Dynamic gear shifting transmission-gear box suitable for engineering machinery

A technology of power shifting and construction machinery, applied in the field of power shifting gearbox, can solve the problems of complexity and multiple transmission routes of parts, and achieve the effects of reduced loss of parts, compact gearbox structure, and effective power transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

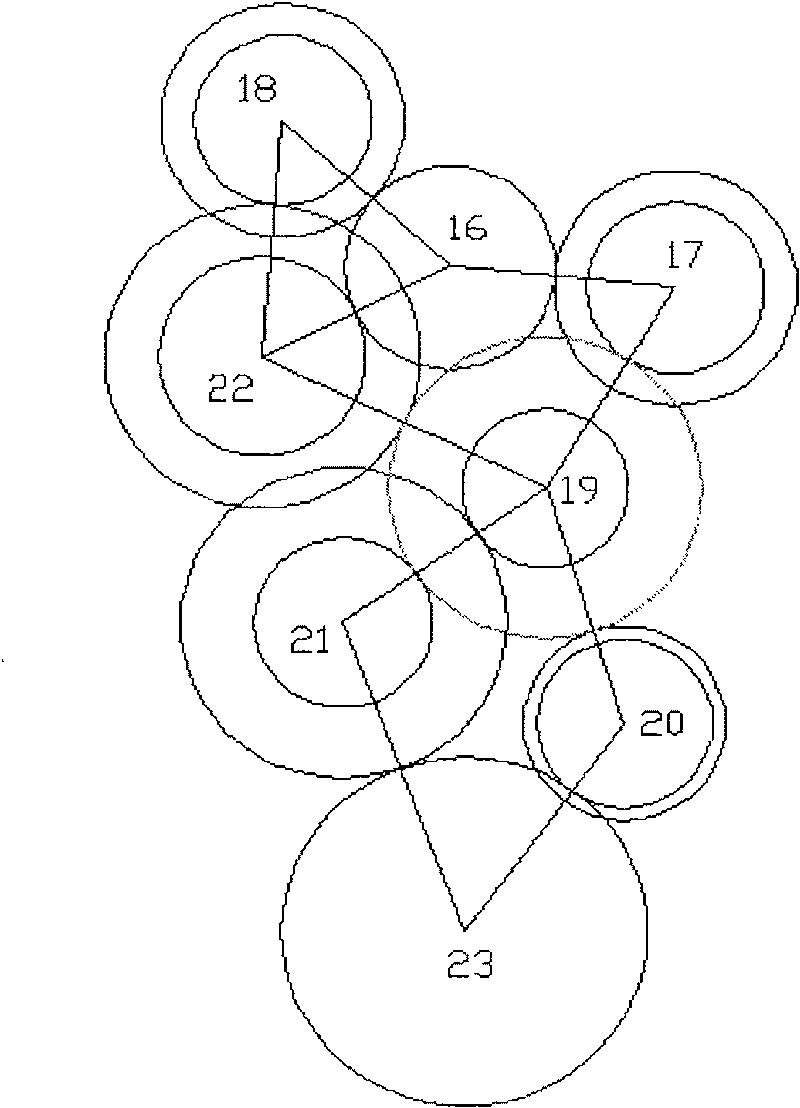

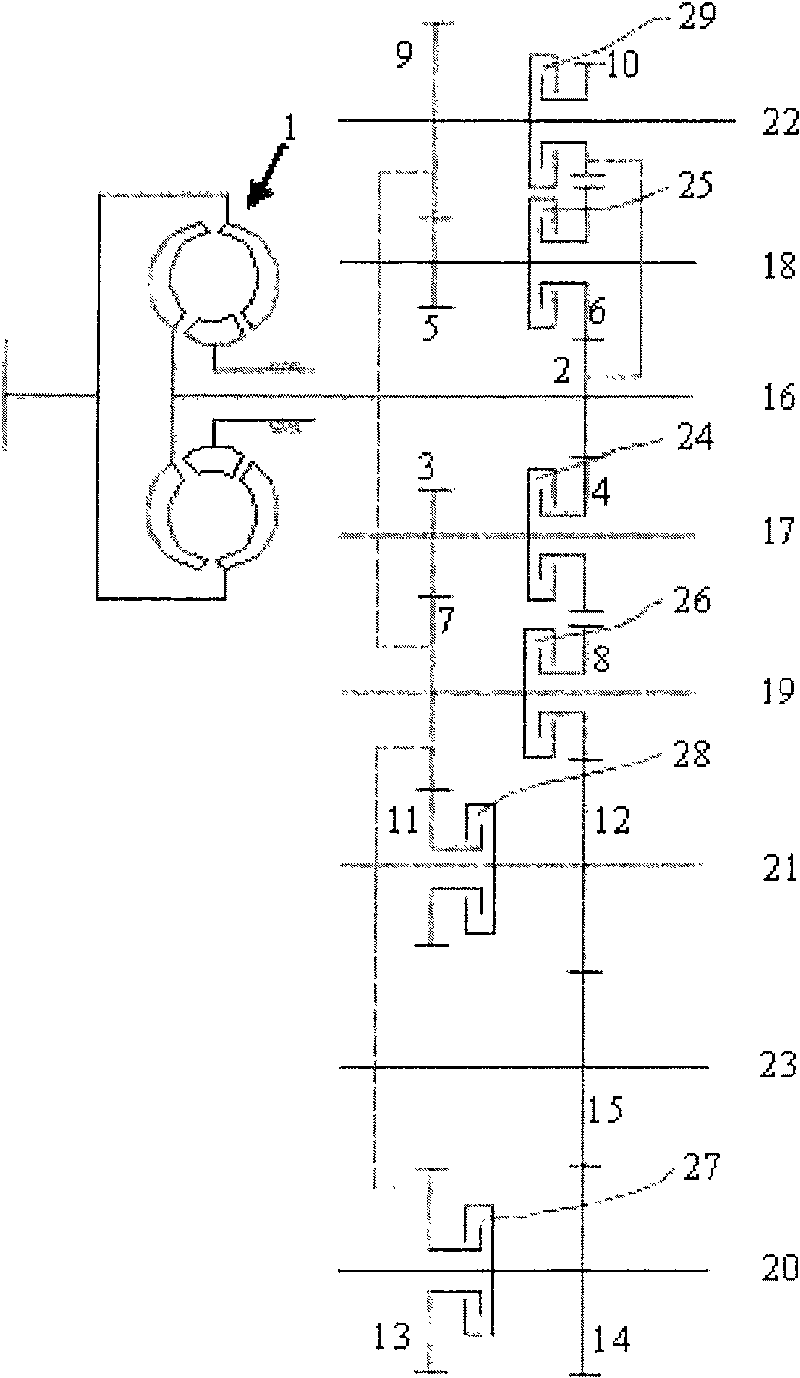

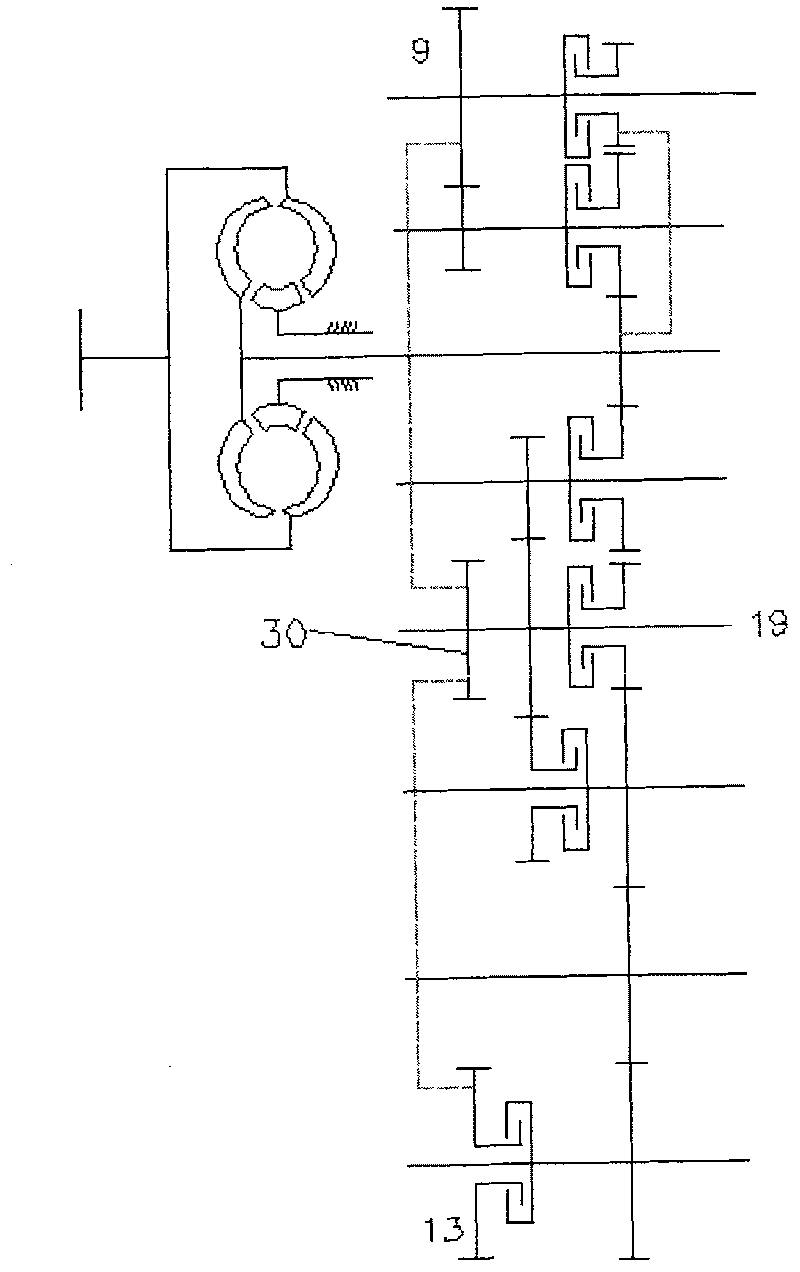

[0012] Depend on figure 1 and figure 2 Shown, the present invention is by an input shaft 16, an output shaft 23, some intermediate shafts 17,18,19,20,21,22 and some clutches 24,25,26,27,28,29 and gear 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, wherein the input shaft 16 and some intermediate shafts 17, 18, 22 and the gears 2, 3, 4 on them . The fixed gear 2 on the input shaft 16 is in permanent mesh with the three movable gears 4, 6, 10 on the first countershaft 17, the second countershaft 18, and the sixth countershaft 22 at the same time, and the fixed gear on the second countershaft 18 5 is permanently meshed with the fixed gear 9 on the sixth countershaft 22, the fixed gear 7 on the third countershaft 19 is simultaneously engaged with the two fixed gears 3, 9 on the first countershaft 17, the sixth countershaft 22 and the fourth The two movable gears 13 and 11 on the intermediate shaft 20 and the fifth intermediate shaft 21 are permanently meshed, and the fixed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com