Dual suction type mechanical core

A suction type, movement technology, applied in the field of double suction movement, can solve the problems of high failure rate, complex structure, poor high temperature resistance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

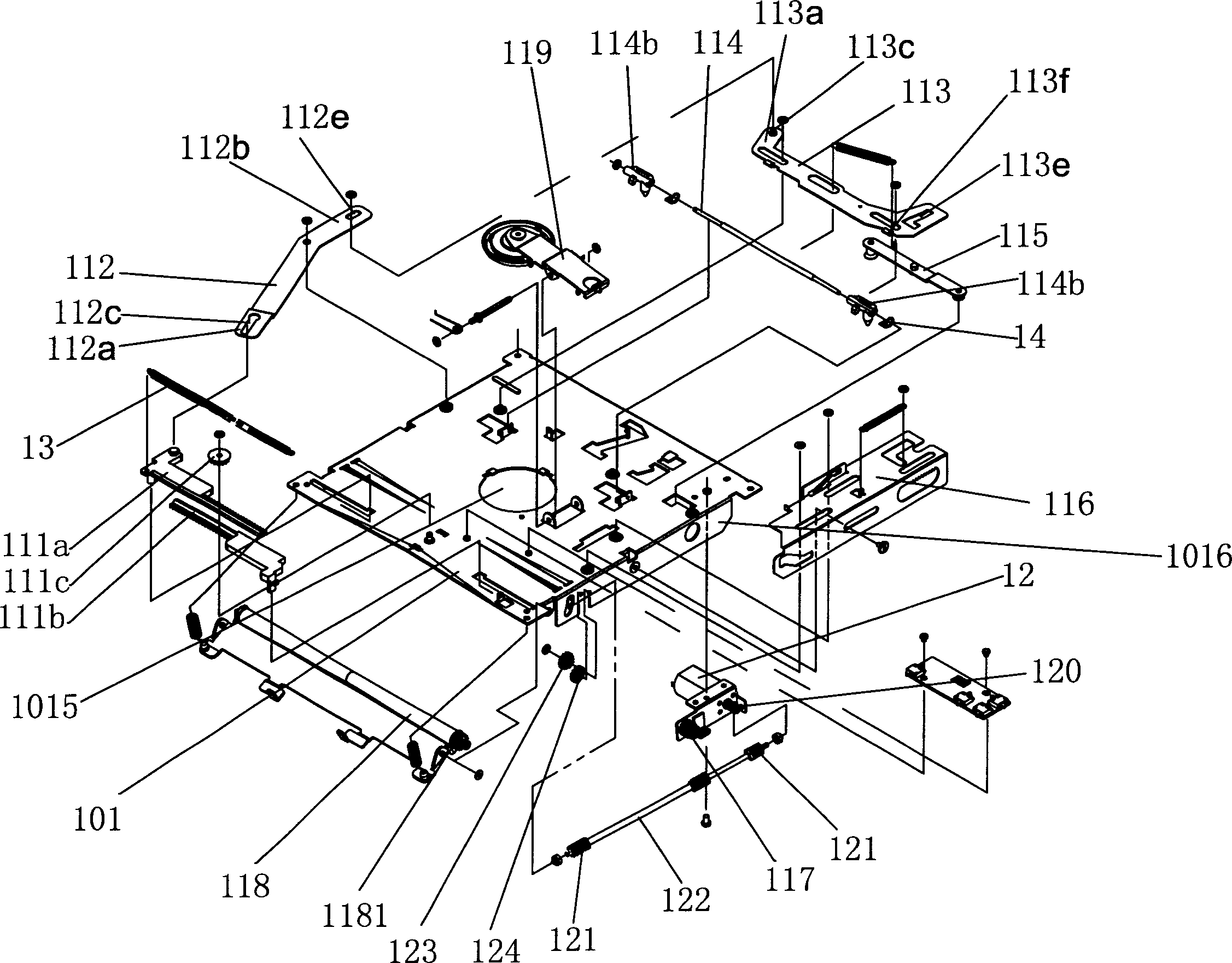

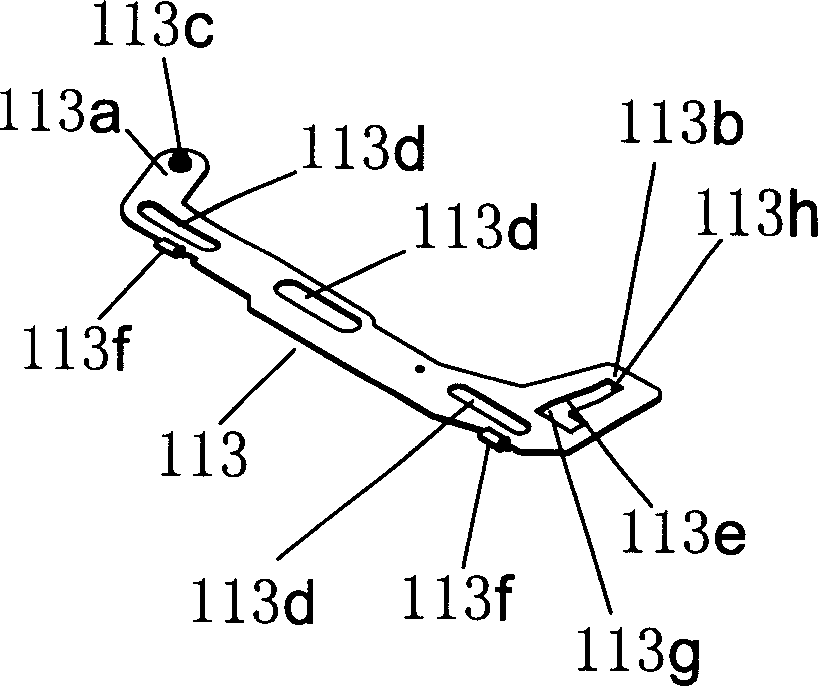

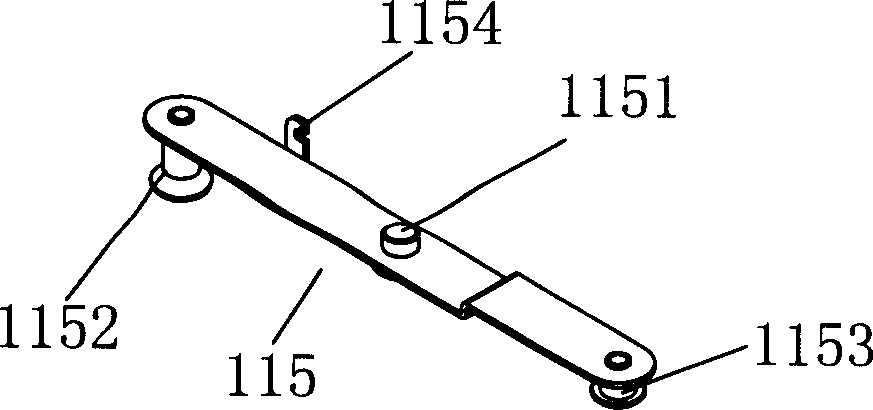

[0022] see Figure 1 to Figure 10 , the double suction movement of the present invention can realize the suction of large and small discs. The double-suction movement includes a base plate, a disc suction transmission mechanism, a pressure plate mechanism, a driving part, a linkage part, a push plate, a planetary plate, a locking plate and a limiter. The drive roller on the upper plate and the power mechanism that drives its rotation. The platen mechanism includes a platen and a power mechanism that drives the platen to move vertically. The active part is installed on the base plate and can move laterally and horizontally under the push of the disc. , the active part drives the push plate through the linkage to move against the moving direction of the active part, the push plate is provided with an "L"-shaped limiting groove, the planetary plate is a lever structure, and its fulcrum is located in the limiting groove Among them, the force-receiving end is located on the moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com