Transmission mechanism for mini-tiller

A technology of transmission mechanism and micro-tiller, which is applied in the direction of tillage implements, agricultural machinery and implements, etc. It can solve the problems of unfavorable development in the direction of miniaturization, high precision requirements, and large volume of the whole machine, so as to achieve less parts and less transmission The effect of stability and simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

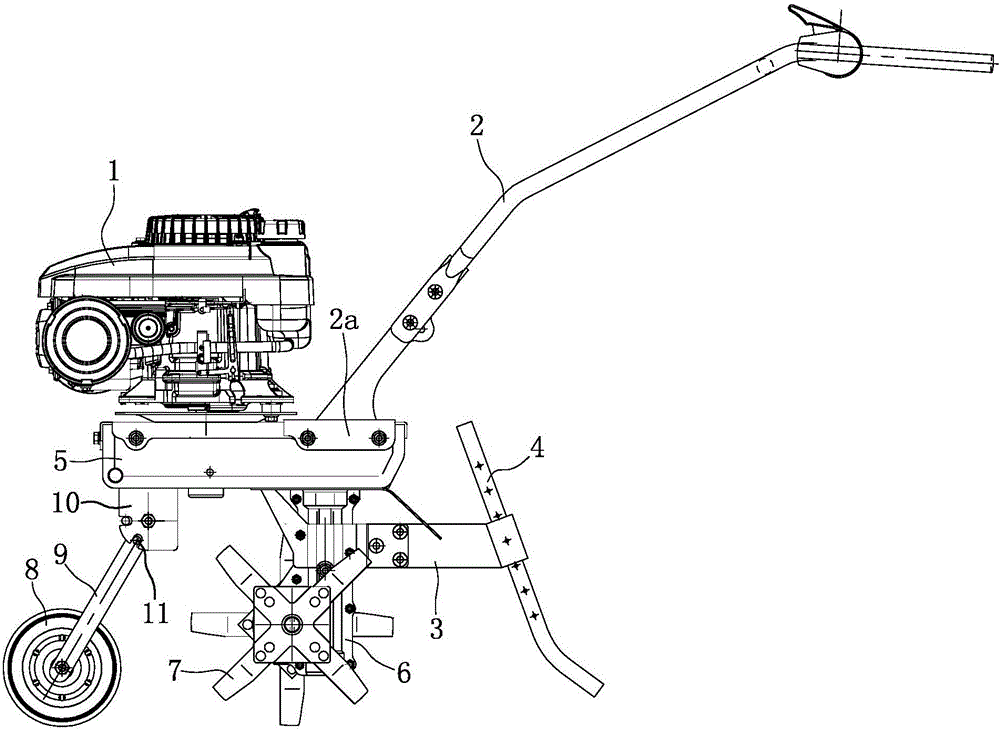

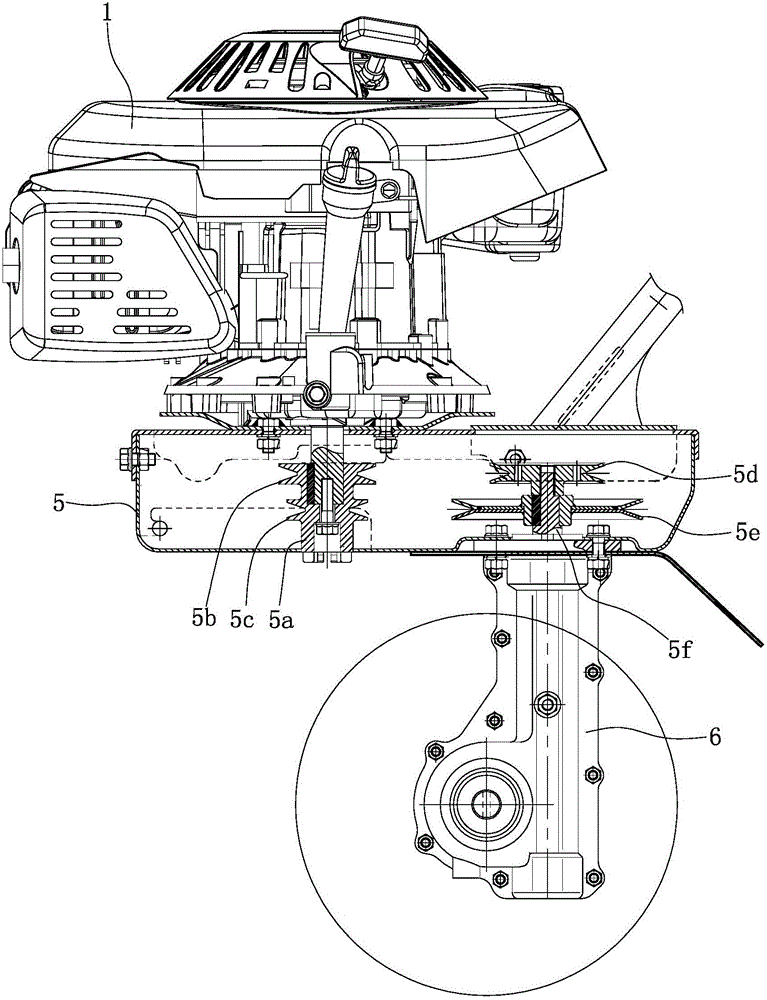

[0013] Such as figure 1 , figure 2 As shown, engine 1 is installed at the front end of main transmission case 5 top, and this engine 1 is the vertical axis engine that output shaft is vertically downward, and the output shaft of engine 1 stretches in the main transmission case 5, and is connected with driving wheel shaft 5a, A high-speed driving wheel 5b and a low-speed driving wheel 5c are integrally formed on the driving wheel shaft 5a, and the high-speed driving wheel 5b is located above the low-speed driving wheel 5c. The high-speed driving wheel 5b can be connected with the high-speed driven wheel 5d through a belt, and the low-speed driving wheel 5c can be connected with the low-speed driven wheel 5e through a belt. Both the high-speed driven wheel 5d and the low-speed driven wheel 5e are arranged on the driven wheel shaft 5f, and the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com