a belt, so that the transmission mechanism for the mini-tiller is stable and reliable to transmit and wide in application range.

Owner:CHONGQING JIAMU MACHINERY

Needle bed swing mechanism for multi-bar Raschel warp knitting machine

The invention discloses a needle bed swing mechanism for a multi-bar Raschel warp knitting machine, which comprises a transmission spindle, an eccentric wheel fixedly mounted on the transmission spindle, an oil tank output bar, an upper swing arm, a looping swing arm shaft, a guide arm and a connecting rod support. One end of the upper swing arm is fixedly connected with the looping swing arm shaft, the other end of the upper swing arm is rotatably connected with the upper end of the oil tank output bar, the upper end of the guide arm is slidably connected with a grooved needle bed, the lower end of the guide arm is fixedly connected with the looping swing arm shaft, a stylet bed is slidably connected with the grooved needle bed, an eccentric bushing connecting rod and a triangular connecting rod are arranged between the eccentric wheel and the oil tank output bar, the lower end of the eccentric bushing connecting rod is sleeved on the eccentric wheel, the upper end of the eccentric bushing connecting rod is rotatably connected with the bottom end of the triangular connecting rod, the left upper end of the triangular connecting rod is rotatably connected with the connecting rod support, and the right upper end of the triangular connecting rod is rotatably connected with the lower end of the oil tank output bar. The coefficient of swing travel speed ratio of the needle bed swing mechanism is approximate to 1:1, the needle bed swing mechanism is well applicable to high-speed warp knitting and is simple in structure and reliable in operation, and a transmission circuit of the needle bed swing mechanism is short.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

Dynamic power shifting transmission

Owner:XIAMEN UNIV

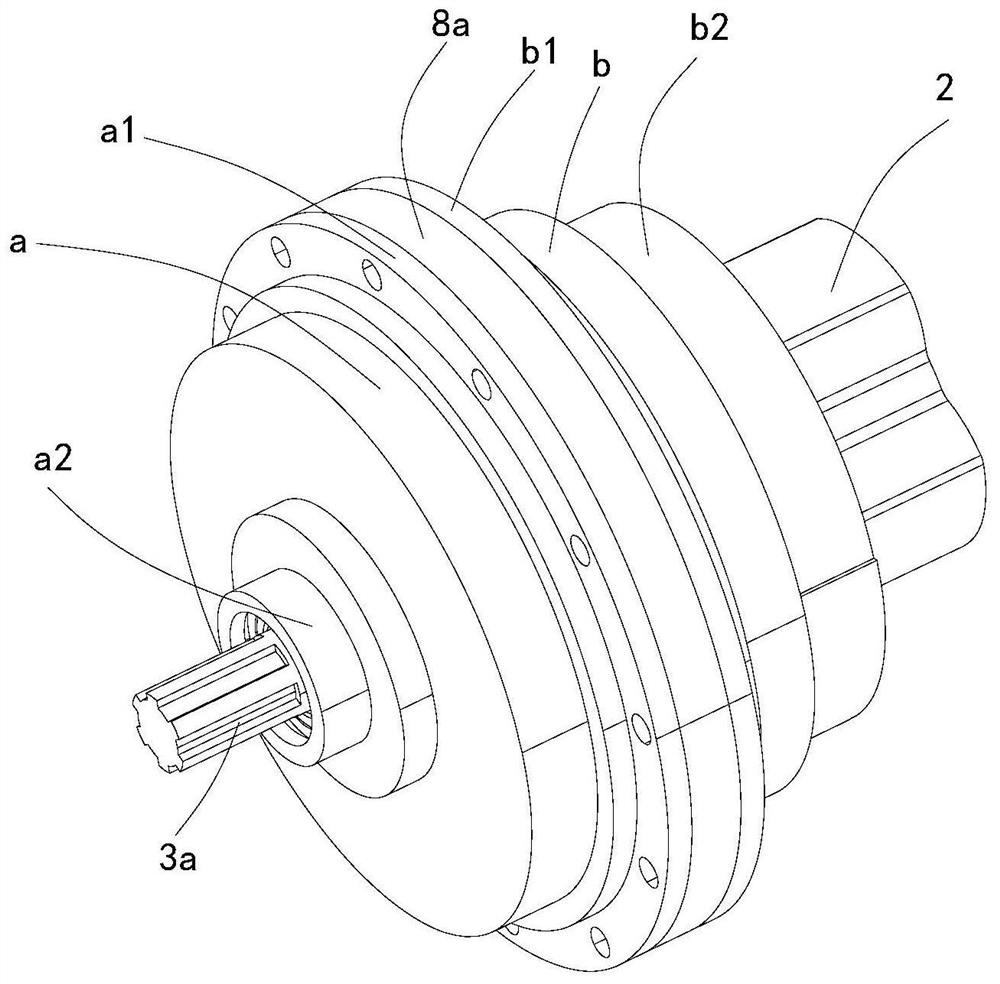

Super Torque Double Helix Double Transcendence Integrated Intelligent Adaptive Electric Drive Rear Drive System

ActiveCN111016645BIngenious designSuitable designElectric propulsion mountingControl devicesElectric machineControl engineering

The invention discloses a super-torque double-helix double-override integrated intelligent adaptive electric drive rear drive system, which includes a motor, a high-speed gear transmission mechanism, a low-speed gear transmission mechanism and a main shaft for outputting power. The motor includes a stator and a rotor. And the motor shaft assembly driven by the rotor. With the above scheme, the space inside the motor is fully utilized, and some parts of the transmission mechanism can be installed inside the motor. Not only is the transmission line short, the transmission efficiency is high, but it is also conducive to the layout of the power mechanism and reduces the impact on the dynamic balance of the wheels; Compared with the traditional single-row overrunning clutch, the overrunning clutch doubles the load-bearing capacity and breaks through the load limit of the traditional overrunning clutch; thus, it can adapt to the change of driving resistance and automatically change gears without cutting off the driving force. , make the motor always on the high-efficiency platform as much as possible, greatly increasing the range of high-efficiency operation of the motor.

