Chained jacquard shedding device

A technology of shedding device and jacquard machine, which is applied in the fields of cam shedding mechanism, textile, textiles and paper making, etc. It can solve the problems of difficult mass popularization for users, complex transmission links, and many moving parts, so as to achieve simplified transmission links and high return on investment , The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

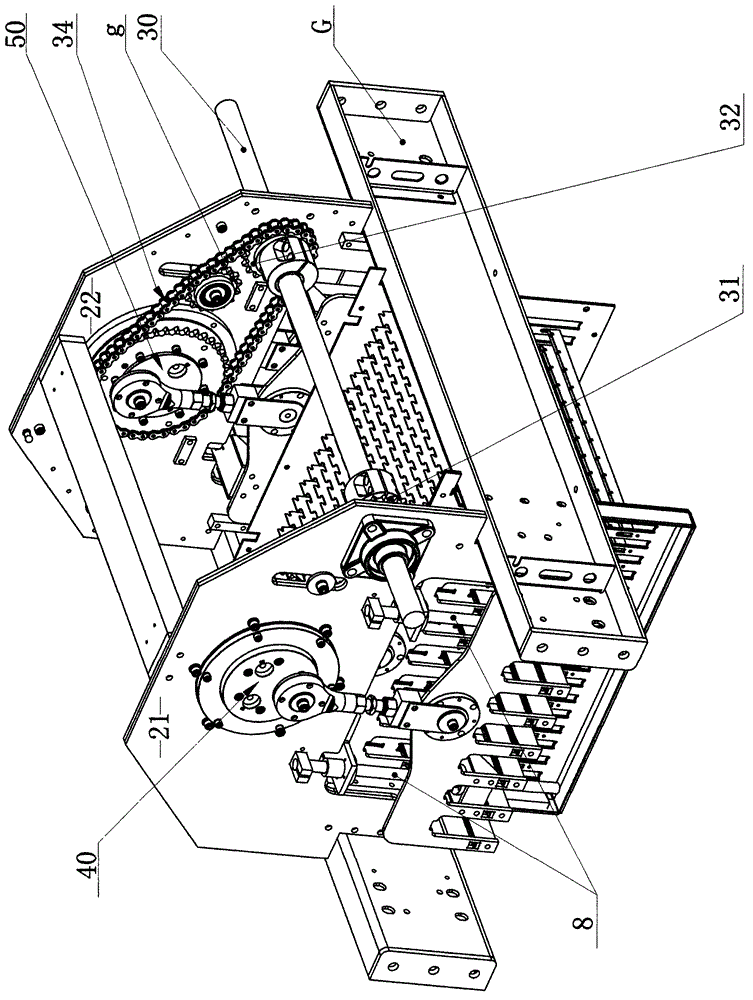

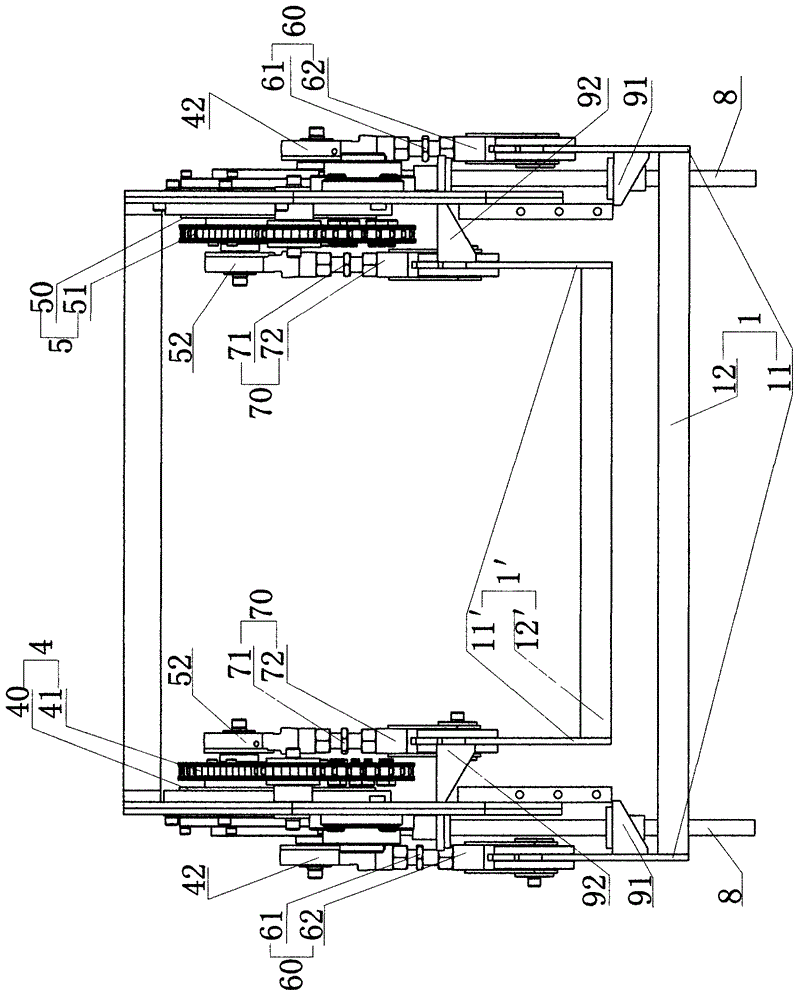

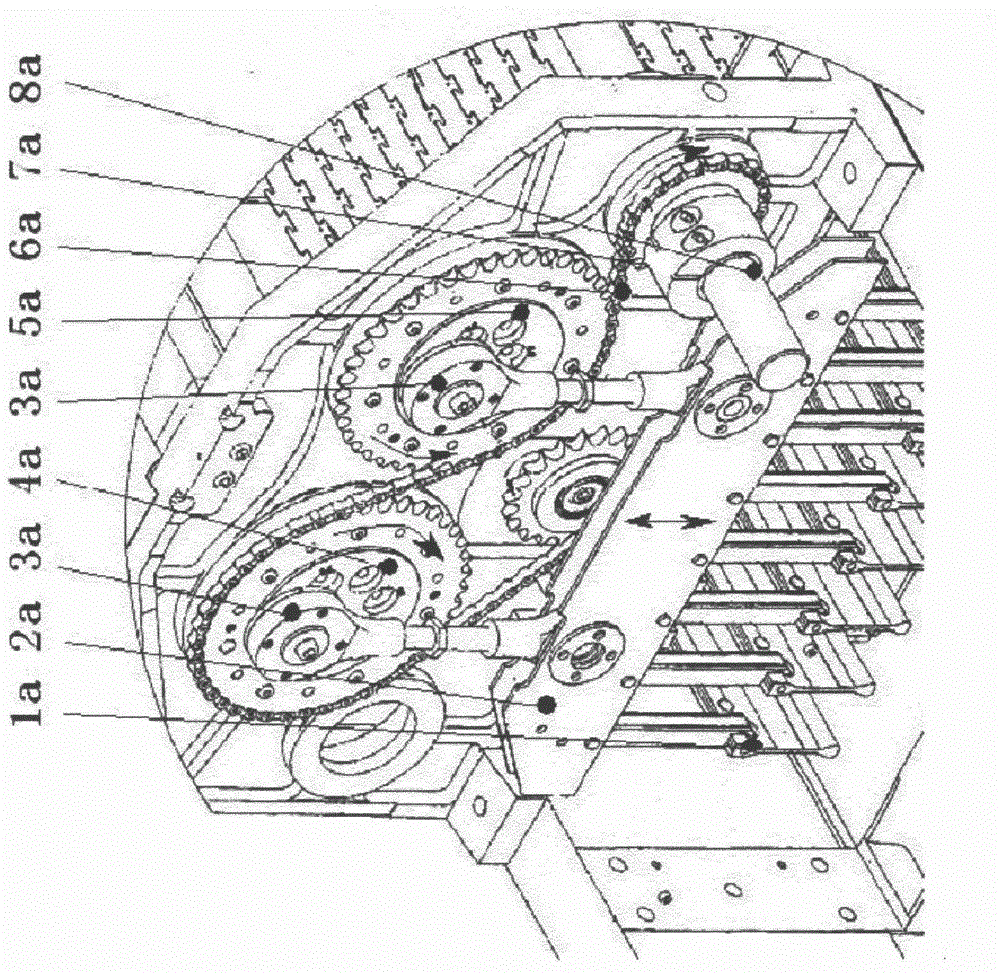

[0019] An opening device for a chain jacquard machine, comprising a main transmission shaft 30 rotatably arranged on the left and right wall panels 21, 22, and inner and outer shafts arranged in the inner and outer sides of the two wall panels to reciprocate up and down in opposite directions. Knife lifting combination frame 1', 1, inner and outer knife lifting combination frame 1', 1 respectively have inner and outer tool lifting frame pair 11', 11 and inner and outer tool lifting group 12', 12, main drive shaft 30 top A pair of driving sprockets 31,32 and closed chains 33,34 are arranged, and left and right wall panels 21,22 are fixed on the frame G in parallel, which is prior art.

[0020] The improvement of this case is that: left and right wallboards 21, 22 are provided with a single driven wheel shaft assembly 4, 5, and the driven wheel shaft assembly 4, 5 is composed of a single driven shaft 40, 50 and a single driven sprocket 41 , 51, the driven sprocket 41 installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com