Gearbox suspension type locking disc connection small module drilling winch

A technology of gear boxes and locking discs, which is applied in gear lubrication/cooling, hoisting devices, clockwork mechanisms, etc., can solve problems that cannot meet the needs of intelligent technology, complex transmission routes, and large space in the frame, and achieve excellent performance. The effects of speed regulation, fewer transmission lines, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

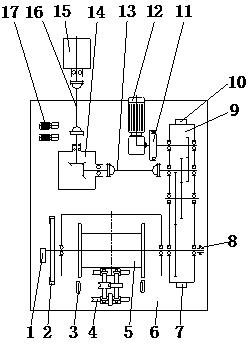

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] In this embodiment, the winch is a single-shaft winch, driven by an AC variable frequency motor, driven by a gearbox, and the control system adopts a full digital vector control voltage source type AC variable frequency speed control device, and has a frequency control method and a magnetic field of the V / f characteristic curve. Orientation vector control mode.

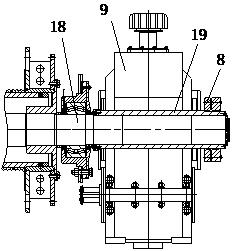

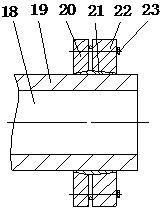

[0026] In this embodiment, the main AC variable frequency motor 15 is connected with the angular gear box 14 through the coupling two 16, the angular gear box 14 is connected with the gear reduction box 9 through the coupling one 13, and the gear reduction box 9 is connected with the roller shaft 18 Connected through the locking disc 8, the left side of the drum shaft assembly 5 is installed with a hydraulic disc brake 2, the left end of the drum shaft 18 is installed with an instrument...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com