Owner:SOUTHWEST UNIV

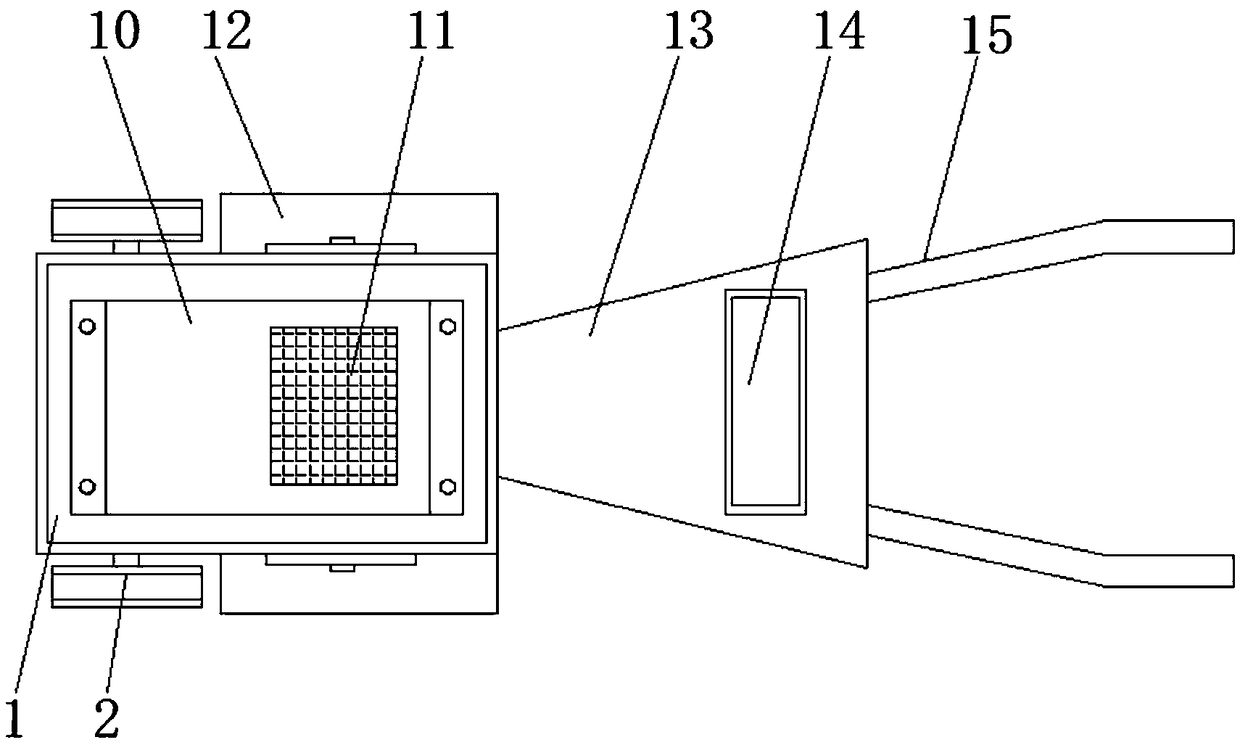

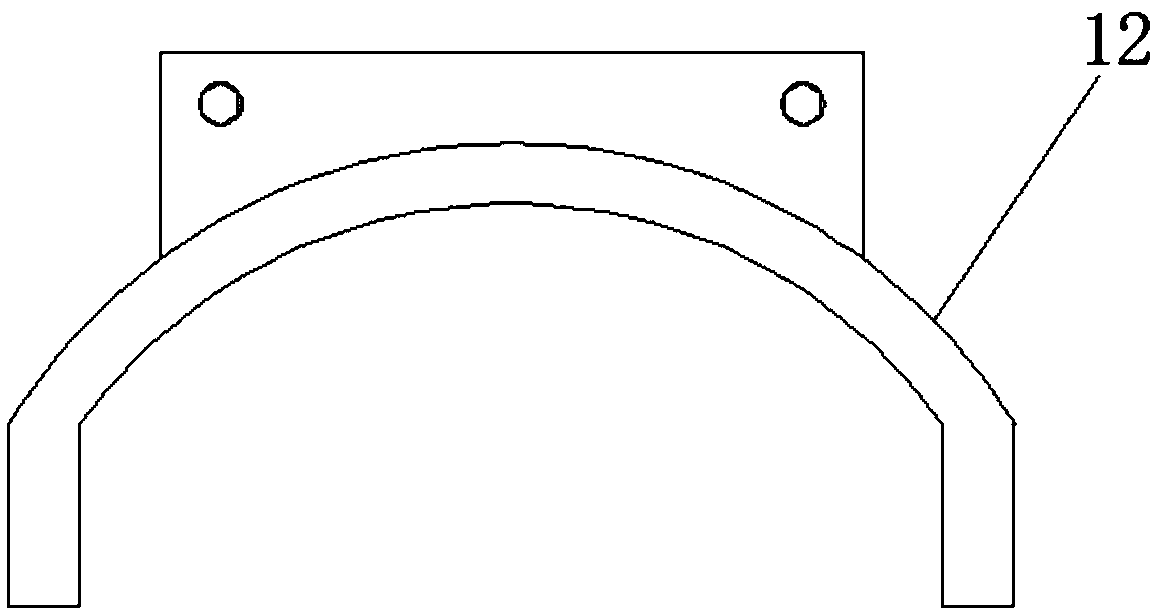

Rotary cultivator with soil turning function

InactiveCN109005701AWith soil turning functionImprove operational efficiencySpadesPloughsGear wheelArchitectural engineering

The invention discloses a rotary cultivator with a soil turning function, comprising a support base, a motor and a storage battery, wherein the front and rear sides of the left end of the support baseare respectively provided with running wheels, the middle section of an output shaft is provided with a gear, the lower right end of the support base is fixedly connected with a soil turning plate, the motor is fixedly mounted on the upper end of the support base, the storage battery is fixedly mounted on the left side of the motor, and a dustproof box body is mounted outside the motor and the storage battery, the upper end of the dustproof box body is provided with a heat-dissipating net cover, the front and rear sides of the right end of the support seat are fixedly provided with a fender respectively, a guard plate is fixedly connected to the upper right end of the support seat, a storage box is arranged at the upper right end of the guard plate, and a hand support rod is arranged at the right end of the guard plate. The rotary cultivator with the soil turning function has a simple overall structure and a short transmission path, saves space, improves the operation efficiency, improves the efficiency of processing the land, and increases the practicality.

Owner:JIXI YUANDAO AGRI IND TECH

Multifunctional Agricultural Management Machine Chassis

ActiveCN106576468BImprove passabilityImprove climbing performanceAgricultural undercarriagesRear quarterVegetation

Owner:CHONGQING JIAMU MACHINERY

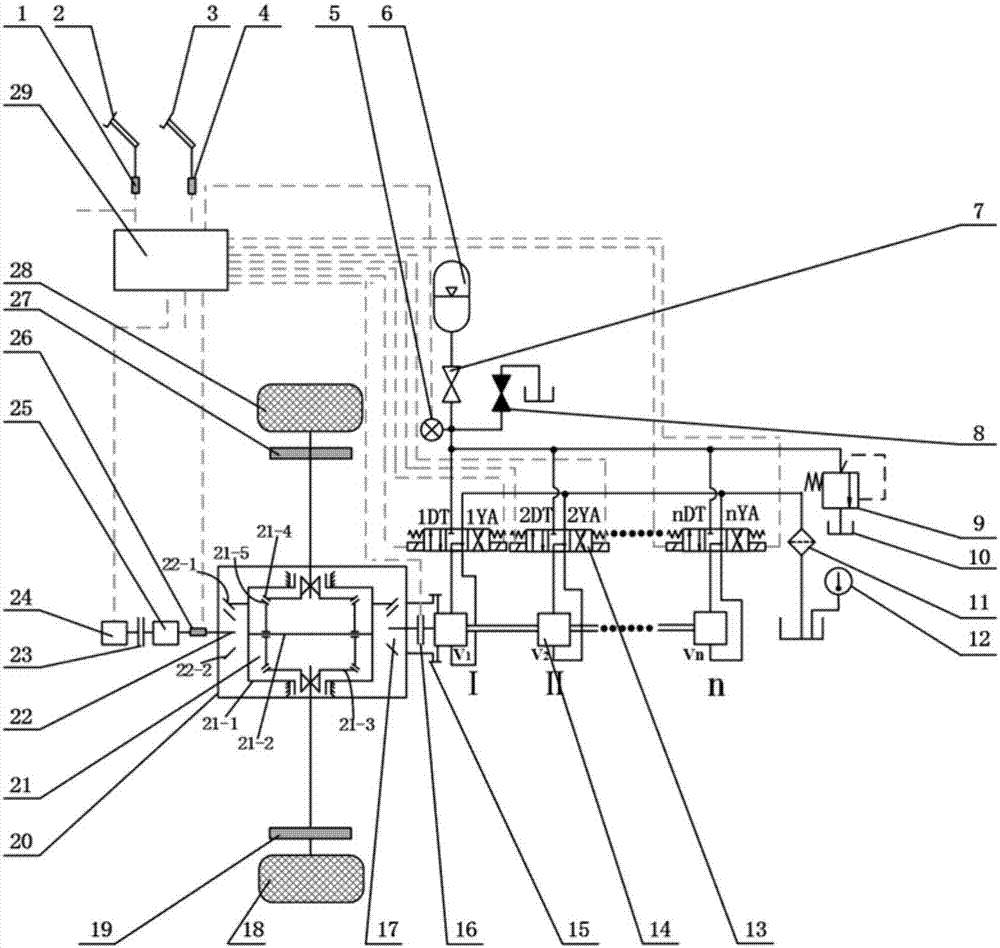

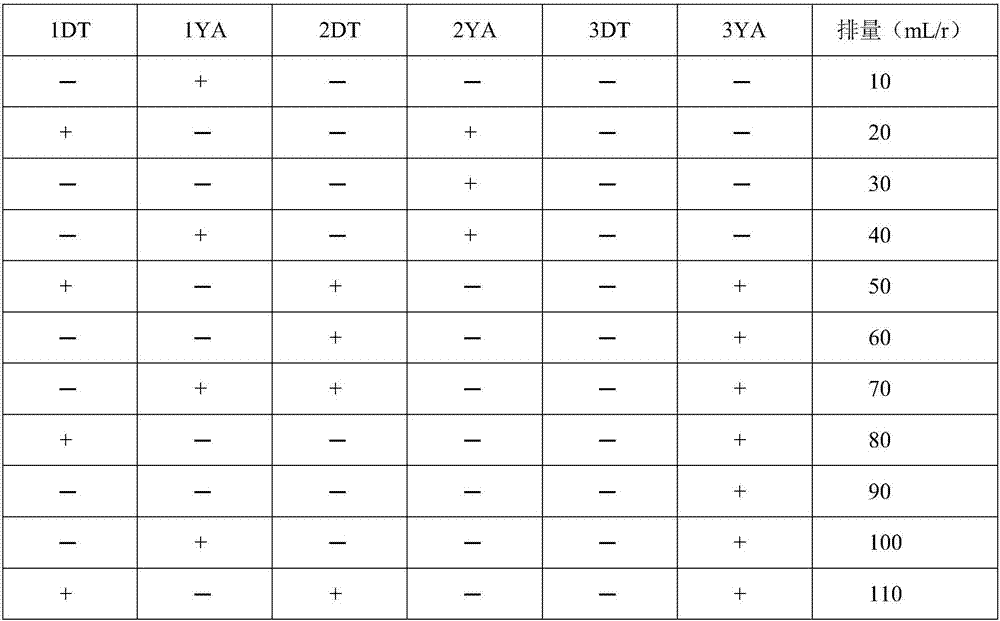

Drive bridge of integrated hydraulic auxiliary air brake device and control method thereof

ActiveCN107985290AImprove mechanical efficiencyCompact structureHybrid vehiclesBraking action transmissionDrive wheelDual mode

The invention discloses a drive bridge of an integrated hydraulic auxiliary air brake device and a control method thereof. The drive bridge of the integrated hydraulic auxiliary air brake device comprises an original car driving system, a level variable hydraulic auxiliary brake system and a drive bridge integrating distribution power, differential speed, drive wheels and other functions. The integrated drive bridge can make up the shortages in traditional hybrid power scheme that the drive system has a large installation space, the car chassis is heavy, the power transmission line is long; the level variable system based on dual-mode working characteristics is adopted to replace traditional hybrid power variable system, it solves the problems that traditional hybrid power core componentsare expensive and less reliable; the working state of the systems are judged according to sensor signals collected by a controller, then the needed displacement of the hydraulic pump / motor is calculated by a program, through a series of control algorithms, the closest displacement combination scheme is selected, and through the controller to control the control valve group, the control of the working state of the hydraulic pump / motor is realized.

Owner:JILIN UNIV

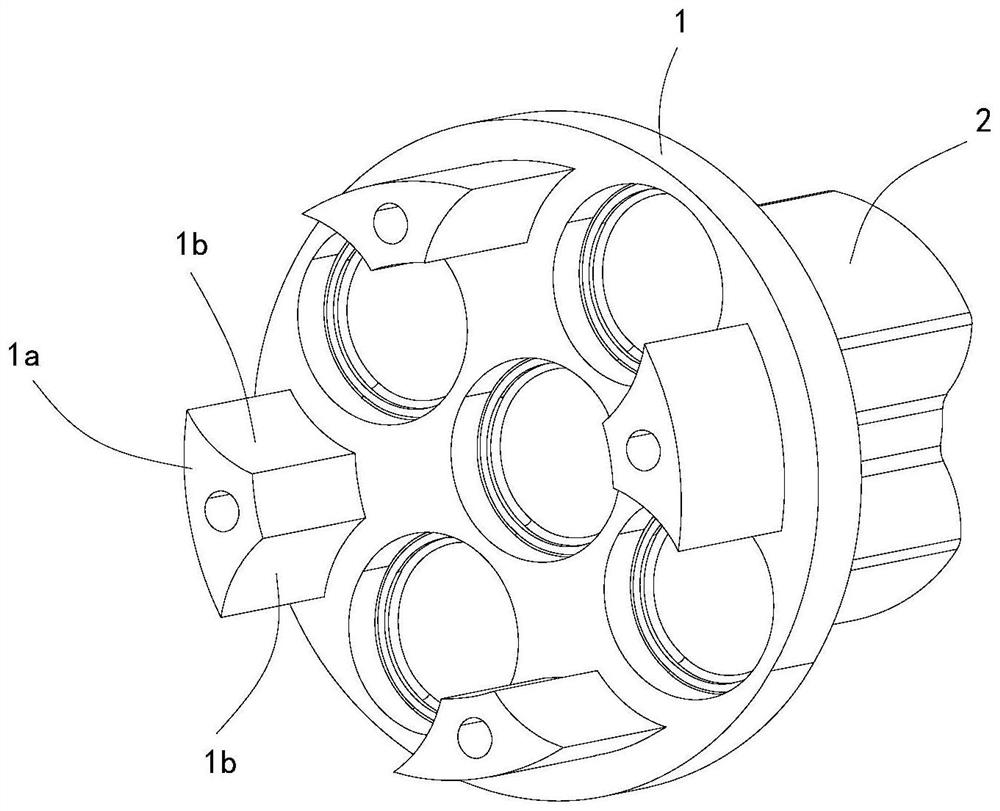

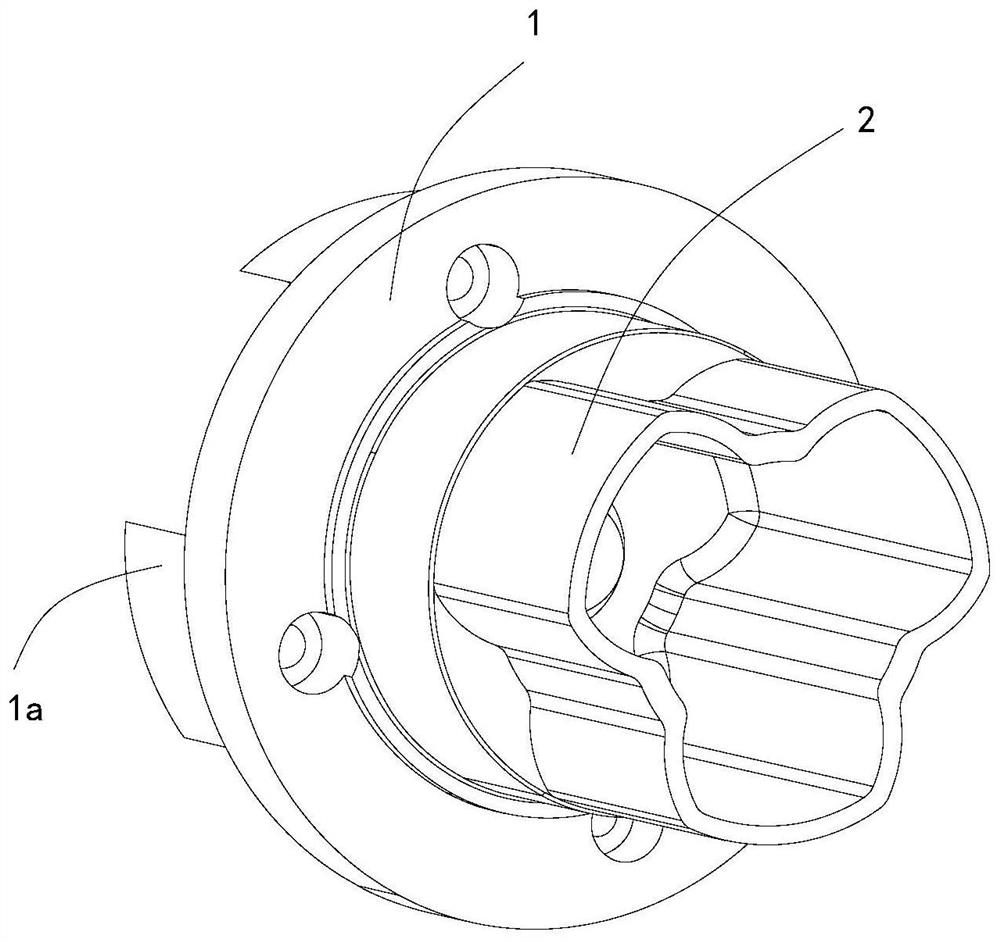

A compact planetary gear reducer and its planet carrier

ActiveCN111577838BReduce the numberRealize miniaturization designToothed gearingsGearing detailsGear driveReduction drive

The invention discloses a planetary carrier, comprising: a planetary carrier body and a spherical cage shell coaxially fixedly connected with the output end of the planetary carrier body, the spherical cage body and the planetary carrier body are integrally formed, the present invention Also provided is a compact planetary gear reducer comprising: an input shaft, a sun gear, a planetary carrier as described above, a planetary carrier cover, a planetary shaft, a planetary gear, an inner ring gear, and the input shaft is used to connect power input equipment , the input shaft transmits the power to the sun gear, and the sun gear transmits the power to the planetary gear that meshes with it. The planetary gear drives the planetary carrier body to rotate, thereby transmitting the power to the cage shell. The body is integrated together, which reduces the number of parts, shortens the transmission route, and realizes the miniaturization design of the planetary gear reducer.

Owner:WUHAN UNIV OF TECH

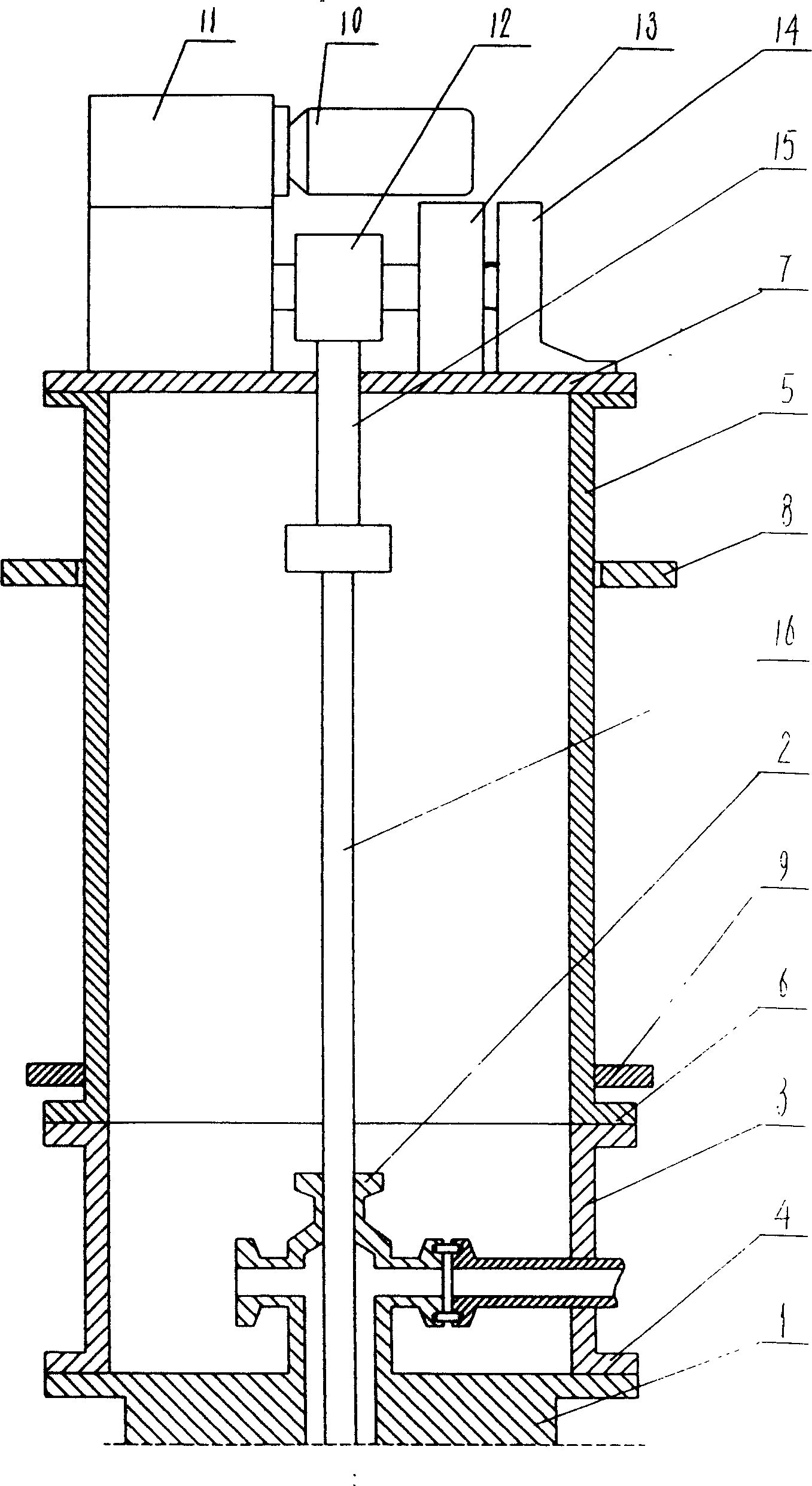

Vertical pipe reciprocating chain pumping unit

The invention relates to a beam-free oil pump comprising wellhead large four-way, wellhead short section, vertical tube, electric machine and reducer, chain wheel, chain and oil pumping rod. The large four-way is fixed at the wellhead and set with wellhead small four-way at the center; the well short section situated on the large four-way; the vertical tube situated on the short section, the top of the vertical tube set with a cap, and a ring balance weight slipping over the periphery of the vertical tube and able to slide upwards and downwards along the vertical tube; the electric machine and reducer fixed on the cap; the chain wheel installed on the cap through the bracket and able to rotate forwards and reversely under the electric machine and reducer drive; one end of the chain linked with the balance weight, and the other one linked with the upper end of the oil pumping rod round the chain wheel; the lower end of the oil pumping rod passing through the small four-way to link up with the underground reciprocating pump.

Owner:李华林

Device of utilisation of waste gases for automobile engine

InactiveCN100582455CStable outputEfficient deliveryInternal combustion piston enginesExhaust apparatusExhaust fumesElectric generator

A utilization device of waste gas from engine on automobile consists of volute, blade set in volute, power transmission unit and speed reduction unit. It is featured as setting power transmission unit and speed reduction unit to be a unified unit and erecting said unified unit between volute and generator.

Owner:CHERY AUTOMOBILE CO LTD

Gearbox suspension type locking disc connection small module drilling winch

PendingCN112551401AShort drive lineTakes up little frame spaceGear lubrication/coolingWinding mechanismsClutchElectric machinery

The invention discloses a gearbox suspension type locking disc connection small module drilling winch, and relates to the field of oil field drilling and repairing machine operation equipment. A winchis driven by an alternating-current variable frequency motor, a gearbox transmits power, a main brake is a hydraulic disc brake, an auxiliary brake is a main motor energy consumption brake, a brake disc is installed on the left side of a single roller shaft, and the right side is connected with the gearbox through an idle sleeve suspension type locking disc locking structure. The winch is composed of the roller shaft, a machine frame, a disc brake, a shock absorber, a locking disc, the gearbox, a drill feeding device, a coupler, an angle box, a motor, a lubricating system, an alternating-current variable-frequency control system and the like, the alternating-current variable-frequency motor drives the angle box, a winch shaft is driven by the gearbox, and a roller is driven to achieve ascending and descending of a traveling block. An all-digital vector control voltage source type alternating-current variable-frequency speed regulation device is adopted, a V / f characteristic curve frequency control mode and a magnetic field orientation vector control mode are achieved, and the drill feeding device is connected with a gearbox clutch and is an independent driving system.

Owner:RG PETRO MACHINERY GROUP

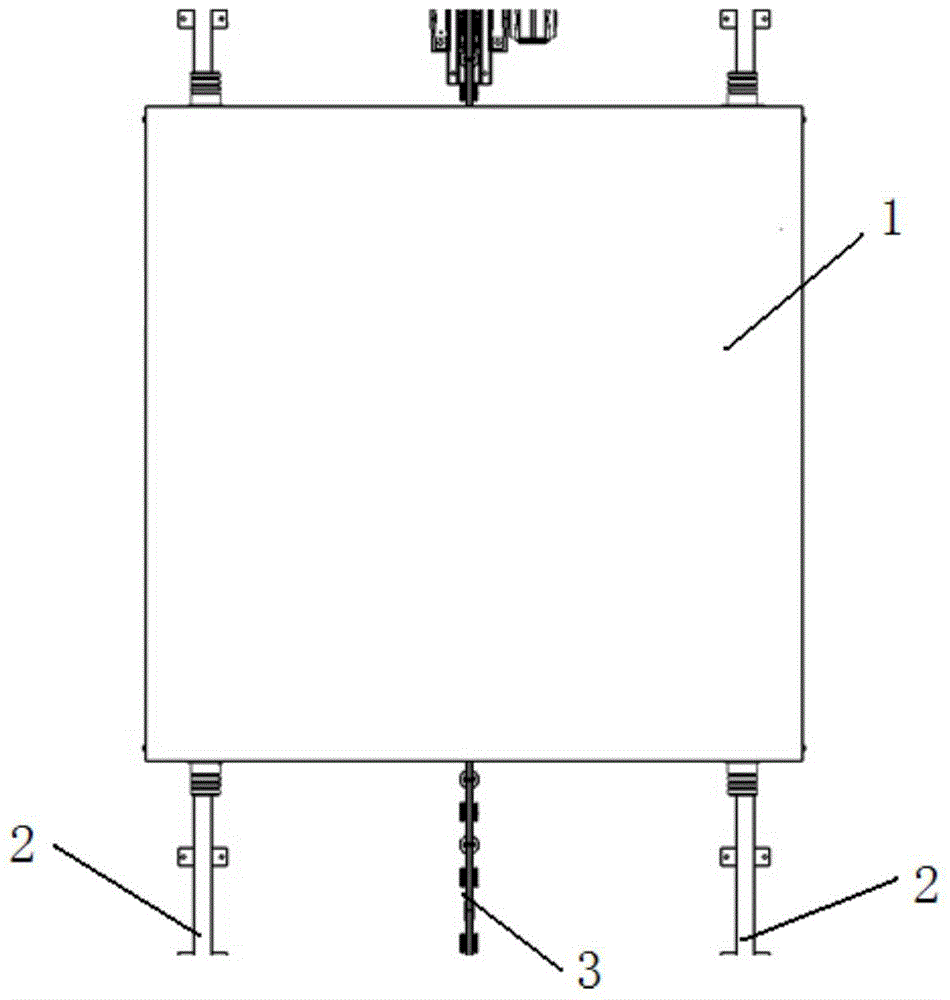

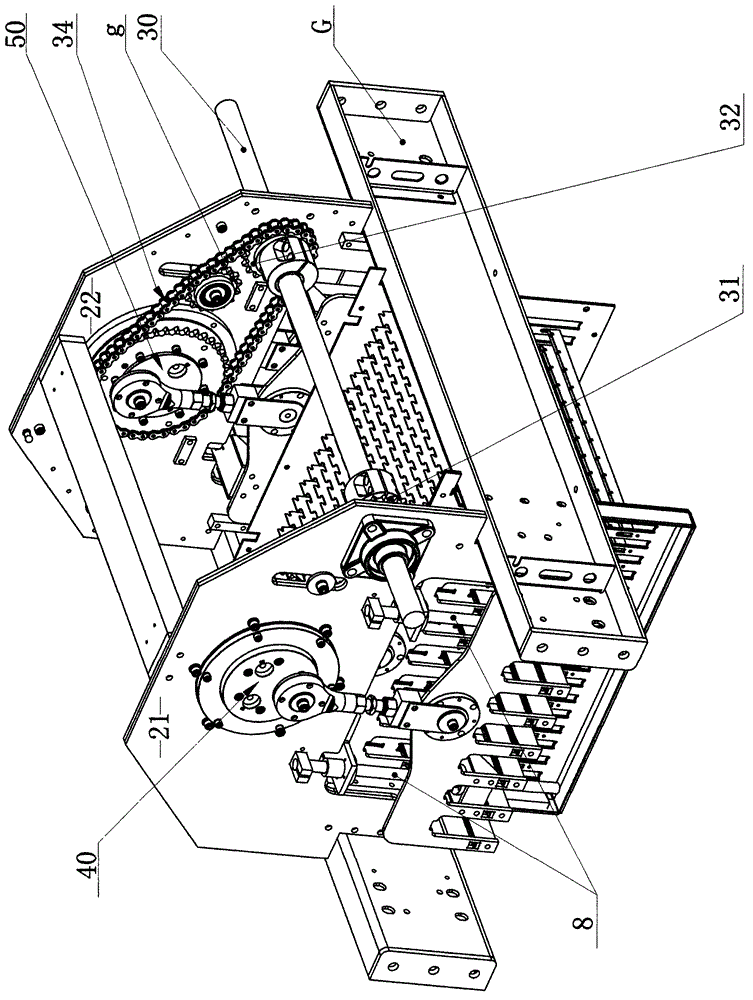

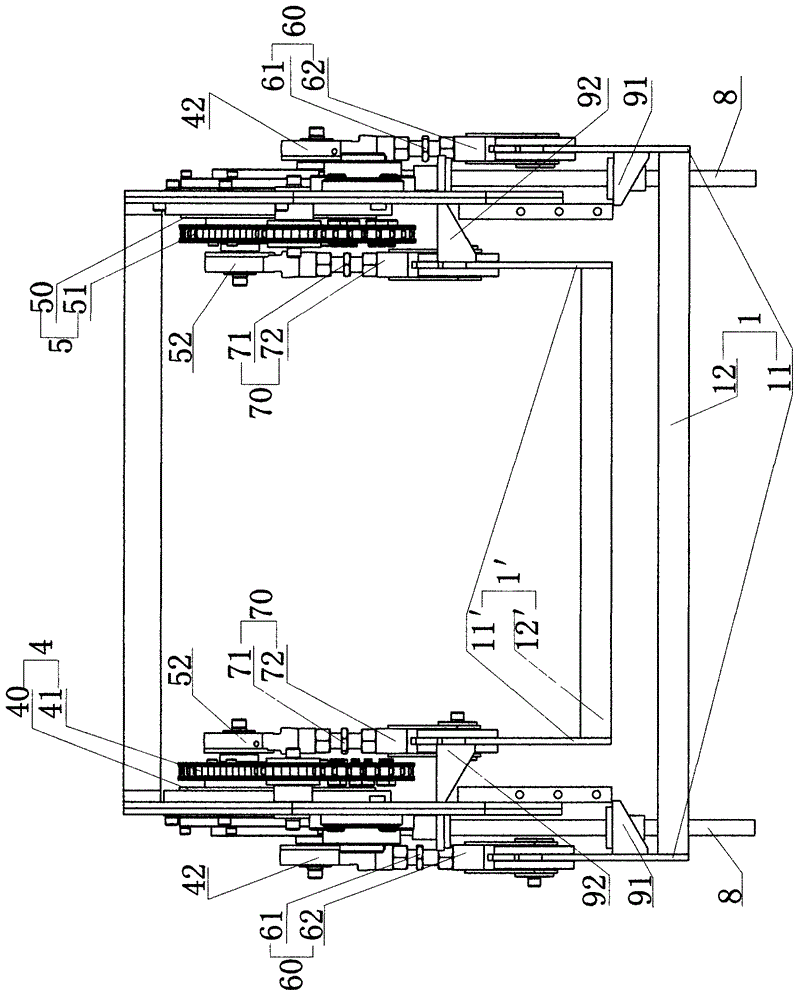

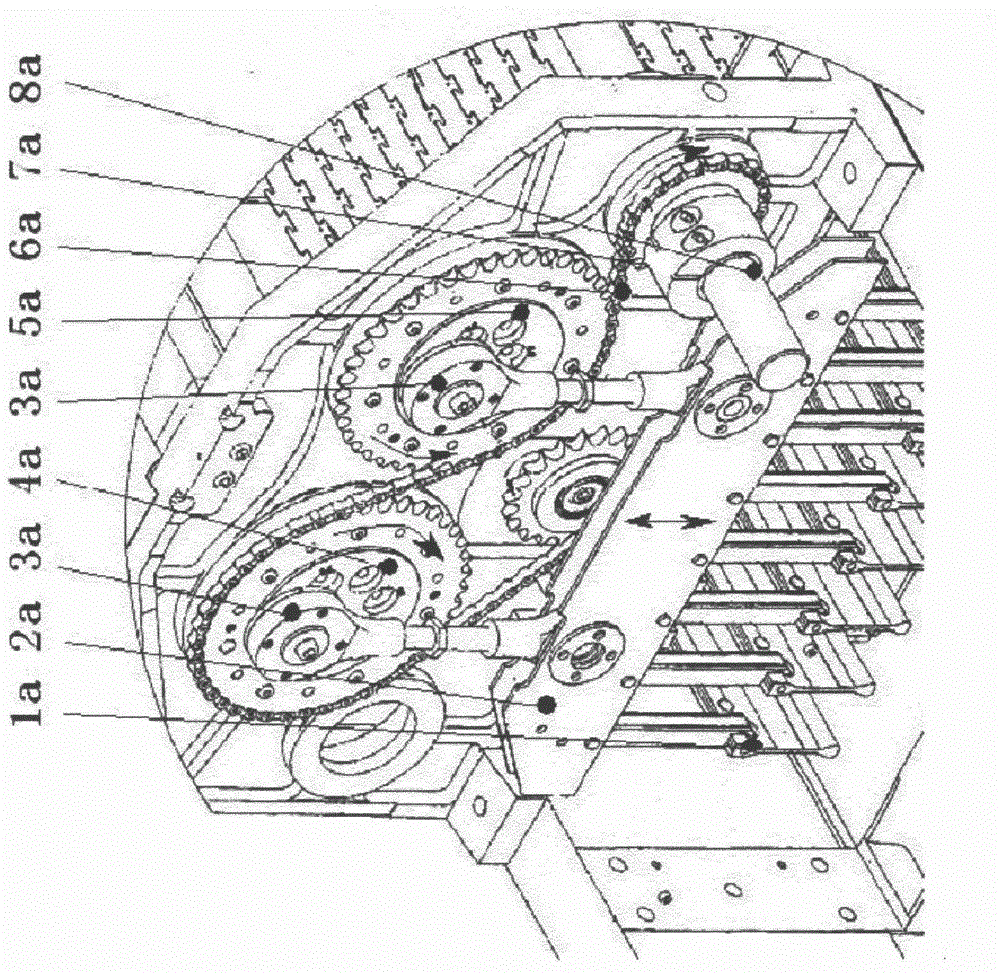

A reciprocating chain drive mechanism

ActiveCN104477589BShort drive lineLess transmission partsMechanical conveyorsReciprocating motionElectric machinery

Owner:XUZHOU CONSTR MACHINERY

Chained jacquard shedding device

InactiveCN102797091BOvercoming cost performance problemsShort drive lineCam shedding mechanismDrive shaftEngineering

Owner:浙江赫诚资产管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com